Blog, homepage-featured-top, Joining Dissimilar Materials, main-blog

The discussions relative to cold stamping are applicable to any forming operation occurring at room temperature such as roll forming, hydroforming, or conventional stamping. Similarly, hot stamping refers to any set of operations using Press Hardening Steels (or Press Quenched Steels), including those that are roll formed or fluid formed.

Automakers contemplating whether a part is cold stamped or hot formed must consider numerous factors. This blog covers some important considerations related to welding these materials for automotive applications. Most important is the discussion on Resistance Spot Welding (RSW) as it is the dominating process in automotive manufacturing.

Setting Correct Welding Parameters for Resistance Spot Welding

Specific welding parameters need to be developed for each combination of material type and thickness. In general, the Hot Press (HP) steels require more demanding process conditions. One important factor is electrode force which should be higher for the HP steel than for cold press type steel of the same thickness. The actual recommended force will depend on the strength level, and the thickness of the steel. Of course, this will affect the welding machine/welding gun force capability requirement.

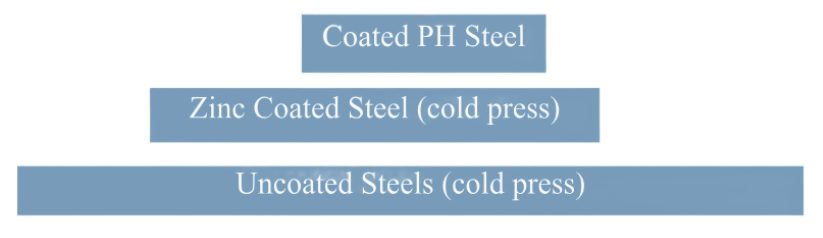

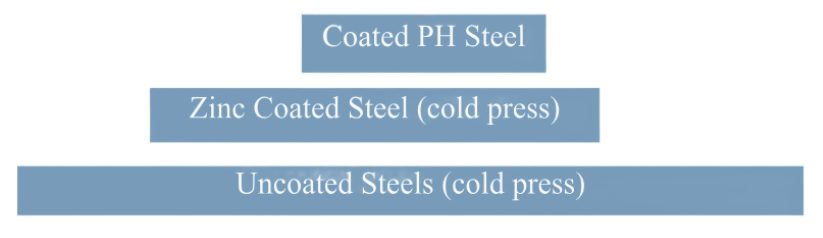

Another important variable is the welding current level and even more important is the current range at which acceptable welds can be made. The current range is weldability measurement, and the best indicator of the welding process robustness in the manufacturing environment and sometime called proceed window. Note the relative range of current for different steel types. A smaller process window may require more frequent weld quality evaluation such as for weld size.

Relative Current Range (process windows) for Different Steel Types

The Effect of Coating Type on Weldability

In all cases of resistance spot welding coated steels, it is imperative to move the coating away from the weld area during and in the beginning of the weld cycle to allow a steel-to-steel weld to occur. The combination of welding current, weld time and electrode force are responsible for this coating displacement.

For all the coated steels, the ability of the coating to flow is a function of the coating type and properties, such as electrical resistivity and melting point, as well as the coating thickness.

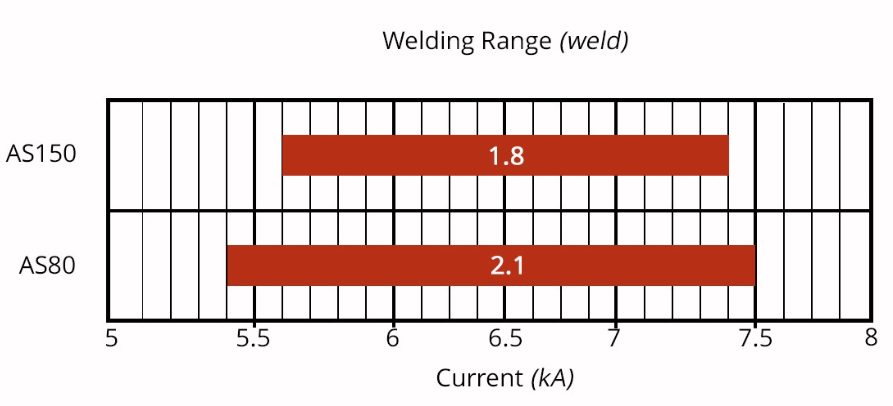

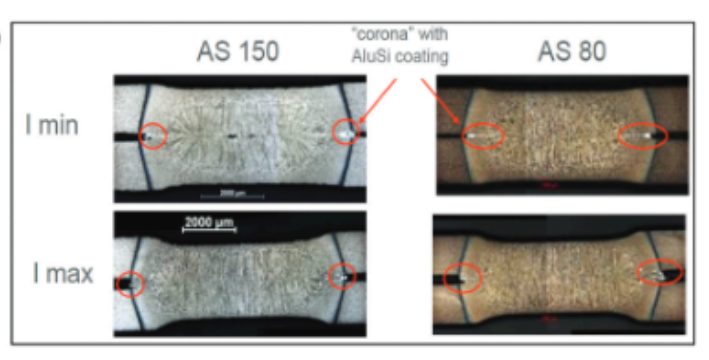

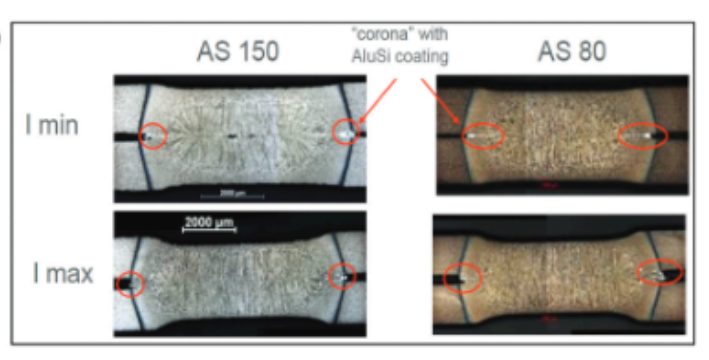

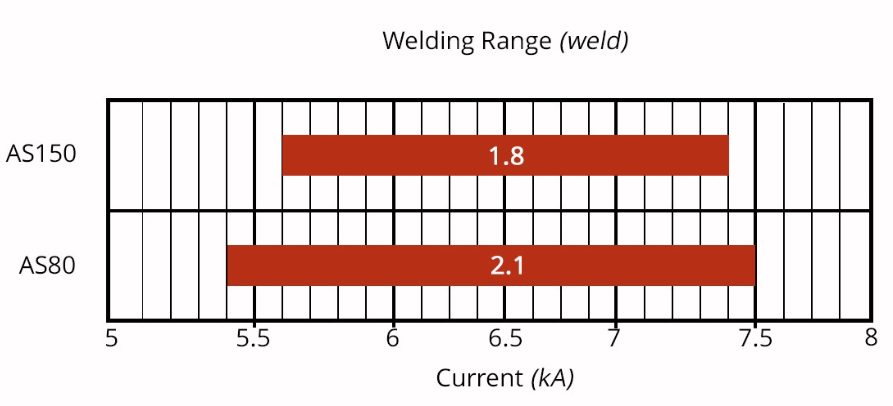

An example of cross sectioned spot welds made on Hot Press Steel with Aluminum -Silicon coating is shown below. It shows two coating thicknesses and the displaced coating at the periphery of weld. This figure also shows the difference in current range for the different coating thickness. The thicker coating shows a smaller current range. In addition, the Al-Si coating has a much higher melting point than the zinc coatings on the cold stamped steels, making it more difficult to displace from the weld area.

Hot Press Steel with Aluminum -Silicon

Liquid Metal Embrittlement and Resistance Spot Welding

Cold-formable, coated, Advance High Strength Steels such as the 3rd Generation Advanced High Strength Steels are being widely used in automotive applications. One welding issue these materials encounter is the increased hardness in the weld area, that sometime results in brittle fracture of the weld.

Another issue is their sensitivity to Liquid Metal Embrittlement (LME) cracking. These two issues are discussed in detail on the WorldAutoSteel AHSS Guidelines website and our recently released Phase 2 Report on LME.

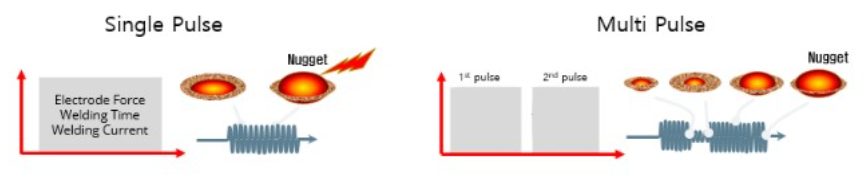

Resistance Spot Welding Using Current Pulsation

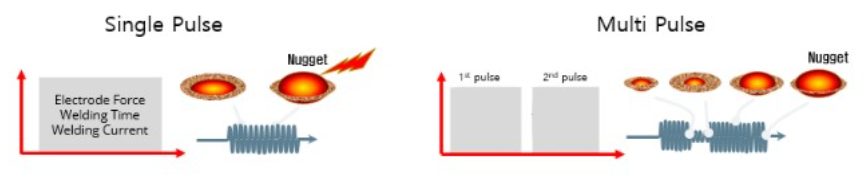

The most effective solution for the issues described above is using current pulsation during the welding cycle. A schematic description is shown below.

The pulsation allows much better control of the heat generation and the weld nugget development. The pulsation variables include the number of pulses (typically 2-4), the current level and time for each pulse, and the cool time between the pulses.

In summery, pulsation (and sometime current upslope) in Resistance Spot Welding proved to be beneficial for the following applications:

- Coated Cold Stamped steels

- Cold stamped Advance High Strength Steels

- Multi materials stack-ups – As described in our articles here on 3T/4T and 5T Stack-Ups

Thanks is given to Menachem Kimchi, Associate Professor-Practice, Dept of Materials Science, Ohio State University and Technical Editor – Joining, AHSS Application Guidelines, for this article.

Blog, homepage-featured-top, main-blog

Grade Options and Corrosion Protection Considerations When Deciding How A Part Gets Formed

Automakers contemplating whether a part is cold stamped or hot formed must consider numerous ramifications impacting multiple departments. Our prior blog on this topic highlighted the equipment differences and the property development differences between each approach. We continue this blog series, now focusing on grade options and corrosion protection.

The discussions below relative to cold stamping are applicable to any forming operation occurring at room temperature such as roll forming, hydroforming, or conventional stamping. Similarly, hot stamping refers to any set of operations using Press Hardening Steels (or Press Quenched Steels), including those that are roll formed or fluid-formed.

Grade Options for Cold Stamped or Hot Formed Steel

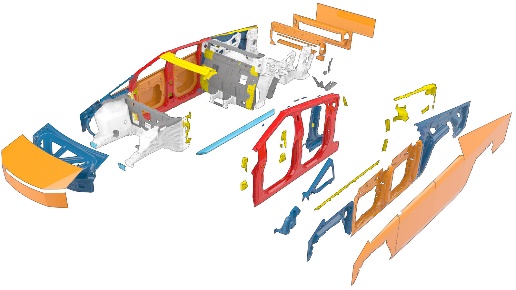

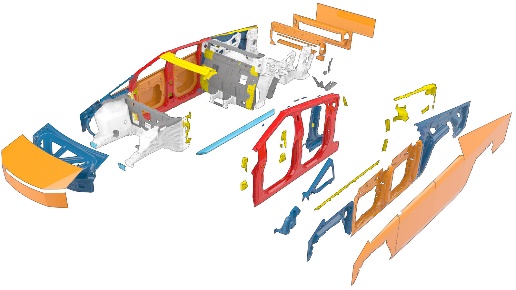

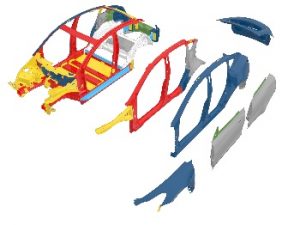

There are two types of parts needed for vehicle safety cage applications: those with the highest strength that prevent intrusion, and those with some additional ductility that can help with energy absorption. Each of these types can be achieved via cold stamping or hot stamping.

When it comes to cold stamped parts, many grade options exist at 1000 MPa that also have decent ductility. The advent of the 3rd Generation Advanced High Strength Steels adds to the tally. Most of these top out at 1200 MPa, with some companies offering cold-formable Advanced High Strength Steels with 1400 or 1500 MPa tensile strength. The chemistry of AHSS grades is a function of the specific characteristics of each production mill, meaning that OEMs must exercise diligence when changing suppliers.

Figure 1: Stress-strain curve of industrially produced QP980.W-35

Martensitic grades from the steel mill have been in commercial production for many years, with minimum strength levels typically ranging from 900 MPa to 1470 MPa, depending on the grade. These products are typically destined for roll forming, except for possibly those at the lower strengths, due to limited ductility. Until recently, MS1470, a martensitic steel with 1470 MPa minimum tensile strength, was the highest strength cold formable option available. New offerings from global steelmakers now include MS1700, with a 1700 MPa minimum tensile strength, as well as MS 1470 with sufficient ductility to allow for cold stamping. Automakers have deployed these grades in cold stamped applications such as crossmembers and roof reinforcements.

Figure 2: Cold-Stamped Martensitic Steel with 1500 MPa Tensile Strength used in the Nissan B-Segment Hatchback.K-57

Until these recent developments, hot stamping was the primary option to reach the highest strength levels in part shapes having even mild complexity. Under proper conditions, a chemistry of 22MnB5 could routinely reach a nominal or aim strength of 1500 MPa, which led to this grade being described as PHS1500, CR1500T-MB, or with similar nomenclature. Note that in this terminology, 1500 MPa nominal strength typically corresponds to a minimum strength of 1300 MPa.

The 22MnB5 chemistry is globally available, but the coating approaches discussed below may be company-specific.

Newer PHS options with a modified chemistry and subsequent processing differences can reach nominal strength levels of 2000 MPa. Other options are available with additional ductility at strength levels of 1000 MPa or 1200 MPa. A special class called Press Quenched Steels have even higher ductility with strength as low as 450 MPa.

The spectrum of grades available for cold-stamped and hot formed steel parts allows automakers to fine-tune the crash energy management features within a body structure, contributing to steel’s “infinite tune-ability” capability which gives automotive engineers design flexibility and freedoms not available from other structural materials.

Corrosion Protection

Uncoated versions of a grade must take a different chemistry approach than the hot dip galvanized (GI) or hot dipped galvannealed (HDGA) versions since the hot dip galvanizing process acts as a heat treatment cycle that changes the properties of the base steel. Steelmakers adjust the base steel chemistry to account for this heat treatment to ensure the resultant properties fall within the grade requirements.

Figure 3: Schematic of a typical hot-dipped galvanizing line with galvanneal capability.

This strategy has limitations as it relates to grades with increasing amounts of martensite in the microstructure. Complex thermal cycles are needed to produce the highly engineered microstructures seen in advanced steels. Above a certain strength level, it is not possible to create a GI or HDGA version of that grade.

For example, when discussing fully martensitic grades from the steel mill, hot dip galvanizing is not an option. If a martensitic grade needs corrosion protection, then electrogalvanizing is the common approach since an EG coating is applied at ambient temperature, which is low enough to avoid negatively impacting the properties. Automakers might choose to forgo a galvanized coating if the intended application is in a dry area that is not exposed to road salt.

Figure 4: Schematic of an electrogalvanizing line.

For press hardening steels, coatings serve multiple purposes. Without a coating, uncoated steels will oxidize in the austenitizing furnace and develop scale on the surface. During hot stamping, this scale layer limits efficient thermal transfer and may prevent the critical cooling rate from being reached. Furthermore, scale may flake off in the tooling, leading to tool surface damage. Finally, scale remaining after hot stamping is typically removed by shot blasting, an off-line operation that may induce additional issues.

Using a hot dip galvanized steel in a conventional direct press hardening process (blank -> heat -> form/quench) may contribute to liquid metal embrittlement (LME). Getting around this requires either changing the steel chemistry from the conventional 22MnB5 or using an indirect press hardening process that sees the bulk of the part shape formed at ambient temperatures followed by heating and quenching.

Those companies wishing to use the direct press hardening process can use a base steel having an aluminum-silicon (Al-Si) coating, providing that the heating cycle in the austenitizing furnace is such that there is sufficient time for alloying between the coating and the base steel. Welding practices using these coated steels need to account for the aluminum in the coating, but robust practices have been developed and are in widespread use.

For more information about PHS grades and processing, see our Press Hardened Steel Primer.

Danny Schaeffler is the Metallurgy and Forming Technical Editor of the AHSS Applications Guidelines available from WorldAutoSteel. He is founder and President of Engineering Quality Solutions (EQS). Danny wrote the monthly “Science of Forming” and “Metal Matters” column for Metalforming Magazine, and provides seminars on sheet metal formability for Auto/Steel Partnership and the Precision Metalforming Association. He has written for Stamping Journal and The Fabricator, and has lectured at FabTech. Danny is passionate about training new and experienced employees at manufacturing companies about how sheet metal properties impact their forming success.

Blog, homepage-featured-top, main-blog

Equipment, Responsibilities, and Property Development Considerations When Deciding How A Part Gets Formed

Automakers contemplating whether a part is cold stamped or hot formed must consider numerous ramifications impacting multiple departments. Over a series of blogs, we’ll cover some of the considerations that must enter the discussion.

The discussions relative to cold stamping are applicable to any forming operation occurring at room temperature such as roll forming, hydroforming, or conventional stamping. Similarly, hot stamping refers to any set of operations using Press Hardening Steels (or Press Quenched Steels), including those that are roll formed or fluid-formed.

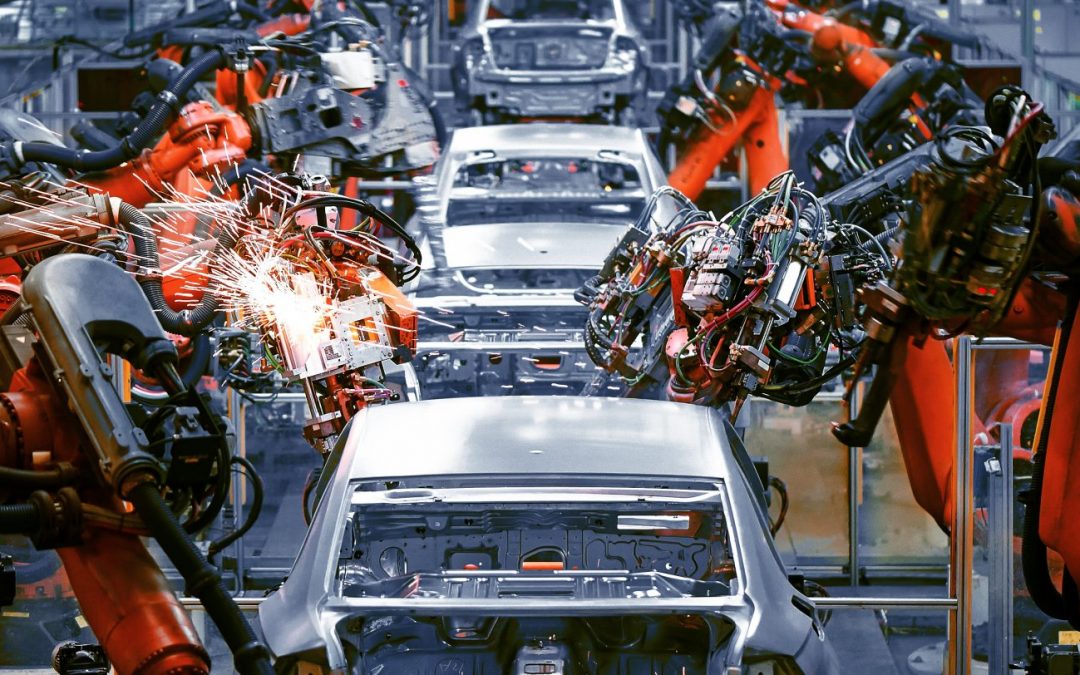

Equipment

There is a well-established infrastructure for cold stamping. New grades benefit from servo presses, especially for those grades where press force and press energy must be considered. Larger press beds may be necessary to accommodate larger parts. As long as these factors are considered, the existing infrastructure is likely sufficient.

Progressive-die presses have tonnage ratings commonly in the range of 630 to 1250 tons at relatively high stroke rates. Transfer presses, typically ranging from 800 to 2500 tons, operate at relatively lower stroke rates. Power requirements can vary between 75 kW (630 tons) to 350 kW (2500 tons). Recent transfer press installations of approximately 3000 tons capacity allow for processing of an expanded range of higher strength steels.

Hot stamping requires a high-tonnage servo-driven press (approximately 1000 ton force capacity) with a 3 meter by 2 meter bolster, fed by either a roller-hearth furnace more than 30 m long or a multi-chamber furnace. Press hardened steels need to be heated to 900 °C for full austenitization in order to achieve a uniform consistent phase, and this contributes to energy requirements often exceeding 2 MW.

Integrating multiple functions into fewer parts leads to part consolidation. Accommodating large laser-welded parts such as combined front and rear door rings expands the need for even wider furnaces, higher-tonnage presses, and larger bolster dimensions.

Blanking of coils used in the PHS process occurs before the hardening step, so forces are low. Post-hardening trimming usually requires laser cutting, or possibly mechanical cutting if some processing was done to soften the areas of interest.

That contrasts with the blanking and trimming of high strength cold-forming grades. Except for the highest strength cold forming grades, both blanking and trimming tonnage requirements are sufficiently low that conventional mechanical cutting is used on the vast majority of parts. Cut edge quality and uniformity greatly impact the edge stretchability that may lead to unexpected fracture.

Responsibilities

Most cold stamped parts going into a given body-in-white are formed by a tier supplier. In contrast, some automakers create the vast majority of their hot stamped parts in-house, while others rely on their tier suppliers to provide hot stamped components. The number of qualified suppliers capable of producing hot stamped parts is markedly smaller than the number of cold stamping part suppliers.

Hot stamping is more complex than just adding heat to a cold stamping process. Suppliers of cold stamped parts are responsible for forming a dimensionally accurate part, assuming the steel supplier provides sheet metal with the required tensile properties achieved with a targeted microstructure.

Suppliers of hot stamped parts are also responsible for producing a dimensionally accurate part, but have additional responsibility for developing the microstructure and tensile properties of that part from a general steel chemistry typically described as 22MnB5.

Property Development

Independent of which company creates the hot formed part, appropriate quality assurance practices must be in place. With cold stamped parts, steel is produced to meet the minimum requirements for that grade, so routine property testing of the formed part is usually not performed. This is in contrast to hot stamped parts, where the local quench rate has a direct effect on tensile properties after forming. If any portion of the part is not quenched faster than the critical cooling rate, the targeted mechanical properties will not be met and part performance can be compromised. Many companies have a standard practice of testing multiple areas on samples pulled every run. It’s critical that these tested areas are representative of the entire part. For example, on the top of a hat-section profile where there is good contact between the punch and cavity, heat extraction is likely uniform and consistent. However, on the vertical sidewalls, getting sufficient contact between the sheet metal and the tooling is more challenging. As a result, the reduced heat extraction may limit the strengthening effect due to an insufficient quench rate.

For more information, see our Press Hardened Steel Primer to learn more about PHS grades and processing!

Thanks are given to Eren Billur, Ph.D., Billur MetalForm for his contributions to the Equipment section, as well as many of the webpages relating to Press Hardening Steels at www.AHSSinsights.org.

Danny Schaeffler is the Metallurgy and Forming Technical Editor of the AHSS Applications Guidelines available from WorldAutoSteel. He is founder and President of Engineering Quality Solutions (EQS). Danny wrote the monthly “Science of Forming” and “Metal Matters” column for Metalforming Magazine, and provides seminars on sheet metal formability for Auto/Steel Partnership and the Precision Metalforming Association. He has written for Stamping Journal and The Fabricator, and has lectured at FabTech. Danny is passionate about training new and experienced employees at manufacturing companies about how sheet metal properties impact their forming success.

Manufacturers embrace Advanced High Strength Steels as a cost-effective way to satisfy functional and regulatory requirements. The following are just a few examples where automakers have attributed improved performance and lightweighting due to the use of these advanced steels.

KIA EV9

The Kia EV9, Kia’s first three-row electric flagship SUV, is based on the Electric Global Modular Platform (E-GMP).K-59 Kia EV9 won the 2024 North American Utility Vehicle of the Year™ (NACTOY) AwardK-60, and was named a 2024 Top Safety Pick by IIHS, the Insurance Institute for Highway Safety.K-61 Kia deployed hot stamped parts in the passenger safety cage for enhanced passenger protection and crash energy management.K-62

Figure 1: Hot stamped parts increase the average tensile strength in the 2024 Kia EV9K-62

Tesla Cybertruck and Model Y

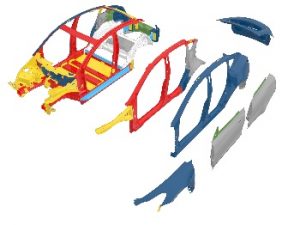

Much press has been given to the “ultra-hard stainless steel” used on the Cybertruck skin panelsT-46, but there are several high strength and advanced high strength steel parts on the vehicle as well. According to the Cybertruck Collision Repair Manual,T-47 Tesla defines mild steel as having a tensile strength less than 270 MPa. The tensile strength of high strength steels ranges from 300 MPa to 700 MPa. Ultra high strength steels are those with a tensile strength greater than 800 MPa. Figure 2 presents a breakdown of materials used in the body structure.

Figure 2: Cybertruck Body Materials. Dark blue = mild steel; yellow = high strength steel; red = ultra high strength steel; orange = stainless steel.T-47

A video by Munro Live with Lars Moravy, Tesla’s Head of Vehicle Engineering, shows that the Cybertruck body side inner is formed from a laser welded press hardened steel.M-65-2 An interview with Thomas Ausmann, former global advanced manufacturing technical advisor at Tesla, confirms that Tesla hot stamps the double-door rings, which represents the first hot-stamped part that Tesla had ever produced internally at any of its plants.B-78 Figure 3 shows a Cybertruck hot-stamped body side inner.

Figure 3: The Cybertruck double door ring made from a laser welded blank is the first hot stamped part that Tesla ever produced internally at any of its plants M-65-2 B-78

The Model Y Collision Repair Procedures ManualT-48 highlights that there are several ultra high strength steel parts in the body structure. Another video from Munro LiveM-70 confirms that the ultra high strength steel in the body side aperture is press hardened, hot stamped steel. Simwon NA is the likely supplier of these hot stamped parts.Y-15

Figure 4: Press Hardened Hot Stamped Steel in the Model Y Body Side Outers and Inners. Dark blue = mild steel; yellow = high strength steel; red = ultra high strength steelT-48

Li Auto L8

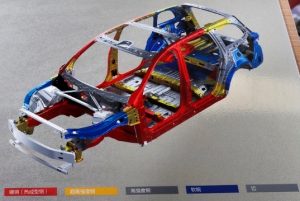

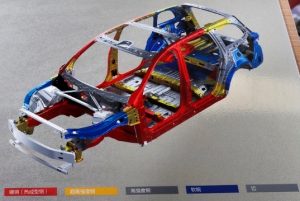

The Li L8 is a luxury range-extended battery electric SUV equipped with an autonomous driving system produced by Chinese manufacturer Li Auto. Hot-formed steel is used in safety-critical areas such as the A-pillar, B-pillar, C-pillar, door sills, and door intrusion beams, accounting for 28.9% of the entire body-in-white, with high strength steels accounting for over 75% of the body structure. Hot-formed steel parts are shown in red in Figure 5, with ultra high strength steel shown in yellow, high strength steel shown in dark gray, and mild steel parts colored in blue.X-2

Figure 5: Nearly 30% of the Li Auto L8 body-in-white is made from Hot Stamped Press Hardened Steels.X-2

Honda Civic

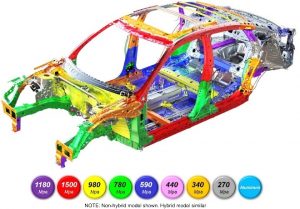

The 2025 Honda Civic Hybrid, based on the 11th Generation Honda Civic platform launched for the 2022 model year, uses high strength and advanced high strength steel throughout their Next-Generation Advanced Compatibility Engineering™ (ACE™) body structure. Honda defines high-strength steel (HSS) as any steel with a tensile strength of 340 MPa or higher. Ultra-high-strength steels (UHSS) are those with a tensile strength of 980 MPa or higher.H-68

Figure 6: The body construction of the 2025 Honda Civic uses high-strength steel and advanced high-strength steel for enhanced passenger protection.H-67

Nissan Rogue

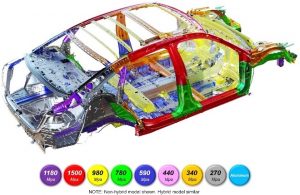

The 3rd Generation Nissan Rogue, launched for the 2021 Model Year, makes extensive use of advanced high strength steels, including 3rd Gen AHSS.

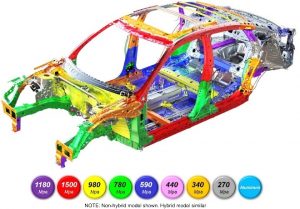

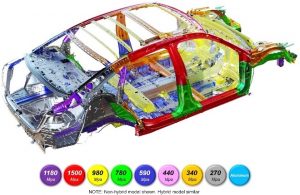

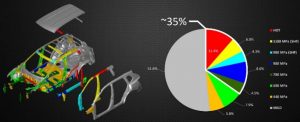

Nissan deploys AHSS grades for 35% of the body structure, an increase of more than 10% compared to the prior version.L-67 Hot stamped press hardened steels, not used in the prior model, helps this Nissan Rogue achieve improved safety, fuel efficiency, and customer satisfaction. Figure 7 shows how various steel grades are deployed in the body structure.

Figure 7: Nissan Rogue Body-in-White Uses Press Hardened Steels and 3rd Generation Advanced High Strength Steel Grades.L-67

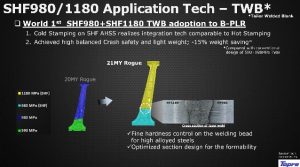

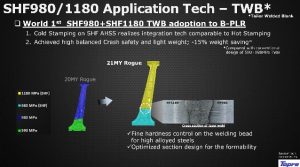

The Rogue’s B-pillar is cold stamped from a tailor welded blank of super high formable 980 (SHF 980) and super high formable 1180 (SHF 1180) steel, allowing Nissan to realize the same benefits of hot stamping at a much higher productivity, as highlighted in Figure 8 L-67. Both of these super high formable grades can be considered 3rd Generation Advanced High Strength Steels. (See the information on the 2018 Infinity QX50 SUV here) .

Figure 8: The Nissan Rogue uses a laser welded blank formed from two 3rd Generation Advanced High Strength Steels. L-67

A critical enabling technology in the use of SHF 980 and SHF 1180 is the development of design guidelines for welding stacks that include those materials. These guidelines use weld gun control and panel positioning to prevent unneeded additional tensile stress in the weld stack.L-66 Minimizing the tensile stress in the weld stack helps address the risk of liquid metal embrittlement as does extending the hold time portion of the spot weld cycle in order to lower the temperature prior to releasing the electrodes.L-67

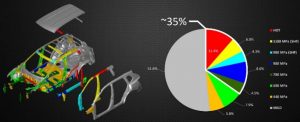

Chevrolet Blazer EV

The Chevrolet Blazer EV is built on the same architecture as the Chevrolet Equinox EV, Cadillac Lyriq, Honda Prologue, Acura ZDX EV, among others.E-14

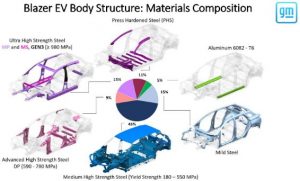

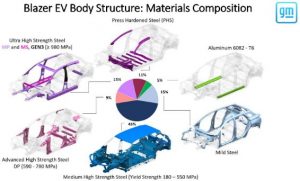

Fifteen percent of the body structure are ultra high strength steels, including multiphase, martensitic, and 3rd Generation Steels having a tensile strength of at least 980 MPa. An additional 11% are stamped from press hardened steels. The breakdown of the Blazer EV body structure is shown in Figure 9.

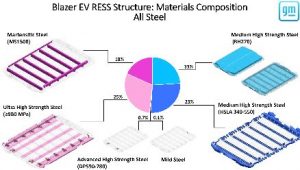

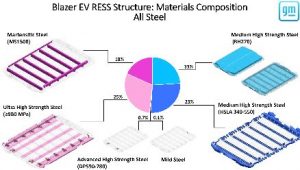

Regarding the battery pack, part of the General Motors battery management system known as the Rechargeable Energy Storage System (RESS), 43% of the all-steel construction is made from grades with tensile strength of at least 980 MPa. (Figure 10).

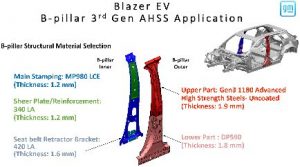

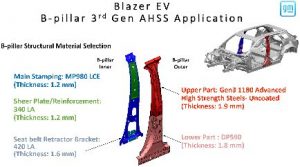

Instead of using press hardening steels for the B-pillar, General Motors stated that there was a cost savings in addition to a mass savings by using 3rd Generation AHSS in this application. This required development of a material grade specification capable of use globally, along with forming and welding practices for robust production. (Figure 11).

Figure 9: 35% of the Chevrolet Blazer EV body structure is made from Advanced High Strength Steels with a tensile strength of at least 590 MPa. E-14

Figure 10: 43% of the Chevrolet Blazer EV Rechargeable Energy Storage System structure is made from Advanced High Strength Steels with a tensile strength of at least 980 MPa. E-14

Figure 11: Use of 3rd Generation Advanced High Strength Steels in the B-Pillar of the Chevrolet Blazer EV led to cost savings and mass savings while maintaining crash and safety performance. E-14

Blog, homepage-featured-top, main-blog, News

This month’s blog was contributed by Peter Ulintz, Precision Metalforming Association. This content originally appeared in the September 2023 issue of MetalForming Magazine under the title “Stronger AHSS Knowledge Required for Metal Stampers” and has been reproduced with the permission of MetalForming Magazine.

Metal stampers and die shops experienced with mild and HSLA steels often have problems making parts from AHSS grades. The higher initial yield strengths and increased work hardening of these steels can require as much as four times the working loads of mild steel. Some AHSS grades also have hardness levels approaching the dies used to form them.

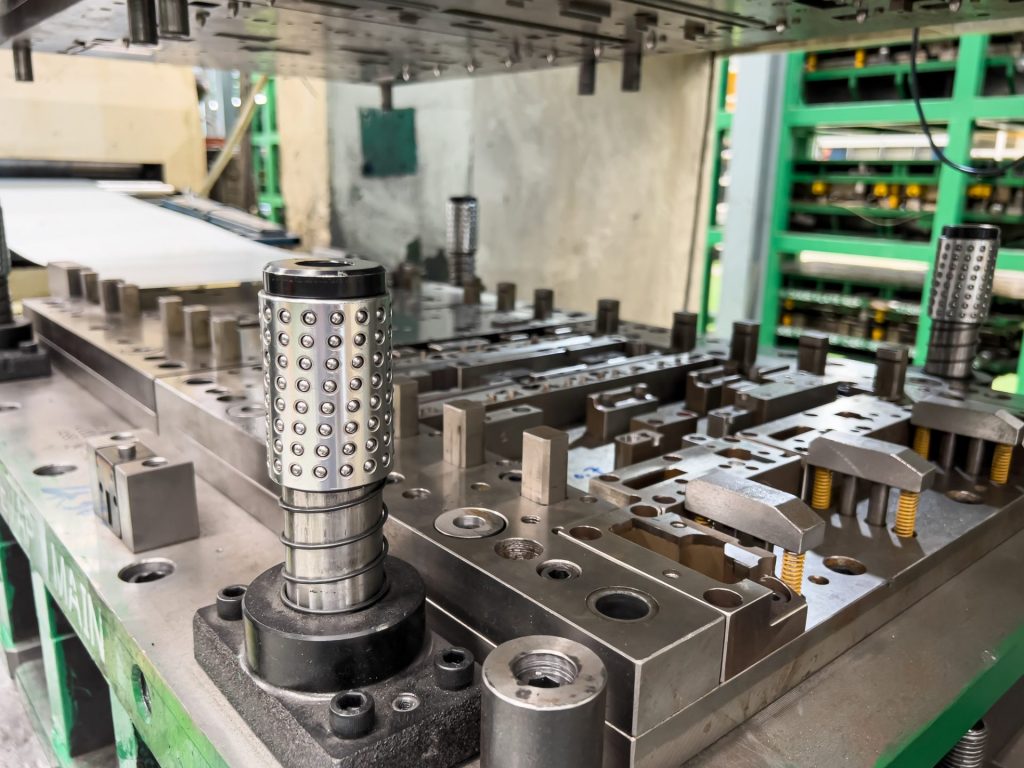

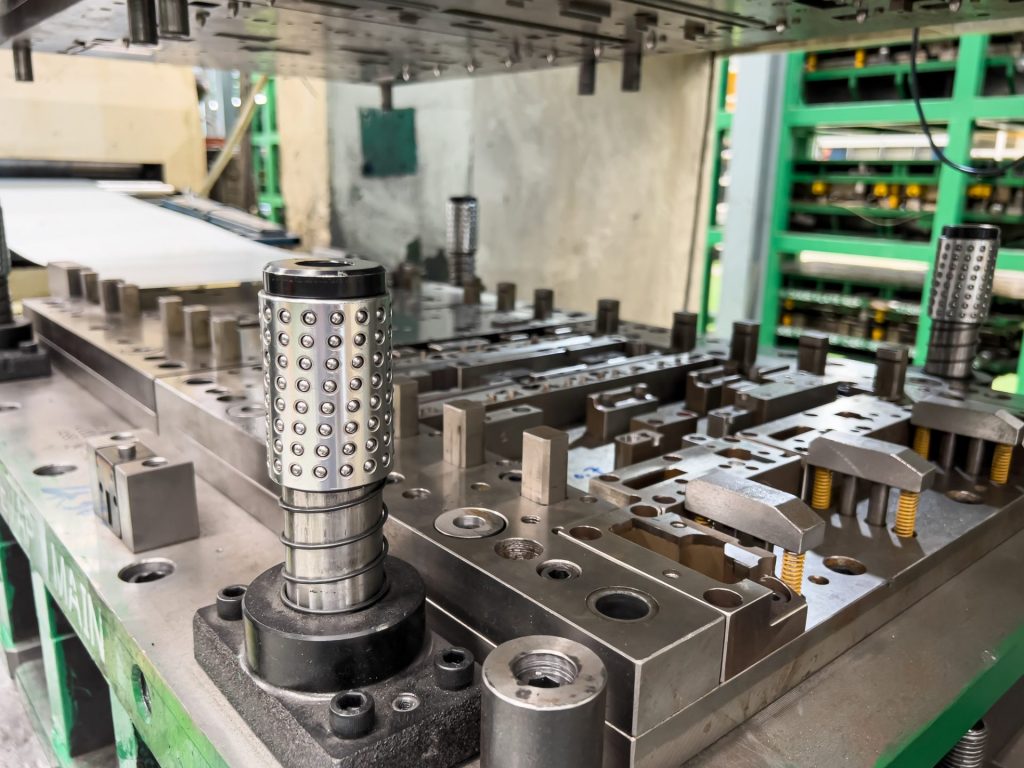

Dies Get Tougher

Metal stampers and die shops experienced with mild and HSLA steels often have problems making parts from AHSS grades. The higher initial yield strengths and increased work hardening of these steels can require as much as four times the working loads of mild steel. Some AHSS grades also have hardness levels approaching the dies used to form them.

The higher stresses required to penetrate higher-strength materials require increased punch-to-die clearances compared to mild steels and HSLA grades. Why? This clearance acts as leverage to bend and break the slug out of the sheet metal. Stronger materials need longer levers to bend the slug. The required clearance is a function of the steel grade and tensile strength, and sheet thickness.

Increasing cutting clearance can result in punch cracking and head breakage due to higher snapthrough loads and reverse-unloading forces within the die. Adding shear angles to the punch face helps reduce punch forces and reverse unloading.

Tight-cutting clearances increase the tendency for die galling and chipping. The severity of galling depends on the surface finish and microstructure of both the tool steel and work material. Chipping can occur when process stresses are high enough to cause low-cycle fatigue of the tooling material, indicating that the material lacks toughness.

Stamping Tool Failure Modes (Citations T-20 and U-7)

Tempering of tools and dies represents a critical heat-treatment step and serves more than one purpose, but of primary concern is the need to relieve residual stresses and impart toughness. Dies placed in service without proper tempering likely will experience early failure.

Dies made from the higher-alloy tool-steel grades (D, M or T grades) require more than one tempering step. These grades contain large amounts of retained austenite and untempered martensite after the first tempering step and require at least one more temper to relieve internal stresses, and sometimes a third temper for even greater toughness.

Unfortunately, heat treatment remains a “black-box” process for most die shops and manufacturing companies, which send soft die details to the local heat treat facility, with hardened details returned. A cursory Rockwell hardness test may be conducted at the die shop when the parts return. If they meet hardness requirements, the parts usually are accepted, regardless of how they may have been processed—a problem, as hardness alone does not adequately measure impact toughness.

Machines Get Stronger

The increased forces needed to form, cut and trim higher-strength steels create significant challenges for pressroom equipment and tooling. These include excessive tooling deflections, damaging tipping-moments, and amplified vibrations and snapthrough forces that can shock and break dies—and sometimes presses. Stamping AHSS materials can affect the size, strength, power and overall configuration of every major piece of the press line, including material-handling equipment, coil straighteners, feed systems and presses.

Here is what every stamper should know about higher-strength materials:

- Because higher-strength steels require more stress to deform, additional servo motor power and torque capability may be needed to pull the coil material through the straightener. Additional back tension between the coil feed and straightening equipment also may be required due to the higher yield strength of the material in the loop as the material tries to push back against the straightener and feed system.

- Higher-strength materials, due to their greater yield strengths, have a greater tendency to retain coil set. This requires greater horsepower to straighten the material to an acceptable level of flatness. Straightening higher-strength coils requires larger-diameter rolls and wider roll spacing in order to work the stronger material more effectively. But increasing roll diameter and center distances on straighteners to accommodate higher-strength steels limits the range of materials that can effectively be straightened. A straightener capable of processing 600-mm-wide coils to 10 mm thick in mild steel may still straighten 1.5-mm-thick material successfully. But a straightener sized to run the same width and thickness of DP steel might only be capable of straightening 2.5 mm or 3.0-mm thick mild steel. This limitation is primarily due to the larger rolls and broadly spaced centers necessary to run AHSS materials. The larger rolls, journals and broader center distances safeguard the straightener from potential damage caused by the higher stresses.

- Because higher-strength materials require greater stress to blank and punch as compared to HSLA or mild steel, they generate proportionally increased snapthrough and reverse-unloading forces. High-tensile snapthrough forces introduce large downward accelerations to the upper die half. These forces work to separate the upper die from the bottom of the ram on every stroke. Insufficient die-clamping force could cause the upper-die half to separate from the bottom of the ram on each stroke, causing fatigue to the upper-die mounting fasteners.

- Because energy is expended with each stroke of the press—and this energy must be replaced—critical attention must focus on the size (horsepower) of the main drive motor and the rotational speed of the flywheel in higher-strength-steel applications. The main motor, with its electrical connection, provides the only source of energy for the press and it must generate sufficient power to meet the demands of the stamping operation. The motor must be properly sized to replace the increased energy expended during each press stroke. For these reasons, some stampers consider the benefits of servo-driven presses for these applications.

As steels becomes stronger, a corresponding increase in process knowledge is required in terms of die design, construction and maintenance, and equipment selection.

You can read more about these topics at these links:

Tooling and Die Wear

Coil Processing Straightening and Leveling

Press Requirements

Thanks go to Peter Ulintz, of the Precision Metalforming Association (PMA) for authoring this article. Ulintz was employed in the metal stamping and tool & die industries for 38 years before joining Precision Metalforming Association (PMA) in 2015. He provides industry-related training and seminars in Stamping Press Operation and Setup; Designing and Building Metal Stamping Dies; Die Maintenance and Troubleshooting; Metal Stamping Design for Manufacturability; Deep Draw Tooling and Process Technology; Stamping Higher Strength Steels; and Problem Solving in the Press Shop. Peter is a contributor to ASM Handbook, Volume 14B, Metalworking: Sheet Forming (2006) and writes the monthly column, Tooling by Design, for PMA’s monthly publication, MetalForming Magazine.