AHSS Insights Blog

Press Hardening Steel Grades: Unlocking Strength Through Innovation

You’ll find most of this content as part of our page on Press Hardening Steel Grades, but this month, we want to highlight it in our AHSS Insights blog. Thanks to Eren Billur, Ph.D., President, Billur Metal Form, for providing this information. What...

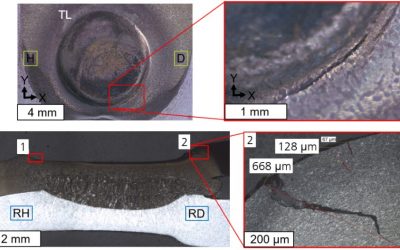

Four Steps to Mitigate Liquid Metal Embrittlement When Welding Steel

Liquid Metal Embrittlement (LME) during Resistance Spot Welding (RSW) can cause cracks when welding advanced high strength steels. Recent advances in steel metallurgy, resistance spot welding processing and accompanying simulation tools have substantially improved the...

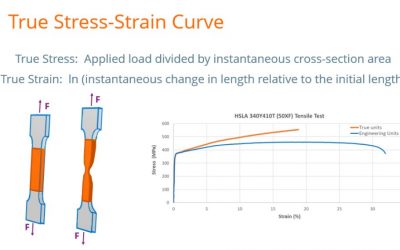

Tensile Testing: Engineering Stress-Strain Curves vs. True Stress-Strain Curves

Tensile testing is one of the most basic formability characterization methods available. Results from tensile testing are a key input into metal forming simulations, but if the right information isn’t included, the simulation will not accurately reflect material...

Resistance Spot Welding with Advanced High-Strength Steels: Cold Stamped and Hot Formed

The discussions relative to cold stamping are applicable to any forming operation occurring at room temperature such as roll forming, hydroforming, or conventional stamping. Similarly, hot stamping refers to any set of operations using Press Hardening Steels (or Press...

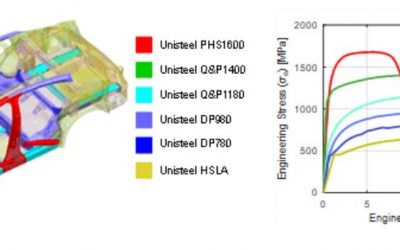

Cold Stamped or Hot Formed? Part II

Grade Options and Corrosion Protection Considerations When Deciding How A Part Gets Formed Automakers contemplating whether a part is cold stamped or hot formed must consider numerous ramifications impacting multiple departments. Our prior blog on this topic...

Cold Stamped or Hot Formed? Part 1

Equipment, Responsibilities, and Property Development Considerations When Deciding How A Part Gets Formed Automakers contemplating whether a part is cold stamped or hot formed must consider numerous ramifications impacting multiple departments. Over a series of blogs,...