This is a summary of a paper by M. Mazar Atabaki, et al, entitled, “Pore formation and its mitigation during hybrid laser/arc welding of advanced high strength steel”M-66, referenced by permission.

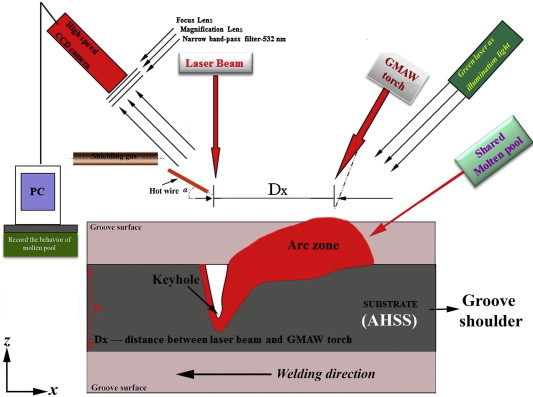

Hybrid laser-arc welding (HLAW) is a popular welding process for thick sections. HLAW combines the high penetration depth and speed of laser welding with the volume and high deposition of gas metal arc welding (Figure 1).

Figure 1: HLAW Diagram.M-66

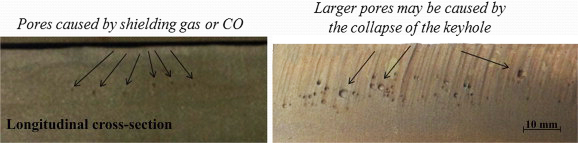

A common issue with this process is the formation of pores, which researchers from Southern Methodist University in Dallas addressed by optimizing various variables to reduce the presence of pores. HLAW was used to weld two coupons of Advanced High-Strength Steel (AHSS) with a carbon equivalent (CE) of 0.75 wt% (Figure 2). The pores appeared to be caused by two different sources. One type of pore appeared to form when the filling rate of the collapsing keyhole is slower than the solidification rate of the molten material. This left voids (pores) in the material. Other pores were caused by the trapping of shielding gas in the weld pool, a result of the fast solidification rate of laser welding.

To address the porosity, four variables were focused on:

- Increasing heat input in HLAW; creating a larger weld pool and slower solidification rates, giving more time for gases to escape from the weld pool.

- Optimization of the stand-off distance of the filler wire.

- Application of a side shielding gas.

- Use of a hot wire.

The researchers also found that the presence of certain alloying elements could affect the stability of the keyhole (alloys with a low boiling point). It was also important to find the optimum stand off distance for the wire. When the filler wire was too close, the arc got in the way of the laser and reduced power to the keyhole, causing instability. When a hot wire was used, the fusion zone microstructure consisted of martensite and bainite. Fracture testing showed brittle fracture surface with indications of gas entrapment, emphasizing the need to diffuse gases out of the molten weld pool.

The researchers found that the optimum stand-off distance between the laser and the arc was 8mm. At this distance, the molten weld pool was allowed to widen, which helped with degassing the liquid metal. When combined with a 92%Ar/8%CO side shielding gas, much of the porosity was alleviated. The use of a hot wire also improved the stability of the weld pool reducing some of the longitudinal porosity.