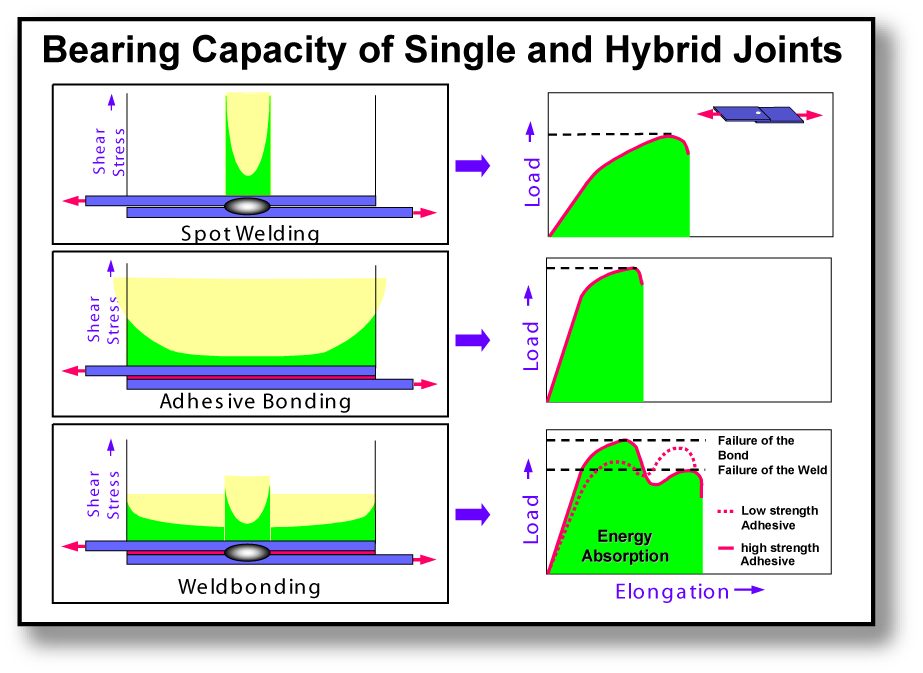

As with mild steels, AHSS-hybrid joints can be made by combining adhesive bonding with RSW, clinching, or self-piercing riveting. These hybrid joints result in higher strength values (static, fatigue, and crash) than the spot welding alone (Figure 1). If local deformation and buckling can be avoided during in-service applications of weld bonding/adhesive hybrid joining, the potential for component performance is enhanced.

Figure 1: Comparison of bearing capacity for single and hybrid Joints.B-3

Hybrid RSW and Adhesives

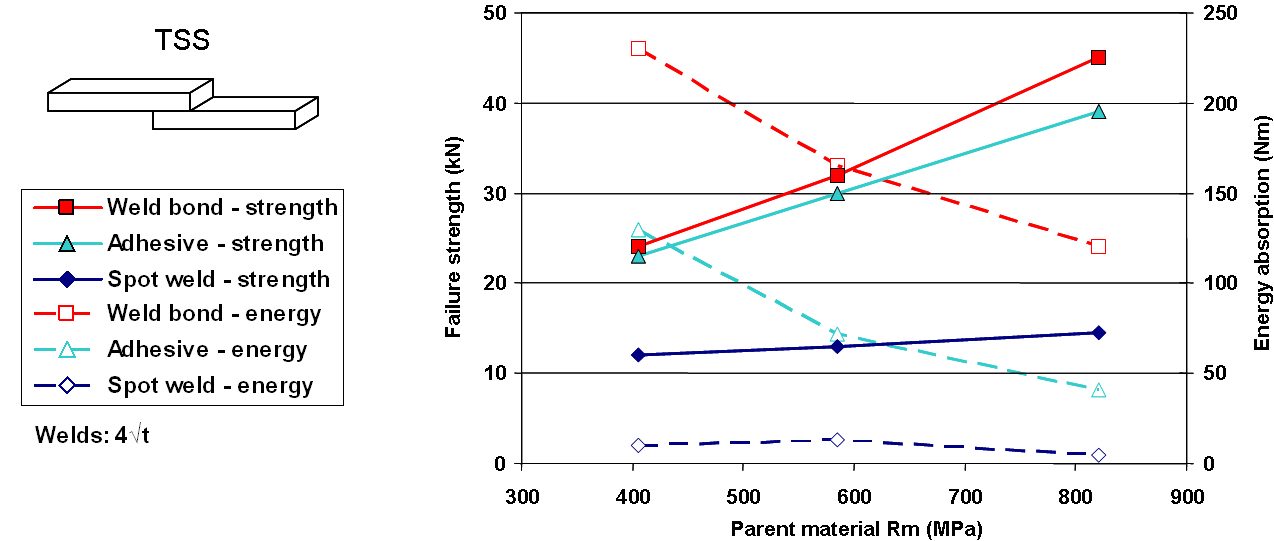

Many automotive joining BIW applications are using the combination of RSW together with adhesives to obtain superior joint performance. This combination is referred to as WB. Figure 2 shows a tensile shear test for resistance spot welds, adhesives, and weld bonds. There were trends of fracture strength increasing slightly with material strength with the spot welds. Also, the fracture strength was very high, increasing significantly with increasing material strength for adhesive bonds. The fracture strength was the highest for welded bonds and increased significantly with increasing material strength.

Figure 2: TSS failure strength and energy absorption for all joints and materials.T-10

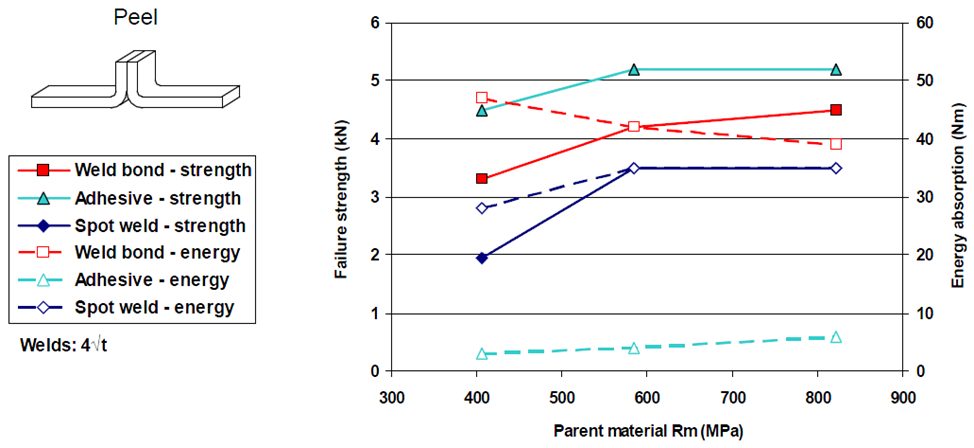

Figure 3 represents a peel test for the same samples. Trends observed were fracture strength increasing slightly with material strength but is lower than the other joining methods for spot welds. Fracture strength for adhesive bonding is greater than Weld Bonding (WB) and spot welding. Energy absorption was not very sensitive to material strength. The bond using adhesive alone had poor failure strength as well as poor energy absorption.

Figure 3: Peel strength data for all joint types.T-10

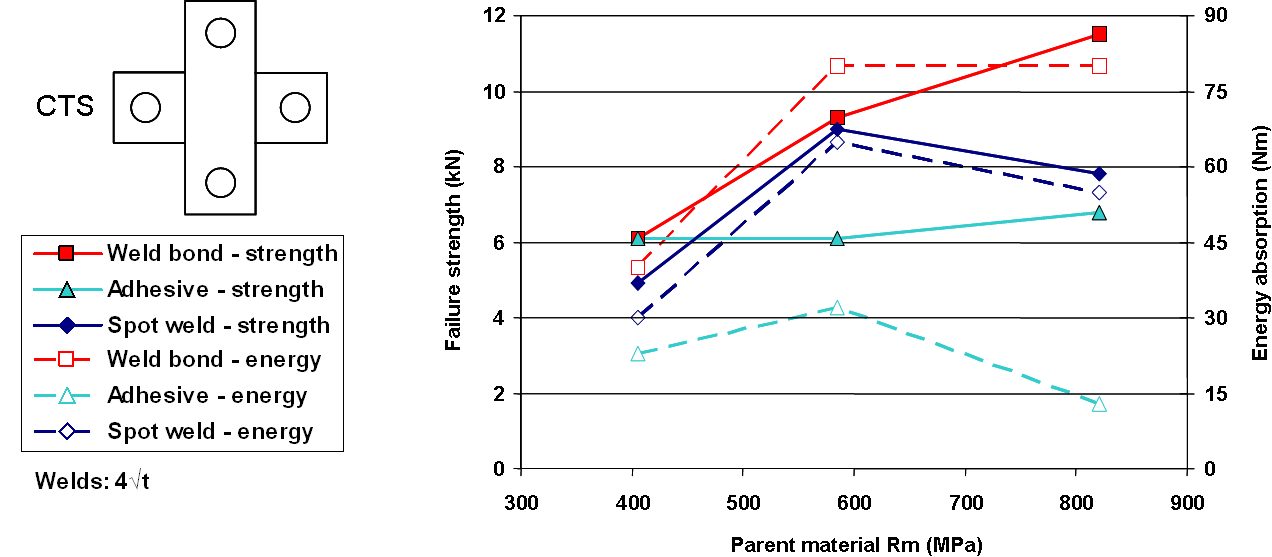

Figure 4 shows cross tensile results for the three samples. Spot welds showed fracture strength reaching a maximum for DP 600. Adhesive fracture strength increased slightly with increasing material strength. The welded bond’s fracture strength was greater than the other joint types and increased significantly with increasing material strength.

Figure 4: CTS fracture strength and energy absorption for all joints and materials.T-10

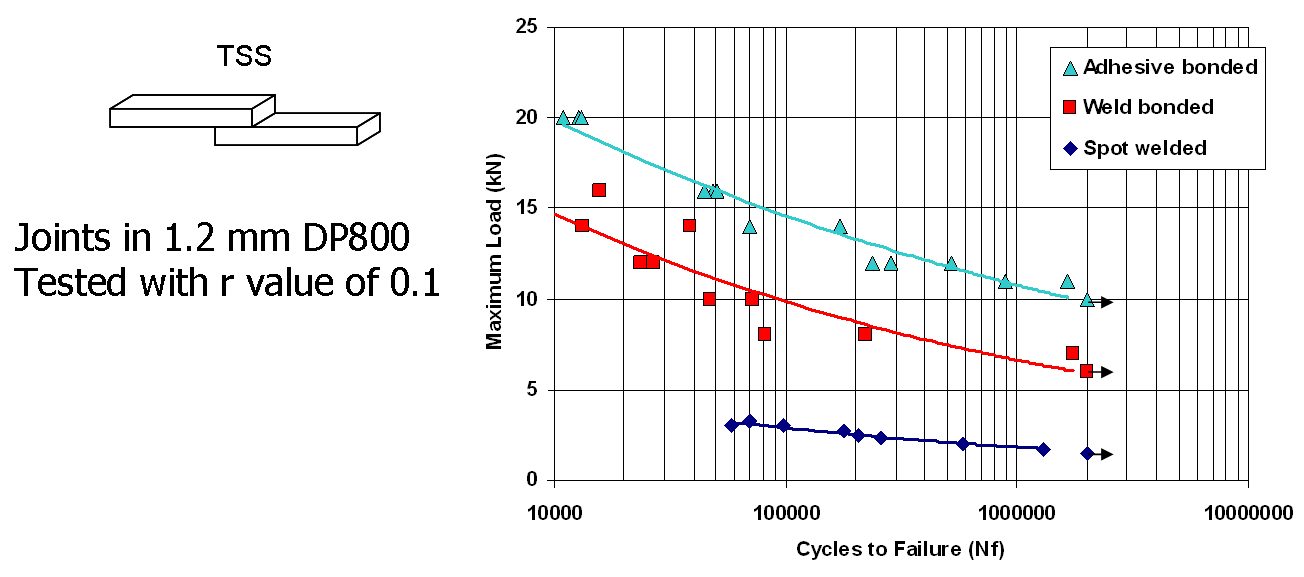

Figure 5 shows the fatigue testing performed in tensile shear mode on DP 800 [LINK TO DP steel page in Metallurgy] material (1.2-mm gage). Spot welds showed the lowest fatigue properties of the test samples. While the weld-bonded samples performed much better than conventional spot welds, they were still weaker than the adhesive joints. Adhesive had the best fatigue performance. The parent material properties had little influence upon the fatigue properties of spot welds because the spot weld itself acts as a fatigue crack initiator.

Figure 5: DP 800 fatigue results.T-10