RSW Masterclass

Four Steps to Mitigate Liquid Metal Embrittlement When Welding Steel

Liquid Metal Embrittlement (LME) during Resistance Spot Welding (RSW) can cause cracks when welding advanced high strength steels. Recent advances in steel metallurgy, resistance spot welding processing and accompanying simulation tools have substantially improved the way that LME can be handled in industrial practice. This article gives a brief overview of easy measures to implement when LME might potentially occur during production.

Introduction

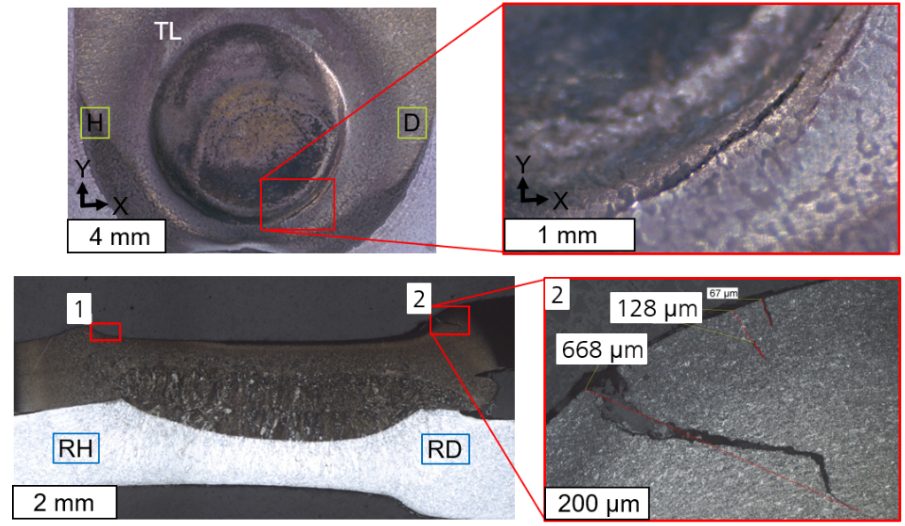

During resistance spot welding of zinc-coated advanced high strength steels (AHSS) liquid metal embrittlement -related cracking may be observed. Since LME is often associated with a reduction of steel’s mechanical properties, it is desired to control its occurrence during production. An exemplary LME crack, forced with increased weld heat and deliberate electrode misalignment, is shown below.

Figure 1: A typical LME crack created under laboratory conditions by deliberately increasing the welding time and introducing 5° electrode tilt

Over the past several years, LME has been a a focus in welding research. It is now well-understood to the degree that it can be predicted and avoided with easy measures. Below is an overview of four key steps to address the potential of LME during automotive production.

Obtain the latest steel grades from your steel supplier

Over the past decade, steel producers have released AHSS with improved chemical compositions, helping to significantly reduce the occurrence of LME iIt is beneficial to talk with steel suppliers and ask about their latest AHSS grades, as these are likely far less sensitive to LME than previously tested grades. A recent study commissioned by WorldAutoSteel demonstrated that all five chosen material stack-ups from current production data did not show any LME even under exacerbated conditions. Only by choosing an especially difficult material stack-up could LME be forced to appear at all to conduct the study.

Read up on the current state of research for LME

WorldAutoSteel has published two studies on liquid metal embrittlement: One focused on lab conditions and the second on real-life stamped components. These studies provide an overview of all aspects of LME and how to manage and avoid LME issues.

Establish in-house testing protocols to gauge the sensitivity of your material stack-ups

To investigate LME in-house, it’s critical to establish a testing protocol that forces the cracks to appear and allows for comparison of different steels, stack-ups and welding parameters. as there There is currently no industry-wide agreed-upon testing standard.

Still, there is a good selection of well-documented procedures to choose from. The easiest procedure is to increase the welding time until cracks start to appear – keep in mind that you need to remove the zinc coating before you can observe any cracks on the surface.

Other methods are based on so-called “Gleeble testing” or on deliberately introducing imperfections like tilted electrodes or large gaps into the welds. As you establish a testing procedure in your lab, you can use it to evaluate LME occurrence in the stack-ups that you want to implement into body-in-whites.

Think about implementing LME mitigation strategies in your most difficult welds

Suitable measures should always be adapted to the specific use case. Generally, the most effective measures for LME prevention or mitigation are:

- Avoidance of excessive heat input (e.g. excess welding time, current)

- Avoidance of sharp edges on spot welding electrodes; instead use electrodes with larger working plane diameter, while not increasing nugget-size

- Employing extended hold times to allow for sufficient heat dissipation and lower surface temperatures

- Avoidance of improper welding equipment (e.g. misalignments of the welding gun, highly worn electrodes, insufficient electrode cooling)

These measures can be implemented in the planning stage and in an ongoing production environment to increase the LME-free process windows.

In Conclusion

While Liquid Metal Embrittlement may present a challenge when welding AHSS, it’s no longer an unpredictable threat. Thanks to advancements in steel development, welding techniques, and testing methods, manufacturers have the tools they need to reliably mitigate LME during production.

Staying informed, working closely with steel suppliers, implementing smart testing protocols, and applying targeted welding strategies can help automakers maintain both strength and quality in AHSS joints. With this proactive approach, LME doesn’t have to stand in the way of innovation in automotive manufacturing.

Download the Phase 2 LME Report

Download the Phase 1 LME Report

Fraunhofer IPK simulation site

|

Thanks go to Dr.-Ing Max Biegler, Group Lead, Joining & Coating Technology at Fraunhofer Institute for Production Systems and Design Technology IPK |

Resistance Spot Welding AHSS to Magnesium

This blog is a short summary of a published comprehensive research work titled: “Peculiar Roles of Nickel Diffusion in Intermetallic Compound Formation at the Dissimilar Metal Interface of Magnesium to Steel Spot Welds” Authored by Luke Walker, Carolin Fink, Colleen Hilla, Ying Lu, and Wei Zhang; Department of Materials Science and Engineering, The Ohio State University

*****

There is an increased need to join magnesium alloys to high-strength steels to create multi-material lightweight body structures for fuel-efficient vehicles. Lightweight vehicle structures are essential for not only improving the fuel economy of internal combustion engine automobiles but also increasing the driving range of electric vehicles by offsetting the weight of power systems like batteries.

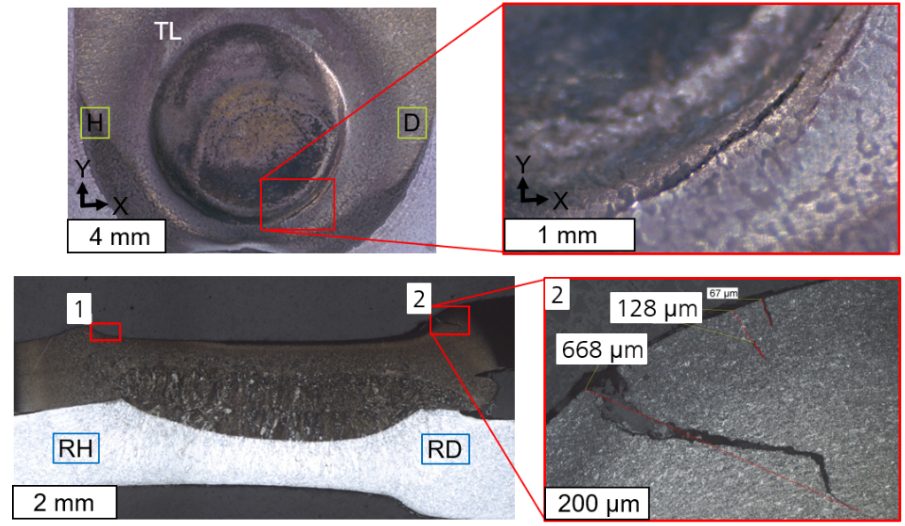

To create these structures, lightweight metals, such as magnesium (Mg) alloys, have been incorporated into vehicle designs where they are joined to high strength steels. It is desirable to produce a metallurgical bond between Mg alloys and steels using welding. However, many dissimilar metal joints form intermetallic compounds (IMCs) that are detrimental to joint ductility and strength. Ultrasonic interlayered resistance spot welding (Ulti-RSW) is a newly developed process that has been used to create strong dissimilar joints between aluminum alloys and high-strength steels. It is a two-step process where the light metal (e.g., Al or Mg alloy) is first welded to an interlayer (or insert) material by ultrasonic spot welding (USW). Ultrasonic vibration removes surface oxides and other contaminates, producing metal-to-metal contact and, consequently, a metallurgical bond between the dissimilar metals. In the second step, the insert side of the light metal is welded to steel by the standard resistance spot welding (RSW) process.

For resistance spot welding of interlayered Mg to steel, the initial schedule attempted was a simple single pulse weld schedule that was based on what was used in our previous study for Ulti-RSW of aluminum alloy to steel . However, this single pulse weld schedule was unable to create a weld between the steel sheet and the insert when joining to Mg. Two alternative schedules were then attempted; both were aimed at increasing the heat generation at the steel-insert interface. The first alternative schedule utilized two current pulses with Pulse 1, high current displacing surface coating and oxides and Pulse 2 growing the nugget. The other pulsation schedule had two equal current pulses in terms of current and welding time.

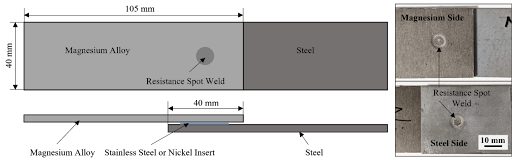

Lap shear tensile testing was used to evaluate the joint strength using the stack-up schematically, shown below. Note the images of Mg and steel sides of a weld produced by Ulti-RSW.

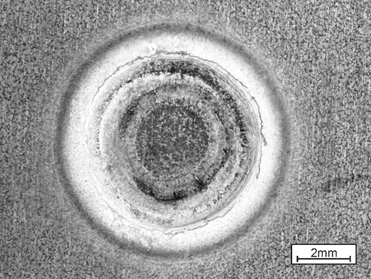

An example of a welded sample showed a distinct feature of the weld that is comprised of two nuggets separated by the insert: the steel nugget formed from the melting of steel and insert and the Mg nugget brazed onto the unmelted insert. This feature is the same as that of the Al-steel weld produced by Ulti-RSW in our previous work. Although the steel nugget has a smaller diameter than the Mg nugget, it is stronger than the latter, so the failure occurred on the Mg sheet side.

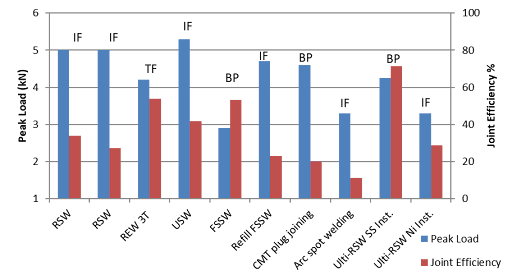

Joint strength depends on several factors, including base metal strength, sheet thickness, and nugget size, making it difficult to compare how strong a weld truly is from one process to another. To better compare the dissimilar joints created by different processes, joint efficiency, a “normalized” quantity was calculated for various processes used for dissimilar joining of Mg alloys to steels in the literature, and those results, along with the efficiencies of Ulti-RSW with inserts, are shown together below. Most of the literature studies also used AZ31 as the magnesium base metal. The ones with high joint efficiency (about 53%) in the literature are resistance element welding (REW) and friction stir spot welding (FSSW). In our study, Ulti-RSW with SS316 insert was able to reach an excellent joint efficiency of 71.3%, almost 20% higher than other processes.

Thanks are given to Menachem Kimchi, Associate Professor-Practice, Dept of Materials Science, Ohio State University, and Technical Editor – Joining, AHSS Application Guidelines, for this article.

Resistance Spot Welding: 5T Dissimilar Steel Stack-ups for Automotive Applications

Urbanization and waning interest in vehicle ownership point to new transport opportunities in megacities around the world. Mobility as a Service (MaaS) – characterized by autonomous, ride-sharing-friendly EVs – can be the comfortable, economical, sustainable transport solution of choice thanks to the benefits that today’s steel offers.

The WorldAutoSteel organization is working on the Steel E-Motive program, which delivers autonomous ride-sharing vehicle concepts enabled by Advanced High-Strength Steel (AHSS) products and technologies.

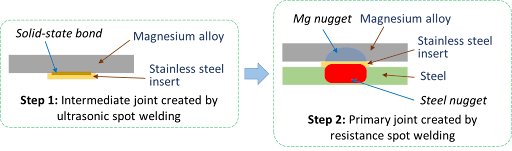

The Body structure design for this vehicle is shown in Figure 1. It also indicates the specific joint configuration of 5 layers AHSS sheet stack-up as shown in Table 1. Resistance spot welding parameters were developed to allow this joint to be made by a single weld. (The previous solution for this welded joint is to create one spot weld with the bottom 3 sheets indicated in the table and a second weld to join the top 2 sheets, combining the two-layer groups to 5T stack-up.)

NOTE: Click this link to read a previous AHSS Insights blog that summarizes development work and recommendations for resistance spot welding 3T and 4T AHSS stack-ups: https://bit.ly/42Alib8

Table 1. Provided materials organized in stack-up formation showing part number, name, grade, gauge in mm, and coating type. Total thickness = 6.8 mm

The same approach of utilizing multiple current pulses with short cool time in between the pulses was shown to be most effective in this case of 5T stack-up. It is important to note that in some cases, the application of a secondary force was shown to be beneficial, however, it was not used in this example.

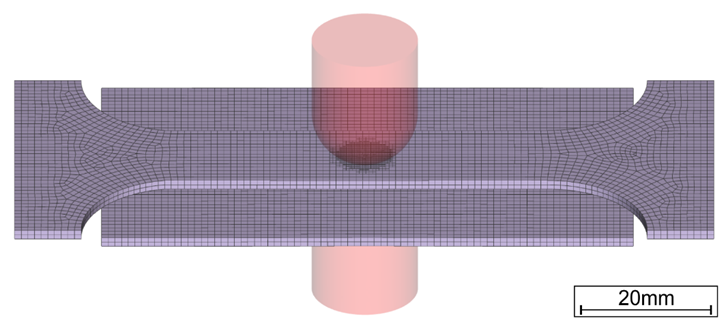

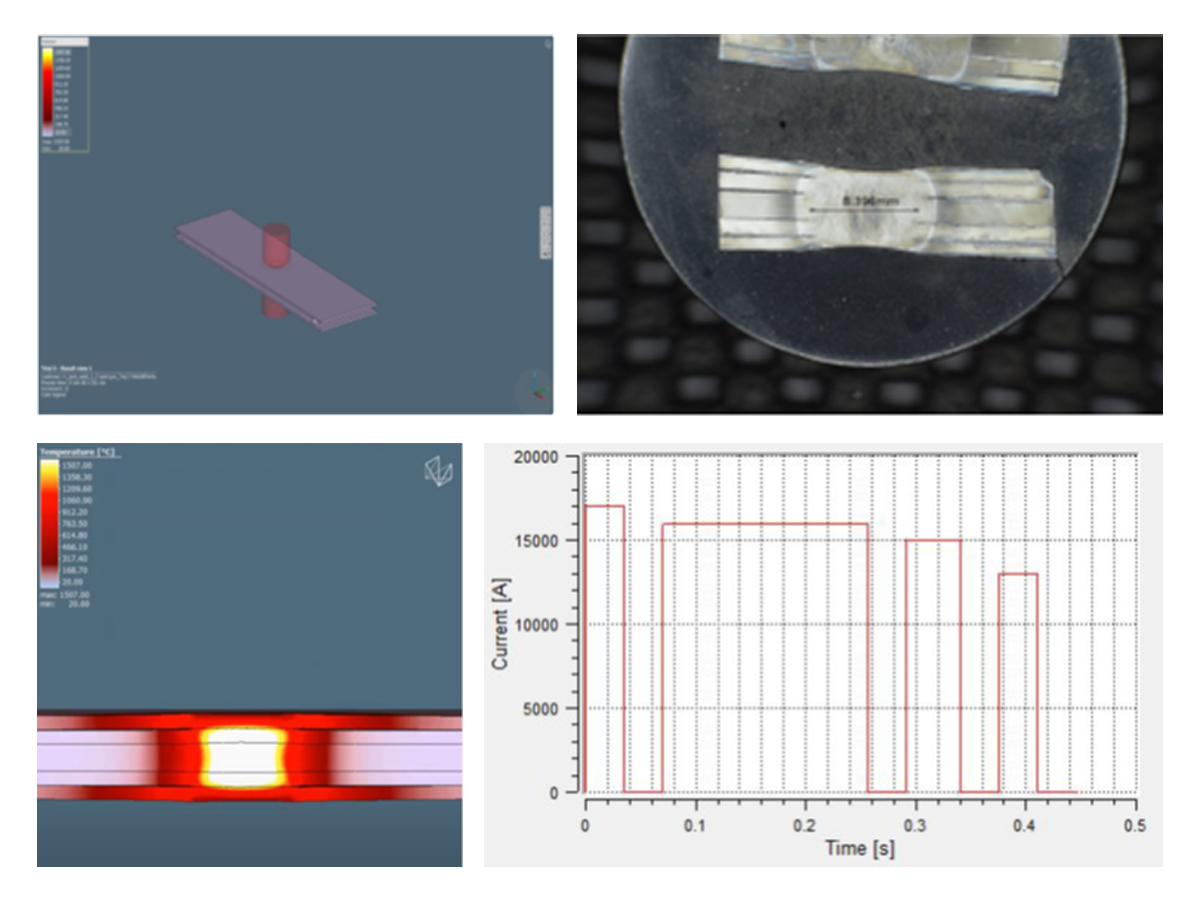

To establish initial welding parameters simulations were conducted using the Simufact software by Hexagon. As shown in Figure 2, the final setup included a set of welding electrodes that clamped the 5-layer AHSS stack-up. Several simulations were created with a designated set of welding parameters of current, time, number of pulses, and electrode force.

Figure 2. Example of simulation and experimental results showing acceptable 5T resistance spot weld (Meets AWS Automotive specifications)

Thanks is given to Menachem Kimchi, Associate Professor-Practice, Dept of Materials Science, Ohio State University and Technical Editor – Joining, AHSS Application Guidelines, for this article.

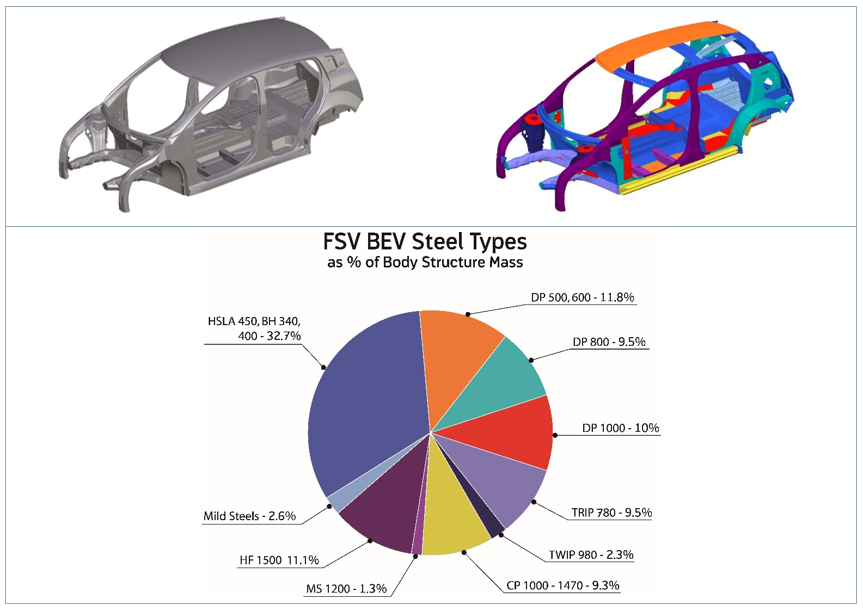

LME Simulation during RSW

Modern car bodies today are made of increasing volumes of Advanced High-Strength Steels (AHSS), the superb performance of which facilitates lightweighting concepts (see Figure 1). To join the different parts of a car body and create the crash structure, the components are usually welded to achieve a reliable connection. The most prominent welding process in automotive production is resistance spot welding. It is known for its great robustness, and easily applicable in fully automated production lines.

Figure 1: AHSS Content in Modern Car Body.W-7

There are, however, challenges to be met to guarantee a high-quality joint when the boundary conditions change, for example, when new material grades are introduced. Interaction of a liquefied zinc coating and a steel substrate can lead to small surface cracks during resistance spot welding of current AHSS, as shown in Figure 2. This so-called liquid metal embrittlement (LME) cracking is mainly governed by grain boundary penetration with zinc, and tensile stresses. The latter may be induced by various sources during the manufacturing process, especially under ‘rough’ industrial conditions. But currently, there is a lack of knowledge, regarding what is ‘rough’, and what conditions may still be tolerable.

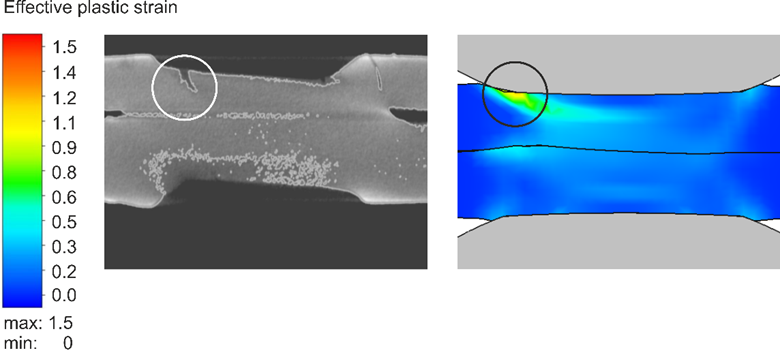

The material-specific amount of tensile stresses necessary for LME enforcement can be determined by the experimental procedure ‘welding under external load’. The idea of this method, which is commonly used for comparing cracking susceptibilities of different materials to each other, is to apply increasing levels of tensile stresses to a sample during the welding process and monitor the reaction. Figure 3 shows the corresponding experimental setup.

Figure 3: Welding under external load setup.L-51

However, the known externally applied stresses are not exclusively responsible for LME, but also the welding process itself, which puts both thermally and mechanically induced stresses/strains on the sample. Here, the conventional measuring techniques fail. A numerical reproduction of the experiment grants access to the temperature, stress and strain fields present during the procedure, providing insights on the formation of LME. The electro-thermomechanical simulation model is described in detail in Modelling RSW of AHSS. It is used to simulate the welding under external load procedure (see Figure 4).

The videos that can be found in the link above show the corresponding temperature and plastic strain fields. As heat dissipates quickly through the water-cooled electrode, a temperature gradient towards the adjacent areas and a local temperature maximum on the surface forms. The plastic strains accumulate mainly at the electrode indentation area. The simulated strain field shows a local maximum of plastic deformation at the left edge of the electrode indentation, amplified by the externally applied stresses and the boundary conditions implied by the procedure. This area correlates with experimentally observed LME cracking sites and paths as shown in Figure 5.

The simulation shows that significant plastic strains are present during welding. When external stresses (in reality e.g. due to poor part fit-up or distorted parts) contribute to the already high load, LME cracking becomes more likely. The numerical simulation model facilitates the determination of material-specific safety limits regarding LME cracking. Parameter variations and their effects on the LME susceptibility can easily be investigated by use of the model, enabling the user to develop strict processing protocols to reduce the likelihood of LME. Finally, these experimental procedures can be adapted to other high-strength materials, to aid their application understanding and industrial set-up conditions.

For more information on this topic, see the paper, co-authored by Fraunhofer and LWF Paderborn, documented in Citation F-23. You may also download the full report documenting the WorldAutoSteel LME project for which this work was conducted.

|

Dr.-Ing Max Biegler, Group Lead, Joining & Coating Technology Fraunhofer Institute for Production Systems and Design Technology IPK |