![Press Tonnage Predictions]()

Press Requirements

For a stamping operation, knowing the press tonnage required to produce a part is essential. Running a part in a press without enough capacity can cause press fatigue, damage and significant downtime. Also, an operation that must run a part in a much larger press than anticipated in order to get enough tonnage will see decreases in throughput and efficiency, resulting in increased cost. Therefore, it is critical to be able to predict a part’s stamping tonnage requirements early in the design phase of the component and the stamping process. This is even more important with the continual developments in Advanced High-Strength Steels (AHSS) that the steel industry has made. These steels offer similar formability of traditional high-strength steels with twice the strength or more, as shown in Figure 1. In this article, I will explain why typical rules of thumb that appeared to work in the past are no longer applicable and touch on how the automotive and steel industries are addressing the changes.

Figure 1: AHSS add to the spectrum of options available for automotive body construction.A-69

Tonnage Requirements and Press Capacity

When discussing the press capacity requirements, it is typical to mainly refer to ‘tonnage’ as the measurable needed. Tonnage is the peak load required during a stamping operation. The tonnage rating for a press refers to the peak load that the press can safely deliver without causing damage to the press frame, ram, bushings, etc. For a mechanical press, the peak tonnage is only available at the bottom of the stroke.

Besides peak load requirements, it is also important to understand the total energy required to form a part. It is typical for the force available from a mechanical press just a few inches off bottom to be 50% of the press tonnage rating. For drawing operations that may start several inches off bottom, it is important to predict the part tonnage requirements through the entire stroke and to compare that with the force curve from the press manufacturer. Integrating this press force curve over the entire stroke is a measure of the total energy capacity of the press. Many times, when a press stalls at bottom dead center, the issue may not be that the peak load of the press was exceeded, rather the full amount of energy that was stored in the flywheel had been expended. More information about press force and press energy are found on our page highlighting Press Requirements.

A few years ago, I saw an example of energy vs. tonnage requirements. The part was a relatively thick gage AHSS frame bracket. The design was a simple flanged hat section. In plan view, the part was only about 6-inch x 6-inch with the depth of the hat being about 4-inch. Based on the tonnage require to flange, trim and pierce a hole, the part should have easily been able to fit in a small 600-ton press. However, in order to have enough energy to produce the part, this small die was placed in the center of the 180-inch bed of a 1200-ton press. Not only was it ergonomically difficult for the operator, but the large press burden rate was much higher, and the speed was much slower than that of the smaller press, causing a significant cost increase.

Furthermore, it is good to know how off-center the load required to form a part is. Obviously, the die setter will center the die under the ram. However, most parts are not symmetric, causing the load going into the ram, bushings and press frame to be biased to one side or the other. This becomes more exaggerated in a large transfer press that may have a major draw operation at the entry end and a minor trim operation at the exit end.

Putting this all together, having the ability to predict not only the peak load required to form a part, but also the total energy through the stroke and the off-center bias gives us the ability to design a stamping process that is safe and efficient. Also, in lean manufacturing terms, a predicted through-stoke force curve provides a good baseline defining the basic condition of the die. Comparing this to actual force curves and evaluating any changes over time will help to develop preventive maintenance schedules and will offer many new capabilities with servo presses as they become more prevalent.

Conventional Rule-of-Thumb Calculations Lead to Inaccurate Press Tonnage Predictions, Especially in AHSS

In 1989, I worked for an automotive stamping supplier as a college intern. One of my tasks was to do basic calculations of part size and tonnage requirements that were used by the process engineers to design the die process and quote the manufacturing and die costs to produce the part. The rule of thumb estimates used at that time were simple calculations for the peak load. Tonnage for trim and pierce operations were dependent on the length of line of trim, material thickness and the shear strength of the material. Tonnage for forming operations were dependent on the size of the form, material thickness and material tensile strength. These calculations typically over-predicted the tonnage requirement, but because of the relative low strength steels used, as compared to today’s AHSS, most times, the limiting factor was the overall part size that dictated the size of the press to be used rather than the tonnage requirement.

So why do we hear today that these same rules of thumb do not work, or worse, that they now under predict the tonnage requirements? To understand this, let us look at a few guidelines I used over 30 years ago.

For piercing a hole: Tonnage = d * t * 80 Equation 1

In this equation d is the punch diameter in inches, t is the material thickness in inches, and it gives the tonnage in tons. This was a very simple and effective way to estimate the tonnage of all the holes pierced. Let us look at how this rule of thumb was derived. The equation is a simplification of the fact that the actual calculation is the length of line doing the work, in this case the circumference of a circle, multiplied by the material thickness and the material’s shear strength (ꚍ). The generic equation for any type of piercing or trimming is Tonnage = P * t * ꚍ where P is the perimeter or length of line of the trim, t is the material thickness and ꚍ is the shear strength of the material. A typical estimate for the shear strength (ꚍ) is 60% of the tensile strength (T) for the material. Therefore, the equation development for a simple hole piercing looks like:

| Generic trim equation: |

Tonnage = P * t * ꚍ |

Equation 2 |

| Specific for a round hole: |

Tonnage = πd * t * 0.6T |

|

| Simplifying: |

Tonnage = d * t * 0.6Tπ |

|

| Mild steel T = 300 MPa = 43.5 ksi: |

0.6 * 43.5 * 3.14 = 82 |

|

| Pierce a round hole: |

Tonnage = d * t * 80 |

|

Now that we know how the rule of thumb was derived, we can point out some possible sources of error. First, the equation uses the full thickness of the material. In reality, a typical trim operation for steel consists of 20% to 50% trimming and the remainder is breakage. The press only needs to produce load for the trimming portion. Second, the shear strength of the material is not a fixed percentage of the tensile strength. The actual shear strength should be measured for each specific grade as the microstructure differences of the AHSS will affect the material strength in shear. Lastly any of these errors are multiplied since today’s AHSS material has an overall tensile strength of three, four or even five times that of mild steel – taking any error in this estimate and magnifying it. To see this, we can take a look at a simple example of piercing a 1-inch hole in 1.5 mm thick mild steel. The steel tensile strength has a range of 40 ksi to 55 ksi (280 MPa to 380 MPa). If we look at Equation 1 with the high- and low-end assumptions, we see:

| Equation 1 estimate |

Tonnage = 1 * 0.06 * 80 = 4.8 tons |

| Equation 2 minimum |

Tonnage = 3.14 * 0.06(20%) * 0.6(40) = 0.9 tons |

| Equation 2 maximum |

Tonnage = 3.14 * 0.06(50%) * 0.6(55) = 3.1 tons |

In this very simple example, we see sources of error that could lead to an estimate of 0.9 to 4.8 tons to pierce a single hole. A similar exercise could be taken on a drawing operation. In this situation, most rules of thumb attempt to use the perimeter or surface area of the part, the material thickness and the material tensile strength to predict the tonnage needed. Sources for error in this type of calculation include: 1) Using the perimeter of the draw area, tending to under predict; 2) Using the surface area of the part, tending to overpredict; and 3) Using the tensile strength of the material, also tending to over predict as it assumes the material is stretched right to the level of splitting. Correction factors have been developed overtime, but it is still easy to see there are many possible sources of error in these types of calculations.

AHSS Magnifies Press Tonnage Prediction Challenges

We can see that there are inherent challenges with the old school rules of thumb, but why are they so exaggerated with today’s AHSS? There are a number of reasons.

- Strength: The strength of today’s cold stamped steels is quite incredible. Where a mild steel may have a tensile strength of 280 MPa, it is now common to cold stamp dual phase (DP) steels and 3rd Generation steels with up to 1180 MPa. In addition, new materials having a tensile strength of 1500 MPa with enough elongation to allow for cold stamping are starting to enter the market. This five-fold increase in strength acts as a multiplying factor for any errors in traditional predictions.

- Formability: The formability of AHSS has also increased dramatically. Today a DP 590 steel and even a 980 3rd Generation steel can have nearly the same elongation as a high-strength low alloy (HSLA) steel of 30 years ago. This affords the part designers the ability to incorporate more complex forms into a part including using darts and beads to increase a part’s stiffness, tight radii and deeper draws. All of these add to the tonnage used and are generally not part of the old school rule of thumb calculations.

- Springback Corrections: Springback is linearly related to the yield strength of a material. Therefore, stamping AHSS grades require more features to be added to the die process to control springback. These may include draw beads (used to control material flow early in the press stroke), stake beads (used at the bottom of the stroke to minimize springback) and tighter radii (Figure 2). These features are typically off product, in the addendum, and are easily ignored by typical rule of thumb calculations.

Figure 2: Draw and Stake Bead PlacementA-6

- Hardening Curves: The complex microstructure of AHSS offers many advantages to increase formability. All AHSS grades produce microstructural phase transformations during the stamping process. This allows the lower yield strength in the as-rolled material, which aids in formability, to increase during the stamping operation. This yield strength increase can be as much as 100 MPa. Models that estimate these hardening curves of the material are ignored when doing hand calculations.

- Other Considerations: Lastly the typical rule of thumb calculations, as we have discussed, only consider the part characteristics. They generally do not include the other sources that consume energy during the stamping process including off-product feature (beads, pilot holes, etc.), spring stripper pressure, pad pressure from nitrogen springs or air cushions, driven cams and part lifters. Many of these could be ignored 30 years ago with mild steels, but they become more significant with the strength of today’s AHSS.

Accurate Tonnage Predictions Require Accurate and Complete Inputs

The answer in recent years is to rely more on simulations using finite element analysis (FEA) software. Care must be taken when using these sophisticated software packages. Many times, the software is blamed when inaccurate press tonnage predictions are given. However, we know that if any of the characteristics mentioned above are ignored, the user will develop a very precise but very inaccurate tonnage prediction.

Next Steps

The issue with accurately predicting press requirements is industry-wide and has been around for decades. The recent advances in AHSS have multiplied the sources of errors that exist in the past rules of thumb and from the incorrect usage of advanced software packages. Many people within the steel and automotive industries are working on improving the reliability of these predictions including the Auto/Steel Partnership (A/SP). A/SP, founded in 1987, is a partnership between automotive OEMs, steel mills and affiliate suppliers. A/SP has teamed up with formability software suppliers to collaborate on this subject. A/SP’s project will work to measure sources of error and develop guidelines to address these in the areas of material characterization, modeling techniques and numerical analysis techniques. A/SP’s efforts, including this project, looks to bridge the gap between research laboratories and the shop floor.

What can stamping manufacturers do? First, prepare for the digital manufacturing era (often call the 4th Industrial Revolution) by keeping press tonnage monitors in good working order. Also, consider upgrading to systems that can capture full through-stroke force curves. Secondly, do not go it alone. Engage with organizations like A/SP, OEMs and steel mills. When evaluating new parts using AHSS, get the steel mill involved early, even in the die design phase. All steel mills have teams of application engineers to help OEMs and their suppliers to transition into using the newest grades of steel – they want stampers to succeed and have the tools and data to help.

Back To Top

Tooling

topofpage

Tool and die wear occurs due to the friction produced from the contact between the sheet metal and the tooling surface. Damage to the die surface can cause a gradual loss of tooling material, and scoring or burnishing damage to the sheet metal surface may be stress risers leading to premature failure in formed parts.

Impacting tool wear are the die material, strength of sheet metal, contact pressure, surface finish of the sheet and tooling, sliding velocity, temperature, coating of the die, and lubrication used. Advanced steel grades, where work hardening during stamping further increases the strength of an already high strength product, may result in additional die wear. Die wear beyond a critical point calls for replacement of the current die, impacting turnaround times and to production losses.

New die materials and better die coatings exist which minimize the impact of excessive tooling wear when forming AHSS. These new die materials include wrought and cast tool steels as well as powder metallurgy tool steels, which retain hardness without compromising the toughness of the material. Furthermore, hard material coatings and nitriding can improve the tribological properties of die surfaces.

Most tool materials for sheet metal forming are cast iron, cast steel, or tool steels.N-12 Cast iron grades used for stamping applications are gray cast irons (like G2500, G25HP and G3500) and pearlitic ductile irons (D4512, D6510, and D7003, among others). Cast steel grades include S0030, S0050A, S7140, and S2333. Tool steels include TD2 (a high wear / low shock resistant tool steel), TS7 (a high shock / low wear resistant tool steel) and TA2 (a balanced medium wear / medium shock resistant tool steel). These designations come from Reference NAAMS, with other designations in Citations A-37, A-38, I-11, J-7, J-8, J-9 Many of these designations overlap and represent the same or highly similar product. For example, ASTM A681 D2, JIS G4404 SKD11, and ISO 4957 X153CrMoV12 cover the same alloy tool steel.

In general, existing tool and die shop procedures to select the appropriate die material are applicable to select dies made to stamp Advanced High Strength Steels. However, the considerably higher strength level of these grades exerts proportionally increased load on the die material. AHSS grades might reach hardness values 4 to 5 times higher than mild steel grades. This is partially due to the microstructure of the sheet metal itself since some grades achieve higher strength from the microstructural phase martensite. Some martensitic grades (MS) have a tensile strength higher than 2000 MPa. This strength level corresponds to Rockwell C values higher than 57, meaning that the sheet metal hardness is approaching the tooling hardness.

The higher forces required to form AHSS require increased attention to tool specifications. The three primary areas are:

- Stiffness and toughness of the tool substrate for failure protection.

- Harder tool surface finishes for wear protection.

- Surface roughness of the tool.

The accepted amount of wear/galling between maintenance periods is a key factor in determining the performance requirements of draw dies, punches, and other tooling components. Some of the key elements that affect the die material specification include:

- The chosen sheet metal to be processed, as characterized by strength, thickness, surface coating, and surface profile (roughness and peak count).

- Die construction, machinability, radii sharpness, surface finish, and die hardness, specifically on draw beads and radii.

- Lubrication.

- Targeted cost per part.

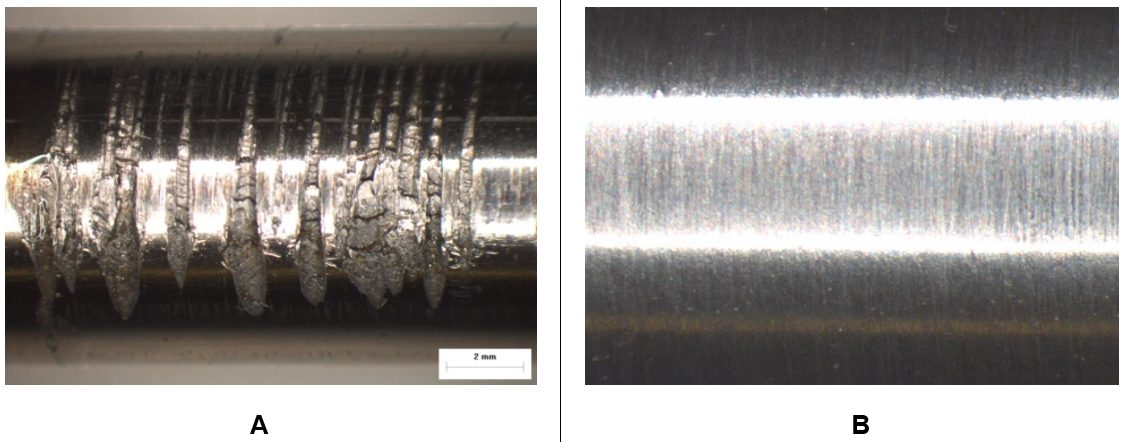

Counteracting the increased applied load required to form AHSS grades is a potential reduction in sheet thickness. This thickness reduction leading to lighter weight parts is one of the key drivers promoting expanded use of Advanced High Strength Steels. Unfortunately, the reduced thickness of the steel increases the tendency to wrinkle. Suppressing these wrinkles requires higher blankholder forces. Any formation of wrinkles will increase the local load and accelerate the wear effects. Figure 1 shows a draw die with severe die wear due to excessive wrinkling on a DP980 part. It is not uncommon to replace these high wear areas with a more durable tool steel insert to minimize this type of excessive wear condition.

Figure 1: Draw die with significant wear due to excessive wrinkling on a DP980 part. S-45

Surface Hardening Treatments and Coatings

Surface treatments and coatings help increase tool life and reduce friction. Flame or induction hardening heat treatments, nitriding, and chrome plating are common surface treatment techniques used. However, each of these can fail under the high contact pressure that is present when stamping advanced high strength steels. Coating the inserts adds additional wear and friction benefits.

Many surface hardening options exist which improve the wear resistance.A-7 Carbon content limits the achievable surface hardness with either flame hardening or induction hardening. Tools hardened with either approach must be quenched after heating, which increases the risk of distortion. Laser beam hardening relies on the high thermal conductivity of underlying base tool steel to self-quench, which reduces the magnitude of distortion. Further minimizing distortion: the energy input in laser beam hardening is approximately 10% of flame hardening.

Carbon and nitrogen increase the strength and hardness of sheet steels. Similarly, carburizing and nitriding tool steels create a hard, wear-resistant surface layer. Carburizing is done at a higher temperature, which carries the risk of distortion. Nitriding takes primarily one of two forms: gas nitriding and plasma (ion) nitriding. Ion nitriding is faster than gas nitriding, accomplished at a lower processing temperature, and minimizes the thickness of the brittle “white layer.” A-39

Chrome plating of tools and dies has been an option to increase wear resistance, but may exhibit microcracking. Environmental concerns further limit its use. In addition, studies show that is it not the best option for tools used to form advanced high strength steels.Y-6

A high hardness, low friction coating results in a wear resistant surface that lowers the risk for galling. Coatings include titanium nitride (TiN), titanium carbide (TiC), titanium carbonitride (TiCN), titanium aluminum nitride (TiAlN) and chromium nitride (CrN). Common application methods are physical vapor deposition (PVD), chemical vapor deposition (CVD), and thermal diffusion (TD).

The strength of metallurgical bonds produced in the CVD and TD processes are greater than physical bond associated with the PVD approach. However, application of CVD and TD coatings occurs at around 1000 degrees C, which is likely in the austenite region of the tool steel. This high temperature can soften the die, which then necessitates a subsequent rehardening process, and may also cause dimensional distortion. For these reasons, several global automakers specify only PVD coatings.

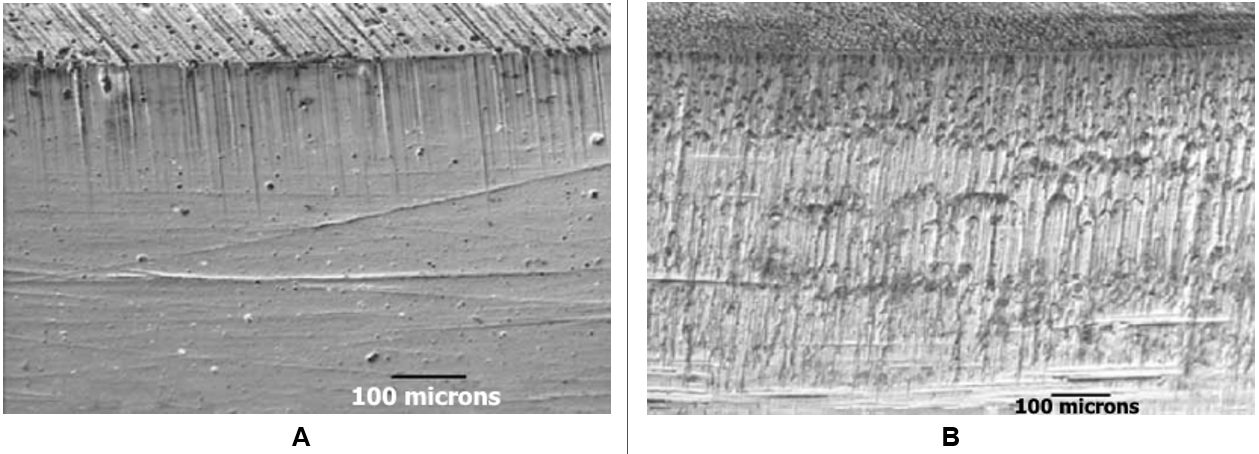

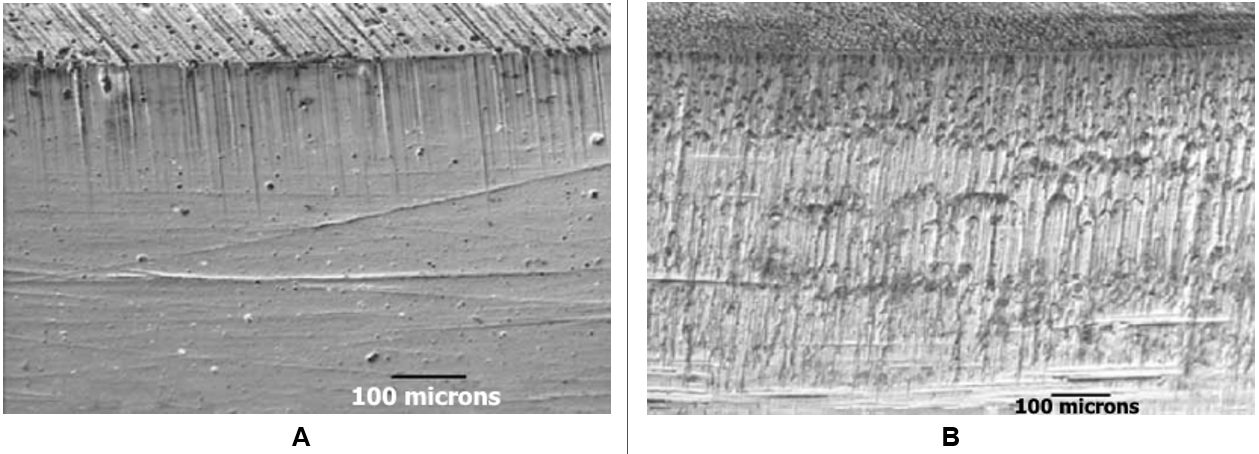

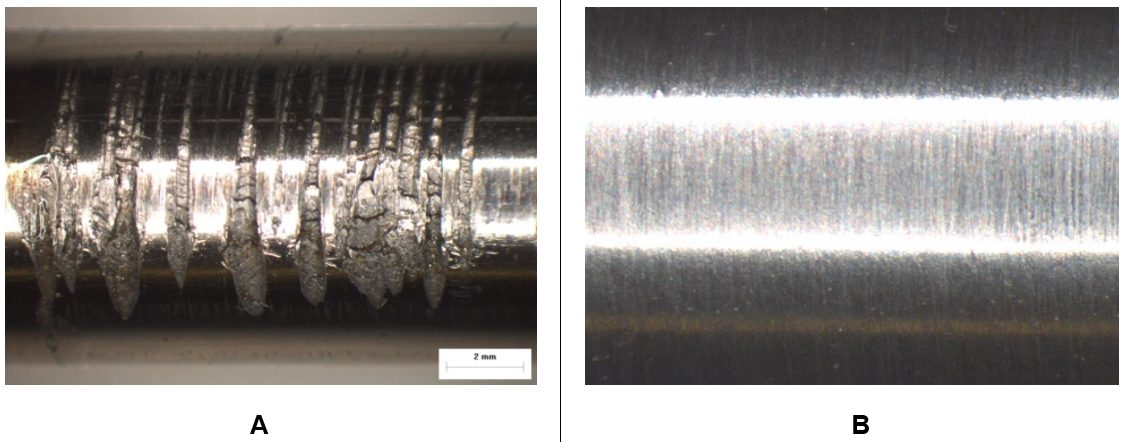

The benefits of PVD coatings in reducing galling are apparent in Figure 2, which compares a cut edge after blanking of 200,000 parts of CR 500Y/800T-DP. Use of cutting steels with a PVD-applied TiAlN coating results in a cleaner, more uniform edge.

Figure 2: PVD-applied TiAlN-coated cutting steel (image A) reduces galling compared with an uncoated cutting steel (image B). Edges are shown after 200,000 parts produced from CR 500Y/800T-DP. T-20

Since coatings may crack, it is important that the substrate has sufficient hardness/strength to avoid even the slightest plastic deformation of the tool surface. Therefore, the recommended practice is to perform an initial surface hardening treatment, typically flame or induction hardening followed by ion nitriding, to develop substrate hardness and strength before applying the coating. Surface roughness must be as low as possible before coating, with average surface roughness (Ra) values below 0.2 μm recommended. This roughness level approximates a 600-grit sandpaper finish.

Considering the high cost of coated tool steels, a recommended approach is to construct large forming tools from relatively inexpensive and soft materials, such as cast iron or low-grade tool steel. Locations subject to severe wear are candidates for inserts of high-grade tool steels with an appropriate coating engineered for the application.

Ceramic tool inserts have extreme hardness for wear resistance, high heat resistance, and optimum tribological behavior, but have poor machinability and severe brittleness. Potentially offsetting the higher cost are reduced maintenance and increased productivity. While not commonly used, the ceramic tool inserts offer a possible solution to high interface loading and wear.

Select tool steel inserts for forming dies according to the sheet metal and the forming severity. These inserts should have a surface coating when processing DP 350/600 and higher grades. Initial tryout should be completed before coating, so that die adjustments and springback compensation efforts do not lead to removal of the newly applied coating. Allow for tooling recuts during this tryout loop to ensure the resulting tool has sufficient mass and stiffness. Different friction and metal flow conditions should be expected between the initially uncoated and the ultimately coated tool steels.

The optimal surface treatment may increase upfront cost, but will reduce the rework and die maintenance cost over the life of the die. Shown in the top two lines of Figure 3 are the benefits of plasma ion nitriding a flame hardened graphite-bearing cast iron tool (GGG70L) when forming 1 mm thick electrogalvanized dual phase steel. The bottom two lines show the effect on AISI D2 (DIN 1.2379 or JIS SKD11), highlighting only minimal tooling wear over the 5000 parts evaluated.

Figure 3: Plasma ion nitriding leads to reduced tool wear. GGG70L is a flame hardened spheroidal graphite-bearing cast iron and DIN 1.2379 is AISI D2 or JIS SKD11 cold work tool steel.T-11

Coating technologies may enhance the durability of cutting edges, depending on the chosen approach. When punching 1.6 mm 1180 MPa sheet steel with a variant of D2 (“improved SKD11”), different coatings led to more than a 10x difference.Y-16 Thermo-reactive deposition and diffusion (TRD) treatment applied to the tool steel had a life of approximately 100 hits in the selected test conditions. A chemical vapor deposition (CVD) treatment achieved 2000 hits, and physical vapor deposition (PVD) treatment yielded 3000 hits before failing. The longest life of 5000 hits was achieved when a 50 μm nitrided layer was applied on top of the PVD treatment.

Figure 4 compares the surface appearance of the same tool steel with different coatings. On the left is a chrome-plated tool which exhibited adhesive and abrasive wear, and ran for only 50,000 parts. Shown on the right is an ion nitrided tool steel which was chromium nitride coated using PVD, and produced more than 1.2 million parts.

Figure 4: Tool steel surface. Left image: Chrome plated, failed after 50,000 parts; Right image: Ion nitride tool steel, chromium nitride PVD coating, produced more than 1.2 million parts. J-10

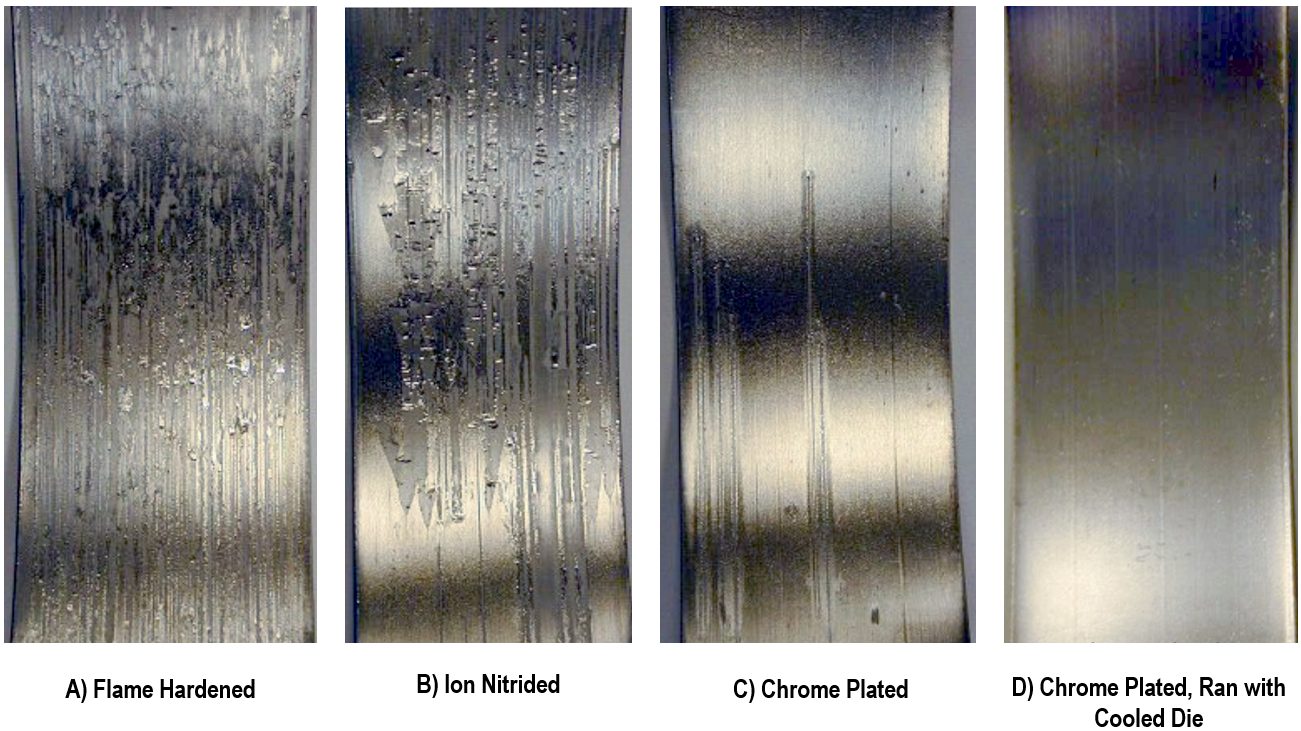

Heat produced from stamping AHSS grades interacts with the tool material and coating, which may impact friction and metal flow. 1mm thick hot dip galvannealed CR340Y/590T-DP-GA was evaluated in a laboratory set-up.S-46 Initially at room temperature, die surface temperature increased to 65 °C (150 °F) after 10 cycles of passing this DP590 grade across a tool radius and significant zinc powdering occurred. Less powdering occurred with the use of a die coolant. Cooling the dies also helped to reduce the surface scoring and associated friction [Figure 5].

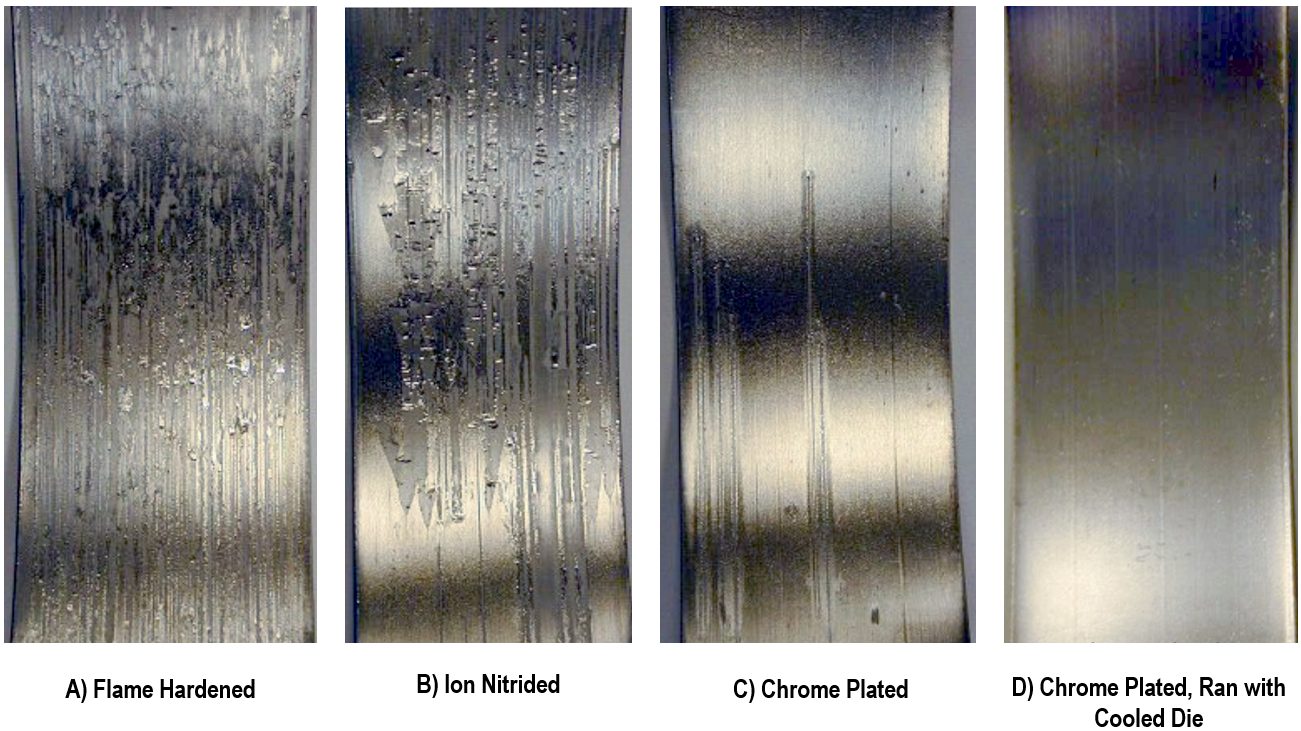

Figure 5: Coatings and Die Coolant on D2 Tool Steel Reduce Scoring and Friction with galvannealed dual phase steel. A) Flame Hardened; B) Ion Nitrided; C) Chrome Plated; and D) Chrome Plated with die coolant.S-46

Selection of tool steels for cutting, trimming, and punching tools have similar considerations as forming tools. The base tool steel must have excellent chipping and cracking resistance. Coatings will reduce tool wear. Hardening of the substrate prior to coating will minimize failure due to plastic deformation of the substrate. Coatings reduce the severity of the shock wave produced when cutting advanced high strength steels. See the Cutting / Blanking / Shearing / Trimming page for more information.

It is not advisable to use only one tooling solution for all Advanced High-Strength Steels. One study showed that die material and coating methods used in large volume production of steel grades up to and including those with 980 MPa minimum tensile strength were not suitable for forming a grade with 1180 MPa minimum tensile strength.W-18 Furthermore, this study recommends avoiding die materials such as ductile iron and low alloy cast steel when stamping 1180 grade steels.

In addition to selecting the correct die material, it must be processed appropriately. Figure 6 shows the effects of proper heat treatment when stamping a dual phase steel with 980MPa minimum tensile strength.S-45 This same study showed that a PVD coated tool performed best when forming a DP steel without a galvanized coating, yet the PVD coating led to significant zinc buildup when forming a galvanized DP steel. An ion nitride tool coating worked best for galvanized steels.

Figure 6: Effect of Heat Treatment on Tools to Stamp Dual Phase Steel. Image A) No heat treatment leads to wear; Image B) Proper heat treatment results in a surface without damage.S-45

There are five main types of cold work failure modes involving tool steels – wear, plastic deformation, chipping, cracking, and galling. There is also interaction between these failure modes. Figure 7 shows examples of these failure modes.T-20, U-7

Figure 7: Stamping Tool Failure Modes. T-20, U-7

Wear is damage to the tooling surface resulting in material loss and is related to the tooling material hardness, and the type, volume, and distribution of hard particles like oxides or carbides. Wear can also be related to material type and process conditions and involves sliding contact between the tooling and the material. There are two types of wear: abrasive and adhesive.

Abrasive wear occurs when hard particles forced into a surface during the sliding contact leads to removal of metal from the tool steel. Tool steel properties promoting abrasive wear resistance include high hardness of the tool steel and of the carbides, as well as a high volume of large carbides. However, the high hardness targeted for wear resistance makes the material sensitive to notches. Large carbides act as crack initiators, increasing the risk of fatigue cracking.

Adhesive wear occurs with material transfer from one metal surface to another. The friction and heat generated as the sheet metal slides across the tool surface results in micro-welding between the asperities (peaks) on each surface. Failure of these micro-welds occurs with continued relative motion between the two surfaces, with small fragments torn from the weaker side surface and adhering to the other surface. The material ripped out of the tool steel will occasionally stick to the sheet metal surface. With continued metal motion, these pieces may score and damage the tool steel surface resulting in a combination of adhesive and abrasive wear known as mixed wear.

Galling is a physical/chemical adhesion of the sheet metal to the tool surface. The severity of the galling depends on the surface finish and chemical composition of the material and the tool steel and involves the friction and sliding contact between the tooling and the material. Galling, abrasive wear, and adhesive wear are related, and can be minimized through the use of proper surface treatments or coatings on top of a tool steel with high hardness (Figure 8).

Figure 8: Adhesive wear of the tooling leads to abrasive wear scratches on the DP600 sheet surface. Continued abrasive wear leads to galling of the sheet surface. Higher magnification images are shown on the bottom. G-18

Plastic deformation occurs when the stress from contact with the sheet metal exceeds the compressive yield strength of the tool material. A high hardness tool steel helps to avoid this damage.

Chipping occurs when the operating stress levels exceed the fatigue strength of the tool steel, typically found at sharp edges. Microcracks initiate in the high contact area of the tool surface, propagate, and ultimately result in pieces chipping out along edges or at corners. Chipping may initiate in areas affected by adhesive wear. Here, microcracks can nucleate, deepen, and spread, leading to a fatigue failure. A tool steel with high ductility has good chipping resistance, since microcrack initiation and propagation are more difficult.

Cracking occurs when the operating stress levels exceed the fracture toughness of the tool material. Crack formation occurs in the presence of stress concentrators, like grinding and machining marks or design features such as sharp corners or radii. Once the crack forms, unstable crack propagation leads to failure. Microstructural toughness promotes good cracking resistance, as does low hardness. However, low hardness has a detrimental effect on the resistance to the other failure mechanisms and is not normally a good solution.

Higher strength steels lead to greater demands on the wear resistance and mechanical strength of the tool material. Forming operations require high wear and galling resistance and compressive strength. Cutting operation require a combination of high wear resistance, high galling resistance, high compressive strength, high chipping, and total cracking resistance.

Tool materials must balance compressive strength and toughness with resistance to wear, thermal, and mechanical stresses.

Conventional highly alloyed tool steels are produced from large ingots. The slow solidification leads to microstructural segregation, forming large carbide networks which turn into carbide stringers after processing. These networks are beneficial for wear resistance, but reduces fatigue strength and toughness.

Alternate approaches minimizing segregation reduces these concerns. Two such production methods are electroslag remelting and powder metallurgy.T-20

Electroslag remelting (also known as electroslag refining, ESR) is a progressive melting process used to produce porosity-free ingots of uniform chemistry. Under a protective atmosphere, only a small portion of the ingot is liquid at any one time, and solidification occurs in a controlled manner. This processing approach results in tool steels with increased cleanliness, smaller carbides, and improved ductility and fatigue properties. It is relatively expensive, leading to its use in some specialized tool steel applications.

Rather than slowly solidifying in a large ingot, powder metallurgy (PM) production involves first atomizing a stream of molten metal using a high pressure inert gas, resulting in droplets that rapidly solidify into powder. Segregation is typically a fraction of the powder diameter, which is on the order of 100 μm. Hot isostatic pressing (HIPing) consolidates the collected powders, which is subsequently rolled or forged in a similar manner used for ingots.

Without the concern of macro-segregation or large carbides, the PM approach allows for manufacturing of more highly alloyed tool steels than is possible with conventional ingot metallurgy. Here, the carbides are smaller and more evenly distributed even compared with the ESR approach, leading to a balance of wear resistance and fatigue life. PM tool steels have enhanced resistance to abrasive wear, adhesive wear, chipping, and cracking. Coatings improve galling resistance.

Metal stampers and die shops experienced with mild and HSLA steels often have problems making parts from AHSS grades. The higher initial yield strengths and increased work hardening of these steels can require as much as four times the working loads of mild steel. Some AHSS grades also have hardness levels approaching the dies used to form them.

The higher stresses required to penetrate higher-strength materials require increased punch-to-die clearances compared to mild steels and HSLA grades. Why? This clearance acts as leverage to bend and break the slug out of the sheet metal. Stronger materials need longer levers to bend the slug. The required clearance is a function of the steel grade and tensile strength, and sheet thickness.

Increasing cutting clearance can result in punch cracking and head breakage due to higher snapthrough loads and reverse-unloading forces within the die. Adding shear angles to the punch face helps reduce punch forces and reverse unloading.

Tight cutting clearances increase the tendency for die galling and chipping. The severity of galling depends on the surface finish and microstructure of both the tool steel and work material. Chipping can occur when process stresses are high enough to cause low-cycle fatigue of the tooling material, indicating that the material lacks toughness.

Tempering of tools and dies represents a critical heat-treatment step and serves more than one purpose, but of primary concern is the need to relieve residual stresses and impart toughness. Dies placed in service without proper tempering likely will experience early failure.

Dies made from the higher-alloy tool-steel grades (D, M or T grades) require more than one tempering step. These grades contain large amounts of retained austenite and untempered martensite after the first tempering step and require at least one more temper to relieve internal stresses, and sometimes a third temper for even greater toughness.

Unfortunately, heat treatment remains a “black-box” process for most die shops and manufacturing companies, who send soft die details to the local heat treat facility, with hardened details returned. A cursory Rockwell hardness test may be conducted at the die shop when the parts return. If they meet hardness requirements, the parts usually are accepted, regardless of how they may have been processed—a problem, as hardness alone does not adequately measure impact toughness.

Consider this scenario: An automotive structural part has been in production for years as a conventional high strength steel with a minimum yield strength of 280 MPa, CR280Y350T-LA. In order to meet increasing global safety regulations, the automaker converts the part to a dual phase steel, CR340Y590T-DP. Even though these grades have relatively close minimum yield strength levels as produced at the steel mill, dual phase steels have excellent work hardening characteristics and are bake hardenable. These are among the reasons for their favorable response in crash events in comparison to HSLA grades.

The stamping location attempted to do a direct swap, substituting the DP steel for the HSLA grade with no changes to the part or process. Immediately after the grade change, scrap rates increased significantly. The failures were all determined to be local formability edge fractures; investigation revealed that the edge of the configured blank remained as the final product edge which split during forming and subsequent flanging. Examination of the edge revealed a burr as well as a non-uniform cut edge appearance. The tool showed signs of chipping.

Issues found, along with corrective actions:

- The tool steel used for HSLA (uncoated D2) was not appropriate for stamping DP590. Upgrade to a more durable tool steel with good chipping resistance. Add a surface treatment or coating if needed for additional wear resistance.

- The stamper used the traditional 10% tooling clearance when blanking HSLA. The recommended clearance for DP590 at the thickness studied is 15%.

- The flanging operation further expanded the edge beyond what occurred in the draw die. DP steels work harden to a much greater degree than HSLA steels. As such, stretch flanging a cut edge significantly increases the potential for edge fracture in this stronger product. Adding a metal gainer to the draw die ensures the flanging operation performs only bending and straightening, and does not further stretch a cut edge.

Making these changes to accommodate the new grade eliminated scrap from this process.

Upgraded Sheet Metal Forming (M-20)

Multi-phase steels are complex to cut and form, requiring specific tooling materials. The tooling alloys which have been used for decades, such as D2, A2 or S7, are reaching their load limits and often result in unacceptable tool life. The mechanical properties of the sheet steels achieve tensile strengths of up to 1800 MPa with elongations of up to 40%. Additionally, the tooling alloys are stressed by the work hardening of the material during processing.

The challenge to process AHSS quickly and economically makes it necessary for suppliers to manufacture tooling with an optimal tool steel selection. The following case study illustrates the tooling challenges caused by AHSS and the importance of proper tool steel selection.

A manufacturer of control arms changed production material from a conventional steel to an Advanced High-Strength Steel (AHSS), HR440Y580T-FB, a Ferrite-Bainite grade with a minimum yield strength of 440 MPa and a minimum tensile strength of 580 MPa. However, the tool steels were not also changed to address the increased demands of AHSS, resulting in unacceptable tool life and down time.

According to the certified metal properties, the 4 mm thick FB 600 material introduced into production had a 525 MPa yield strength, 605 MPa tensile strength, and a 20% total elongation. These mechanical properties did not appear to be a significant challenge for the tool steels specified in the existing die standards. But the problems encountered in production revealed serious tool life problems.

To form the FB 600 the manufacturer used D2 steel. D2 was successful for decades in forming applications. This cold work tool steel is used in a wide variety of applications due to its simple heat treatment and its easily adjustable hardness values. In this case, D2 was used at a hardness of RC 58/60.

While tools manufactured from D2 can withstand up to 50,000 load cycles when forming conventional steels, these particular D2 tools failed after only 5,000 – 7,000 cycles during the forming of FB 600. The first problems were detected on a curl station where mechanical overload caused the D2 tools to break catastrophically, as seen in Figure 9 below. Since the breakage was sudden and unforeseeable, each failure of the tools resulted in long changeover times and thus machine downtime.

Figure 9: Breakage seen in control arm curl tool made from D2, leading to premature failure. Conversion to a PM tool steel having higher impact resistance led to 10x increase in tool life.M-20

Since the cause of failure was a mechanical breakage of the tools, a tougher alternative was consequently sought. These alternatives, which included A2 and DC53® (a registered trademark of International Mold Steel) were tested at RC 58-60 and unfortunately showed similar tool life and failures.

Metallurgical analysis indicated that the failure resulted from insufficient impact strength of the tool steel. This was caused by the increased cross-cut that the work-hardened AHSS exerted on the curl. As an alternative material, a cold work steel with a hardness of 58-60, a tensile strength of about 2200 – 2400 MPa and high toughness was sought. These properties could not be achieved with conventional tool steels. The toolmaker used a special particle metallurgy (PM) tool steel to obtain an optimum combination of impact strength, hardness and wear resistance.

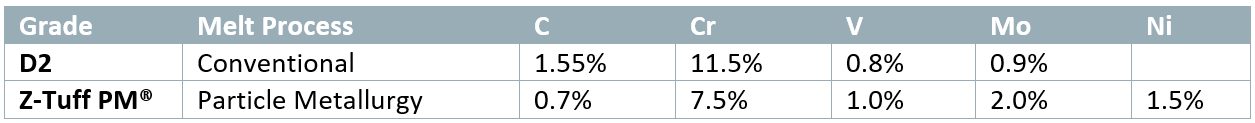

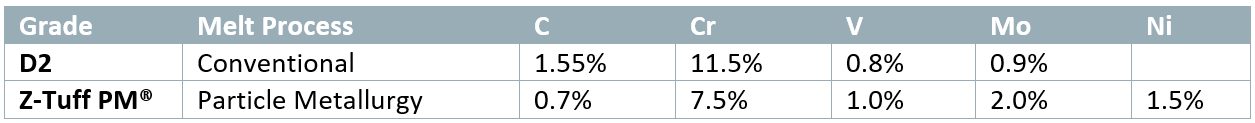

Particle metallurgy (PM) tool steels, due to their unique manufacturing process, represent improvements in alloy composition beyond the capabilities of conventional tool steels. Materials with a high alloy content of carbide formers such as chromium, vanadium, molybdenum and tungsten are readily available. The PM melting process ensures that the carbides are especially fine in particle size and evenly distributed (reference Table 1). This process results in a far tougher tool steel compared to conventional melting practices.

Table 1: Elemental Composition of Chosen Tool Steel

The manufacturer selected Z-Tuff PM® to be used at a hardness of RC 58-60. Employing the identical hardness as the conventional cold work steel D2, a significant increase in impact strength (nearly 10X increase as measured by un-notched Charpy impact values) was realized due to the homogeneous microstructure and the more evenly distributed precipitates. This positive effect of the PM material led to a significant increase in tool life. By switching to the PM tool steel, the service life is again at the usual 40,000 – 50,000 load cycles. By using a steel with an optimal combination of properties, the manufacturer eliminated the tool breakage without introducing new problems such as deformation, galling, or premature wear.

AHSS creates tooling demands that challenge the mechanical properties of conventional tool steels. Existing die standards may not be sufficient to achieve consistent and reliable performance for forming, trimming and piercing AHSS. Proper tool steel grade selection is critical to ensuring consistent and reliable tooling performance in AHSS applications. Powder metallurgical tool steels offer a solution for the challenges of AHSS.

- Areas seeing higher working loads require improved tool materials and coatings for both failure protection and wear protection.

- The higher initial yield strengths of AHSS, plus the increased work hardening of DP and TRIP steels can increase the working loads by 400% compared to Mild steels.

- Strength levels of some AHSS grades are associated with the same hardness as the tools intended to form them.

- Advanced powder metallurgy (PM) tool materials are appropriate for some AHSS applications.

- The dominant mode of failure of tool steels should be identified and communicated to the tool steel supplier to select the tool steel with the best properties to combat the tool failure mode for a given AHSS grade.

- PVD coated tool steels are appropriate for stamping AHSS grades without a galvanized coating but may result in zinc buildup when forming galvanized steels. Here, an ion nitride coating may be appropriate.

- Complete initial tryout before application of tool coating. Allow for tooling recuts during tryout loop to ensure the resulting tool has sufficient mass and stiffness.

- Proper selection of tool material, surface treatment, and coating leads to a reduction in maintenance, repair, and scrap/rework costs. Further offsetting the upfront tooling costs are improved process uptime, improved quality, and greater consistency.

Back to the Top

Hydroforming

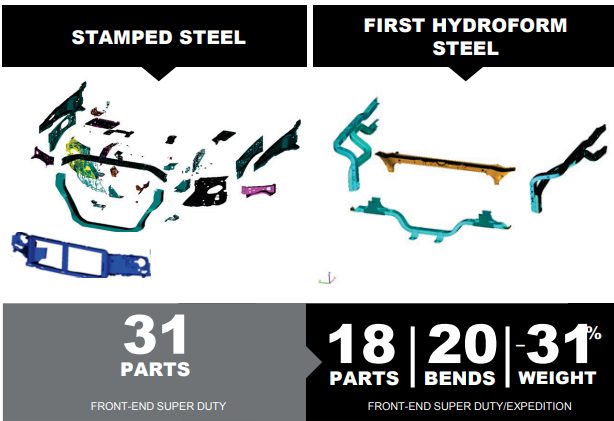

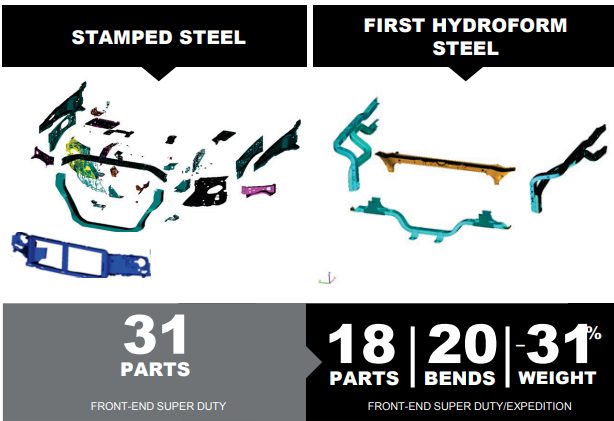

Tube hydroforming creates complex shapes by using internal pressure to expand a tube against a die cavity. Frame rails, engine cradles, roof rails and bows, instrument panel beams, cross members, pillars, and seat frames are among the parts created using hydroforming. Benefits of this approach can include part consolidation, weight reduction, improved stiffness and strength, tighter dimensional tolerances, fewer secondary operations, and reduced cost compared with conventional stamping and welding approaches.

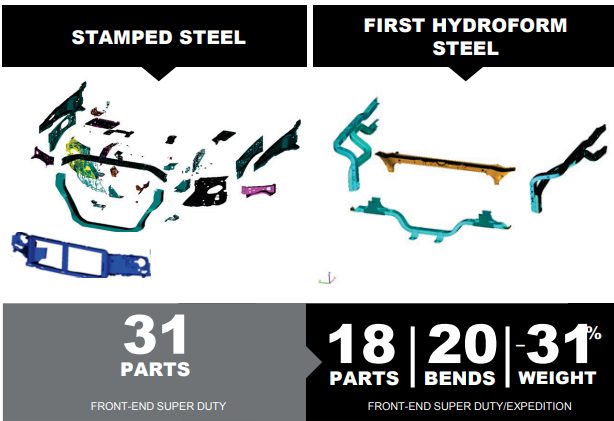

These benefits are highlighted in a truck front end structure shown in Figure 1, where hydroforming allowed for consolidation of 31 parts into 18, and resulted in a 31% weight reduction. M-67

Automotive body structures have incorporated hydroformed parts for several years, with recent vehicles using AHSS grades to improve crash energy management and impact performance. Some specific examples:

The hydroformed A-Pillar on the 2015 Mustang Convertible (Figure 2) distributes impact loads to the windshield header and the hinge pillar.M-16

Hydroforming facilitates part consolidation and weight reduction relative to a stamped truck front end structure.M-67

Figure 2: 2015 Mustang Convertible: A-Pillar.M-16

The Door-to-Roof Support on the 2016 Nissan Titan XD (Figure 3) extends from the rocker/hinge pillar through the A-pillar and almost to the B-Pillar. Hydroforming this part from a Dual Phase Steel with 980MPa minimum tensile strength allowed for 25% section strength improvement allowing for thinner material at the same performance level. T-18, L-18

Figure 3: 2016 Nissan Titan XD: Door-To-Roof Support.T-18, L-18

The hydroformed Upper Load Beams of the 2017 Chrysler Pacifica (Figure 4) saved 1.8 kg per vehicle compared with a conventional approach.T-19

Figure 4: 2017 Chrysler Pacifica: Upper Load Beams.T-19

Each of the two hinge pillars on the 2019 Jeep Wrangler (Figure 5) contain 2 hydroformed tubes made from TRIP 400/690.B-8

Figure 5: 2019 Jeep Wrangler: Hinge Pillars.B-8

Tube hydroforming, as the name suggests, starts with a linear-welded tube, produces either with high frequency induction welding or laser welding. The tube is then bent to the general shape, and a pre-forming operation helps to put steel in the optimal position. After placing the preformed tube in the hydroforming die, end-plugs create a seal for subsequent internal pressurization. Figure 6 shows the changes to tube shape along the process of producing the hydroformed roof rails from DP800/1000 for the 2015 Ford Edge.H-13

Figure 6: Shape evolution to achieve a hydroformed roof rail from DP 800/1000.H-13

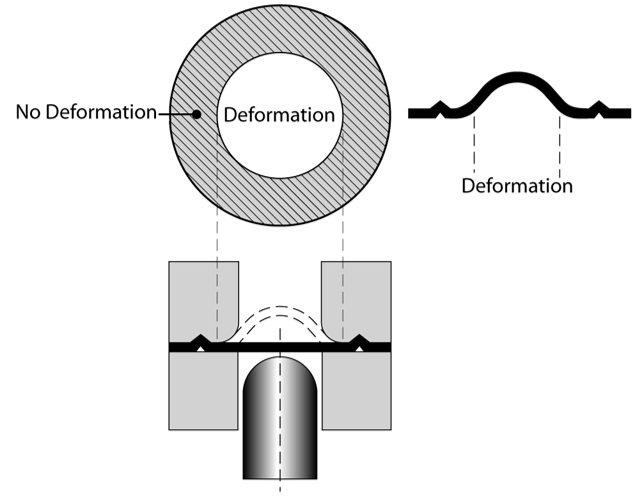

If the hydroforming process does not result in a change in the length of the pre-formed tube, then the only change is an increase in the local section diameter. This corresponds to a strain state of plane strain, which is the strain path associated with the greatest risk of cracks. Mounting the end-plugs on actuators allows for application of axial loads on the ends of the tube as the internal pressure changes. End feeding in this manner changes the strain state favorably, creating compression in the axial direction as the tube diameter stretches. With axial feeding, the strain state near the ends move to the left hand side of the Forming Limit Diagram, allowing for higher strains to be reached prior to failure – meaning that more complex shapes can be created. Away from the tube ends, the axial feeding has limited effect, so plane strain formability (the lowest point on the Forming Limit Curve) limits the product shape.

Formability is further limited compared with the incoming sheet, since the rolling, welding, sizing, bending, and pre-forming operations all decrease the available ductility prior to hydroforming. Understanding the effect of each operation which changes the strain and thickness in the tube allows for small process changes which may help to improve the amount of residual ductility for the subsequent tube hydroforming operation. The strains generated from each step results in the work hardening of the sheet steel, leading to an increase in strength and decrease in ductility.

Product and tool designs must account for these increased strengths and reduced formability parameters. The deformation available for the pre-form bend process and the subsequent hydroforming process will depend on the material selected, tube D/T ratio, tube manufacturing process, centerline radius of the pre-form bend, and the included angle of the bend. Tubes of higher strength AHSS will have limited elongation available. Avoid exceeding the available total elongation for bending limits or forming limits – especially in the work hardened areas of the pre-form bends. Refer to Figure 4 in the Tube Bending article for anticipated elongation values for several illustrative high strength steels formed into tubes of various D/T ratios.

The hydroforming process for tubes usually involves expanding the tube diameter from 3% to 30% depending on the design, materials selected and pressures available for forming. Tube production commonly utilizes one of three basic methods of hydroforming tubes, categorized by the internal pressure used for the expansion.

In high-pressure tube hydroforming (Figures 7 and 8), the tube is placed in the die and the die is closed. Pressurizing the tube now causes the metal to stretch as the circumference increases to conform to the inner circumference of the die – often with tight radii in corners and product features. Higher strength steels may be unable to expand sufficiently to fill the die geometry or create small radii without failure. Furthermore, high pressure could be necessary to obtain the correct geometry with minimum springback or fewer wrinkles compared to low-pressure hydroforming.

Figure 8: Animation of High Pressure Hydroforming, courtesy of ANDRITZ Schuler Inc.

Pressure Sequence tube hydroforming (Figures 9 and 10) begins with a tube whose circumference is slightly less than the final circumference of the finished geometry. Tube pressurization occurs after placing the tube in an open die, prior to closing. As the die closes, the circumference of the tube changes shape to conform to the closing die. The internal pressure is sufficient to prevent the tube from buckling during the shape change. A small circumference increase combined with a uniform wall thickness means that high strength and lower-formability metals can achieve tighter radii without failure. Pressure Sequence Hydroforming is suitable for tubes made from AHSS. This approach results in a change of the shape of the tube cross-section, rather than tube expansion. Hydroforming simulation with commercially available programs is beneficial to optimize the pressurization sequence.

Figure 10: Animation of Pressure Sequence Hydroforming, courtesy of ANDRITZ Schuler Inc.

Enhanced circumferential expansion can be achieved by incorporating end feeding. Special end pistons push additional material into the die cavity from the tube end to provide more material for higher expansion of the tube circumference. This method of tube circumference expansion involves bi-directional strain. The end feeding is beneficial for hydroforming tubes from AHSS. Note that excessive end-feeding may increase the pressure required to form small corner radii.S-43

To assist with pre-production process and die design, computerized forming-process development is an excellent tool for examining the validity of applying different AHSS to potential part designs. However, proper inputs are critical: hydroforming tubes made from advanced high strength steels require highly developed forming limit curves generated which consider different tube D/T ratios, degrees of pre-form bend, and final geometrical shape. Each step as the straight tube is converted to a hydroformed part represents a non-linear strain path, which increases the importance of using the proper Forming Limit Curve. The FLC generated for the initial sheet steel will give a false indication of the available formability since it does not account for the impact of the forming steps prior to hydroforming.

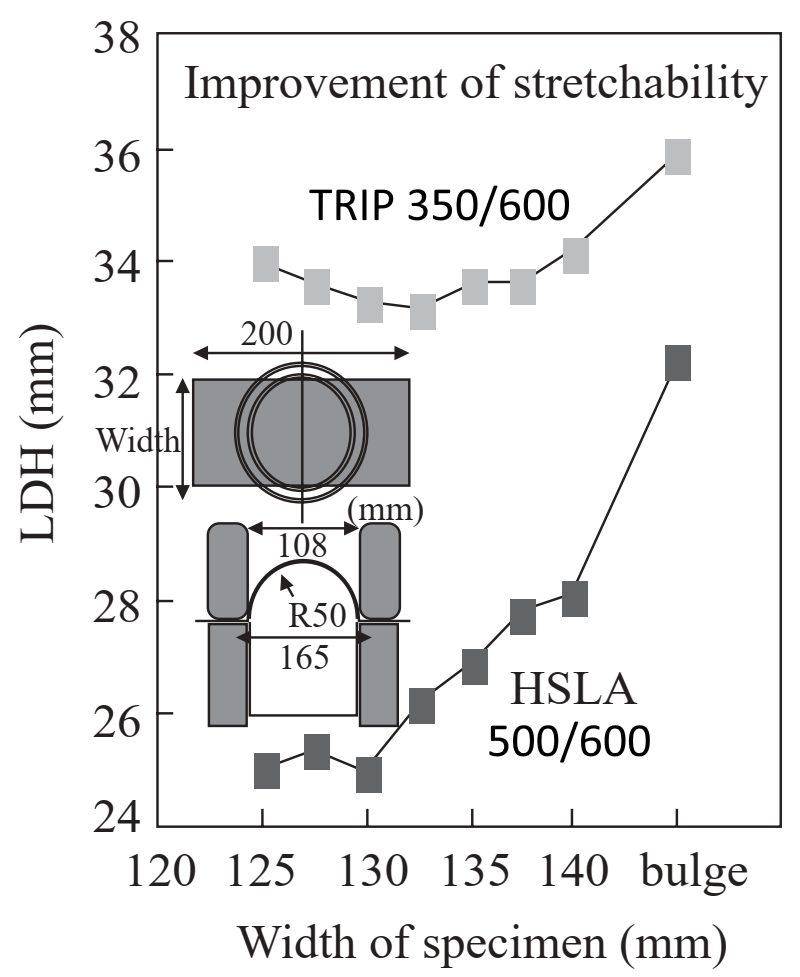

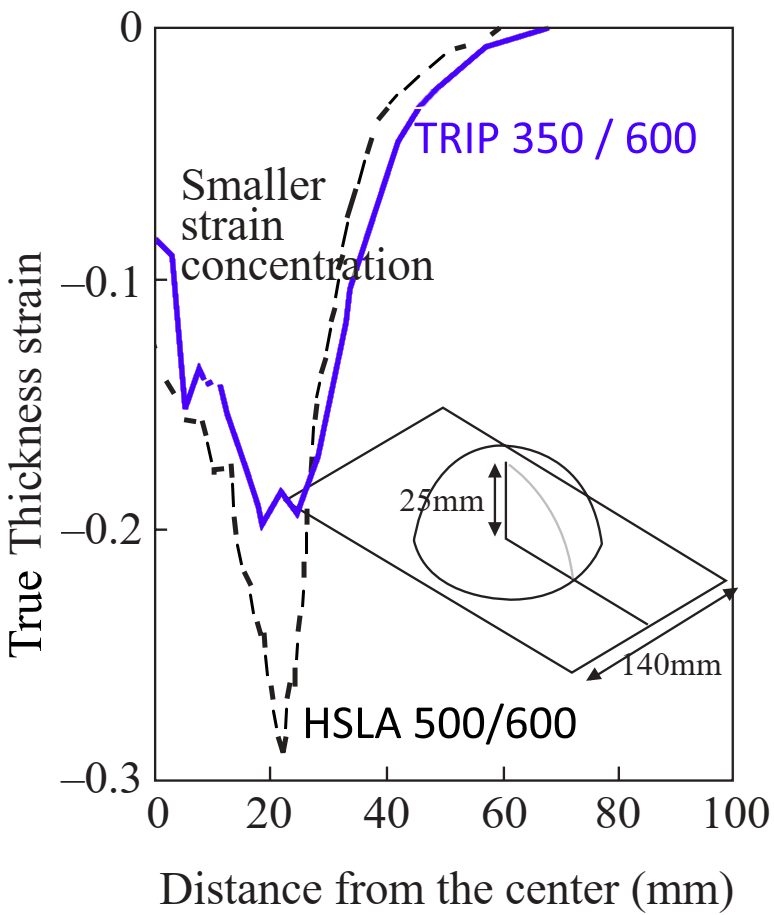

An example of the material property changes from tube creation comes from Figure 11, which compares 1.88 mm thick mild steel (labeled as DDQ), HSLA 350/450, and DP 350/600 formed into a 76.2 mm (3 inch) diameter tube. Figure 11 shows the summary of average properties for the three steels. The much larger jump associated with tube forming of the dual phase steel grade is associated with the higher n-value of this product.

Figure 11: Strength Comparison on samples taken from the flat sheet and after tube forming.S-43

For trimming and piercing, the same general cautions utilized for stamped AHSS parts apply to hydroformed AHSS parts. Since Advanced High Strength Steels have higher tensile strength than conventional high-strength steels, engineering the trim tools to withstand higher loads is a requirement. Proper support for the trim stock during the trim operation will minimize edge cracking. Laser trimming, which is common for hydroformed parts, is still an excellent choice. However, the trimmed edge may see some hardening associated with the local heating and cooling from the laser beam.

Design Considerations

In general, the same design guidelines that support hydroforming of conventional steels apply to AHSS. However, consideration of part function and the available elongation for forming is necessary during development of the part design and manufacturing processes.

- Hydroforming tools need to be stiff and rigid in all directions, or else there is the risk of deviation from the targeted.

- Springback and shape distortion is more likely on longer tubes made from thinner sheet steels. Tight bending radii on higher strength steels increases the risk of springback. The tube diameter to wall thickness (D/t) ratio, cross section shape, forming process (bending, preforming method, hydroforming parameters) also affects springback.

- Pierce holes in the tube by cutting against the water pressure.

- Place welds in areas with low forming strains.

- The cross section can change, but the circumference should stay the same to minimize cracks.

- Avoid sharp radius/thickness due to forming forces.