Blog, General, main-blog, News

The Steel E-Motive program–commissioned by WorldAutoSteel in partnership with Ricardo plc–has developed the world’s first fully autonomous electric vehicle body structure concept purpose-fit for ride-sharing. This global steel industry initiative showcases the strength and durability of steel with an eye on playing a pivotal role in reaching net zero emissions targets.

Download the Steel E-Motive Engineering Report

Here, we break down the many benefits of the Steel E-Motive concept that only Advanced High-Strength Steel (AHSS) can enable.

Steel E-Motive Was Conceived as a Level 5 Autonomous Vehicle

The Steel E-Motive concept is designed to be a Level 5 autonomous vehicle, so it does not include any driver interfaces. The design features a spacious, airy cabin with rear-facing front-passenger seat configurations. The B-pillarless structure and unique battery system design offer easy ingress and egress.

The Steel E-Motive concept is designed to be a Level 5 autonomous vehicle.

Designed to Exceed Future Mobility Safety Standards

Modern Advanced High-Strength Steels innovations allow the Steel E-Motive autonomous vehicle to exceed current global high-speed crashworthiness standards. By using AHSS, the Steel E-Motive vehicle is the first to acknowledge compliance with NHTSA and IIHS safety standards publicly.

For example, the 4-passenger B-sized urban concept SEM1 introduced a new front-end passenger protection zone. This design features the small overlap Glance Beam, which forces the car to “glance” off the barrier and reduces passenger cabin intrusion. It also lowers the crash pulse and ultimately minimizes passenger injury. Advanced High-Strength Steels also offer strong battery protection and preserve door ring integrity in this autonomous vehicle.

The Evolution of Advanced High-Strength Steel

Over the past quarter century, vehicle concept projects have showcased the continuous advancement of steel. In 1998, global steelmakers introduced the Ultralight Steel Auto Body, which used one of the earliest forms of AHSS. This project demonstrated steel’s ability to reduce weight without compromising safety.

By 2010, we introduced the Future Steel Vehicle concept. Using 27 AHSS materials, the body structure design reduced mass by over 35%. Steel materials enable these massive reductions while allowing the design to meet global crash and durability requirements.

The Steel E-Motive concepts benefit from no fewer than 64 materials under the AHSS umbrella. The “infinite tunability” of AHSS allows product customization by designers and engineers to select exactly the right steel for every need and purpose in the vehicle.

Key Attributes of the Steel E-Motive Autonomous Vehicle

From lowering the carbon footprint to massively reducing weight, the Steel E-Motive vehicle offers first-of-its-kind benefits for future mobility made possible by AHSS.

Steel allows the vehicle to reduce weight without sacrificing strength. For example, 66% of the Steel E-Motive autonomous vehicle structures’ materials have an Ultimate Tensile Strength of at least 1,000 MPa, and these materials’ weighted average tensile strength is 1259 MPa.

By using 33% Press Hardened Steels and 11% 3rd Generation AHSS, the design includes complex geometries fully formed by hot and cold-stamped gigapascal steels.

In another example, 43% of the Steel E-Motive structure is fabricated from material-efficient processes such as press hardening, hydroforming, roll forming, and roll stamping. With these processes, the steel body design maximizes material utilization and minimizes scrap rate. This means less material is produced, lowering the structure’s carbon footprint. These achievements reduce manufacturing costs to support a profitable margin both for the vehicle manufacturer and the mobility service provider.

Using AHSS, the Steel E-Motive autonomous vehicle’s body structure mass is 25% lower than benchmark vehicles of a similar volumetric footprint. Additionally, Steel E-Motive realizes a 27% lower battery frame cost than a fully enclosed battery design, with 37% mass savings.

In conclusion, the Steel E-Motive program stands as a remarkable testament to the innovative potential of steel in shaping the future of mobility and autonomous vehicles. With its groundbreaking design, the Steel E-Motive concept paves the way for Level 5 autonomous electric vehicles prioritizing safety, sustainability, and efficiency.

Harnessing the unique attributes of AHSS, this global steel industry initiative also showcases the remarkable evolution of steel materials over the years. From Ultralight Steel Auto Body to Future Steel Vehicle, the journey of AHSS has been one of continuous improvement, leading to Steel E-Motive’s exceptional achievements in weight reduction, enhanced safety, and minimized environmental impact.

As we venture into an era of net-zero emissions and advanced mobility solutions, the Steel E-Motive concept proudly positions steel as a driving force in shaping a cleaner, safer, and more connected future.

Download the Steel E-Motive Engineering Report

Blog, homepage-featured-top, main-blog, News

WorldAutoSteel has a 30-year legacy of steel demonstration all the way back to the Ultra-Light Steel Auto Body (ULSAB), whose engineering report is still being downloaded from our worldautosteel.org site today. The one you may remember best is the FutureSteelVehicle (FSV), results of which we launched in 2011. FSV demonstrated steel innovation for not only Battery Electric vehicles (BEV) but also Fuel Cell vehicles (FCV). Steel E-Motive is the sixth of our global steel industry programs.

So Why Mobility as a Service?

The Automotive sector is undergoing the most rapid change in 40 years. This transformation shifts our thinking – from the movement of vehicles to the efficient movement of people and goods. Over the past eight years, we have conducted extensive research into global trends such as urbanization, transport emissions reduction, as well as the waning interest in vehicle ownership among the young and old. This is especially prevalent in megacities characterized by pollution, congestion, limited parking and enormous ownership costs. Our research concluded that mobility as a service (MaaS) will grow exponentially in high population areas and would place a significant challenge on vehicle design and manufacturing. Therefore, we needed to make sure we as an industry were active and visible in providing STEEL solutions in this new market place.

Steel E-Motive will demonstrate the benefits of steel, linking the properties of the material to the required architectures and attributes for MaaS vehicles.

This program will demonstrate the benefits of steel, linking the properties of the material to the required architectures and attributes for MaaS vehicles. It connects us with original equipment manufacturers (OEMs) and future mobility providers (FMPs), reinforcing steel’s advantages in strength, durability, sustainability and affordability.

An autonomous BEV structure aligns perfectly with steel’s best attributes, however most new concepts trial alternative materials. The global steel industry is investing significantly in product and fabrication development to continually prepare for the next challenge. High Strength and Advanced High-Strength Steel (AHSS) portfolios have grown from the 11 highlighted in the ULSAB program, to more than 60 grades available for use in designing and optimizing Steel E-Motive’s autonomous BEV architecture. Third Generation AHSS (3rd Gen AHSS) will have a prominent role in Steel E-Motive’s body-in-white, taking strength levels ever higher while improving manufacturability. And our industry continues to evolve Press Hardened Steels (PHS) with strength levels upwards of 2000 MPa.

Finally, efficient fabrication processes such as roll stamping, press hardening, and hydroforming use less steel and therefore contribute lower vehicle production emissions. These are the details being highlighted in Steel E-Motive, where we hope to demonstrate that only Steel can make it Real.

Steel E-Motive: A game changing, world first?

Many OEM’s and mobility service providers follow the typical vehicle development process where they adapt an existing vehicle structure to the new vehicle requirements. We don’t have that in Steel E-Motive We believe Steel E-Motive is one of the world’s firsts.

- The first for a Level 5 autonomous vehicle that is compliant with global high-speed crash requirements.

- The first autonomous vehicle to be a conventional high-volume stamped steel body construction, creating an affordable platform for the mobility service provider.

- First to offer a competitive, robust, and sustainable MaaS solution.

For engineers, being first is very exciting but a little nerve wracking – there are no benchmarks out there. There is less to “hang on to.” We’re on our own. Target setting is more challenging; we are the benchmark. Time will tell if we make it to the automotive hall of fame.

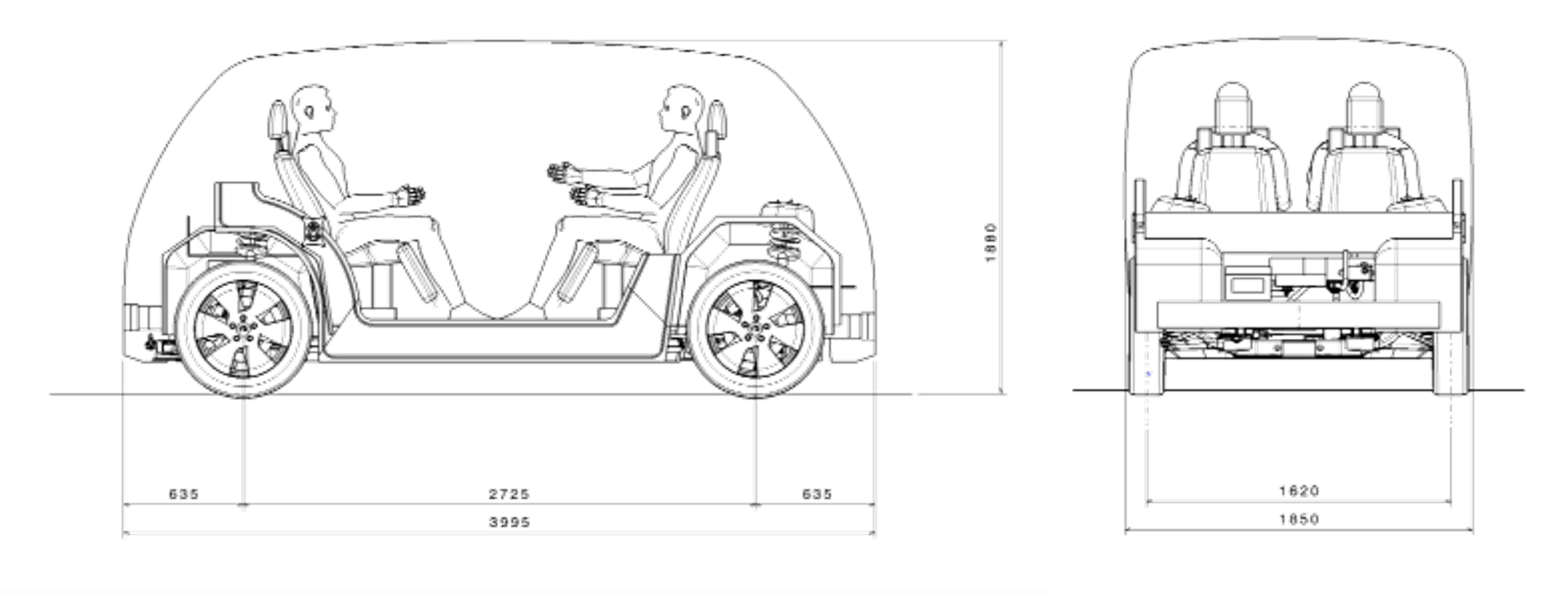

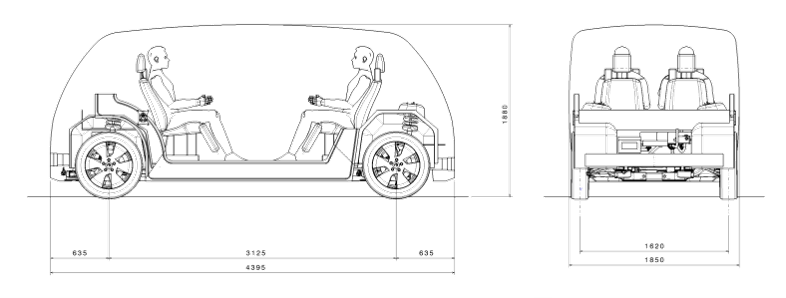

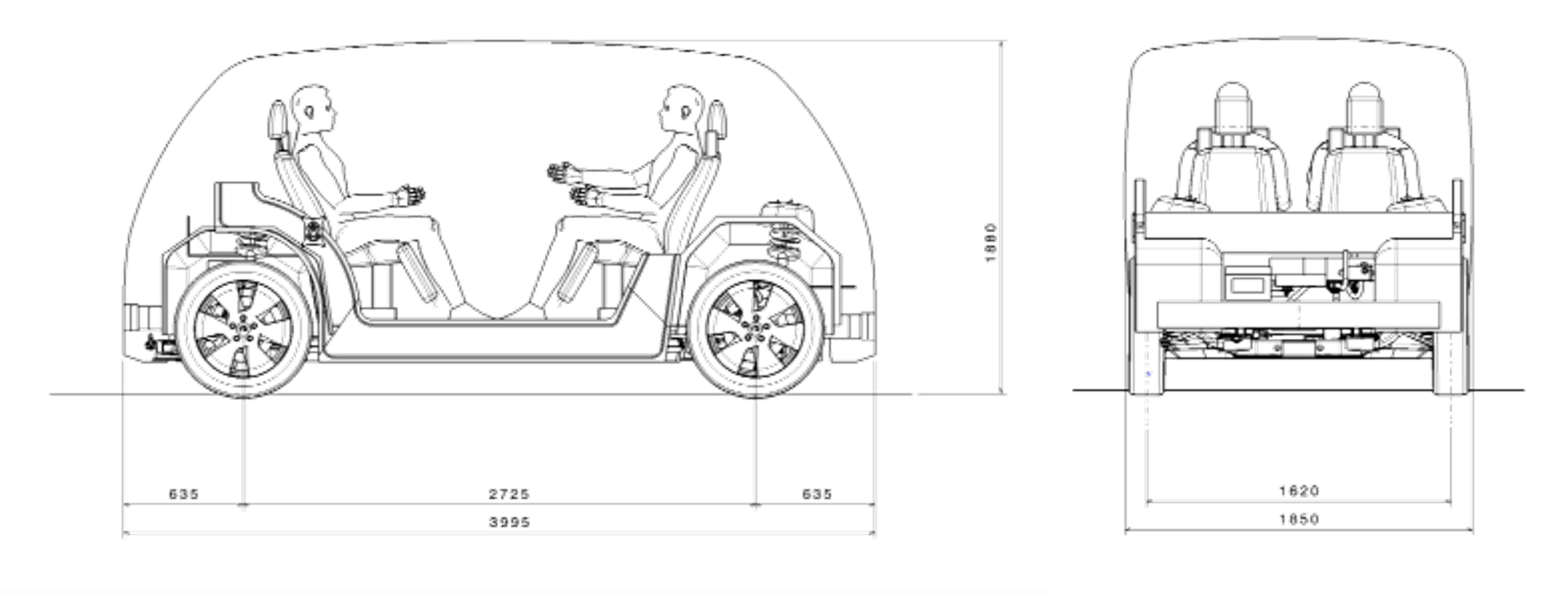

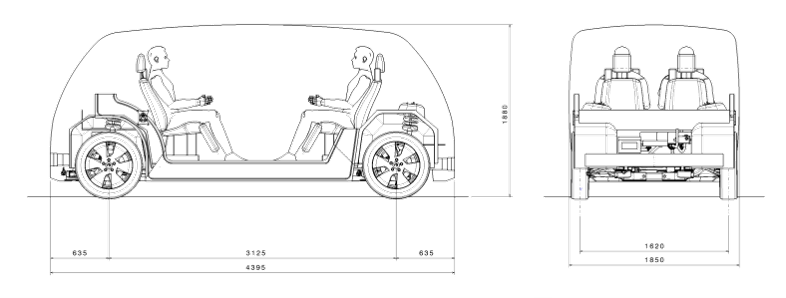

We are producing concepts for two BEVs based on a single modular platform. SEM1 (Figure 1) is a front-wheel drive short wheelbase urban version for inter-city travel for four passengers. It has a compact design and vehicle footprint, comparable in footprint to a European B/C segment size. SEM2 (Figure 2) is an all-wheel drive, long wheelbase extra urban version designed to carry up to six passengers. It has an adaptable interior volume that can result in additional luggage capacity compared to SEM1.

Figure 1: SEM1 Vehicle Specifications (© WorldAutoSteel 2022)

Figure 2: SEM2 Vehicle Specifications (© WorldAutoSteel 2022)

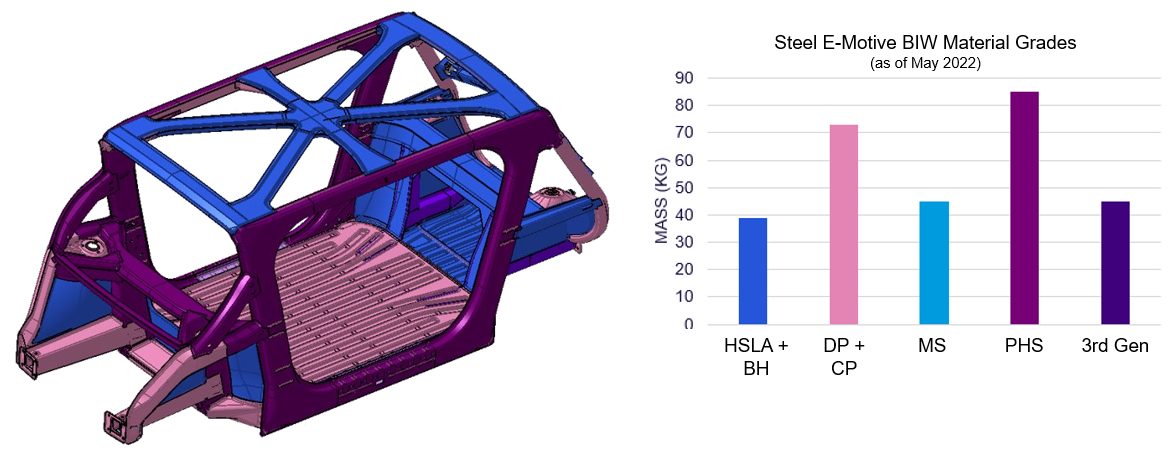

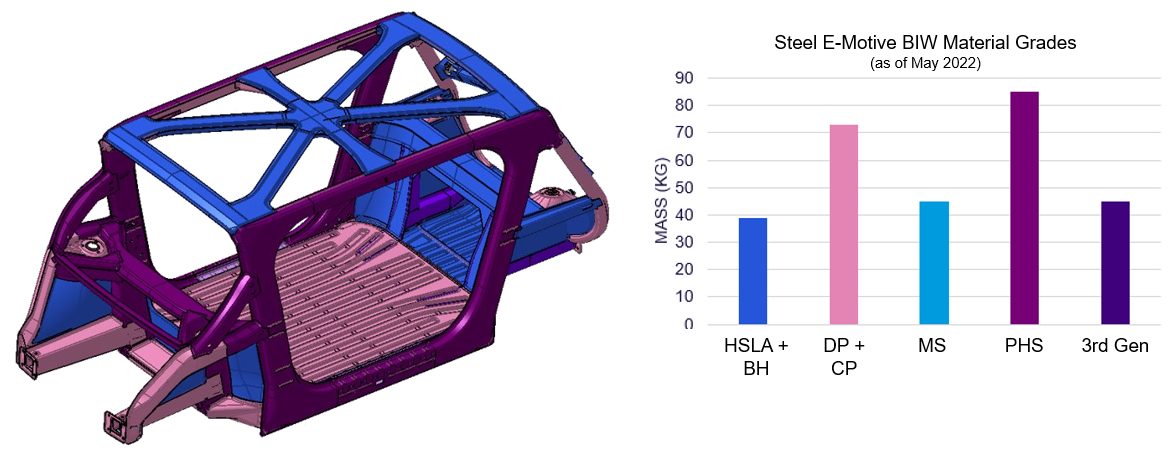

Body in White Steel Usage

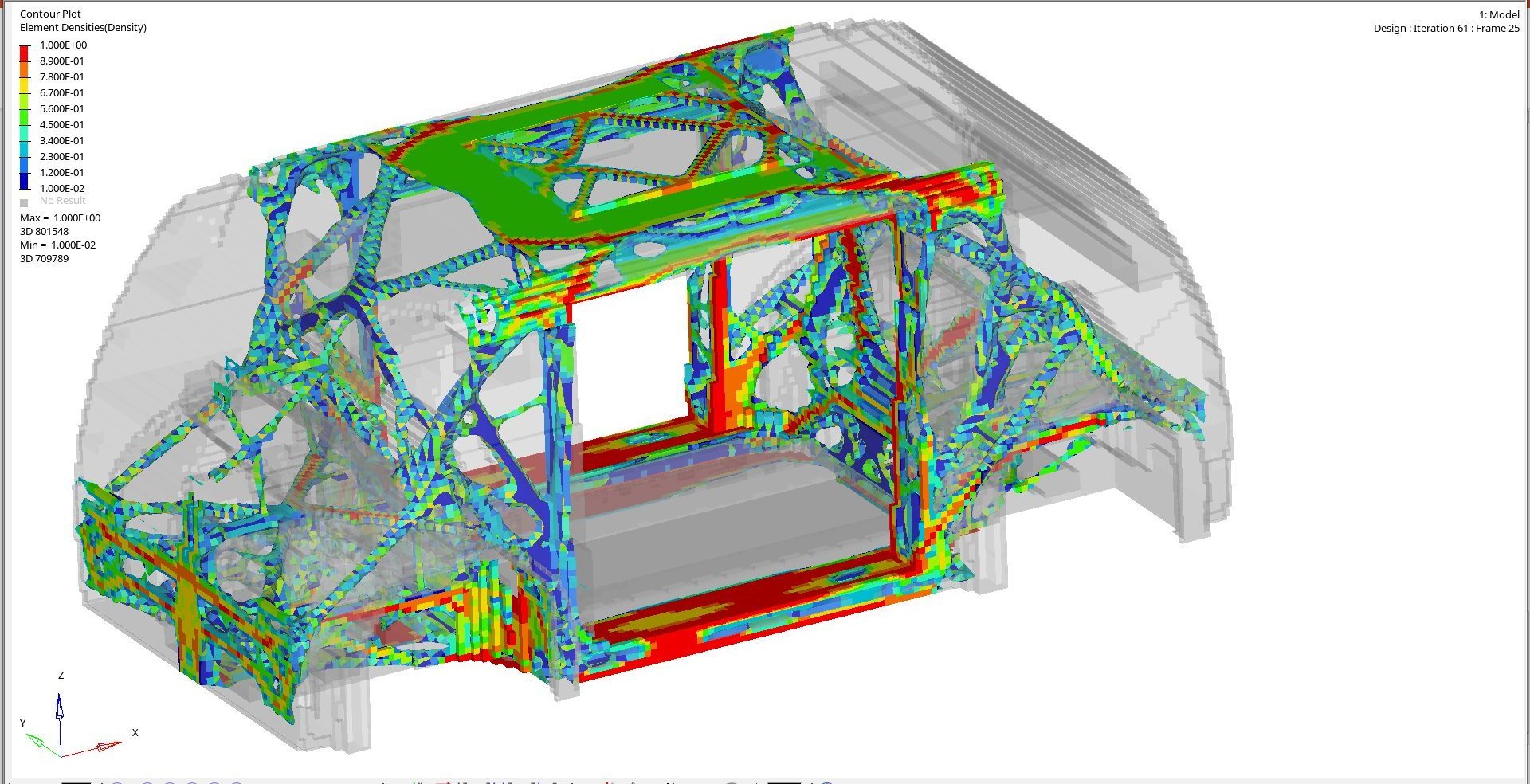

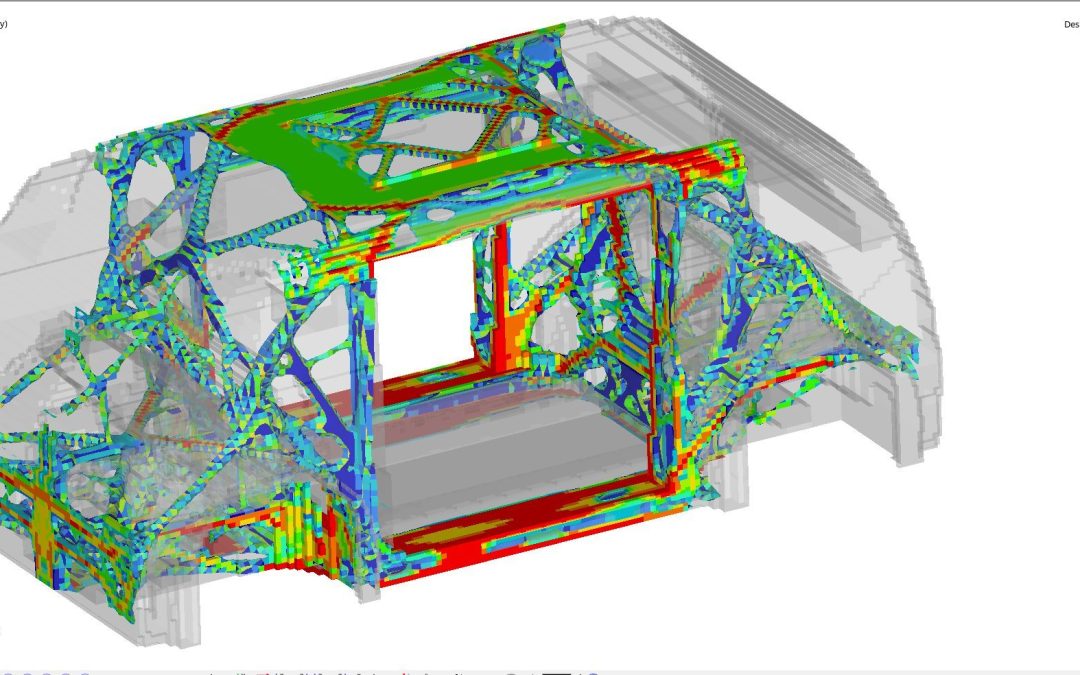

Steel E-Motive benefits from a broad portfolio of steel grades and fabrication process, as identified by our member steel experts. The design is nearly finalized, and material selections are being evaluated against various performance targets with the representative structure shown in Figure 3 with high PHS usage at this stage in the design (as of May 2022). This is mainly driven by the safety requirements. Steel E-Motive BIW steel and steel technologies include:

- Right steel grade in the right place

- Significant proportion of >1500MPa grades, primarily for occupant and battery intrusion zones

- Mixture of stamped, roll formed, roll stamped, press hardened steel and hydroformed parts

- Spotweld, laser weld and structural adhesive

Figure 3: Steel E-Motive’s Body-in-White Steel usage as of May 2022. (© WorldAutoSteel 2022)

At the Core of the Steel E-Motive Concept Is an Innovative Battery Design

Figure 4 shows Steel E-Motive’s battery frame design’s construction:

- Battery modules and cooling plates are mounted to an AHSS carrier frame (off-line).

- The carrier frame is mounted to the body structure (in general assembly).

- The BIW floor acts as the top cover and provides sealing.

- The AHSS bottom cover plate provides impact protection.

This design provides significant cost and weight savings, as well as improved NVH. This extremely efficient package does not compromise safety and enables a flat floor with a lower step-in height.

Figure 4: Steel E-Motive Battery package assembly. (© WorldAutoSteel 2022)

Competitive Body Stiffness with an Open B-Pillarless Body Structure

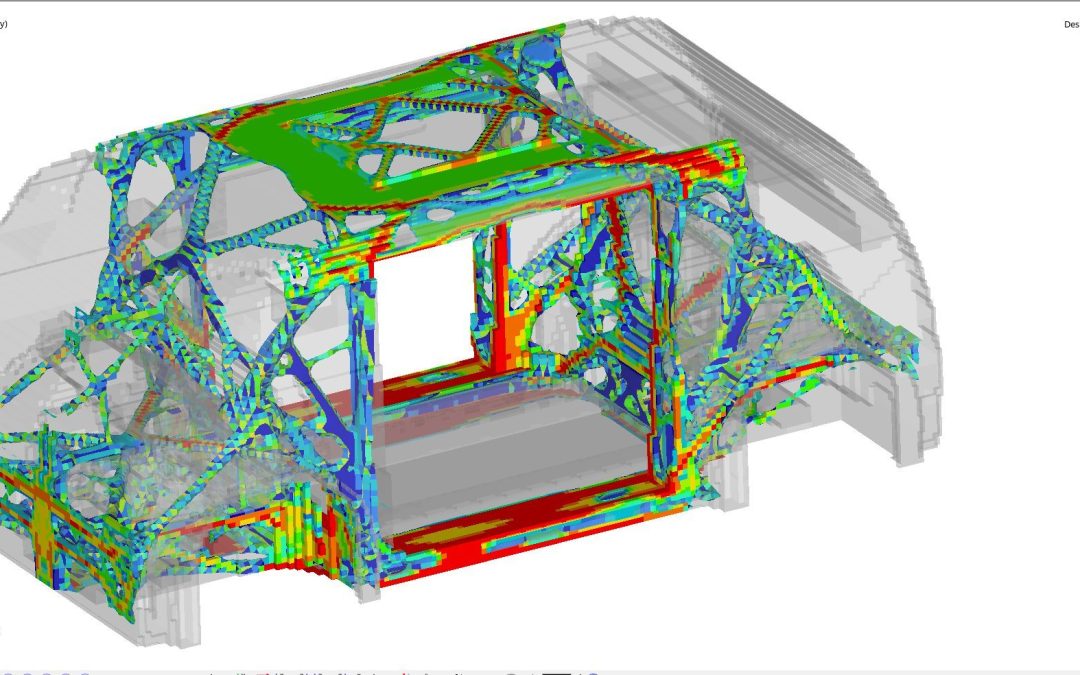

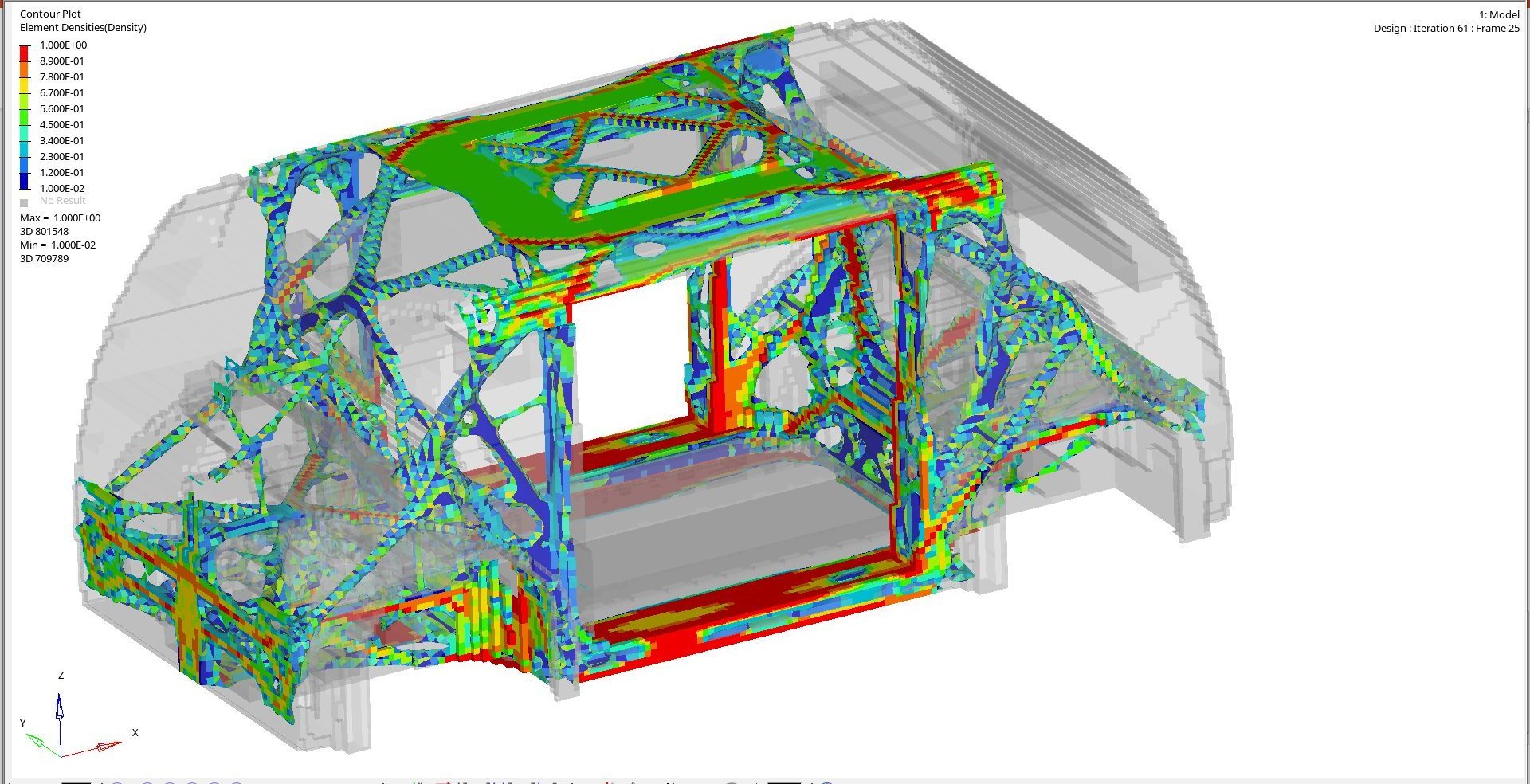

With clean sheet design, and generally less package constraints in a Level 5 vehicle, our design teams have had more freedom to engineer and optimize the crash and stiffness structural loadpaths. We used topology, optimization, and Virtual Reality tools to determine the most efficient structural loadpaths (Figure 5). The results informed the joint designs and enabled optimization of the joining and structural adhesives. These steps and the advantage of steel’s high modulus resulted in impressive performance.

Figure 5: Topology Load Path Optimization. (© WorldAutoSteel 2022)

The approach for achieving body stiffness was as follows. Results are shown in Figure 6 following.

- Topology load path optimization

- Appropriate section size, profiles, part integration and flange / joint design

- Strut towers integrated with key body members, such as A-pillars, vertical dash brace

- Contribution from structural battery frame and battery cover closing, roof structure trusses

- Rigidly connected front and rear subframes

- Optimized joining and use of structural adhesives

- Capitalizing on the Inherent high modulus of steel

Figure 6: SEM Torsional Rigidity animation. (© WorldAutoSteel 2022)

Static torsional stiffness 38,000Nm/deg

Global trimmed BIW modes >28Hz

Local attachment static stiffness ten times bushing stiffness

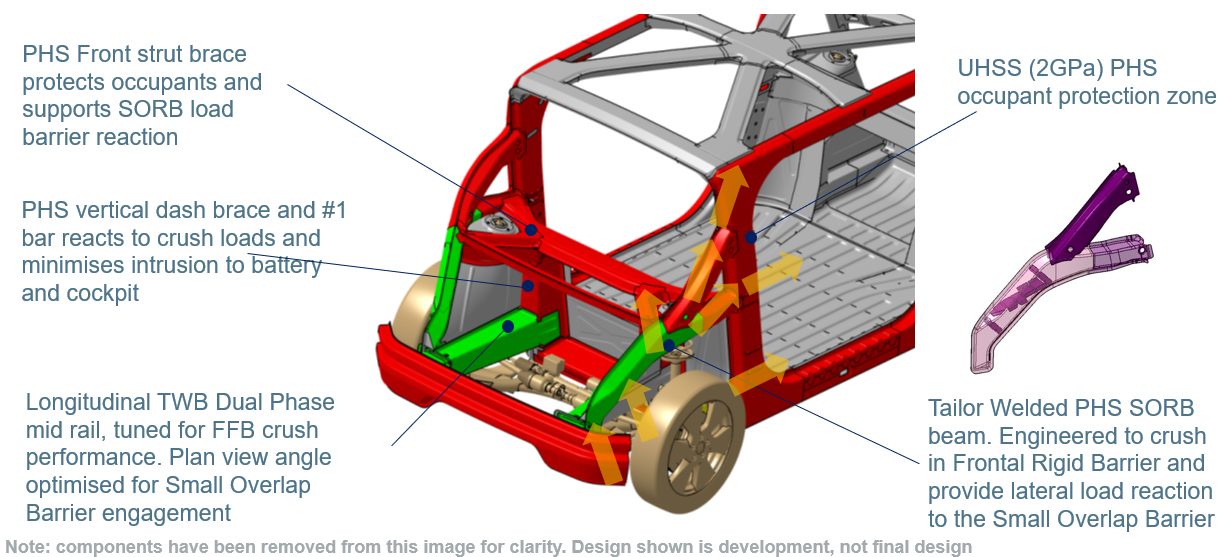

Front Crash Structure Engineered to Balance the Requirements of 56kph USNCAP FFB, IIHS ODB, IIHS SORB and EuroNCAP MPDB Load cases

One of the most challenging aspects of the Steel E-Motive program has been achieving the front crash performance that minimizes occupant injury. The challenge has been compounded by the overall compact size of the vehicle and the short front overhang dimensions, meaning less space to manage and balance the required crush energy with intrusion resistance.

For the IIHS 25% Small Overlap test, we worked from the outset to achieve a barrier “glance off.” The goal is to deflect the vehicle off the barrier by the time the barrier reaches the hinge pillar. This results in a reduced amount of vehicle kinetic energy converted to crush energy. The vehicle continues after the impact with some onward velocity and kinetic energy. This strategy results in reduced intrusion to the passenger compartment and a much lower vehicle pulse (below 20g), which translates into lower occupant injury. We are very excited by this outcome, as in our benchmarking we have not seen many (if any) vehicles of this size managing to achieve a glance off for this test. Figures 7 and the bullets following provide a look at the results.

Figure 7: IIHS 25% Small Overlap test. (© WorldAutoSteel 2022)

- IIHS “good” rating achieved (based on predicted intrusions).

- Our strategy for IIHS Small Overlap test was to achieve a “glance off” the barrier, which is a significant challenge given the vehicle’s short front overhang.

- Front suspension engineered to detach on impact. This is important for achieving glance off.

- Glance off results in some continued onward vehicle velocity after the impact.

- This results in reduced crush energy, lower vehicle pulse and intrusions = enhanced occupant protection

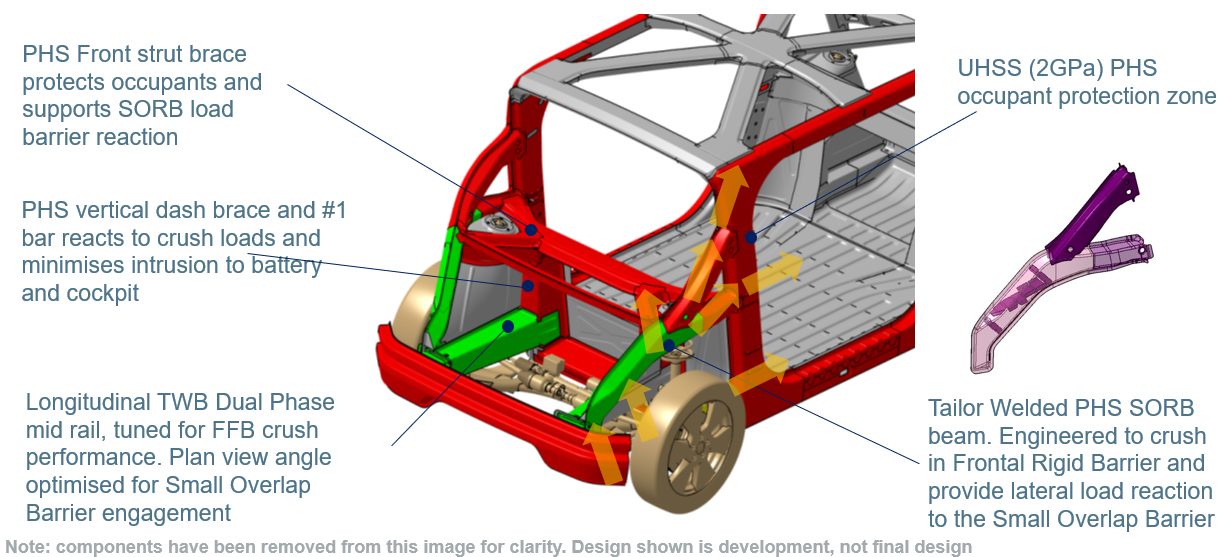

Figure 8 points out features of the front crash structure. Most of the crush energy in FFB and ODB is absorbed by conventional longitudinal mid-rails, which are made of cold stamped, tailor welded blank Dual Phase steels. The plan view angle of the longitudinals has been optimized to provide load reaction early in the SORB event while remaining largely inside of the SORB barrier.

Figure 8: Front crash structure engineered to balance the requirements of 56kph USNCAP FFB, IIHS ODB, IIHS SORB and EuroNCAP MPDB load cases. (© WorldAutoSteel 2022)

Following in Figures 9 and 10 are animations of the FFB results:

|

| Figure 9: USNCAP 56kph Rigid Barrier – Top View. (© WorldAutoSteel 2022) |

|

| Figure 10: USNCAP 56kph Rigid Barrier – Side View. (© WorldAutoSteel 2022) |

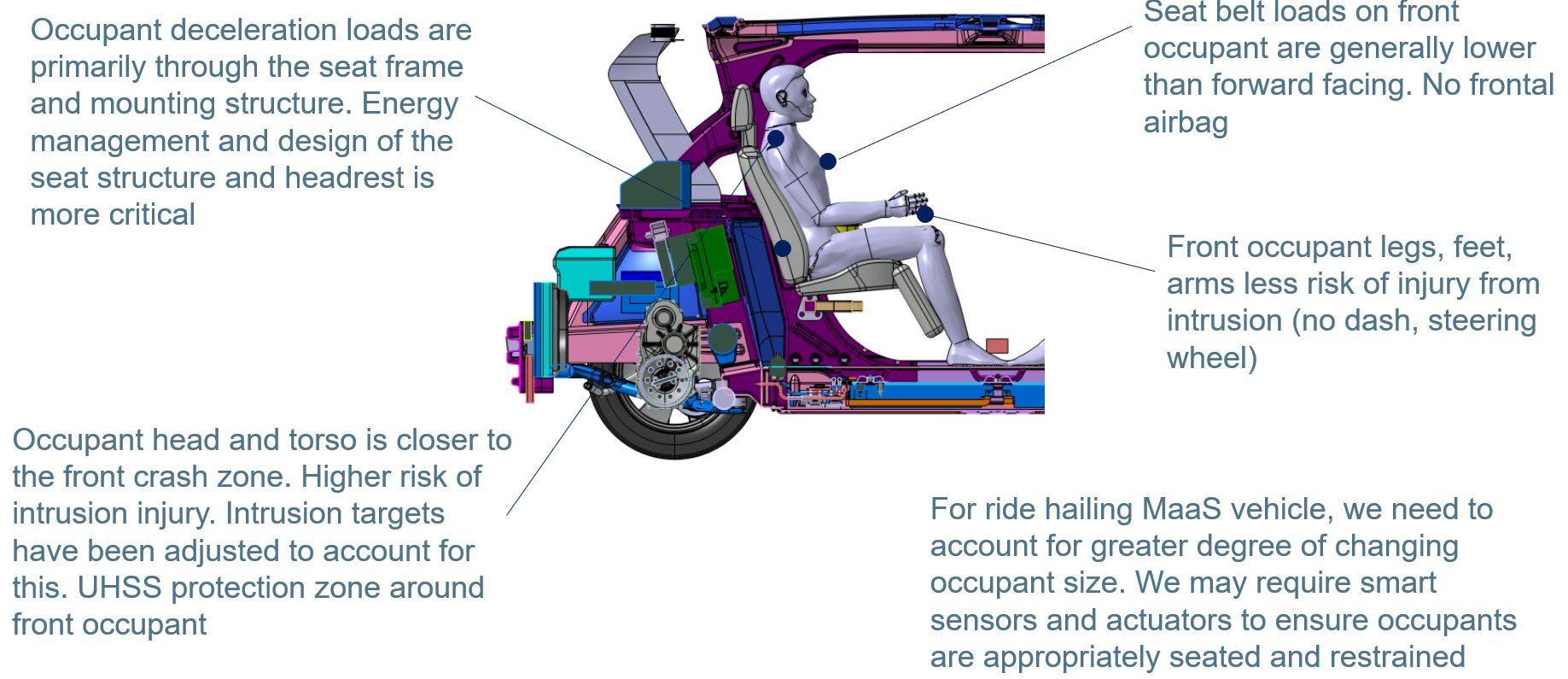

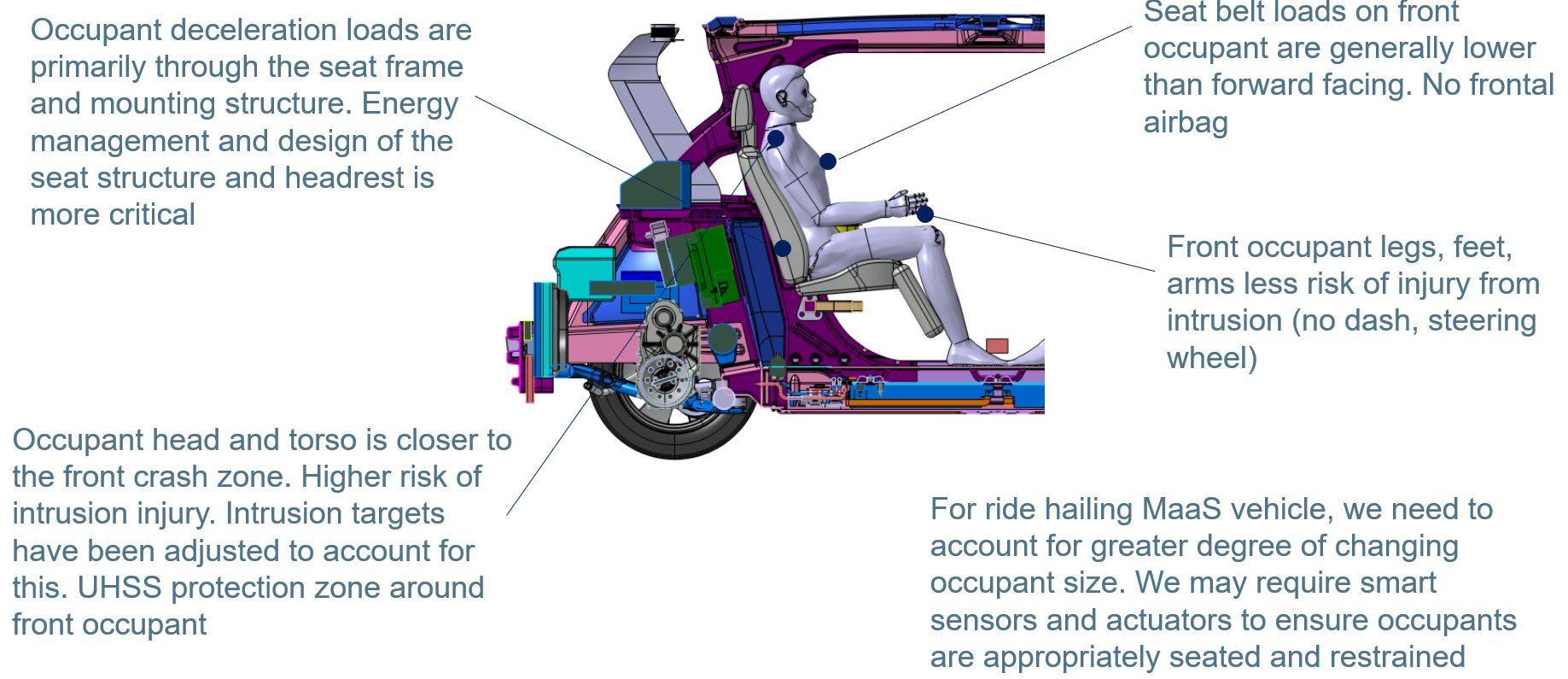

MaaS vehicles will need to accommodate quick ingress and egress as well as provide comfort and safety for the occupants. Consequently, we have flipped the front occupant around to a rear facing configuration and provided a B-Pillarless wide door aperture to enable comfortable and quick access for passengers. This changes the approach required for occupant protection in a front crash. Effectively we are dealing with a high-speed rear impact situation for the occupant. Current rear impact tests cover lower speed rear end shunts. Figure 11 notes the key points and challenges that Steel E-Motive is designed to meet.

Figure 11: Different approach and considerations are required for the protection of rear facing front occupants. We are effectively addressing a high-speed rear impact event. (© WorldAutoSteel 2022)

Side Crash Structure Consists of Absorption and Intrusion Prevention Zones, Compensating for Large Body Aperture

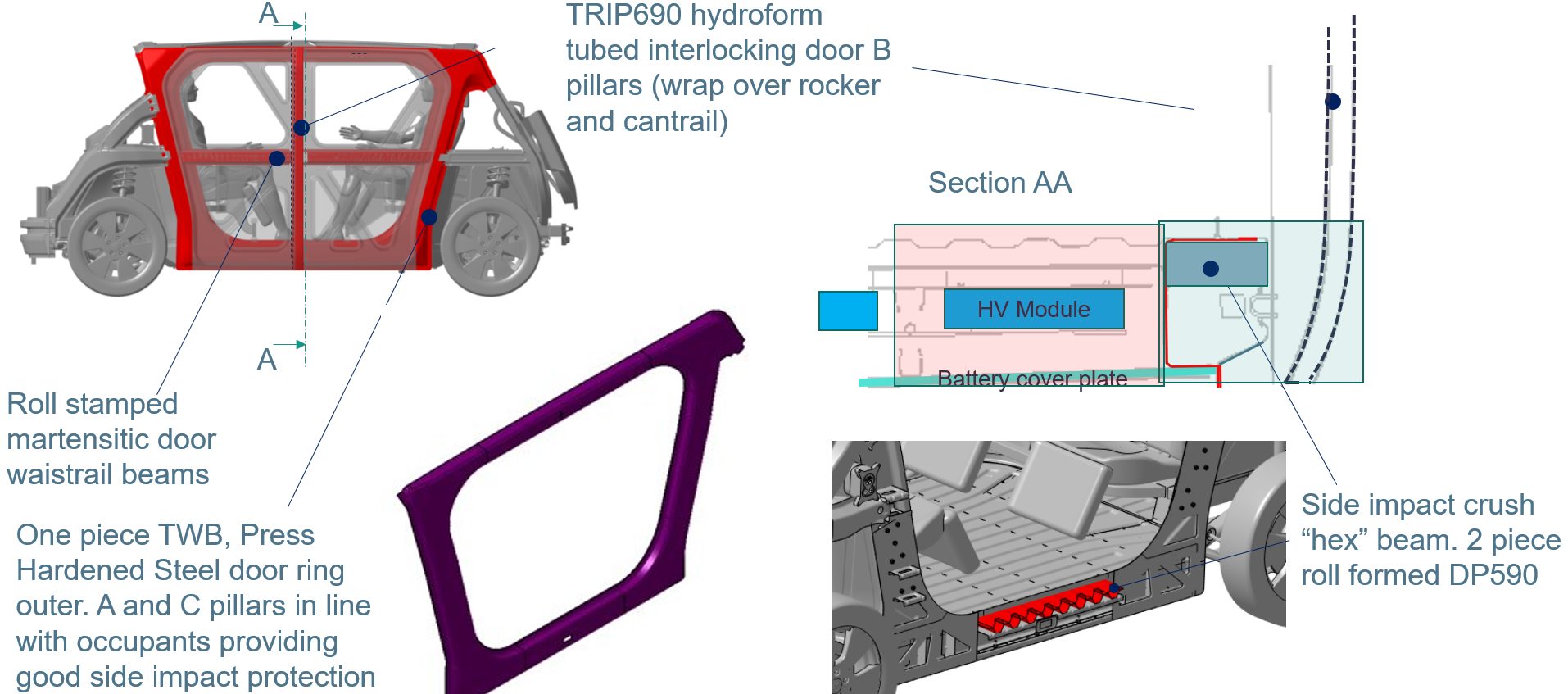

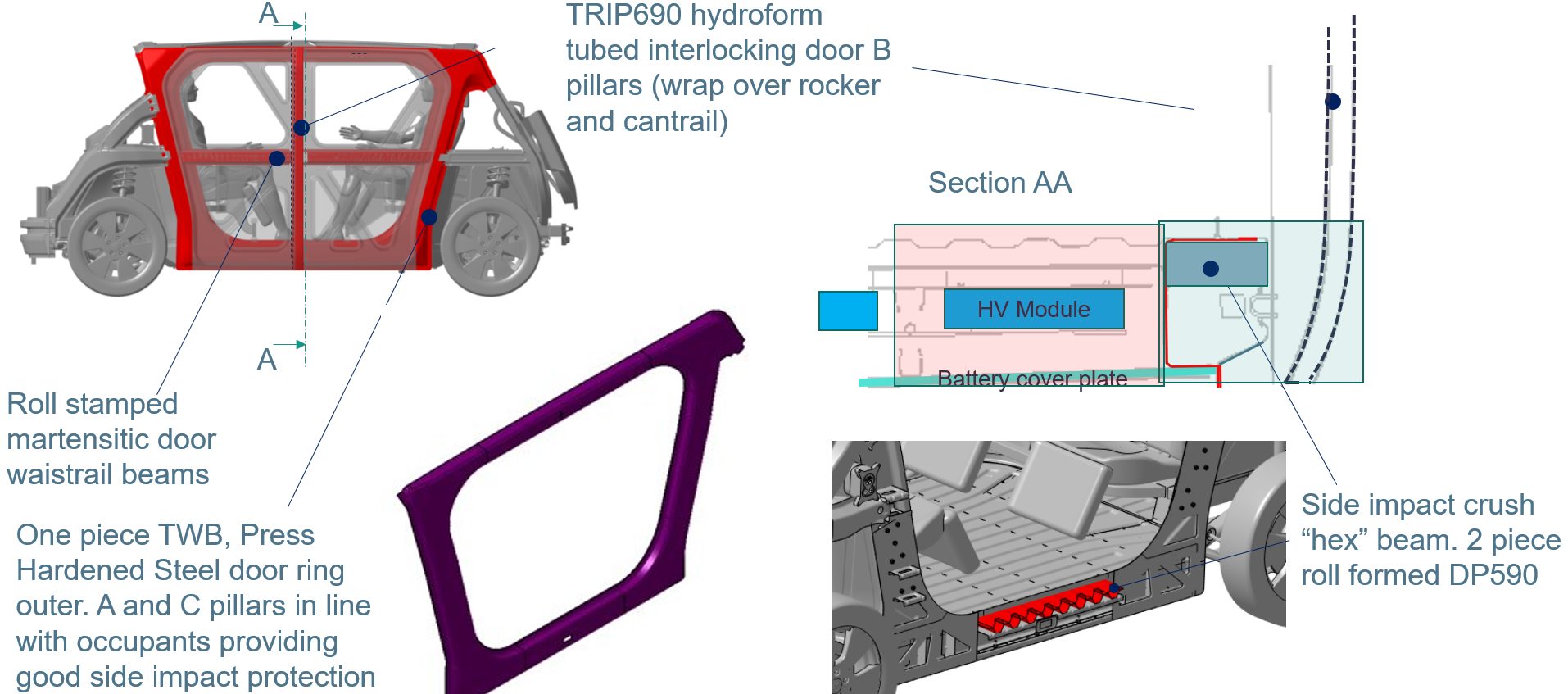

The side structure includes roll-stamped martensitic door waist rail beams and a one-piece Tailor Welded Blank, Press Hardened Steel door ring outer. A- and C-pillars in line with occupants provide good side impact protection. (You can learn more about the door design in our May blog).

In the section AA schematic in Figure 12 the TRIP690 hydroformed tube interlocking door B-pillar is shown (wrapped over the rocker and cantrail). The load travels through the side impact crush “hex” beam, which is a two-piece roll formed DP590 component.

Figure 12: Side crash structure consists of absorption and intrusion prevention zones, compensating for large body aperture. (© WorldAutoSteel 2022)

Steel E-Motive Design Demonstrates Good Side Crashworthiness and Good Levels of Occupant and Battery Protection

In addition to occupant protection tests, additional side impact load cases have been simulated to ensure optimal battery protection. The design maintains a less than 30 mm clearance to the battery.

In reviewing the design according to IIHS standards and based on the predicted intrusions, we are confident this vehicle would achieve an IIHS “good” rating. See Figures 13 and 14 following:

Figure 13: USNCAP 32kph side pole (battery protection). (© WorldAutoSteel 2022)

In addition to occupant protection test, additional side pole load cases to ensure battery protection

>30mm clearance to battery maintained

Figure 14: IIHS 60kph side barrier II (occupant protection). (© WorldAutoSteel 2022)

IIHS “good” rating (based on predicted intrusions).

Total Cost of Ownership: Vehicle and Body Is Designed for Conventional Fabrication and Assembly Processes

The Steel E-Motive body has been designed with low cost in mind to provide the foundation for a lower total cost of ownership for fleet owners. The steel body design is optimized to maximize material utilization and minimize scrap rate. Steel E-Motive is suitable for >250,000 units/year production and is compatible with existing global automotive manufacturing facilities using conventional press and fabrication tools. We are also using Life Cycle Assessment as an integral part of the engineering process to ensure that Steel E-Motive is responsible for the lowest possible emissions throughout its entire life cycle. We will report on environmental performance and sustainability as a part of our final results.

Steel E-Motive Key Outcomes

The Steel E-Motive program is delivering an exciting futuristic vehicle, optimized from the ground up for autonomous MaaS application. We are addressing key challenges through careful design, application of simulation tools and efficient use of the latest Advanced High-Strength Steels and fabrication processes. Steel’s inherent characteristics of low production emissions, lightweighting capabilities for mass efficiency, infinite recyclability and product durability underscores its suitability as an integral part of stakeholder strategies to offer sustainable mobility solutions, today and in the future.

Be sure to follow us on our journey as we enter our final months of design, engineering and reporting by subscribing at the Steel E-Motive website. We welcome your questions about this program using the Comment box below.

Images are not for use without permission. Contact steel@worldautosteel.org.

homepage-featured-top, main-blog, News

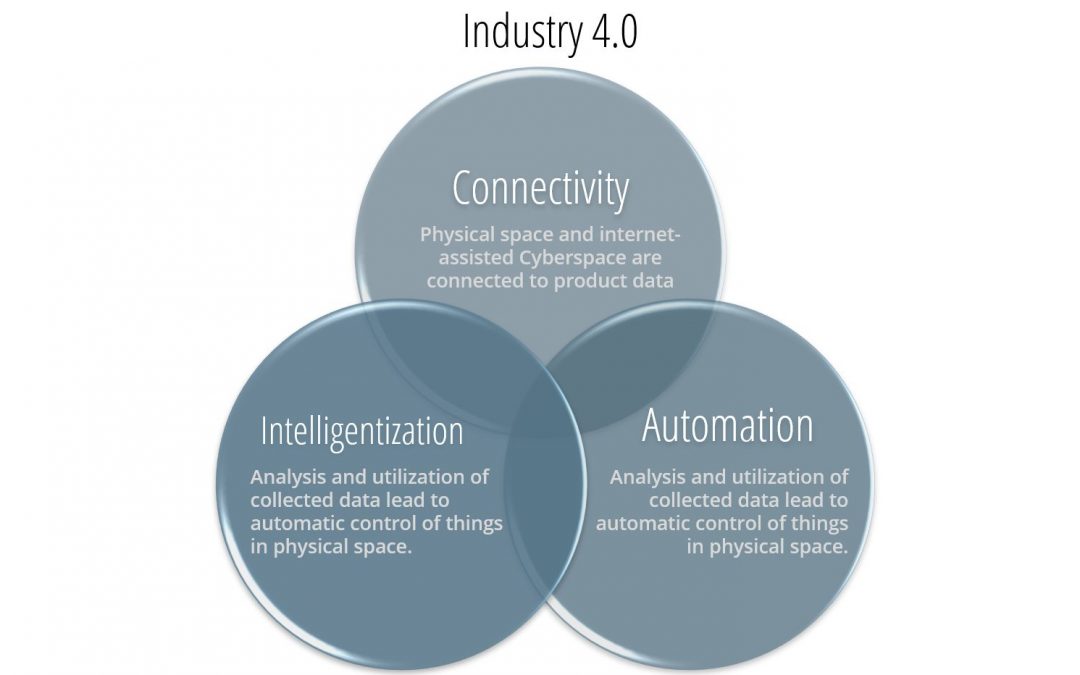

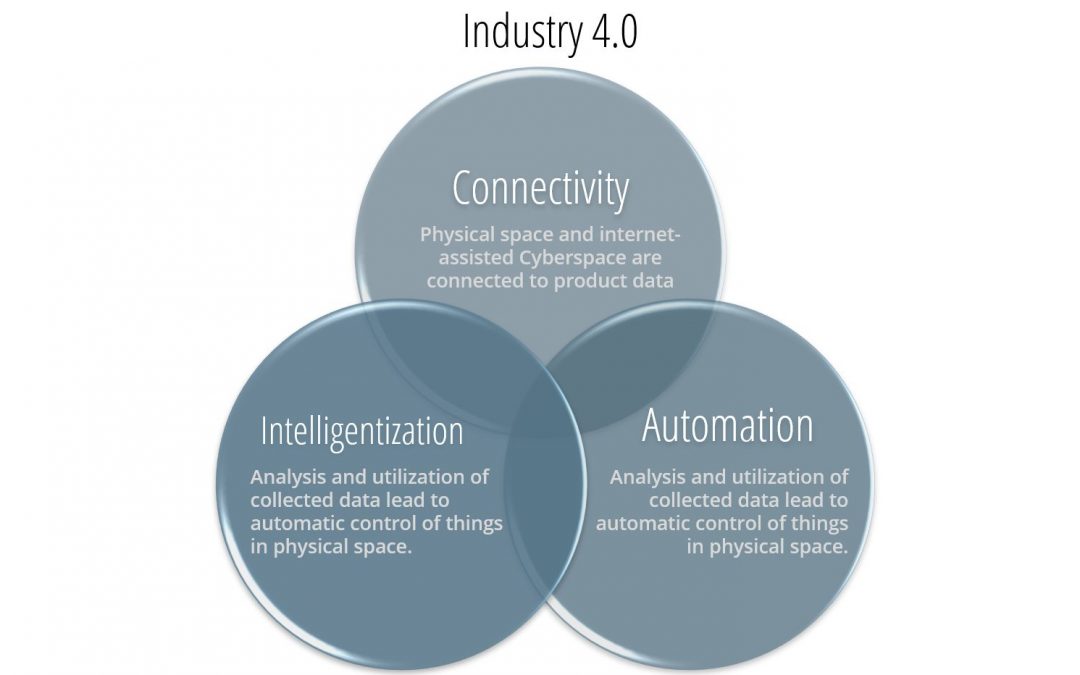

There is interest in the sheet metal industry on how to adopt Industry 4.0 into their legacy forming practices to significantly improve productivity and product quality. Figure 1 illustrates four important variables influencing part quality: material properties, die friction response, elastic deflection of the tool, and press dynamic characteristics. These variables are usually difficult to measure or track during the production runs. When these variables significantly influence the part quality and the scrap rate increases, the operators manually adjust the forming press parameters (speed and pressure), lubricant amount, and tooling setup. However, these manual adjustments are not always possible or effective and can be costly for the increased part complexity.

Figure 1: Important variables influencing the stamping quality.H-35

The ultimate vision for Industry 4.0 in sheet metal forming is an autonomous forming process with maximum process efficiency and minimum scrap rate. This is very similar to the full self-driving (FSD) vision of the electric vehicle today. This will be valuable for the automotive industry that has to process large production volumes with various steel grades.

For example, normal variations of the incoming material properties for Advanced High-Strength Steel (AHSS) may have a significant effect on part quality associated with necking, wrinkling, and cracking, which in turn drastically increases the production cost. This variation of the incoming material properties increases uncertainty in sheet metal forming by making consistent quality more challenging to achieve, thereby increasing the overall manufacturing cost. A nondestructive evaluation (NDE) can be a useful tool to measure incoming material properties.

There are several types of NDE sensors. Most of the sensors need further development or are not suitable for production applications. However, some of the NDE sensors, such as the eddy current tools, laser triangulation sensors equipment, and equipment developed by Fraunhofer IZFP called 3MA (micromagnetic, multiparametric microstructure, and stress analysis), have already been applied to a few limited production applications. These sensors can be used to provide data during production to select the optimal parameters. They also can be used to obtain material properties for finite element model (FEM) analysis. Studies in deep drawing of a kitchen sink production used a laser triangulation sensor to measure the sheet thickness and an eddy-current sensor to measure the yield strength, tensile strength, uniform elongation, elongation to break, and grain size of the incoming material. The material data is used as an input for simulations to generate the metamodels to determine the process window, and it is used as an input for the feed-forward control during the process.K-27

Figure 2 shows how NDE tools are used for feed-forward controls and cameras for feedback control to determine the optimum press setting on sink forming production.

Figure 2: Process control for sheet metal forming of kitchen sink production.H-36

Another study proposed the use of Fraunhofer’s 3MA equipment to determine the mechanical properties of incoming blanks for a sheet forming process. The 3MA sensor correlates the magnetic properties of the material with the mechanical properties and calibrates the system with the procedure outlined in Figure 3. The study showed a good correlation between the measurements from the sensor and the tensile testing results; however, the sensor should be calibrated for each material. Also, the study proposed to use a machine-learning algorithm instead of a feed-forward control to predict the most effective parameters during the drawing process.K-28

Figure 3: Calibration procedure for 3MA sensors.K-28

Technologies associated with Industry 4.0 have a natural fit with AHSS. The advanced slide motion capabilities of servo presses combined with active binder force control can be paired with stamping tonnage and edge location measurements from every hit to create closed-loop feedback control. With press hardening steels (PHS), vision sensors and thermal cameras can be used for controlling the press machine and transfer system.

Have a look at the Dr. Kim’s detailed article on Industry 4.0 for more examples of NDE sensors, as well as information on applying Industry 4.0 to forming process controls.

Blog, homepage-featured-top, News

We thank Dennis McPike, Zapp Tooling Alloys, Inc. for contributing this insightful case study.

Multi-phase steels are complex to cut and form, requiring specific tooling materials. The tooling alloys which have been used for decades, such as D2, A2 or S7, are reaching their load limits and often result in unacceptable tool life. The mechanical properties of the sheet steels achieve tensile strengths of up to 1800 MPa with elongations of up to 40%. Additionally, the tooling alloys are stressed by the work hardening of the material during processing.

The challenge to process AHSS quickly and economically makes it necessary for suppliers to manufacture tooling with an optimal tool steel selection. The following case study illustrates the tooling challenges caused by AHSS and the importance of proper tool steel selection.

A manufacturer of control arms changed production material from a conventional steel to an Advanced High-Strength Steel (AHSS), HR440Y580T-FB, a Ferrite-Bainite grade with a minimum yield strength of 440 MPa and a minimum tensile strength of 580 MPa. However, the tool steels were not also changed to address the increased demands of AHSS, resulting in unacceptable tool life and down time.

According to the certified metal properties, the 4 mm thick FB 600 material introduced into production had a 525 MPa yield strength, 605 MPa tensile strength, and a 20% total elongation. These mechanical properties did not appear to be a significant challenge for the tool steels specified in the existing die standards. But the problems encountered in production revealed serious tool life problems.

To form the FB 600 the manufacturer used D2 steel. D2 was successful for decades in forming applications. This cold work tool steel is used in a wide variety of applications due to its simple heat treatment and its easily adjustable hardness values. In this case, D2 was used at a hardness of RC 58/60.

While tools manufactured from D2 can withstand up to 50,000 load cycles when forming conventional steels, these particular D2 tools failed after only 5,000 – 7,000 cycles during the forming of FB 600. The first problems were detected on a curl station where mechanical overload caused the D2 tools to break catastrophically, as seen in Figure 1 below. Since the breakage was sudden and unforeseeable, each failure of the tools resulted in long changeover times and thus machine downtime.

Figure 9: Breakage seen in control arm curl tool made from D2, leading to premature failure. Conversion to a PM tool steel having higher impact resistance led to 10x increase in tool life.M-20

Since the cause of failure was a mechanical breakage of the tools, a tougher alternative was consequently sought. These alternatives, which included A2 and DC53 were tested at RC 58-60 and unfortunately showed similar tool life and failures.

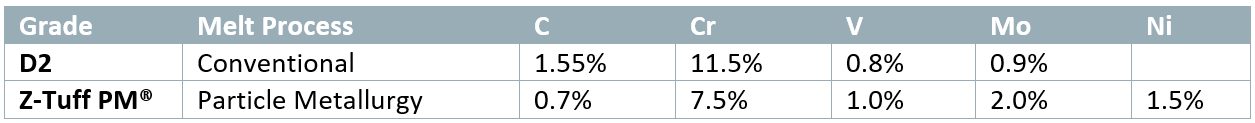

Metallurgical analysis indicated that the failure resulted from insufficient impact strength of the tool steel. This was caused by the increased cross-cut that the work-hardened AHSS exerted on the curl. As an alternative material, a cold work steel with a hardness of 58-60, a tensile strength of about 2200 – 2400 MPa and high toughness was sought. These properties could not be achieved with conventional tool steels. The toolmaker used a special particle metallurgy (PM) tool steel to obtain an optimum combination of impact strength, hardness and wear resistance.

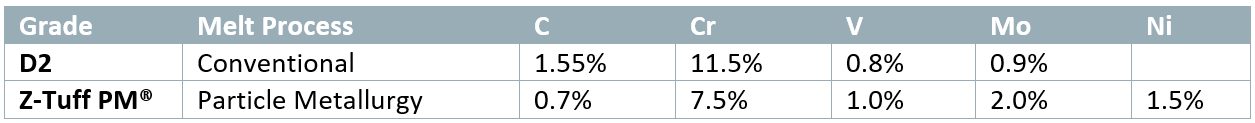

Particle metallurgy (PM) tool steels, due to their unique manufacturing process, represent improvements in alloy composition beyond the capabilities of conventional tool steels. Materials with a high alloy content of carbide formers such as chromium, vanadium, molybdenum and tungsten are readily available. The PM melting process ensures that the carbides are especially fine in particle size and evenly distributed (reference Table 1). This process results in a far tougher tool steel compared to conventional melting practices.

Table 1: Elemental Composition of Chosen Tool Steel

The manufacturer selected Z-Tuff PM® to be used at a hardness of RC 58-60. Employing the identical hardness as the conventional cold work steel D2, a significant increase in impact strength (nearly 10X increase as measured by un-notched Charpy impact values) was realized due to the homogeneous microstructure and the more evenly distributed precipitates. This positive effect of the PM material led to a significant increase in tool life. By switching to the PM tool steel, the service life is again at the usual 40000 – 50000 load cycles. By using a steel with an optimal combination of properties, the manufacturer eliminated the tool breakage without introducing new problems such as deformation, galling, or premature wear.

AHSS creates tooling demands that challenge the mechanical properties of conventional tool steels. Existing die standards may not be sufficient to achieve consistent and reliable performance for forming, trimming and piercing AHSS. Proper tool steel grade selection is critical to ensuring consistent and reliable tooling performance in AHSS applications. Powder metallurgical tool steels offer a solution for the challenges of AHSS.

News

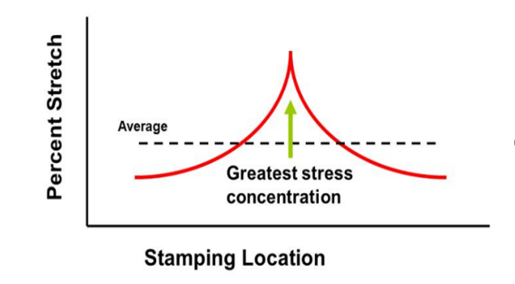

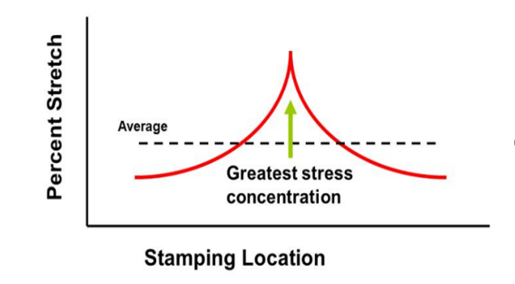

To understand the difference between localized and global fractures, you must first understand strain gradients (see the article in our blog, AHSS Strain Hardening and Gradients). Gradients can result in highly concentrated strains (peak strain condition) that typically occurs in an embossment or character line where the deformation mode is in plane strain. Peak strains can develop rapidly in a very localized area (Figure 1). Under additional loads, this can result in the onset of localized necking, which means the material has reached its tensile strength and will fail at its weakest point or highest strain. When a slight increase in strain is applied, the material will fracture, sometimes at deformation levels less than predicted. This condition can be found in AHSS products, where multiple phases exist within the steel’s microstructure, each with different properties. A global fracture also typically occurs in plane strain, but more commonly down a sidewall or other area with more moderate geometry complexity.

Figure 1: Peak strain in the localized area or embossment

Peak (concentrated) strains are susceptible to localized fractures when even slight variation exists in the forming process. Examples of variation include lubrication pattern and volume, die recipe including blank position, press conditions, and material characteristics.

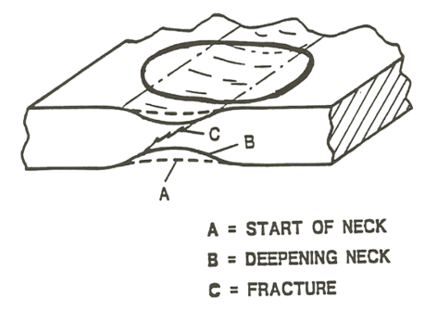

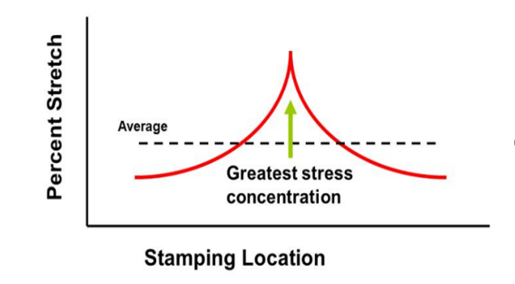

A localized neck and/or fracture (Figure 2) reduces the sheet metal’s thickness, reducing part strength, and compromising functional performance such as fatigue life, crash worthiness, and stamping stiffness. There are a number of formability analysis tools that can differentiate localized and global fractures and enable die makers to implement die and process improvements that minimize fracture susceptibility. The result is a more robust stamping process.

Figure 2: Schematic of Localized Necking and Fracture

Process control is critical; die recipe discipline is needed to minimize tinkering with die recipe, press settings, and lubrication settings. Mechanical properties of the sheet metal should be tracked to identify trends or variations in the material, and establish the material forming window. Typical mechanical properties that are available from the steel supplier are yield strength, tensile strength, n-value, total and uniformed elongation, and sheet thickness. Additional properties that should be determined include hole expansion and deep cup draw ratios. Failure to identify strain levels, process variables and variation will lead to a reactionary approach to controlling the output. This will lead to an increase in scrap, die-related downtime, and of course, costs.

Contributions made by Phoenix Group.

News

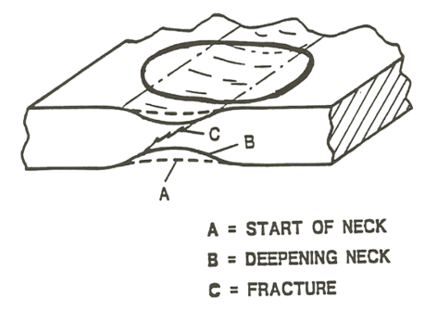

A common problem in every stamping plant is trim edge burrs. As new materials have been introduced, special trim breakage (clearance) or entry amounts may be required. Researchers are still trying to understand the edge stretching limits of these new materials. Edge stretching limits are directly linked to the reduction of the work hardening exponent (n-value) due to the cutting operation. As the material is cut during the coil slitting, blanking, trimming, or piercing operations, the tensile stretching on the sheared edge reduces the amount of formability remaining in the material. Finding the proper trim breakage and trim edge condition is critical. New test studies help steel producers understand the maximum stretch limits of the material they produce.

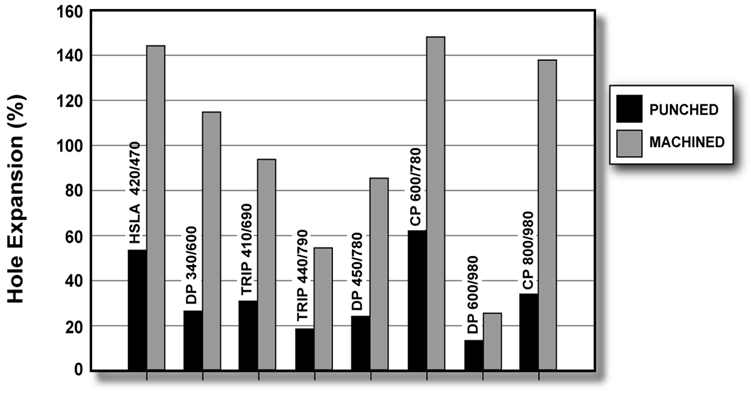

The Hole Expansion Test (HET) is the accepted form of measuring edge stretching limits. The test is performed by punching a hole in the center of a flat blank which is then clamped down, while a conical punch is pushed up through the hole, creating a stretch-flanged edge (see Figures 1 & 2). The output is the ratio of final hole diameter/initial hole diameter. The hole in the blank can be produced by various processes, to simulate manufacturing conditions. Some of the best results are produced by utilizing milled edges, laser cutting, EDM, and water jet.

In the world of stamping operations, reduced formability of a trim or pierced edge can equate to downtime, scrap, or rework. Since the use of EDM and Waterjets are not practical solutions, we evaluate current methods and materials that are available. The intention is to provide information to the people on the shop floor who might deal with this issue on any given day. Worn or chipped trim steels, improper clearances, and worn punches need to be repaired and maintained. New Advanced High-Strength Steels have lower forming limits compared to mild steel, and the introduction of a worn tool will reduce that forming range significantly. The use of powder metallurgy or cutting steels can help improve the number of hits between preventive maintenance intervals significantly. Some surface treatments can also extend tool life, achieving the same relative tool wear as conventional mild steels.

Figure 1: Schematic of a typical hole expansion test (HET)

conical punch/die setup.

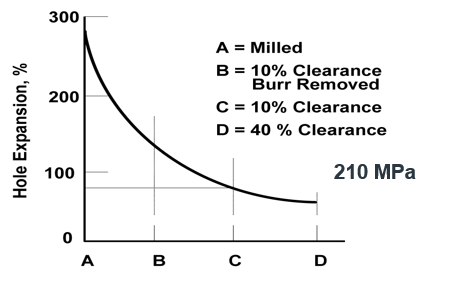

Figure 2: Schematic showing hole expansion capability for a 200 MPa mild steel for various punch conditions.

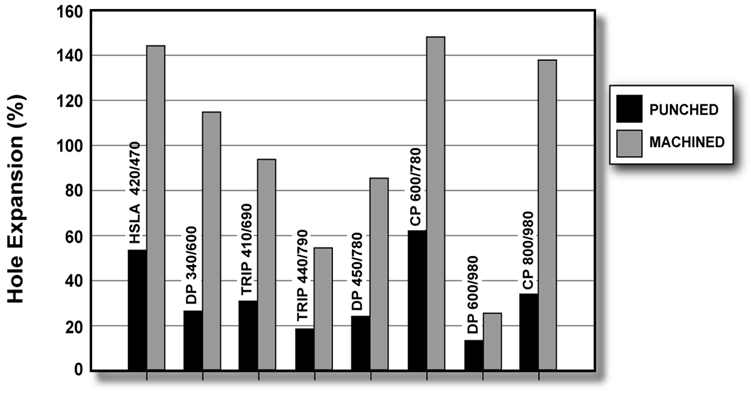

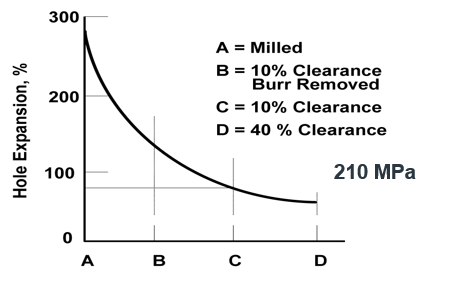

New grades such as Complex Phase (CP) steels have great strength, but also perform well in edge or stretch flange conditions because of bainite and grain refinement due to thermo-mechanical processing in the steel mill. Yet, the lack of proper tool maintenance can strip these steels of their performance advantage, as shown in Figure 3.

Figure 3: Hole expansion results for various AHSS grades, comparing effect of tool conditions.

Understanding the effects of tool wear rates, trim breakage, surface coating, and surface treatments will reduce downtime, scrap, and extend preventive maintenance intervals on trim and pierce dies. Providing training to the die makers on the newest materials, die components, and surface treatments available will help them make longer lasting corrections to stamping dies. Research and processes are evolving every day, resulting in new methods, products, and information for the successful stamping of Advanced High-Strength Steels.

Note: AHSS Application Guidelines Section 3.C.2 – Tool Materials and Die Wear contains more information that you may find helpful. Download the Guidelines free at www.worldautosteel.org.

Image References:

- Figure 1: (Schematic): H. Mohrbacher, “Advanced metallurgical concepts for DP steels with improved formability and damage resistance” – NiobelCon bvba

- Figure 2: R. Hilsen et al, “Stamping Potential of Hot-Rolled, Columbium-Bearing High-Strength Steels,” Proceedings of Microalloying 75 (1977).

- Figure 3: Courtesy of C. Walch, voestalpine Stahl GmbH.

Contributions made by Phoenix Group.