AHSS Insights Blog

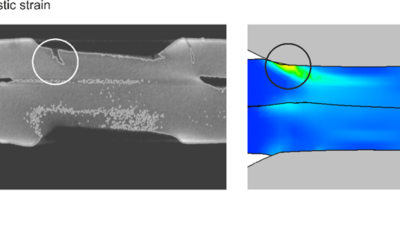

LME Simulation during RSW

Modern car bodies today are made of increasing volumes of Advanced High-Strength Steels (AHSS), the superb performance of which facilitates lightweighting concepts (see Figure 1). To join the different parts of a car body and create the crash structure, the components...

Modelling RSW of AHSS

Modelling resistance spot welding can help to understand the process and drive innovation by asking the right questions and giving new viewpoints outside of limited experimental trials. The models can calculate industrial-scale automotive assemblies and allow...

PHS in Vehicles: An Abridged History

The Beginnings of PHS Use Press hardening, as we know it today, was developed in Luleå, Sweden, by Norrbottens Järnverks AB (abbreviated as NJA, translated as Norrbotten Iron Works). The first patent application was completed in 1973 and awarded in 1977.N-23 The...

Case Study: Upgraded Tool Steels for Upgraded Sheet Metal Forming

We thank Dennis McPike, Zapp Tooling Alloys, Inc. for contributing this insightful case study. Multi-phase steels are complex to cut and form, requiring specific tooling materials. The tooling alloys which have been used for decades, such as D2, A2 or S7, are reaching...

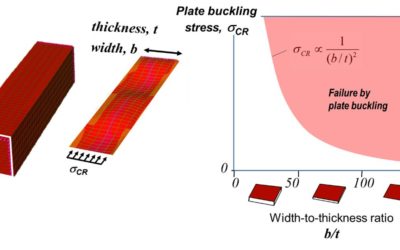

Geometric Analysis of Sections – GAS2.0

A New Software Application for Thin Wall Section Analysis Advanced High-Strength Steel (AHSS) grades offer increased performance in yield and tensile strength. However, to fully utilize this increased strength, automotive beam sections must be designed carefully to...

Inventing the First AHSS Road Bike

An inspiring story You are most likely wondering why WorldAutoSteel is writing a blog about a bicycle. It is because when we talked to Jia-Uei Chan, Regional Business Development at our member company, thyssenkrupp Steel Europe (TKSe), about the journey of...