Blog, homepage-featured-top, main-blog, News

Resistance spot welding (RSW) is the most utilized joining process in car body assembly with exceptionally high demands on quality and reproducibility. Expulsion in RSW leads to ejection of metal from the weld and can cause equipment deterioration and re-working.

As the RSW process has many variables both from the process itself and from the to-be-welded component, prediction and avoidance of expulsion is challenging. This creates a large demand for new technologies that allow for RSW of steels with improved expulsion control.

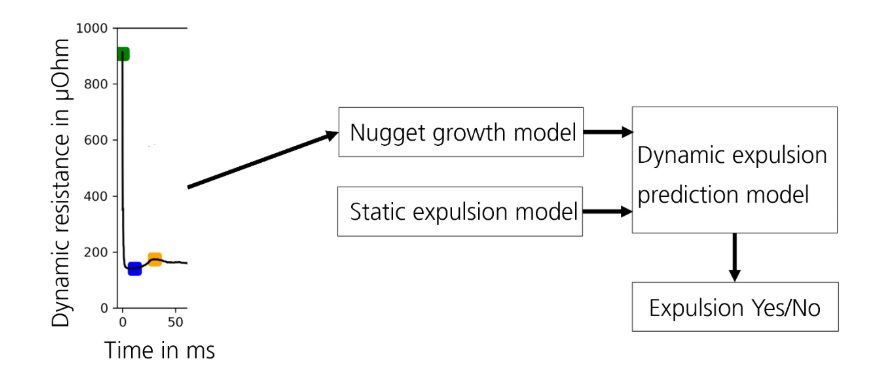

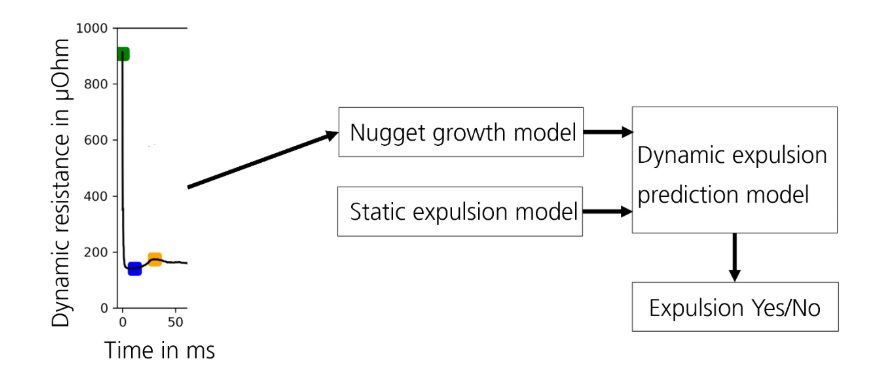

Recent developments aim to predict – and ultimately avoid – expulsion using artificial intelligence data analysis. Process data on current, voltage and dynamic resistance are readily available in RSW and can be augmented with simulation data for non-measurable phenomena such as the nugget growth rate to create predictive algorithms that eventually aim to avoid expulsion altogether.

An Introduction to AI Expulsion Prediction

This work focuses on utilizing artificial intelligence modeling for the prediction of expulsion during resistance spot welding (see Figure 1 for an image of expulsion on the left and metal residue on the surface after expulsion on the right). The primary objective is to forecast the formation of expulsion before it occurs, with the aim of improving the quality of the welding process. This effort is supported by a dataset of 500 welded spots of 2-sheet stack-ups made from one advanced high-strength steel (AHSS) and one mild steel joining partner. Two sequential AI models are trained: one for nugget growth prediction and another for spatter prediction.

Figure 1: Left: Expulsion leads to the ejection of molten metal. Right: Residues may form on the surface after expulsion.

Feature Engineering

A key aspect is the integration of multi-source data: The models leverage both static and dynamic inputs. Static inputs include input process parameters such as current, force, and weld time, which are set at the machine in accordance with a pre-determined weld lobe. Dynamic inputs encompass transient process signals like dynamic resistance and electrode force. In resistance spot welding, this data is usually readily available, because the welding power source measures electric flow and weld gun opening and forces. A further step is to include non-measurable data from simulation results concerning nugget growth rate.

To give time for process intervention, the predictive quality of the models was determined after only 30 ms of welding time, depicted in Figure 2.

Figure 2: Only 30 ms of dynamic resistance measurements are used as input for the AI models.

Data evaluation and feature engineering are critical components of the modeling process. A welding and data-science expert needs to identify significant features from sensor time series data as input for the neural network AI models. These features can be physically meaningful, such as the minimum resistance during the process, or purely statistical with values such as longest continuous time above the average resistance.

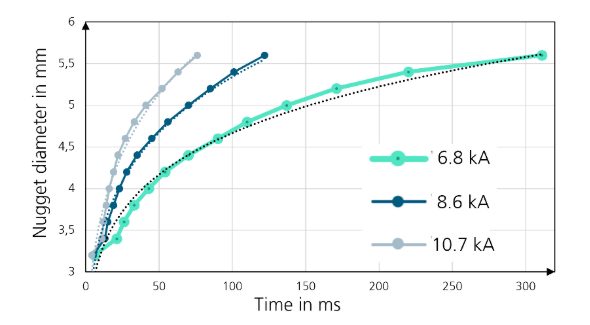

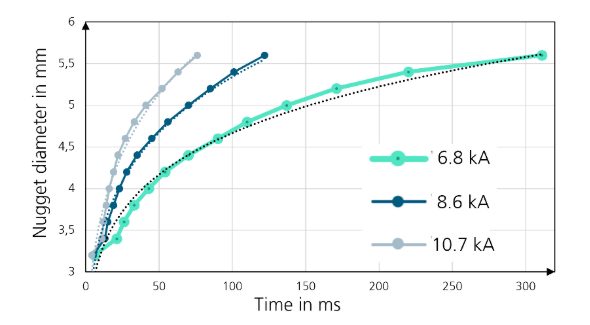

The simulation of resistance spot welding allows for the extraction of the non-measurable nugget growth rate. It is well documented that the nugget growth rate strongly correlates with expulsion formation and conducting simulations for different welding cases (gaps, misalignments, slightly changed contact resistances…) can add this physical behavior to the data-driven AI model. Figure 3 depicts different nugget growths extracted from the simulation with different welding currents. High currents lead to significantly faster growth rates and facilitate expulsion.

Figure 3: Weld nugget growth behavior for different welding currents extracted from a numerical welding simulation. Solid lines are simulation results; dashed lines depict a polynomial fit used to reduce data for AI input.

Model Accuracy

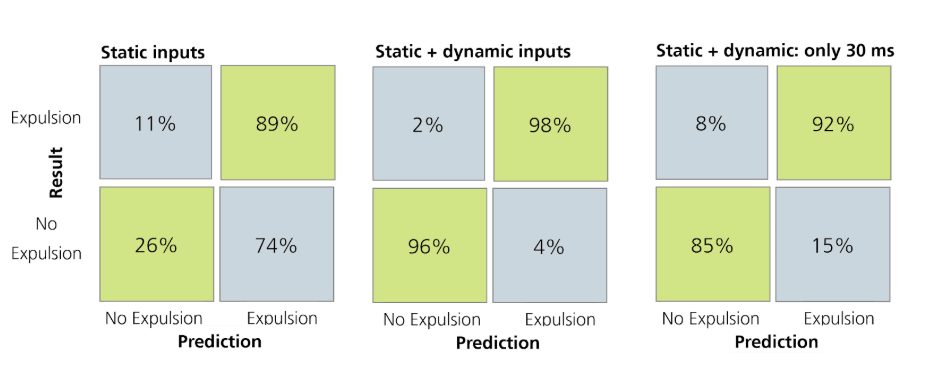

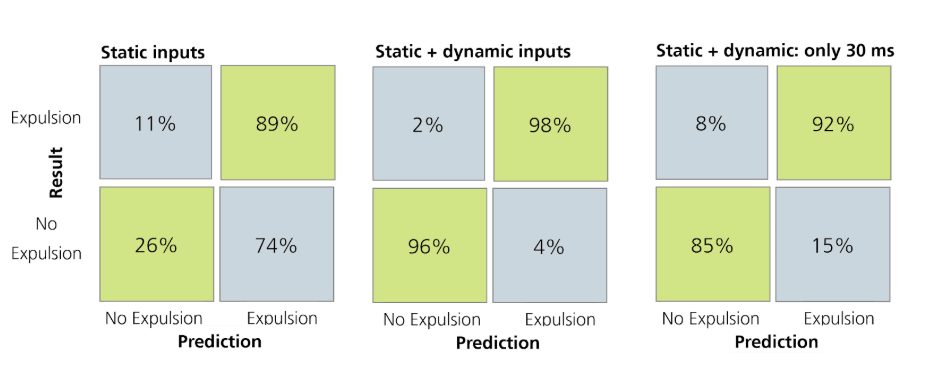

Figure 4 depicts the confusion matrices for the three different models. The bottom left and top right fields are the desired predictions, and the other fields depict false results of the models. The first model stage, which relies solely on static inputs, yields moderate prediction quality. However, when dynamic data from experiments and simulations are included, the prediction quality jumps to approximately 96%. The analysis focusing on the first 30 milliseconds to give time for subsequent intervention in the process, achieves a reduced, but still good, result quality of around 90%. Further improvements in prediction accuracy are expected with additional data.

Figure 4: Confusion matrices for static, static and dynamic and static and dynamic: only 30 ms inputs. A reliable prediction is possible using dynamic process and simulation data. If only 30 ms of dynamic data are utilized the predictive quality decreases.

The presented approach uses a data-driven AI model with different levels of input data to predict resistance spot welding expulsion. The data-gathering and feature engineering procedures are highlighted, explaining a need for in-depth knowledge of the welding process as well as data engineering. The approach yields a neural network with excellent predictive quality, if dynamic data is included in the model. Even if only 30 ms of transient data are used to allow for a subsequent process intervention, the result quality is still good. It is expected that the predictive quality improves when the data set is increased and additional data sources both from measurements and simulations are included. This approach can improve the control of automotive welding systems and ultimately avoid excessive re-working and equipment wear due to expulsion in resistance spot welding of advanced high-strength steels.

Blog, homepage-featured-top, main-blog

Steel’s performance starts at the atomic scale, where tiny changes in how iron and carbon atoms arrange themselves create dramatically different properties. This article explores how those atomic structures evolve into the ferrite, austenite, and advanced microstructures that power today’s high-strength automotive steels.

Understanding Steel at the Atomic Level

Atoms arrange themselves in three-dimensional patterns called lattices. Think about billiard balls in multiple layers. The balls can be one layer directly above the prior one, or they can be shifted and rest in the crevice formed by adjacent balls in the layer below. The balls are all the same material, but the gap size changes with different arrangements.

A crystal lattice shows atoms in a defined, repetitive pattern. In this simple example the atoms can arrange in a square or triangle pattern. The atom size is the same, but the gap size where small elements like carbon can go depends on the lattice arrangement.

Ferrite and Austenite: The Building Blocks of Steel

This is what happens with steel, which for most automotive grades are at least 97% iron. At temperatures below 725 °C, a maximum of only 0.02% carbon fits in the gap between the iron atoms. This orientation is called ferrite. At higher temperatures, a different atomic orientation is stable, which we call austenite. Up to 2% carbon can fit into this arrangement of atoms. For low-carbon steels under normal conditions, austenite cannot exist at room temperature – when the steel is slowly cooled, it changes from austenite to a combination of ferrite and a mixture of phases called pearlite.

Ferrite: Soft, Ductile, and Low-Strength

100% iron is very soft. Ferrite at room temperature is iron with no more than 80 parts per million carbon. That’s really close to pure iron, so when discussing ferrite, think of something soft, low-strength, and ductile.

Carbon-Manganese Steels: Structural Strength

If additional strength is needed, then more alloying elements must be used in addition to carbon. The next most cost-effective alloying element for strengthening is manganese which produces higher-strength steels called carbon-manganese steels. These grades have limited ductility, especially at higher carbon and manganese contents, so they are used in structural applications that do not need a lot of formability and are therefore also called structural steels (SS).

Microalloying: The Birth of HSLA Steels

Around 1980, steelmakers rolled out a new approach to getting higher strength levels while minimizing the loss of elongation usually seen with higher strengths. They accomplish this by strengthening the ferrite through the addition of very small quantities of titanium, niobium, and vanadium to form carbide and nitride precipitates. These microalloying additions are used in precipitation hardening of the ferrite to create High Strength Low Alloy (HSLA) steels.

Rapid Cooling Enables Martensite Formation

The steels discussed to this point are produced with relatively slow cooling. However, investments by the steel industry resulted in equipment capable of reaching rapid cooling (quenching) rates that allow for production of a very high strength phase called martensite.

Martensite wasn’t commonly found as a microstructural component during most of the history of automotive sheet steels due to the limited number of companies having an annealing line with appropriate quenching capabilities. This started to change around the turn of the millennium when newer annealing lines were installed with capability to achieve complex thermal cycles. This allowed for production of the first generation of Advanced High-Strength Steels (AHSS), including grades that have a microstructure of only martensite.

Dual Phase (DP) Steels: Balancing Strength and Ductility

Dual Phase (DP) steels are the most common AHSS. Ferrite and martensite are the two phases in DP steels: ferrite is super-soft and comprises the majority of the microstructure, while martensite is super-hard and takes up 10% (590DP) to 40% (980DP) of the microstructure. The more martensite, the stronger the steel. Since most of the structure is ferrite, these steels have exceptional elongation as measured in a tensile test for the strength level.

TRIP Steels: Transformation-Induced Plasticity

For as good as DP steels are in tensile ductility, TRIP steels are even better. The magic of these grades comes from retained austenite. Austenite is a very ductile phase. What makes this a special phase is that as austenite-containing steels deform, the atoms rearrange and the austenite transforms into martensite, giving the steel enhanced ductility — which researchers state as greater plasticity. Another way of saying that this enhanced ductility comes from austenite transforming to martensite is that these steels have Transformation Induced Plasticity (TRIP).

Ferrite-Bainite and Complex Phase (CP) Steels: Improved Edge Ductility

In both DP and TRIP steels, the large hardness difference between ferrite and martensite leads to crack initiation sites and results in poor cut-edge ductility during stretch flanging. For applications like stretch flanging that need improved cut-edge ductility, one option are the Ferrite-Bainite grades. Bainite is a little lower in strength than martensite but has higher elongation and toughness. Another option are Complex Phase (CP) steels, which have a microstructure of bainite and precipitation-strengthened ferrite, with martensite and retained austenite also present in lower amounts. Lacking soft ferrite, these steels have relatively high yield strength and low elongation as measured in a tensile test, but the bainite leads to exceptional cut-edge ductility as measured in a hole expansion test.

TWIP Steels: Twinning-Induced Plasticity

TWIP steels containing only austenite, and as such are a high-strength, high-ductility steel. These may be written like TRIP steels, but these steels get their plasticity differently. TWIP steels deform by a mechanism known as twinning, so they are described as Twinning Induced Plasticity Steels (TWIP). Unfortunately, achieving the combination of high strength and fantastic formability requires a lot of alloying. This drives up the steelmaking complexity and cost. The alloying elements also make welding much more challenging. TWIP steels are considered second-generation advanced high-strength steels.

3rd Generation AHSS: Tailoring Microstructures for Performance

Nearly all 3rd Generation Advanced High-Strength Steels (3rd Gen AHSS or 3rd Gen) have retained austenite in the microstructure and therefore benefit from a high strength, high ductility combination through the TRIP Effect. The latest annealing lines allow for the creation of an engineered balance and distribution of ferrite, bainite, martensite, and austenite in the microstructure, providing the resultant alloy with properties that can be tailored to address the requirements and challenges of each automotive part.

The Future of Automotive Steels

Together, there are nearly 70 grades of advanced high strength steels available globally. The days of steel being simply a commodity are in the past as it relates to these highly engineered higher strength steels.

Danny Schaeffler is the Metallurgy and Forming Technical Editor of the AHSS Applications Guidelines available from WorldAutoSteel. He is founder and President of Engineering Quality Solutions (EQS). Danny wrote the monthly “Science of Forming” and “Metal Matters” column for Metalforming Magazine, and provides seminars on sheet metal formability for Auto/Steel Partnership and the Precision Metalforming Association. He has written for Stamping Journal and The Fabricator, and has lectured at FabTech. Danny is passionate about training new and experienced employees at manufacturing companies about how sheet metal properties impact their forming success.

homepage-featured-top, main-blog, News

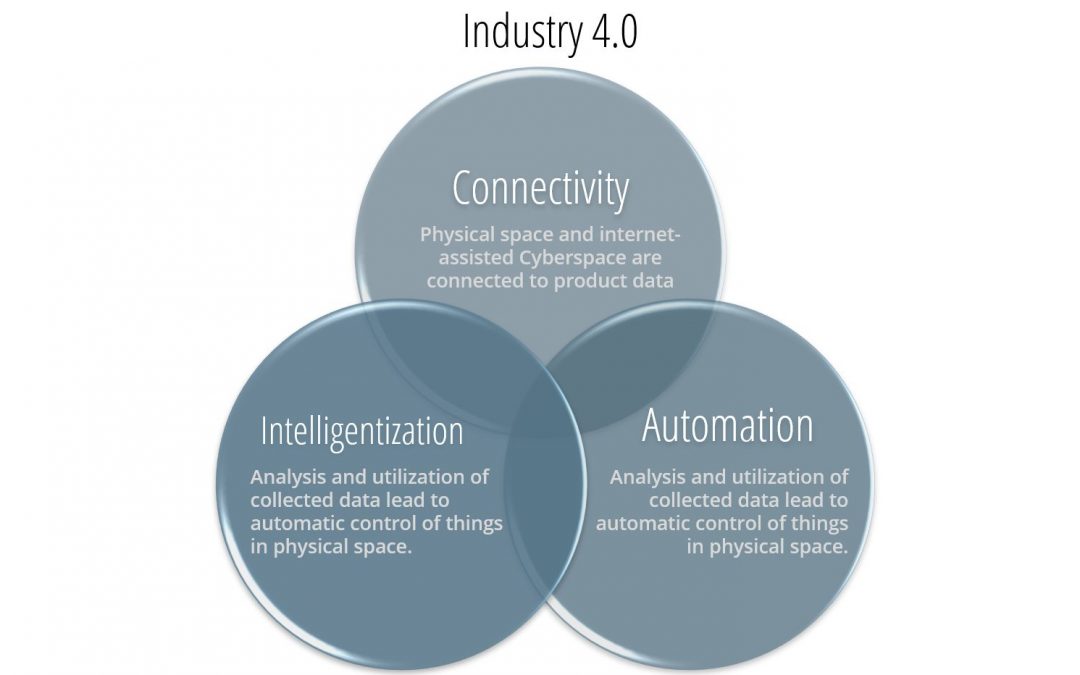

There is interest in the sheet metal industry on how to adopt Industry 4.0 into their legacy forming practices to significantly improve productivity and product quality. Figure 1 illustrates four important variables influencing part quality: material properties, die friction response, elastic deflection of the tool, and press dynamic characteristics. These variables are usually difficult to measure or track during the production runs. When these variables significantly influence the part quality and the scrap rate increases, the operators manually adjust the forming press parameters (speed and pressure), lubricant amount, and tooling setup. However, these manual adjustments are not always possible or effective and can be costly for the increased part complexity.

Figure 1: Important variables influencing the stamping quality.H-35

The ultimate vision for Industry 4.0 in sheet metal forming is an autonomous forming process with maximum process efficiency and minimum scrap rate. This is very similar to the full self-driving (FSD) vision of the electric vehicle today. This will be valuable for the automotive industry that has to process large production volumes with various steel grades.

For example, normal variations of the incoming material properties for Advanced High-Strength Steel (AHSS) may have a significant effect on part quality associated with necking, wrinkling, and cracking, which in turn drastically increases the production cost. This variation of the incoming material properties increases uncertainty in sheet metal forming by making consistent quality more challenging to achieve, thereby increasing the overall manufacturing cost. A nondestructive evaluation (NDE) can be a useful tool to measure incoming material properties.

There are several types of NDE sensors. Most of the sensors need further development or are not suitable for production applications. However, some of the NDE sensors, such as the eddy current tools, laser triangulation sensors equipment, and equipment developed by Fraunhofer IZFP called 3MA (micromagnetic, multiparametric microstructure, and stress analysis), have already been applied to a few limited production applications. These sensors can be used to provide data during production to select the optimal parameters. They also can be used to obtain material properties for finite element model (FEM) analysis. Studies in deep drawing of a kitchen sink production used a laser triangulation sensor to measure the sheet thickness and an eddy-current sensor to measure the yield strength, tensile strength, uniform elongation, elongation to break, and grain size of the incoming material. The material data is used as an input for simulations to generate the metamodels to determine the process window, and it is used as an input for the feed-forward control during the process.K-27

Figure 2 shows how NDE tools are used for feed-forward controls and cameras for feedback control to determine the optimum press setting on sink forming production.

Figure 2: Process control for sheet metal forming of kitchen sink production.H-36

Another study proposed the use of Fraunhofer’s 3MA equipment to determine the mechanical properties of incoming blanks for a sheet forming process. The 3MA sensor correlates the magnetic properties of the material with the mechanical properties and calibrates the system with the procedure outlined in Figure 3. The study showed a good correlation between the measurements from the sensor and the tensile testing results; however, the sensor should be calibrated for each material. Also, the study proposed to use a machine-learning algorithm instead of a feed-forward control to predict the most effective parameters during the drawing process.K-28

Figure 3: Calibration procedure for 3MA sensors.K-28

Technologies associated with Industry 4.0 have a natural fit with AHSS. The advanced slide motion capabilities of servo presses combined with active binder force control can be paired with stamping tonnage and edge location measurements from every hit to create closed-loop feedback control. With press hardening steels (PHS), vision sensors and thermal cameras can be used for controlling the press machine and transfer system.

Have a look at the Dr. Kim’s detailed article on Industry 4.0 for more examples of NDE sensors, as well as information on applying Industry 4.0 to forming process controls.

About

WorldAutoSteel will consider appropriate articles from expert sources for publication on our AHSS Insights blog. In order to be considered, you must meet the requirements set forth below. Please keep in mind, however, that we do not pay for, or charge for, posting guest blogs. But we are more than willing to consider articles that are relevant to educating on best practices and new processes in the forming and joining of Advanced High-Strength Steels (AHSS) in vehicle applications.

If you still have questions about being a Guest Blogger for WorldAutoSteel after reading this page, you may contact the AHSS Guidelines Editor, Lori Jo Vest

Fundamentals

Please keep in mind the following fundamentals before you start writing your blog.

- Your submission must contain references to Advanced High-Strength Steel (AHSS) in vehicle applications. Note that the name of our blog is AHSS Insights, therefore, readers will be expecting to expand their AHSS knowledge base.

- Your submission must be geared towards a technical audience, with appropriate data references. Our audiences include automotive engineers that specialize in design, materials, manufacturing and the environment. We generally do not accept thought-starter type guest blogs.

- Your submission must not be a marketing piece for your organization, proprietary products or services, nor should it contain marketing messages and solicitations. Our readers are smart people. They will appreciate and gain much more insight into your company by simply demonstrating your expertise and showing your products’ purpose in AHSS use, than they would in a sales pitch.

- It should contain information pertinent to our audiences on an aspect of AHSS, such as AHSS characteristics, use, metallurgy, forming or joining. It also may address vehicle or steel industry life cycle assessment or other environmental issues related to automotive and AHSS use.

- Your submission must include graphic references. You may decide what kind of graphics you would like to add such as charts, videos, infographics, etc. We welcome videos as long as they do not include a sales pitch. Graphics need to be submitted as PNG or SVG files, and videos must be a standard format, such as MP4 or WMV.

Submission Requirements

Please meet the following submission requirements before you submit your entry for consideration.

- Submissions should be approximately 1,000 words in length, and include graphics.

- Please include a title.

- Graphics should be provided as separate 72 dpi (PNG or SVG) files, if possible, and sourced appropriately, especially if you do not specifically own the rights. Videos should be 720p resolution.

- Please clearly provide any reference sources in the following format: Author, full title of the work, year published, and if available and it will add to the blog’s content value, provide an internet link to the work.

- Please notify us with your intention to submit with an brief abstract of the information you will cover. This will help us determine if it is a good fit and enable us to potentially provide provisional approval.

- Your first draft must be submitted a minimum of 30 business days prior to any agreed upon publish date. This allows our team to have ample time for review, give you feedback and pursue any required further editing. It also provides time for translation to our Chinese blog edition.

- As your blog will be translated to the Chinese language and published on our channels in China, please do not use English jargon that will be difficult to translate.

We will notify you in advance as to when your entry is scheduled to publish. We strongly encourage you to use your social contact network to share the blog article. Your shares should include our blog hashtag, #AHSSblog.

Submitting Video and Animation Assets

We are always looking for video and animations to help support existing articles with visual information. If you think you have something that would enhance an article, please contact us at the email link above. You can send us a link to what you have, and we will review it. Note, the video must be owned by you in order to be considered and not contain any sales pitches. If we agree to use it, we’ll need to receive the original video file so that it can be uploaded directly to our site. You/your company will receive full citation as a the source of the video. Have a look at our Roll Forming page to see an example of how we have used a video received from Shape Corp.

We look forward to receiving your submission. It is our pleasure to collaborate on AHSS education with you. Thank you!