Blog, homepage-featured-top, main-blog, News

Resistance spot welding (RSW) is the most utilized joining process in car body assembly with exceptionally high demands on quality and reproducibility. Expulsion in RSW leads to ejection of metal from the weld and can cause equipment deterioration and re-working.

As the RSW process has many variables both from the process itself and from the to-be-welded component, prediction and avoidance of expulsion is challenging. This creates a large demand for new technologies that allow for RSW of steels with improved expulsion control.

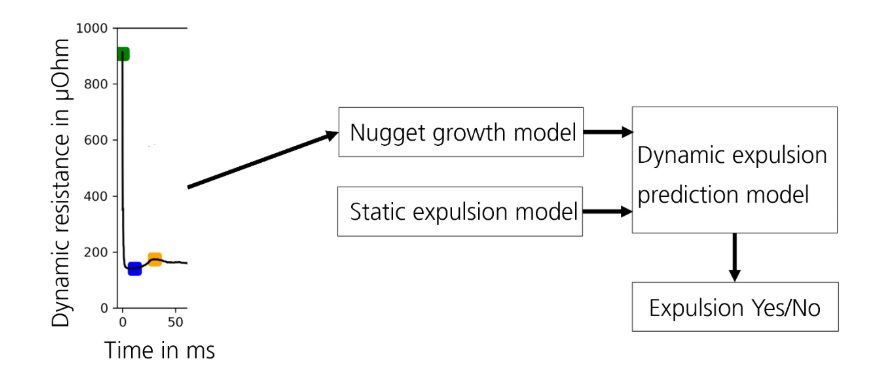

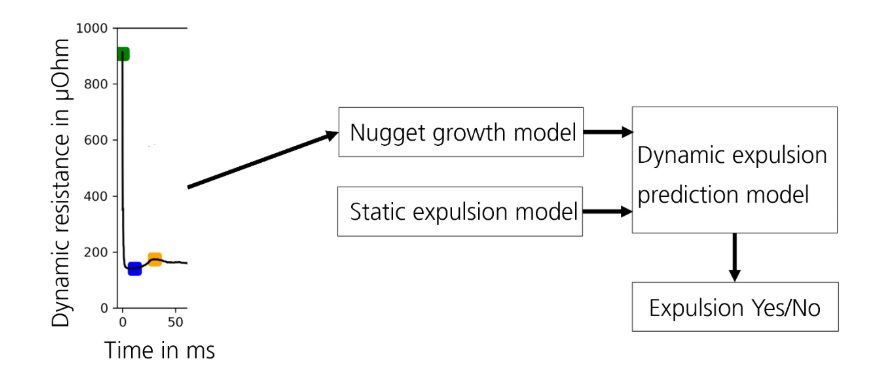

Recent developments aim to predict – and ultimately avoid – expulsion using artificial intelligence data analysis. Process data on current, voltage and dynamic resistance are readily available in RSW and can be augmented with simulation data for non-measurable phenomena such as the nugget growth rate to create predictive algorithms that eventually aim to avoid expulsion altogether.

An Introduction to AI Expulsion Prediction

This work focuses on utilizing artificial intelligence modeling for the prediction of expulsion during resistance spot welding (see Figure 1 for an image of expulsion on the left and metal residue on the surface after expulsion on the right). The primary objective is to forecast the formation of expulsion before it occurs, with the aim of improving the quality of the welding process. This effort is supported by a dataset of 500 welded spots of 2-sheet stack-ups made from one advanced high-strength steel (AHSS) and one mild steel joining partner. Two sequential AI models are trained: one for nugget growth prediction and another for spatter prediction.

Figure 1: Left: Expulsion leads to the ejection of molten metal. Right: Residues may form on the surface after expulsion.

Feature Engineering

A key aspect is the integration of multi-source data: The models leverage both static and dynamic inputs. Static inputs include input process parameters such as current, force, and weld time, which are set at the machine in accordance with a pre-determined weld lobe. Dynamic inputs encompass transient process signals like dynamic resistance and electrode force. In resistance spot welding, this data is usually readily available, because the welding power source measures electric flow and weld gun opening and forces. A further step is to include non-measurable data from simulation results concerning nugget growth rate.

To give time for process intervention, the predictive quality of the models was determined after only 30 ms of welding time, depicted in Figure 2.

Figure 2: Only 30 ms of dynamic resistance measurements are used as input for the AI models.

Data evaluation and feature engineering are critical components of the modeling process. A welding and data-science expert needs to identify significant features from sensor time series data as input for the neural network AI models. These features can be physically meaningful, such as the minimum resistance during the process, or purely statistical with values such as longest continuous time above the average resistance.

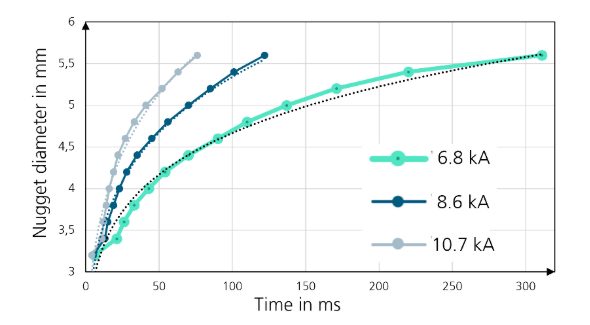

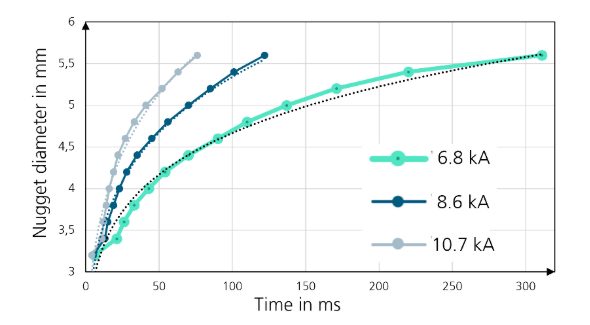

The simulation of resistance spot welding allows for the extraction of the non-measurable nugget growth rate. It is well documented that the nugget growth rate strongly correlates with expulsion formation and conducting simulations for different welding cases (gaps, misalignments, slightly changed contact resistances…) can add this physical behavior to the data-driven AI model. Figure 3 depicts different nugget growths extracted from the simulation with different welding currents. High currents lead to significantly faster growth rates and facilitate expulsion.

Figure 3: Weld nugget growth behavior for different welding currents extracted from a numerical welding simulation. Solid lines are simulation results; dashed lines depict a polynomial fit used to reduce data for AI input.

Model Accuracy

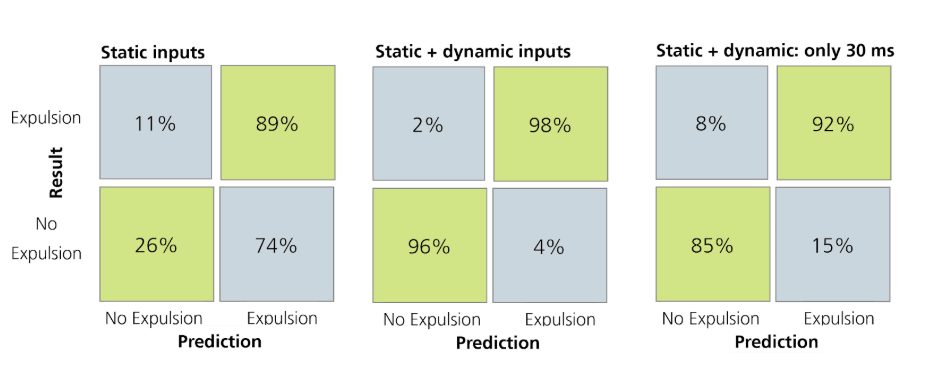

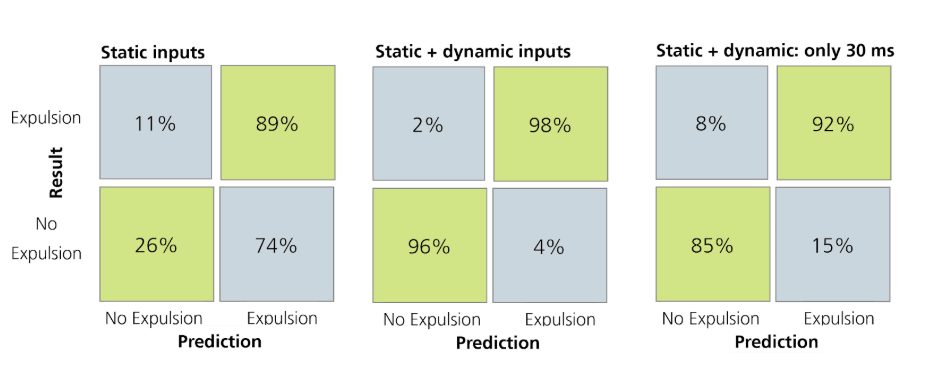

Figure 4 depicts the confusion matrices for the three different models. The bottom left and top right fields are the desired predictions, and the other fields depict false results of the models. The first model stage, which relies solely on static inputs, yields moderate prediction quality. However, when dynamic data from experiments and simulations are included, the prediction quality jumps to approximately 96%. The analysis focusing on the first 30 milliseconds to give time for subsequent intervention in the process, achieves a reduced, but still good, result quality of around 90%. Further improvements in prediction accuracy are expected with additional data.

Figure 4: Confusion matrices for static, static and dynamic and static and dynamic: only 30 ms inputs. A reliable prediction is possible using dynamic process and simulation data. If only 30 ms of dynamic data are utilized the predictive quality decreases.

The presented approach uses a data-driven AI model with different levels of input data to predict resistance spot welding expulsion. The data-gathering and feature engineering procedures are highlighted, explaining a need for in-depth knowledge of the welding process as well as data engineering. The approach yields a neural network with excellent predictive quality, if dynamic data is included in the model. Even if only 30 ms of transient data are used to allow for a subsequent process intervention, the result quality is still good. It is expected that the predictive quality improves when the data set is increased and additional data sources both from measurements and simulations are included. This approach can improve the control of automotive welding systems and ultimately avoid excessive re-working and equipment wear due to expulsion in resistance spot welding of advanced high-strength steels.

Blog, main-blog, News

Smarter Engineering for Tomorrow’s Vehicles

In the fast-evolving world of automotive engineering, the ability to innovate safely and efficiently is paramount. Advanced High-Strength Steels (AHSS) have become the backbone of modern vehicle design. In less than a decade, the AHSS portfolio has nearly doubled—from 38 commercially available grades in 2017 to nearly 70 today—giving automakers unprecedented flexibility to design lighter, stronger, and more sustainable vehicles.

WorldAutoSteel’s newly updated 2025 AHSS Application Guidelines give engineers and designers the knowledge and process confidence they need to master these advanced steel grades and apply them with precision.

What’s New in the AHSS Application Guidelines?

The updated resource reflects a global shift toward smarter, data-driven engineering, offering practical insights into metallurgy, forming, and joining techniques that optimize performance while reducing mass, risk, and production time. Key highlights include:

Smarter materials: AHSS grades and coatings are engineered, characterised, and applied as systems. Chemistry, microstructure, coating, forming route, and joining method are designed together to deliver exactly the performance needed with less mass, lower risk, and faster industrialisation.

Smarter forming: Expanded guidance on simulation and testing support an increasingly digital, “first-time-right” culture in body-in-white engineering, where forming processes are validated virtually before any physical tooling is committed, to reduce costly trial-and-error on the shop floor. New techniques and testing explanations help engineers understand the failure mechanisms that may limit the application of advanced grades.

Smarter joining: New recommendations on techniques such as paint-bake hardening, crash-rate testing, and MIG brazing echo a more data-driven, coatings-aware, and crash-validated approach to joining, ensuring each joint delivers the required strength, ductility, and durability with minimal mass, heat, and risk. For example, new methods for assessing spot weld strength and understanding the effects of bake hardening help manufacturers optimise lightweighting and crash performance. The expanded section on arc welding offers quick, practical tools for engineers, especially those new to AHSS, to avoid common mistakes and ensure robust joints.

The Guidelines also address the unique challenges posed by the shift to electric vehicles (EVs), such as protecting batteries while maintaining lightweight structures and stiffness.

Press hardening steels (PHS) are highlighted as a key tool in automotive body structure design, with new applications and strategies for tailored parts that combine high and low strength in a single stamping.

By curating the latest evidence and technical best practice for AHSS into a single, accessible resource, WorldAutoSteel is supporting the industry’s drive for continuous improvement. As new challenges and opportunities emerge, the Guidelines put lighter structures, outstanding crash performance, faster industrialisation, and lower lifecycle emissions well within reach.

Access the latest AHSS Application Guidelines

Join technical editors Dr.-Ing. Max Biegler and Dr. Danny Schaeffler for a free steelTalk webinar on 2 December, offering an overview of the latest updates and best practices. Register here.

Blog, homepage-featured-top, main-blog, News

With the rise of electric vehicles, evaluating the environmental impact of each manufacturing process is essential. This article presents an EV battery enclosure welding LCA to compare the sustainability of different joining methods. As automotive manufacturers strive to reduce their carbon footprints, understanding the impact of production processes becomes crucial—especially the joining techniques used in car body assembly. Using Life Cycle Assessment, these impacts can be analyzed in terms of their reduction potential. This article focuses on the example of an all-steel EV battery case joined using several different welding methods.

Life Cycle Assessment (LCA) and Why It Matters in Automotive Welding

Life Cycle Assessment is a systematic method for evaluating the environmental impacts of a product or process throughout its life cycle—from raw material extraction to production, use, and disposal. According to DIN EN ISO 14040 standards, LCA is structured into four main components:

- Goal and Scope Definition: Setting the purpose of the assessment, defining the functional unit, and establishing system boundaries.. In this article, the joining processes were in focus with associated inputs of electricity and filler materials as well as outputs of worn consumables.

- Inventory Analysis: Gathering data on material and energy flows using measurements of electricity and consumables consumption as well as database values for associated material extraction and production impacts

- Impact Assessment: Evaluating potential environmental impacts in different impact categories. This article shows global warming potential and acidification to compare climate change emissions and show the effect of different filler materials on acidification. Other impact categories relevant for joining processes are eutrophication, emission of photooxidants and ozone layer depletion.

- Evaluation: Reviewing findings and providing recommendations regarding the environmental impact of the compared processes

Figure 1: Considered system boundaries of the LCA comprising supply of materials and energy, the joining process and disposal of consumables.

Welding Methods Compared: Processes, Assumptions, and System Boundaries

The assessed joining processes include:

- Laser Remote Welding

- Laser Welding with Wire

- Laser Brazing

- Resistance Spot Weld Bonding (RSW-Bonding) with single- and two-component adhesive

In the context of joining processes for EV battery cases, this LCA aims to compare the environmental impacts of different welding methods on a meter of weld length. The assessment uses both primary and secondary data from literature and established LCA databases. As not all data is available in-detail for welding processes, several simplifications and assumptions are required:

For example, filler wires aresimplified to pure steel or copper wire rather than taking their complex chemical composition into account. Therefore, it is likely that the actual impact of the filler material production is higher than assumed here. For electricity emissions, the German grid mix is used and to compare resistance spot welding and laser beam welding per weld length, 20 resistance spot welds per meter are assumed.

The emissions from the structural materials are not considered, as the same design is used for all welding processes. Second-order effects due to the switching a joining technology, i.e. the material savings due to reduced flange-widths for laser welding, are also not considered. The second-order material saving effects are known to be larger in comparison to the environmental impact of the joining processes and should be optimized together with the choice of joining process. Further information on these effects can be found in this study.

Figure 2 All-steel EV battery case with zones marked for laser beam and resistance spot welding

LCA Results: Emissions Impact by Welding Type in EV Battery Enclosures

The results of the LCA are shown in Figure 3 for the two impact categories Global Warming Potential (i.e. CO2 equivalent emissions) and Acidification Potential (i.e. emission of SO2 equivalent). Main driving factors of emissions are electrical energy, compressed air as well as filler material in the form of steel or copper wire (for laser wire and laser brazing respectively) and adhesive for RSW bonding.

Using the German electrical grid mix, RSW bonding shows the lowest GWP impact. As it does not use any filler material, laser remote welding has the largest potential for CO2 emission reduction, if the electricity generation incorporates more renewable energy .

When analyzing the laser processes, a high idle energy consumption of the laser systems is determined. This is due to the electricity demand of the laser source, cooling and control systems. The consumption only rises slightly, when the lasers are operating. This leads to the conclusion that the overall energy efficiency of laser welding systems can be significantly improved by optimizing “beam-on times” in relation to “idle times”.

In terms of the acidification potential, laser brazing stands out with a far larger impact compared to the other processes, because of the emissions associated with mining and extraction of its copper-based filler material. The wear of copper electrode caps also contributes to this impact category.

Figure 3: Environmental impact of the different welding processes in Global Warming Potential (left) and Acidification (right) per meter of weld length.

What This LCA Reveals About Sustainable Welding for EV Manufacturing

Life Cycle Assessment provides invaluable insights into the environmental impacts of joining processes in the automotive industry. By understanding the implications of material choices and energy consumption, manufacturers can make informed decisions that promote sustainability. Both the effect of electricity consumption and filler materials on the environmental impact of automotive joining processes is discussed in this article. Joining processes are one of the major drivers of an OEM’s emissions with ample potential for optimization through LCA analysis.

Source

- Brunner-Schwer, J. Lemke, M. Biegler, T. Schmolke, S. Spohr, G. Meschut, L. Eckstein, M. Rethmeier; A life cycle assessment of joining processes in the automotive industry, illustrated by the example of an EV battery case; Laser in Manufacturing Conference, Munich, 2023

Citations, News

Citation:

A-79. Auto/Steel Partnership (2005). “Lightweight Front End Structure Phase 1 & 2 Final Report,” Available from https://a-sp.org/wp-content/uploads/2020/08/Lightweight-Front-End-Structures.pdf

Blog, homepage-featured-top, main-blog, News

The transportation industry’s contribution to greenhouse gas (GHG) emissions and global warming is well documented and understood. Vehicle OEMs, fleet operators, and transport users all have responsibilities to reduce environmental impacts on the planet and contribute to meeting global emissions regulations.

Mobility as a Service (MaaS) solutions like WorldAutoSteel’s flaghip Steel E-Motive (SEM) program have the potential to contribute to a reduction in GHG emissions, helping to achieve these global targets and specific policy objectives. The Steel E-Motive engineering report, released in 2023, addresses the impact of emissions reduction using Life Cycle Assessment, with key results summarized in this article.

Introduction to Life Cycle Assessment

Life Cycle Assessment (LCA) is a methodology that evaluates the environmental impact of a product across its entire lifecycle. By understanding the impact across the entire vehicle life cycle, vehicle manufacturers evaluate trade-offs and assess the net impact of the product they’re using.

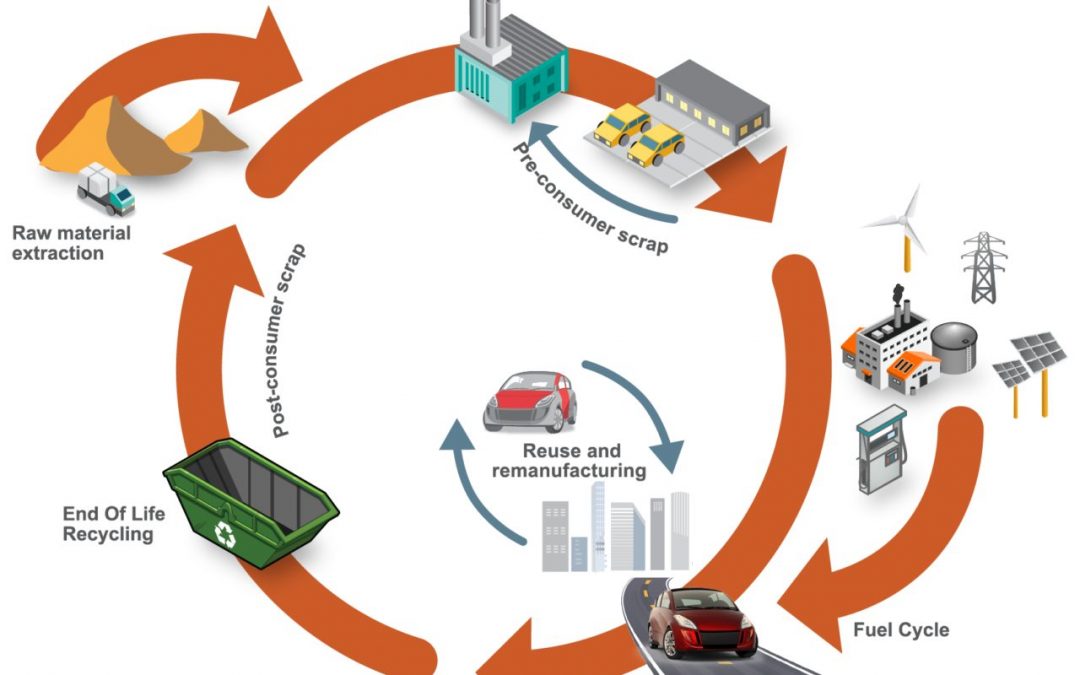

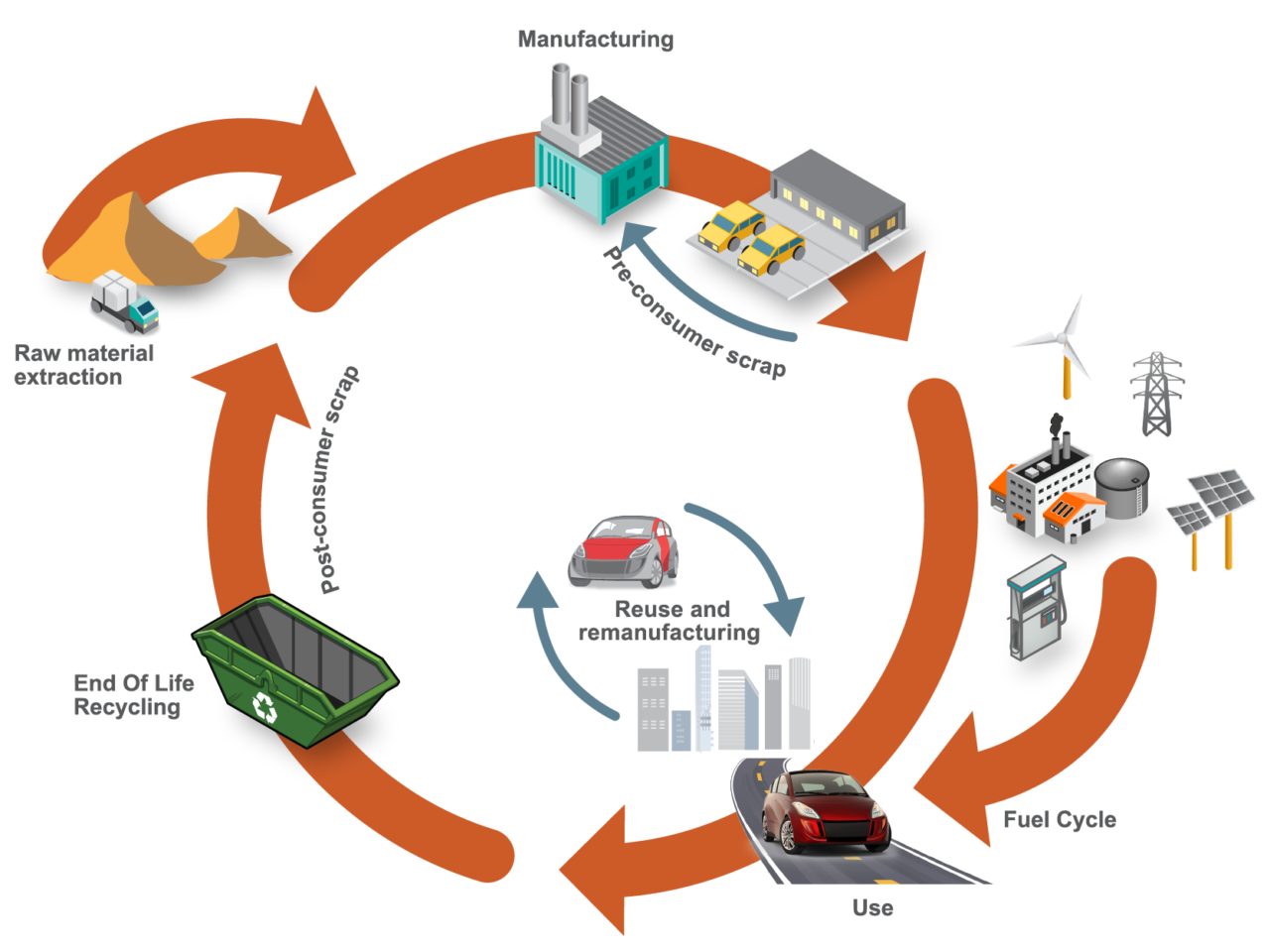

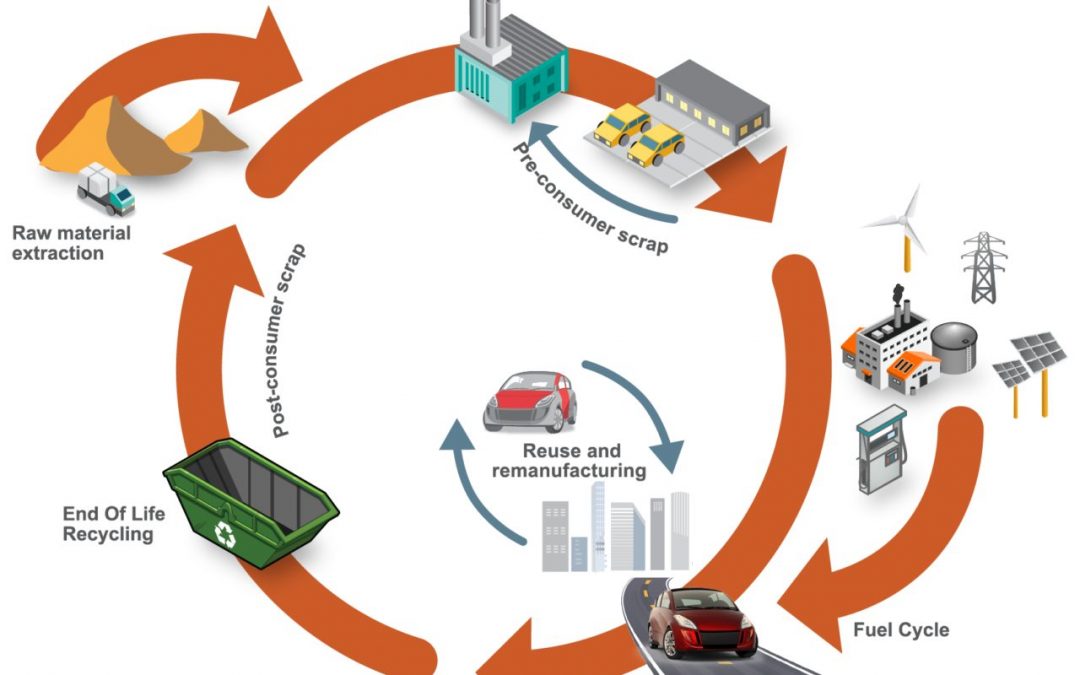

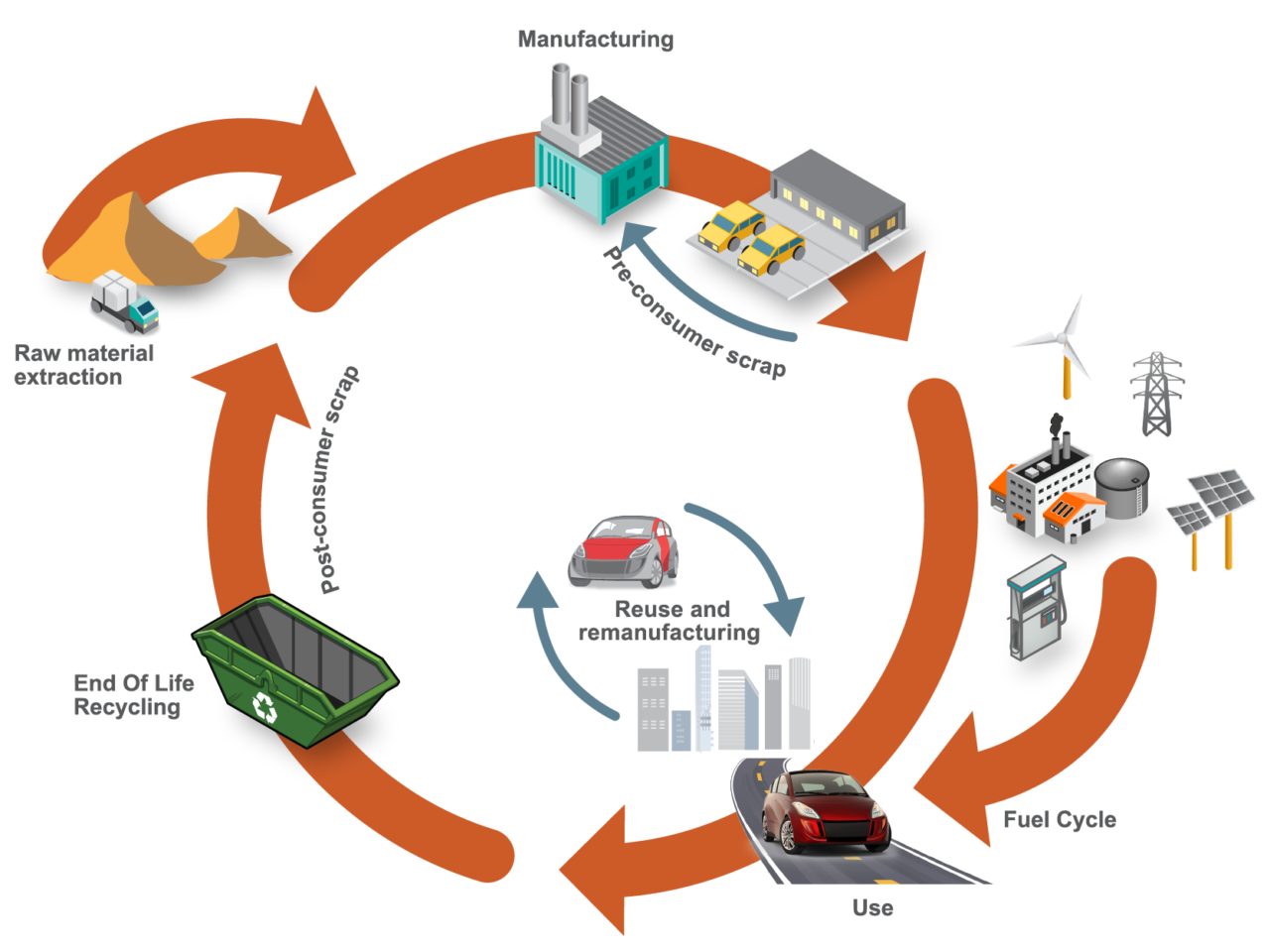

Cradle-to-grave assessments utilize a boundary that includes impacts from the production phase (including raw material extraction and vehicle production), the use phase (including fuel or electricity as well as consumables like tires and fluids) and the end-of-life phase, which could include disposal and/or recyling of the product, as shown in Figure 1. We applied LCA throughout the development of the SEM concept.

Figure 1. SEQ Figure \* ARABIC 1 Life Cycle Assessment, considering the entire life of the vehicle, from raw material extraction to end of life

LCA can cover a range of environmental impacts; however, for the SEM program, we focused on GHG emissions through the GWP-100 indicator and total energy consumption using Cumulative/Primary Energy Demand and Fossil Energy Consumption indicators.

Reference Taxi (Baseline) Vehicle

A key consideration in LCA calculations is establishing an appropriate reference vehicle. For this program, the following criteria was used:

- Present day (~2020) battery electric vehicle (BEV) operating in taxi mode with a driver and one occupant with vehicle/battery lifetime assumptions of 300,000km, and use of 100 percent conventional steel/aluminum.

- Vehicle end-of-life methodology using the Avoided Burden Approach, where recycled metals are assumed to displace equivalent quantities of their virgin counterparts and assigned corresponding emission and energy demand credits.

- Assumption of 50 percent pyrometallurgical recycling for the battery packs.

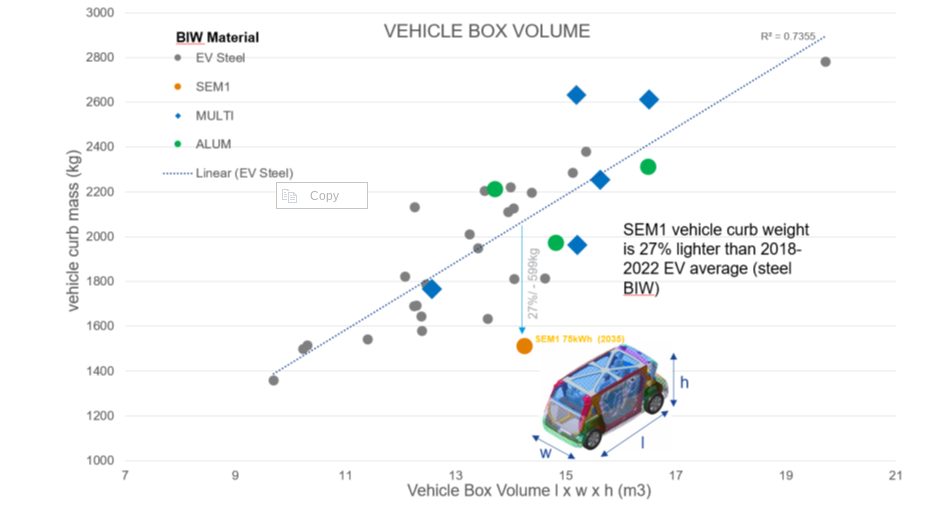

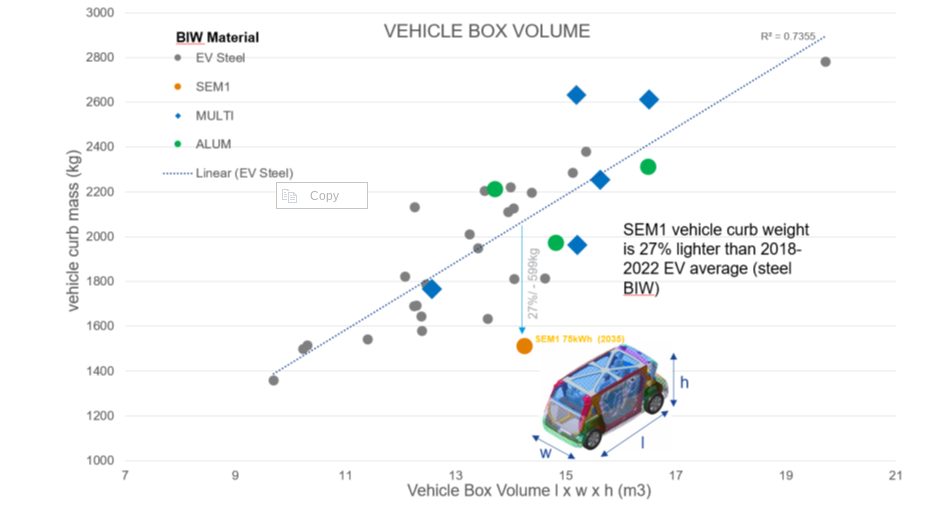

- Estimated reference taxi vehicle curb weight using the statistical reference data study (Figure 2), resulting in an estimated curb weight of 1,949kg.

- Material utilization based on data from a similar vehicle specification, as shown in Figure 3.

- Vehicle occupancy rate assumptions of 1.4, based on a combination of both “empty” and passenger-carrying journeys.

Figure 2. Vehicle curb weight versus box volume comparison. Reference vehicle data; source www.a2mac1.com

Steel E-Motive “Default” Vehicle

SEM vehicle life cycle calculations assume a hypothetical 2030 manufacture and start-of-operation date of 2030 to 2035. We updated the electricity grid supply mix to include the average of the International Energy Agency (IEA) scenario estimates for 2030 and 2040.

- We applied the nominal SEM1 vehicle curb weight of 1,512kg in the LCA model, and updated the vehicle Bill of Materials.

- As with the reference vehicle, we adopted the Avoided Burden Approach as the default for end-of-life calculation.

Life Cycle Assessment Results

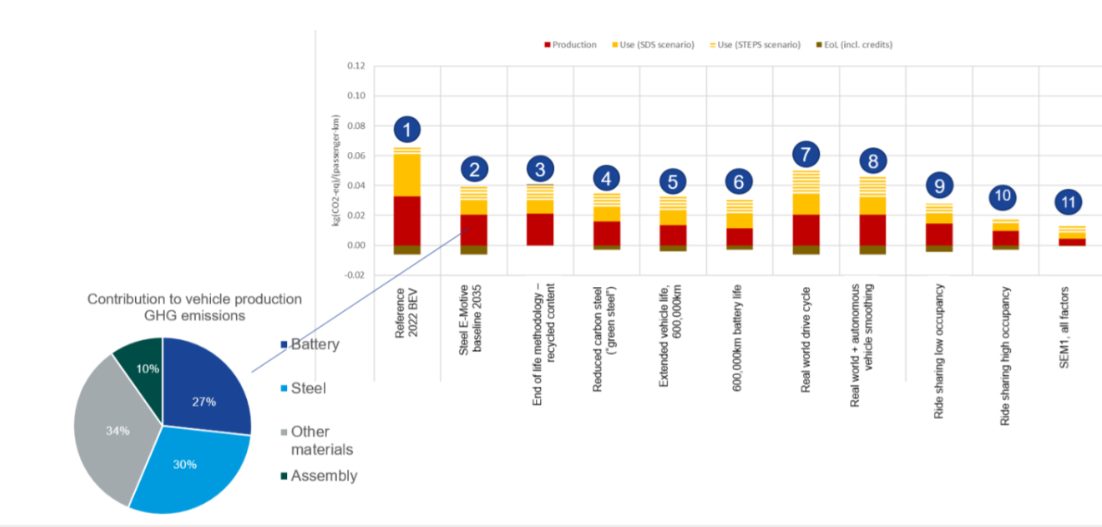

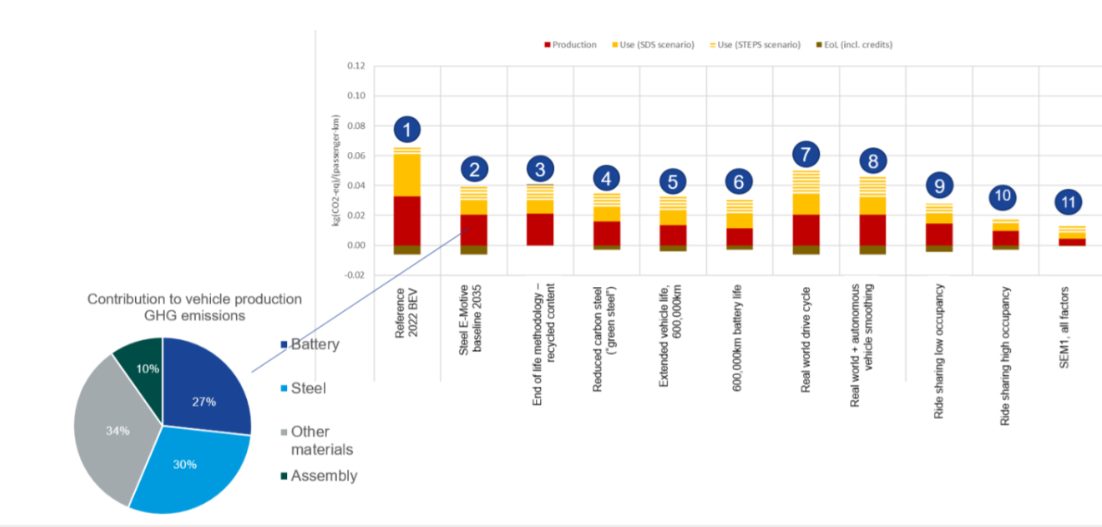

Figure 3 below highlights absolute calculated life cycle GHG emissions, in units of kgCO2e/ passengerꞏkilometer studied, with the individual contributions of vehicle manufacturing, vehicle use, and end-of-life phase presented.

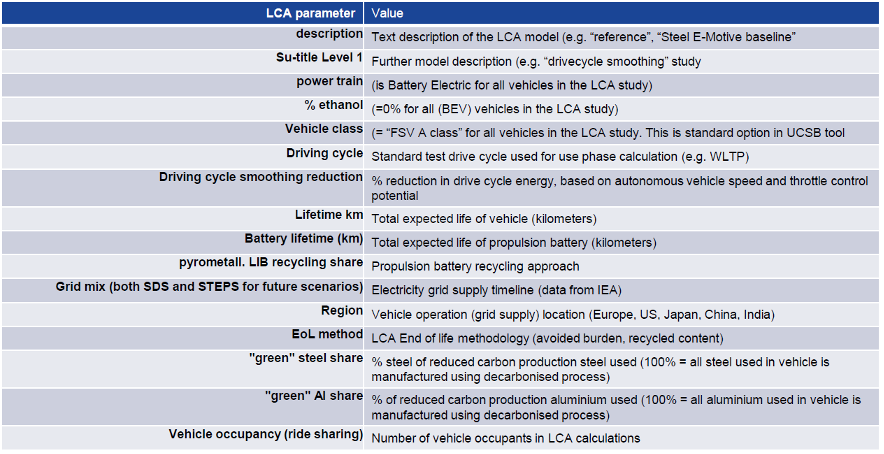

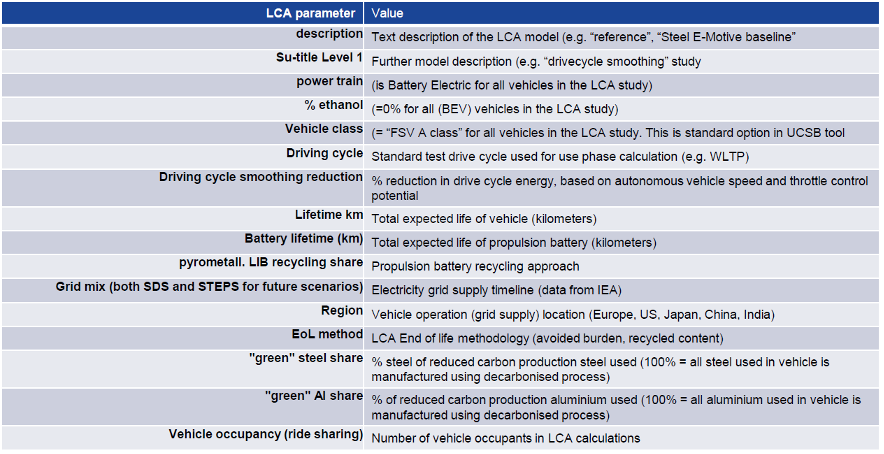

The analysis evaluated two reference/baseline conditions and nine SEM sensitivity studies, see Figure 4. These included alternative assumptions on LCA end-of-life modeling methodology, lifetime vehicle activity (and battery lifetime), alternative operational energy consumption sensitivities, sensitivities on the use of ‘green’ steel, and vehicle occupancy rates.

The accompanying pie chart shows the breakdown and contributions to the vehicle manufacture GHG for the baseline SEM scenario (2).

Figure 3. SEQ Figure \* ARABIC 2 life cycle assessment GHG results

Figure 4. Reference/baseline conditions and SEM sensitivity studies

Life Cycle Assessment Conclusions

Based on the parameters outlined, applying LCA to SEM concept demonstrated the designs’ potential to reduce lifecycle greenhouse gas emissions by up to 86 percent compared to a present-day battery electric vehicle operating as a taxi.

This potential can be realized by adopting the following measures:

- Reducing vehicle production and manufacturing embedded emissions by utilizing 100 percent reduced carbon (“green”) steel

- Improving battery technology and increasing the use of renewable electricity in battery manufacturing; as well as increasing/improving battery recycling

- Ensuring the vehicle weight of autonomous vehicles is managed, and the potential weight reduction benefits realized and implemented. The SEM body structure and battery housing demonstrate good weight efficiency.

- Increasing the overall lifespan of the vehicle and battery. The fatigue and durability properties of AHSS can enable enhanced vehicle lifetime. The SEM battery design allows easy replacement of specific modules, enabling an overall extended battery life.

- Autonomous vehicle control smooths the driving cycle. The vehicle acceleration and deceleration rates can be optimized to match the driving conditions and road topography, reducing energy consumption and subsequent GHG emissions.

- Increasing passenger occupancy rates to at least three per vehicle via MaaS.

The projected net GHG emissions for the SEM vehicle operating with the flexibilities described above already represent a significant reduction when compared to the current baseline.

Achieving net zero emissions would require additional measures like offsetting manufacturing impacts (e.g., through compensatory credits from atmospheric carbon capture and storage) and transitioning to a 100 percent renewable electricity grid.

Moving Toward Net Zero

Taking a Life Cycle Assessment approach to the SEM concept demonstrates the possibilities for engineering future mobility vehicles that continue to move us closer to a net zero future. For more information about the Steel E-Motive program, download the engineering report here: https://bit.ly/SEM_Eng_Report

Thanks go to Russ Balzer for his contribution of this article to the AHSS Insights blog. As.technical director at WorldAutoSteel, he leads technical programs and oversees the organization’s work in research, modeling, and advocacy for Life Cycle Assessment in the automotive sector. An LCA Certified Professional through the American Center for Life Cycle Assessment (ACLCA), he also acts as the WorldAutoSteel liaison to the worldsteel LCA Expert Group.

Blog, homepage-featured-top, main-blog, News

The Steel E-Motive concept features an innovative battery housing design and laser welded blank door ring created using part integration to reduce mass and cost.

Battery Carrier Frame System

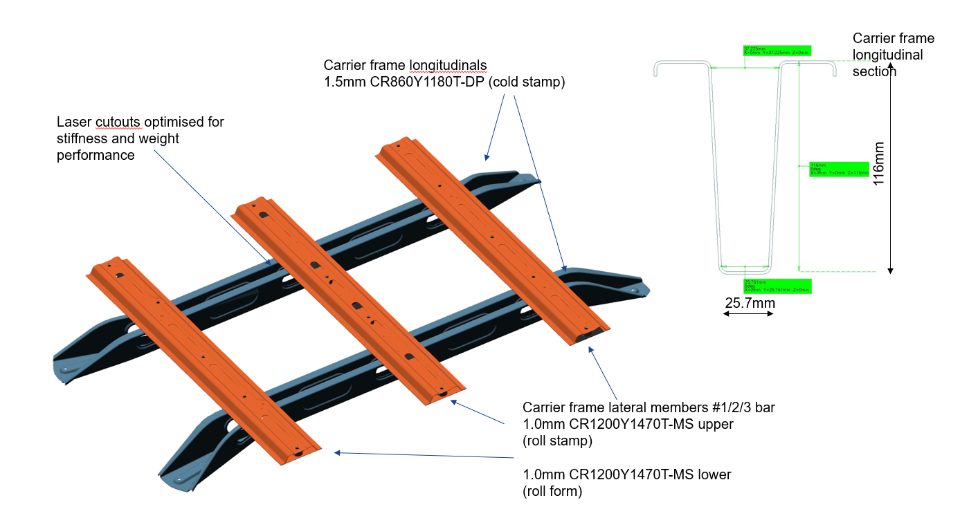

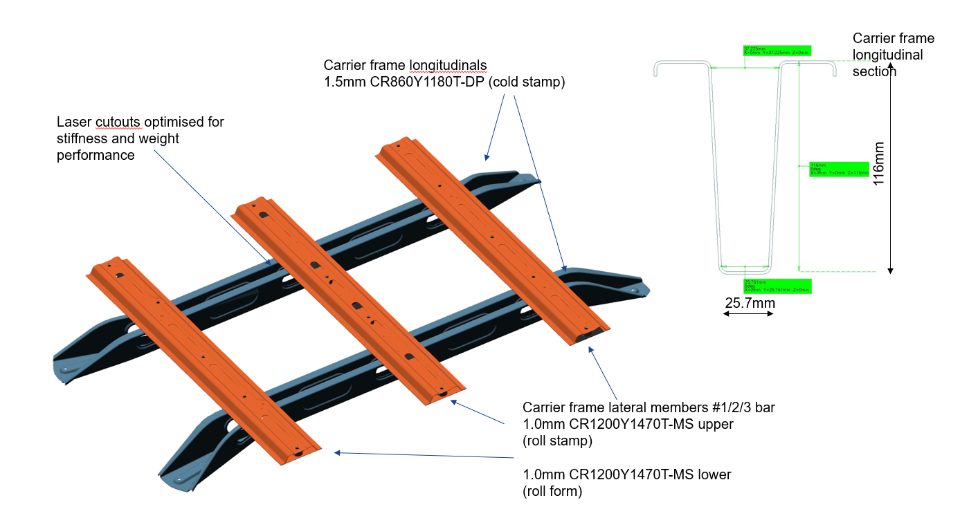

The Steel E-Motive battery modules, cooling plates & hoses, electrical connectors, and battery management system are mounted to an AHSS carrier frame. This assembly is then bolted to the body structure. The body in white floor assumes the role of the battery top cover, providing both cost and weight savings; an AHSS bottom cover seals and provides underbody protection.

You can view the details about the SEM1 final battery concept in section 7.3 in the SEM Engineering Report: https://bit.ly/SEM_Eng_Report

The Steel E-Motive Battery Carrier Frame

The battery carrier frame forms an integral part of the body structure load path. It connects to the front and rear longitudinals and the floor cross members. Two different manufacturing approaches and designs were considered for the longitudinals.

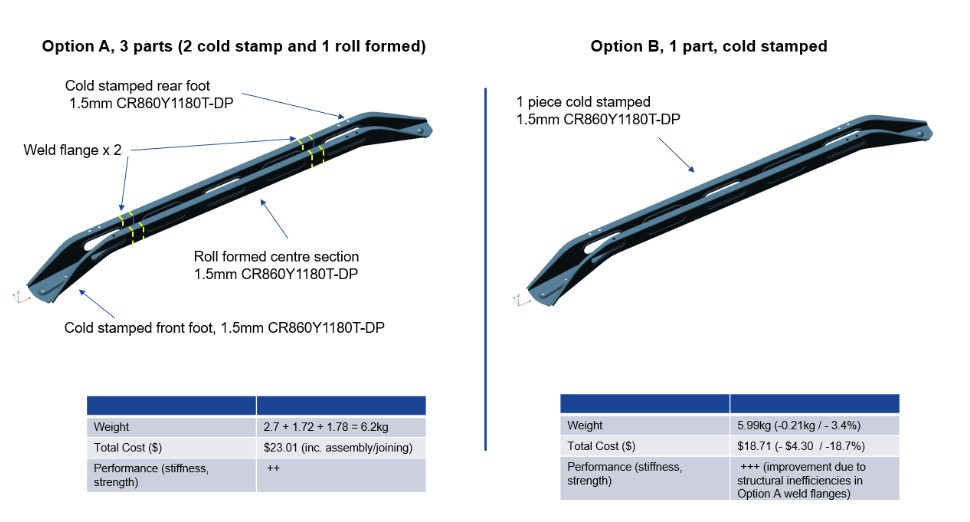

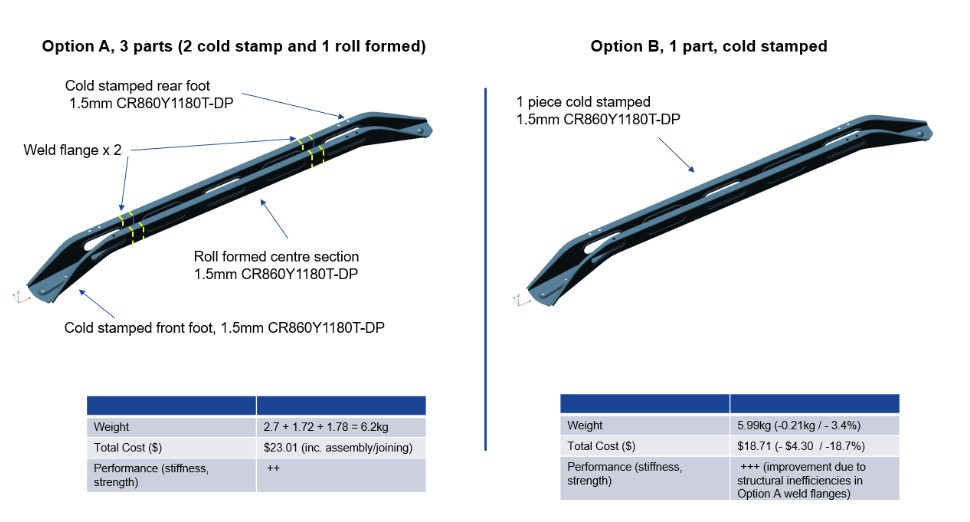

Option A considered a 3-part longitudinal design, with unique cold stampings for the front and rear “feet” and a roll-formed center section. The part integration is accomplished via an overlap weld flange and spot welding. Dual Phase 1180MPa UTS grade AHSS was selected based on the strength required for crash load reaction and enabling a lower 1.5mm gauge thickness. Initially, it was perceived that the roll-formed center section design would enable an overall lower-cost solution.

Option B replaces the 3-piece design with a single, cold-stamped part, again using 1.5mm DP1180 AHSS. The deep draw profile and material’s low ductility presented formability challenges for the cold stamping of the longitudinal. These were overcome by adjustments to the deep draw profile and optimization of the die and stamping parameters.

A comparison of the two designs shows that a small weight saving and a significant cost reduction of $4.30 (18.7%) per longitudinal is achieved with the single cold-stamped design. The vehicle NVH, static stiffness, and crash performance were also calculated to be superior for the integrated design Option B.

Therefore, Option B, provides cost, weight, and performance benefits compared to the multiple part design Option A.

Laser Welded Blank Door Ring Created Using Part Integration

Part integration via laser-welded blanks allows different steel grades, thicknesses, and coating types to be combined into a single blank before the fabrication process. The Steel E-Motive door ring is a hot-formed part consisting of four different blanks with different AHSS grades and thicknesses.

The performance requirements for the specific region determine the grades and thicknesses for each blank. The A-pillar requires very high strength to protect the front occupants in the event of a high-speed frontal or side collision. Lower strengths and grades are required for the rocker, cantrail, and C-pillar parts. The four blanks are cut from the native material grade coil and joined using laser welding to form the single-door ring blank. This then undergoes a hot-forming process to achieve the design door ring shape and the Ultra High-Strength properties of press-hardened steel.

Consolidating four blanks into a single part significantly reduces scrap compared to a single blank part, and simplifies part manufacturing by eliminating other stamping and assembly processes with related cost savings. Higher material utilization means less steel is produced, resulting in lower costs and lower GHG emissions. The laser weld between the blanks helps achieve greater strength and stiffness to spot-welding four individual blanks.

Outlook

The latest AHSS grades and fabrication processes allow engineers to reduce the number of parts or blanks used in automotive body structures. Several part integration and consolidation processes have been applied and demonstrated in the Steel E-Motive concept. Part consolidation results in lower scrap rates, improved material utilization, reduced part cost, and GHG emissions. The integrated structures also improve overall stiffness and strength performance.

Thanks go to Neil McGregor for his contribution of this article to the AHSS Insights blog. As Chief Engineer, Systems Integration at Ricardo, Neil has extensive knowledge of lightweight, advanced materials across all major vehicle sub-systems and leads the Steel E-Motive vehicle engineering program at Ricardo.