AHSS Insights Blog

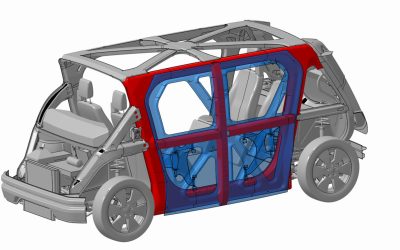

Steel E-Motive Closures: Balancing openness and accessibility to create a safe & strong autonomous vehicle

We at WorldAutoSteel, side-by-side with our engineering partner Ricardo, are rounding the corner on two years in the design process for the Steel E-Motive's SEM1 and SEM2 autonomous, electric, mobility as a service (MaaS) vehicles. The excitement is really building...

Designing For Vehicle Crash Requirements that Don’t Yet Exist

Since June 2020, we've been working with our engineering partners, Ricardo, on Steel E-Motive, a vehicle engineering program which is developing virtual concepts for two fully autonomous and connected electric vehicles designed for mobility as a service (MaaS)...

Using Martensitic Steels as an Alternative to Press Hardening Steel – Laboratory Evaluations

Our colleagues at JFE Steel recently provided us with a new case study based on laboratory evaluations they conducted in Japan. The article is part of our Martensite article, but we this month, we want to highlight it in our AHSS Insights blog. Martensitic...

What are 3rd Gen AHSS?

One of the tasks we took great care in completing during the update of the AHSS Application Guidelines was to provide a definition for what constitutes a third generation (3rd Gen) Advanced High-Strength Steel. We had been asked this question many times, and often in...

Conventional Rule-of-Thumb Calculations Lead to Inaccurate Press Tonnage Predictions

The rule of thumb estimates used in 1989 during my internship with an automotive stamping supplier were simple calculations for the peak load. Tonnage for trim and pierce operations depended on the length of line of trim, material thickness and the shear strength of...

Servo Press Force and Energy Considerations When Working With AHSS

Advanced High-Strength Steel (AHSS) products have significantly different forming characteristics and these challenge conventional mechanical and hydraulic presses. Some examples include the dramatically higher strength of these new steels resulting in higher forming...