Citations

Citation:

M-63. M. Milititsky, M. Garnett, C. Du, J. Wu, L. Zhang, P.J. Belanger, J.M. Prencipe, E.D. Bishop, “Variable Binder Force for Springback Management”, International Conference on Advanced High-Strength Sheet Steels for Automotive Applications Proceedings, June 6-9, 2004, Association for Iron & Steel Technology.

![Bake Hardenable]()

AHSS, Conventional HSS, Steel Grades

BH Grades

Bake Hardenable (BH) steels grades are conventional High Strength Steels that exhibit a Bake Hardening Effect. BH steels exhibit an increase in yield strength after room-temperature stamping followed by processing through a thermal cycle comparable to the time-temperature profile used in paint curing (or baking) – approximately 170 °C for 20 minutes. Bake hardenability is characterized by determining the Bake Hardening Index.

Bake Hardenable steel grades have yield strength at shipment from the steel mills of 180 MPa to 300 MPa (approximately 25 ksi to 45 ksi). The grades at the lower strength levels are capable of being produced with a Class A surface finish and are used in applications where dent resistance is desired in thin sheet steel. Applications for the higher strength BH steels include structural parts where Class A surface is not required. The higher strength after forming and baking is the reason automakers might use these in body structure applications, potentially contributing to vehicle lightweighting efforts.

These grades work harden approximately 30 MPa when 2% strain is introduced, either from stamping or during a tensile test, which is similar to dent resistant IF-HS. In contrast to IF-HS, the paint-bake cycle after forming results in an additional yield strength increase. The minimum strength increase from baking is specified by some automakers as 20 MPa to 35 MPa, measured after applying a defined level of strain.

Higher yield strength directly improves the dent performance. Even though BH grades and their non bake hardening counterpart IF-HS grades may have similar yield strength and thickness after forming, bake hardenable steels will show superior dent resistance due to the increase in yield strength from the paint baking operation.

Ferrite is the main microstructural phase of BH steels. The strengthening from the paint bake cycle is due to the controlled amount of carbon remaining in solid solution (on the order of 25 ppm) when the steel leaves the production mill. At the baking temperatures after the part is formed, the dissolved carbon migrates to pin any free dislocations created from stamping. This increases the yield strength of the formed part for increased dent resistance. Formability does not suffer, since the strength increase occurs after stamping.

Most Advanced High Strength Steel (AHSS) grades also exhibit a Bake Hardening Effect, achieving yield strength increases of 40 MPa to 120 MPa from an appropriate thermal cycle. AHSS grades are not categorized with traditional bake hardenable steels, since their primary characteristics and applications are typically, but not exclusively, different. One exception are some Dual Phase (DP) steels available with a Class A surface, which are used as skin panels to combine excellent dent resistance with lightweighting benefits.

Some of the specifications describing uncoated Bake Hardenable (BH) steel are included below, with the grades typically listed in order of increasing minimum yield strength and ductility. Different specifications may exist which describe uncoated or coated, or steels of different strengths.

- ASTM A1008M, with the terms BHS 26 [180], BHS 31 [210], BHS 35 [240], BHS 41 [280], BHS 44 [300]A-25

- EN10268, with the terms HC180B, HC220B, HC260B, and HC300LAD-3

- JIS G3135, with the term SPFC340HJ-3

- JFS A2001, with the terms JSC270H, JSC340HJ-23

- VDA239-100, with the terms CR180BH, CR210BH, CR240BH, and CR270BHV-3

Bake Hardening Effect

Bake Hardenable Steel Grades and most AHSS grades exhibit a Bake Hardening Effect, meaning that there is an increase in yield strength after room-temperature stamping followed by processing through a thermal cycle comparable to the time-temperature profile used in paint curing (or baking) – approximately 170 °C for 20 minutes.

The degree to which a sample is bake hardenable is characterized by the Bake Hardening Index.

In Bake Hardenable Steel Grades, solid solution hardening elements like phosphorus, manganese, and silicon are used to achieve the desired initial strength. For AHSS, the initial strength is determined by the balance and volume fraction of microstructural components like ferrite, bainite, retained austenite, and martensite. In both cases, a specifically engineered amount of dissolved carbon in the ferritic matrix causes an additional increase in the yield strength through controlled carbon aging during the paint-bake thermal cycle. The bake hardening process in AHSS grades is more complex, and results in substantially higher values of the Bake Hardening Index.

Figure 1 shows the work hardening and bake hardening increases for samples of three High-Strength steel grades having the same as-received yield strength prior to 2% pre-straining and baking. The HSLA steel shows little or no bake hardening, while AHSS such as DP and Transformation Induced Plasticity (TRIP) steels show a large positive bake hardening index. The DP steel also has significantly higher work hardening than HSLA or TRIP steel because of higher strain hardening at low strains. No aging behavior of AHSS has been observed due to storage of as-received coils or blanks over a significant length of time at normal room temperatures. Hence, significant mechanical property changes of shipped AHSS products during normal storage conditions are unlikely.

The higher bake hardening index (BHI) of AHSS grades DP 600 and TRIP 700 is also shown in Figure 2. While BHI is determined at a prestrain of 2%, this graph indicates that even higher levels of bake hardenability can be achieved with increasing strain. In a stamping where most areas have more than 2% strain, combining this higher bake hardenability with the increased work hardening that occurs with increasing strain results in a formed panel having a strength markedly higher than the incoming flat steel. This is beneficial for crash energy management.

Figure 1: Comparison of work hardening (WH) and bake hardening (BH) for TRIP, DP, and HSLA steels given a 2% prestrain. S-1, K-3

Figure 2: Bake hardening responses of several HSS and AHSS products with varying pre-strain, reproduced from Figure 3 in Citation B-6. The bracketed numbers after each grade are references within the cited paper.

Bake Hardenability of Exposed Quality Dual Phase Steels

Dent resistance is a function of the yield strength in the formed panel after it completes the paint baking cycle. Based on this premise, grades with higher bake hardenability, such as AHSS, should have substantially higher dent resistance. Application of AHSS grades to capitalize on improved dent resistance also requires their production at the desired thickness and width along with surface characteristics appropriate for Class A exposed quality panels. Some DP steels meet these tight requirements specified by the automotive industry.

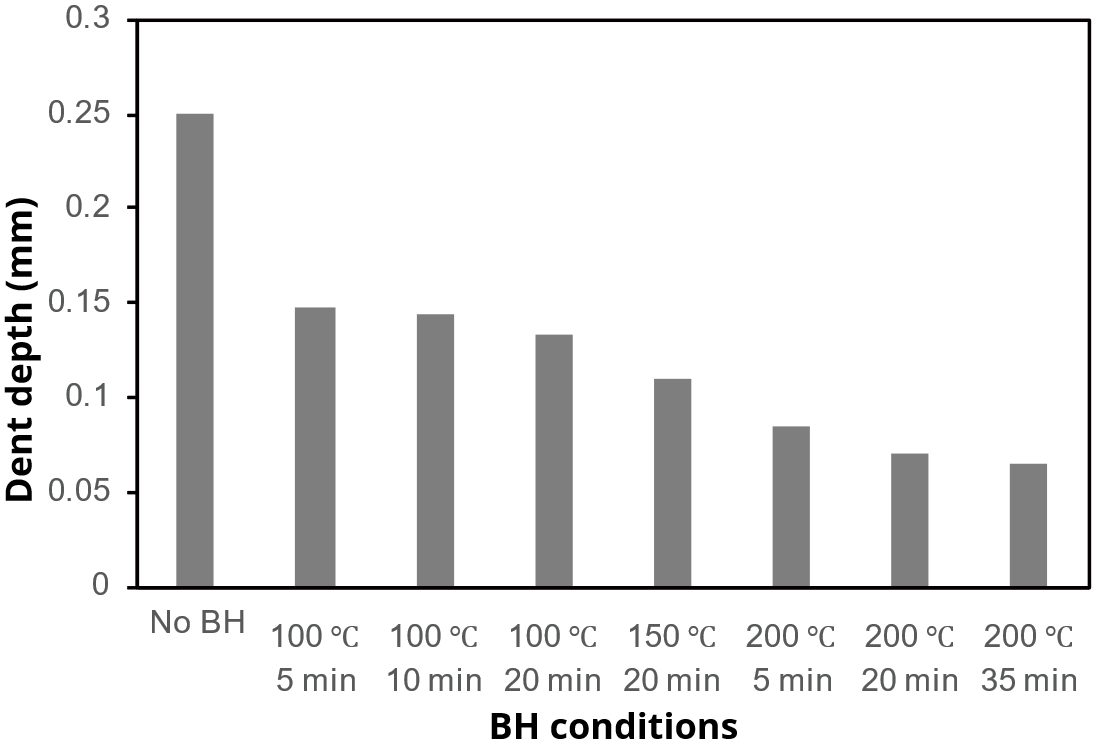

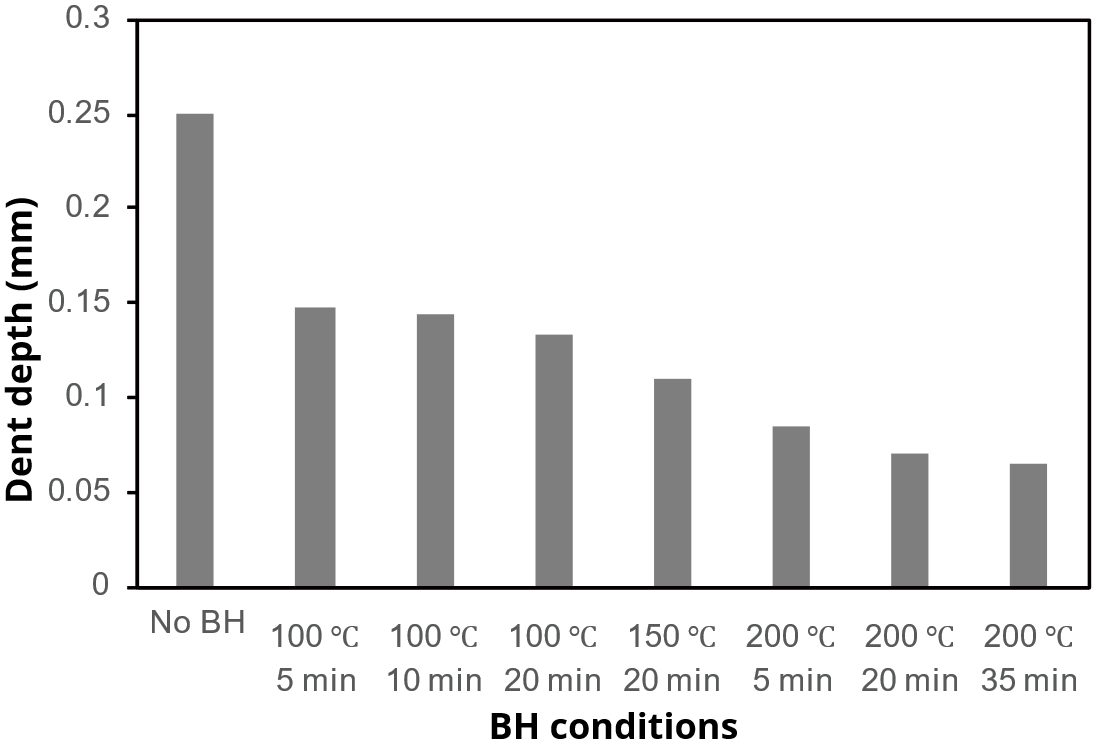

A recent studyK-49 highlights this improved dent resistance. This work presents the experimental results and associated numerical investigation of the dent testing of DP270Y490T, a DP steel grade with 490 MPa minimum tensile strength. Tests performed to the SAE J2575 procedureS-7 measure the resultant dent depth after testing, so therefore smaller depths indicate improved performance. Compared with samples not processed through a bake hardening cycle, dent depth reductions occur with hotter and longer cycles, as shown in Figure 3. Increasing temperature plays a more significant role in dent depth reduction than increasing time. This work also reinforces that bake hardenability must be incorporated into simulation models in order to improve the accuracy of dent resistance predictions.

Figure 3: Dent resistance of DP270Y490T according to SAE J2575S-7 as a function of baking test conditions.K-49 Lower dent depth indicates better dent resistance.

Measuring The Bake Hardenability Index

Bake hardenability is characterized by determining the Bake Hardening Index, or BHI.

The Bake Hardening Index (BH2) is determined by taking a conventional tensile test sample and pulling it to 2% strain. This is known as a 2% pre-strain. The sample is then put into an oven for a thermal cycle designed to be typical of an automotive paint curing (paint baking) cycle: 170 °C for 20 minutes. The temperature and time may be different depending on the end-user specifications.

Some companies may specify BH0, which uses the same thermal cycle without the 2% pre-strain. BH5 or BH10 (5% or 10% pre-strain, respectively) may also be reported.

The experimental procedure and calculation of BH2 is standardized in EN 10325D-4 and JIS G 3135J-3, and is similarly described in several other specifications.

Figure 4 defines the measurement for work hardening (B minus A), unloading to C for baking, and reloading to yielding at D for measurement of bake hardening (D minus B). Note that the bake hardening index shown here is measured up to the lower yield point, which is consistent with the EN 10325 definition. JIS G 3135 prescribes the use of the upper yield point.

Figure 4: Measurement of work hardening index and bake hardening index. BHI is measured using the lower yield point in EN 10325D-4 and with the upper yield point in JIS G 3135J-3.

Back To Top

About

WorldAutoSteel will consider appropriate articles from expert sources for publication on our AHSS Insights blog. In order to be considered, you must meet the requirements set forth below. Please keep in mind, however, that we do not pay for, or charge for, posting guest blogs. But we are more than willing to consider articles that are relevant to educating on best practices and new processes in the forming and joining of Advanced High-Strength Steels (AHSS) in vehicle applications.

If you still have questions about being a Guest Blogger for WorldAutoSteel after reading this page, you may contact the AHSS Guidelines Editor, Lori Jo Vest

Fundamentals

Please keep in mind the following fundamentals before you start writing your blog.

- Your submission must contain references to Advanced High-Strength Steel (AHSS) in vehicle applications. Note that the name of our blog is AHSS Insights, therefore, readers will be expecting to expand their AHSS knowledge base.

- Your submission must be geared towards a technical audience, with appropriate data references. Our audiences include automotive engineers that specialize in design, materials, manufacturing and the environment. We generally do not accept thought-starter type guest blogs.

- Your submission must not be a marketing piece for your organization, proprietary products or services, nor should it contain marketing messages and solicitations. Our readers are smart people. They will appreciate and gain much more insight into your company by simply demonstrating your expertise and showing your products’ purpose in AHSS use, than they would in a sales pitch.

- It should contain information pertinent to our audiences on an aspect of AHSS, such as AHSS characteristics, use, metallurgy, forming or joining. It also may address vehicle or steel industry life cycle assessment or other environmental issues related to automotive and AHSS use.

- Your submission must include graphic references. You may decide what kind of graphics you would like to add such as charts, videos, infographics, etc. We welcome videos as long as they do not include a sales pitch. Graphics need to be submitted as PNG or SVG files, and videos must be a standard format, such as MP4 or WMV.

Submission Requirements

Please meet the following submission requirements before you submit your entry for consideration.

- Submissions should be approximately 1,000 words in length, and include graphics.

- Please include a title.

- Graphics should be provided as separate 72 dpi (PNG or SVG) files, if possible, and sourced appropriately, especially if you do not specifically own the rights. Videos should be 720p resolution.

- Please clearly provide any reference sources in the following format: Author, full title of the work, year published, and if available and it will add to the blog’s content value, provide an internet link to the work.

- Please notify us with your intention to submit with an brief abstract of the information you will cover. This will help us determine if it is a good fit and enable us to potentially provide provisional approval.

- Your first draft must be submitted a minimum of 30 business days prior to any agreed upon publish date. This allows our team to have ample time for review, give you feedback and pursue any required further editing. It also provides time for translation to our Chinese blog edition.

- As your blog will be translated to the Chinese language and published on our channels in China, please do not use English jargon that will be difficult to translate.

We will notify you in advance as to when your entry is scheduled to publish. We strongly encourage you to use your social contact network to share the blog article. Your shares should include our blog hashtag, #AHSSblog.

Submitting Video and Animation Assets

We are always looking for video and animations to help support existing articles with visual information. If you think you have something that would enhance an article, please contact us at the email link above. You can send us a link to what you have, and we will review it. Note, the video must be owned by you in order to be considered and not contain any sales pitches. If we agree to use it, we’ll need to receive the original video file so that it can be uploaded directly to our site. You/your company will receive full citation as a the source of the video. Have a look at our Roll Forming page to see an example of how we have used a video received from Shape Corp.

We look forward to receiving your submission. It is our pleasure to collaborate on AHSS education with you. Thank you!