Advanced High-Strength Steel Repairability

Introduction

The introduction of Advanced High-Strength Steel (AHSS) to light vehicle body structure applications poses a significant challenge to organizations involved in vehicle repair. AHSS grades are typically produced by non-traditional thermal cycles and contain microstructural constituents whose mechanical properties can be altered by exposure to elevated temperatures. This temperature sensitivity can alter the mechanical behavior during repair welding or flame straightening, thus seriously affecting the structural performance of the AHSS components after the repair.

The American Iron and Steel Institute, with automotive partners – FCA US LLC, Ford Motor Company, General Motors Company – and I-CAR, have completed studies examining the mechanical behavior of various AHSS products after exposure to typical repair arc welding and flame straightening temperature cycles. Recommended practices for repairing components made of these materials were also developed. The studies evaluated many of the AHSS grades being applied and built into vehicle structures today.

AHSS Thermal Evaluation

Several steel grades were evaluated for their sensitivity to thermal exposure taking place during heating to soften the material for straightening, typically by flame. The test results, conclusions and recommendations contained herein are the consensus views of the team members.

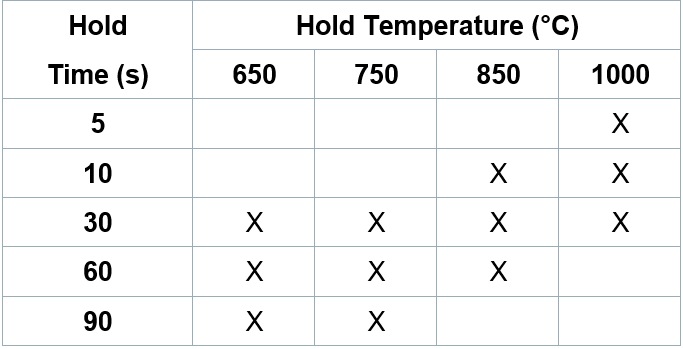

A time-temperature test matrix was developed to represent the various thermal conditions encountered during repair welding and flame straightening as shown in Table 1. Individual steel performance result discussions are based on this test matrix and discussed by grade category and specific type.

Steel Performance

Conventional Steels

Interstitial free (IF) and high strength low alloy (HSLA) steels are conventional steel products which are essentially a single phase ferrite microstructure and obtain their strength by the addition of chemical elements. These steels have been used in body structures and closures for many years and are well-known to be repairable without substantial performance degradation by arc welding and flame straightening. For repair processes, this means conventional steels can be subjected to heat during repair with the finished repaired component having mechanical properties greater than the properties of the as-received steel. However, it is recommended heating is kept below 750 degrees Celsius to ensure no degradation in properties (Figure 1).

Figure 1: Ultimate tensile strength of Grade 4 IF and HSLA 340 steel after exposure to simulated repair thermal cycles.

Advanced High-Strength Steels

Dual Phase (DP) Steel

DP steels range in strength from 500 MPa to 1200 MPa and obtain their properties from the introduction of a martensitic phase into the ferrite microstructure. The ferrite phase provides formability, while the martensitic phase provides the improved strength. This category of steel grades obtains its microstructure, and thus its mechanical properties through a combination of alloying elements and thermomechanical processing. The processing involves some holding time at elevated temperatures and cooling at specific rates.

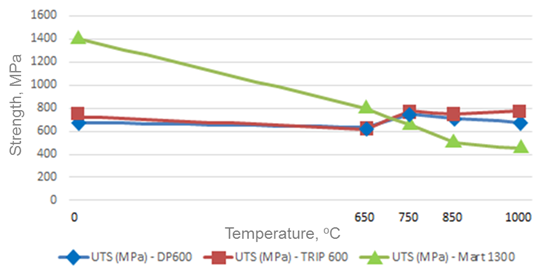

Two grades of DP steel were tested, DP 600 and DP 780. The number indicates the ultimate tensile strength (UTS) level of the material in MPa and is the common way to name these grades. UTS for both grades decreases with elevated temperature at a much faster rate than for conventional steels and is illustrated by DP 600 in Figure 2. At temperatures above 650 degrees Celsius the strength suddenly increases then upon additional heating decreases. This behavior is a result of changing the microstructure created during the original thermomechanical processing of the material. Once the microstructure is changed, it is very difficult to return it to its original state in a repair shop environment. Therefore, it is not recommended to subject DP steels to any kind of elevated temperature process for straightening or removing dents. The recommended repair procedure is to remove and replace the DP component. OEM repair guidelines and procedures should be referenced for approved cut and weld lines for replacement.

Figure 2: Ultimate tensile strength of advanced high-strength steels after exposure to simulated repair thermal cycles.

Transformation Induced Plasticity (TRIP) Steels

TRIP steels have a similar range of strength as DP steels, 500 MPa to 1200 MPa, while providing improved formability. The improved formability is obtained with the introduction of additional phases of austenite and bainite into the microstructure. These phases improve the work hardening properties of steel and provide additional energy absorption characteristics. TRIP steel microstructures are obtained in a similar manner as DP steels, and therefore have similar behaviors when heating.

TRIP 600 and 780 were evaluated in the studies and confirmed the expected results as demonstrated by TRIP 600 in Figure 2. Heating during repair of TRIP steel will also adversely affect their mechanical properties and thus the performance of the as repaired component may be compromised. OEM recommended repair procedures are similar to DP steels.

Martensitic Steel (MS)

MS steels typically have a microstructure of 100 percent martensite and have tensile properties greater than 980 MPa. Martensite is the strongest microstructural phase in steel and is obtained by alloying and rapid controlled cooling. This grade is used in areas where exceptional strength and anti-intrusion are needed, including such applications as the A-pillars, B-pillars, rockers and rails.

The effect of heat on MS 1300 is shown in Figure 2. Like other AHSS, it is adversely affected by heat and the performance of the as repaired component may be compromised. Thus, heat should be used only as outlined in OEM repair procedures.

Summary

The steel industry, working closely with automotive OEMs and the repair community, have developed and validated repair procedures applicable to the new AHSS used in today’s vehicles. Each OEM has taken the results from the AHSS repairability studies and developed their own repair guidelines.

The steel industry continues to develop AHSS grades with strength levels at and above 1000 MPa. These microstructures contain martensite and will be affected by heat exposure during repair as shown in previous studies. Collaborative studies will continue to update repair procedures for higher strength AHSS, including DP, MS and Press Hardened grades, and new 3rd Gen. AHSS as they are introduced.

|

Thanks is given to David Anderson, David Anderson Consulting, for contributing this article. |