Fundamentals and Principles of Hybrid Welding

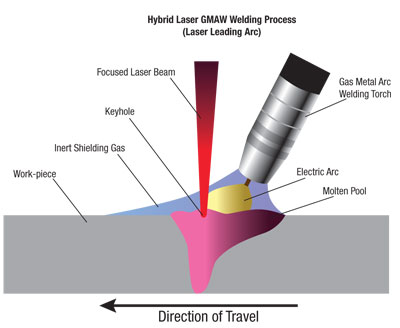

Recent developments in welding include approaches that could be considered novel, as well hybrid, or those that combine more than one established process. A sampling of these unique approaches will be reviewed here. A hybrid process that is being extensively developed known as hybrid laser welding combines both the laser beam and Gas Metal Arc Welding (GMAW) processes (Figure 1). This approach uses a head that carries both the laser focusing optics and the GMAW gun. The laser beam creates a keyhole near the leading edge of the puddle.

Figure 1: Hybrid laser welding.L-11

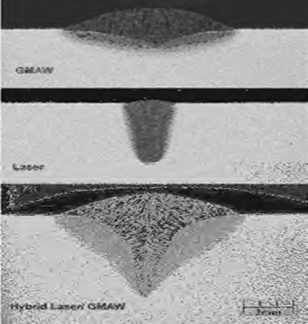

The motivation for this concept is that the best features of each process can be combined (Figure 2) to create an even better process for certain applications. Laser beam welding provides the capability for deep-penetrating single-pass welds at high speeds but requires precise joint fit-up and doesn’t produce weld reinforcement which can add strength to the joint. When combined with GMAW, these limitations are eliminated. The laser beam also helps stabilize the arc, which can be of particular benefit when welding Titanium (Ti).

Figure 2: Hybrid laser welding combines the best features of laser beam and GMAW (top GMAW, middle LBW, bottom hybrid).

PAW, GTAW and GMAW have also been combined into a hybrid process. The benefits are similar to the laser hybrid welding approach, but the equipment has the potential to be much less expensive. The combination of FSW with ultrasonic energy is being explored as an approach to creating friction stir welds with greatly reduced forces, and therefore, smaller machines.