High Energy Density Welding

The word “laser” is an acronym for “light amplification by stimulated emission of radiation.” Lasers produce a special form of light (electromagnetic energy) consisting of photons that are all of a single coherent wavelength. Light of this form can be focused to extremely small diameters allowing for the creation of the high-energy densities used for welding. The laser beam itself is not useful for welding until it is focused by a focusing lens.

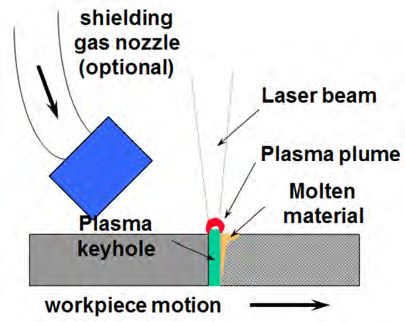

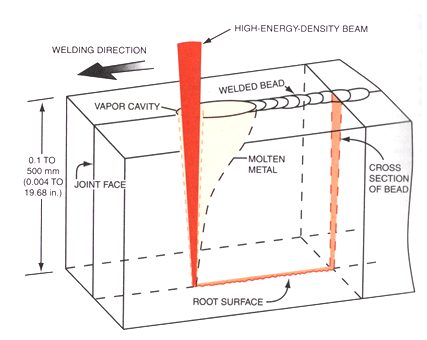

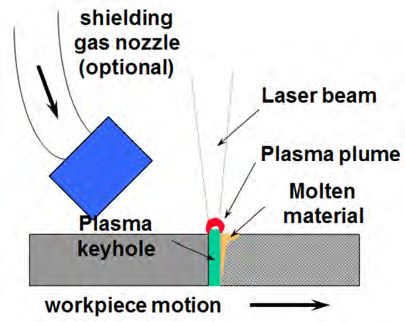

Figure 1: Laser beam welding.

Lasers vary in the quality of the beam produced. A high-quality beam will diffract less when focused, providing for the creation of a smaller spot size. Reflective lenses are important to lasers as well since they are used in the optical cavity where the beam is generated, as well in the beam delivery systems for some lasers. For these reasons, optics play a major role in laser beam welding.

Laser beam welding (Figure 1) does not require additional filler metal and shielding gas is optional. When the beam hits the workpiece, it melts and vaporizes metal atoms, some of which are ionized by the intense beam. This creates what is known as a plume (or plasma) over the weld area that can sometimes interfere with the beam. In these cases, shielding gas may be used to deflect the plume.

The choice of laser type depends on cost, the type and thickness of material to be welded and the required speed and penetration. Lasers are distinguished by the medium used to generate the laser beam, and the wavelength of laser light produced. Although there are many types of lasers, the common lasers for welding include the Nd:YAG, fiber, disk solid-state lasers, and the gas-based CO2 laser. The lasing medium in solid-state lasers are crystals (Nd:YAG and disk lasers) or fibers (fiber laser) that have material added (doped) that will “lase” when exposed to a source of energy, whereas the lasing medium in the CO2 laser is a gas blend consisting of CO2, He, and N2 gas. In all cases, “lasing” occurs when the atoms/molecules of the medium are excited to a higher energy state through the introduction of additional energy (known as pumping). When this occurs, photons are emitted, which, in turn, excite other atoms/molecules. This results in a cascade of photons that travel in coherent waves of a single wavelength, the two properties for which laser light is known.

CO2 lasers produce wavelengths of 10.6 µm, while the wavelength of the solid-state lasers is 1.06 µm. CO2 lasers are generally less expensive, but the longer wavelength of light does not allow its beam to be delivered through fiber optic cables which reduces its versatility. Its light is also more reflective, which limits its use with highly reflective metals such as aluminium. The solid-state lasers are generally more compact and require less maintenance than the CO2 laser. They are more conducive to high-speed production since their beams can be delivered through long lengths of fiber optic cable which can then be attached to a robot. Some of the solid-state lasers such as the fiber laser produce beams of outstanding quality. However, the shorter wavelength of these lasers requires additional safety precautions regarding eye protection.

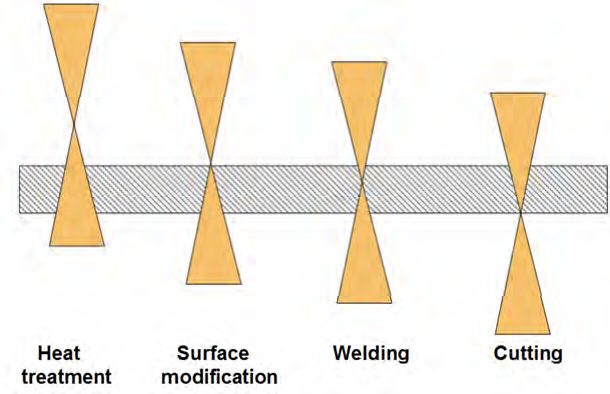

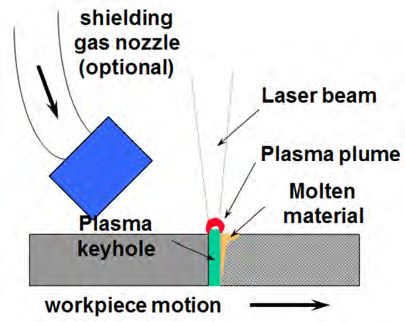

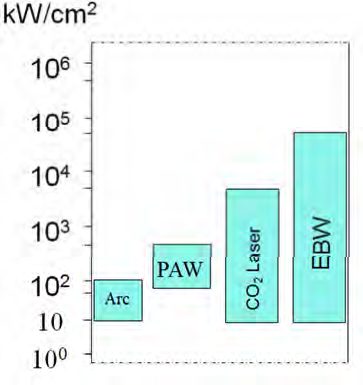

Figure 2: Focusing of the laser beam.

The choices of focus spot size, focus spot location in the joint, and focal length are all important considerations when laser beam welding. Usually, a small focus size is used for cutting and welding, while a larger focus is used for heat treatment or surface modification. As indicated in Figure 2, the location of the beam’s focal point can also be varied based on the application. When welding, it is common to locate the focal point somewhere near the center of the joint. But cutting applications benefit from placing the focal point at the bottom of the joint. Weld spatter onto the focusing lens can sometimes be a problem, especially when there are contaminants on the surface of the parts being welded. Approaches to minimizing the spatter problem include choosing a long focal length lens which keeps the lens a safe distance from the weld area, or the use of an air “knife” to protect the lens. A-11, P-6

In summary, the advantages and limitations of laser beam welding are as follows:

Advantages:

- High energy density process allows for low overall heat input which produces minimal BM degradation, residual stress, and distortion.

- Fast welding speeds.

- No filler metal required.

- Relatively thick (¾ in.) single-pass welds can be made.

- Concentrated heat source allows for the creation of extremely small weld sizes needed for small and intricate components.

- Easily automated, especially with lasers that are conducive to fiber optic delivery.

- Since there is no bulky torch as with most arc welding processes, laser beam welding is capable of welding joints with difficult accessibility.

Limitations:

- Equipment is very expensive

- Portability is usually low

- Requires very tight joint fit-up and accurate positioning of the joint relative to the beam

- Metals that are highly reflective such as Al are difficult to weld with some laser beam welding processes

- High weld CR may create brittle microstructures when welding certain steels

- Laser plume may be a problem

- Energy efficiency of lasers is poor

- Some lasers require special (and expensive) eye protection

- Laser beam welding is complex and requires significant training and knowledge

High Energy Density Welding

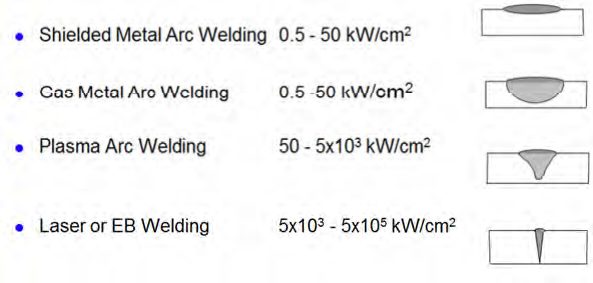

Fundamentals and Principles of High Energy Density Welding

High energy density welding processes are those that focus the energy needed for welding to an extremely small size area. This allows for very low overall heat input to the workpiece, which results in minimal BM degradation, residual stress, and distortion. Welding speeds can be very fast. The two main processes known for extreme energy densities are laser (Figure 1) and Electron Beam Welding (EBW).

Figure 1: Laser welding.

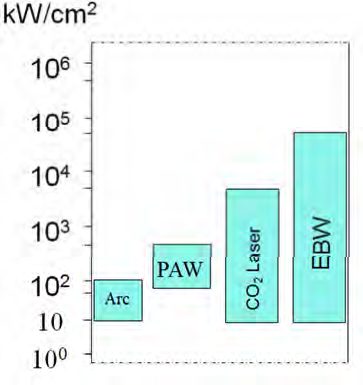

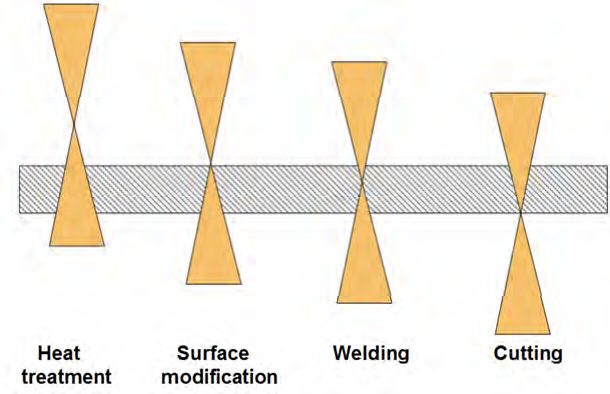

As shown in Figure 2, energy densities of focused laser and electron beams can approach and exceed 104 kw/cm2. These energy densities are achieved through a combination of high power and beams that are focused to an extremely small diameter. Diameters as small as a human hair (0.05 mm) are possible. PAW[KH1] offers greater energy density than conventional arc welding processes and is sometimes referred to as the “poor man’s laser”.

Figure 2: Power densities of various welding processes.

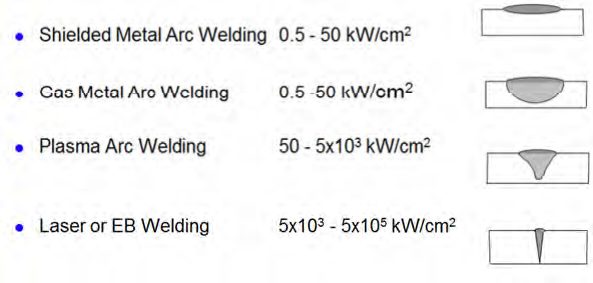

High energy density processes produce weld profiles of high depth-to-width ratio, as compared to other welding processes (Figure 3). As a result, much greater thicknesses can be welded in a single pass, especially with EBW. The figure also illustrates the fact that high energy density processes can produce a weld with minimal heating to the surrounding area as compared to the other processes. However, the high depth-to-width ratio weld profile is much less forgiving to imperfect joint fit-up than the profile produced by arc welding processes.

Figure 3: Comparison of typical weld profiles.

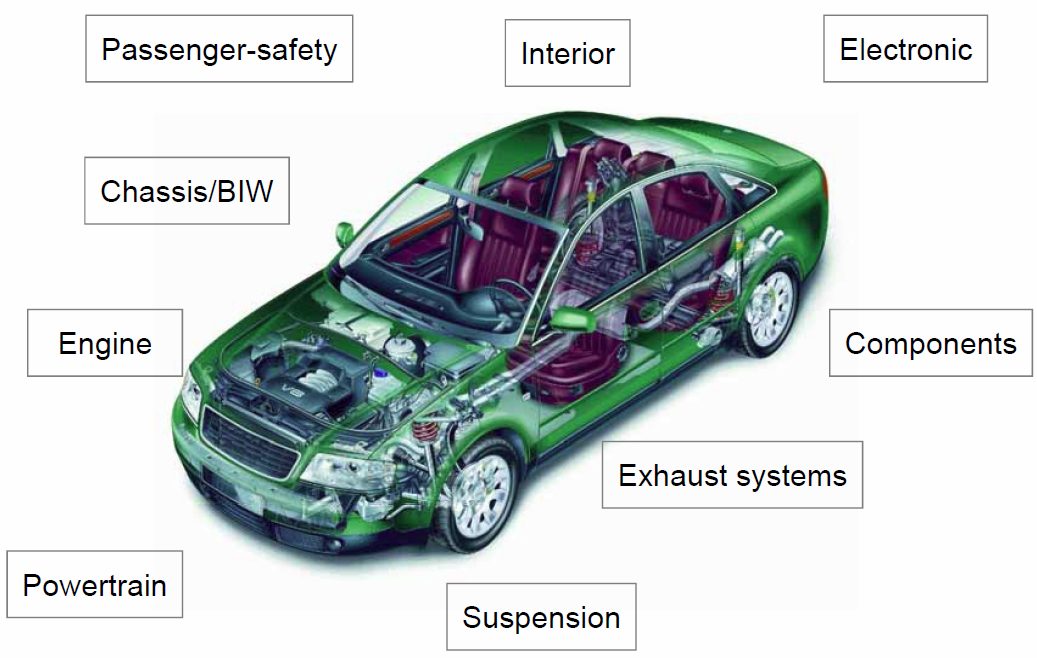

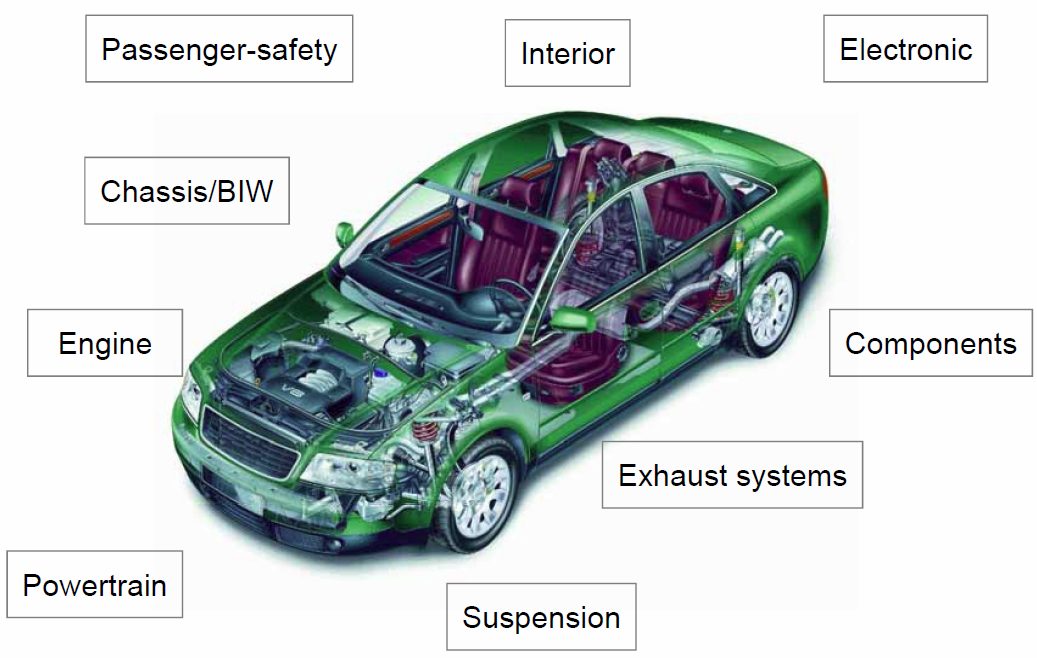

Laser and EBW processes are used in a wide variety of industry sectors. Very high weld speeds are possible and the welds are usually aesthetically pleasing. Laser welding is very adaptable to high-speed production so it is common in the automotive sector. The ability to precisely locate welds on smaller sensitive components with minimal heat input makes laser welding very attractive to the medical products industry.

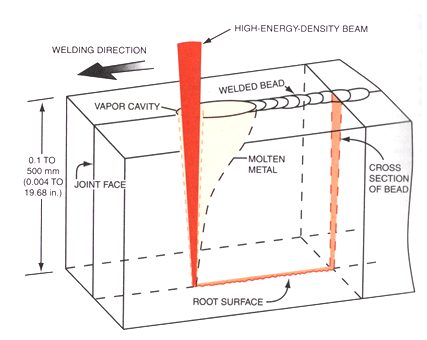

When welding with high energy density processes, the laser or EB is focused along the joint line of the workpieces to be welded. The extreme power density of the beam not only melts the material, but causes evaporation. As the metal atoms evaporate, forces in the opposite direction create a significant localized vapor pressure. This pressure creates a hole, known as a keyhole, by depressing the free surface of the melted metal. The weld solidifies behind the keyhole as it progresses along the joint (Figure 4). This method of welding known as keyhole welding is the most common approach to laser and EB, and produces the characteristic welds of high depth-to-width ratio. There are some cases where the keyhole mode is not used. This mode is known as conductive mode welding. Conductive mode welds have a weld profile closer to that of an arc weld A-11, P-6

Figure 4: Keyhole mode welding.

High Energy Density Welding

Butt Welds and Tailor-Welded Products

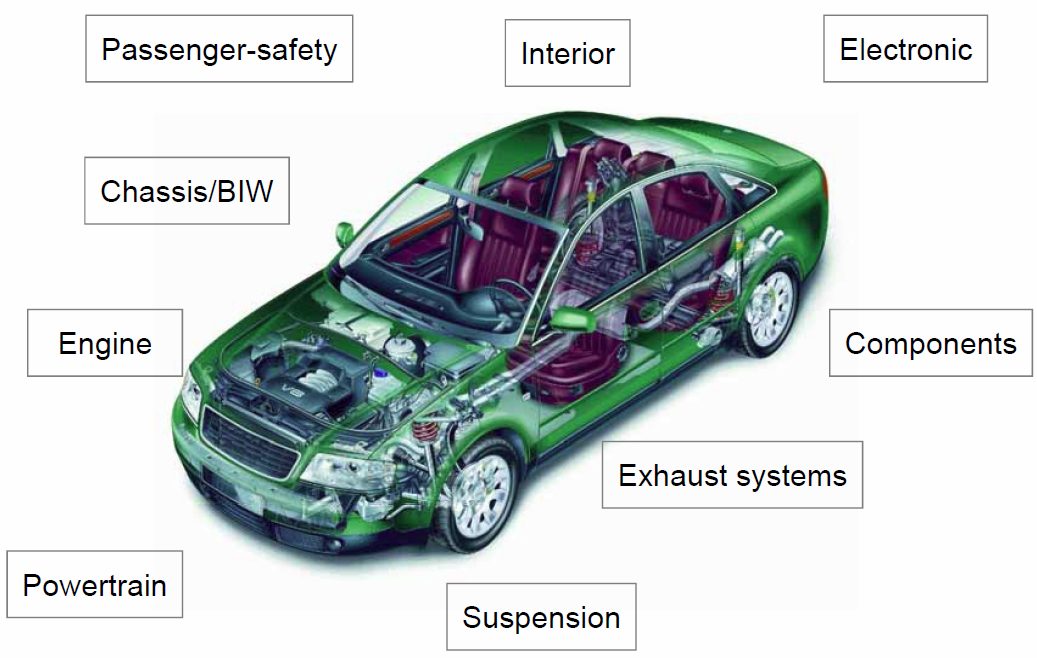

Figure 1: Common automotive applications using laser welding.T-9

AHSS grades can be laser butt-welded and are used in production of tailored products (tailor-welded blanks and tubes). The requirements for edge preparation of AHSS are similar to mild steels. In both cases, a good quality edge and a good fit-up are critical to achieve good-quality welds. The blanking of AHSS needs higher shear loads than mild steel sheets. (see Culling in Blanking, Shearing and Trim Operations)

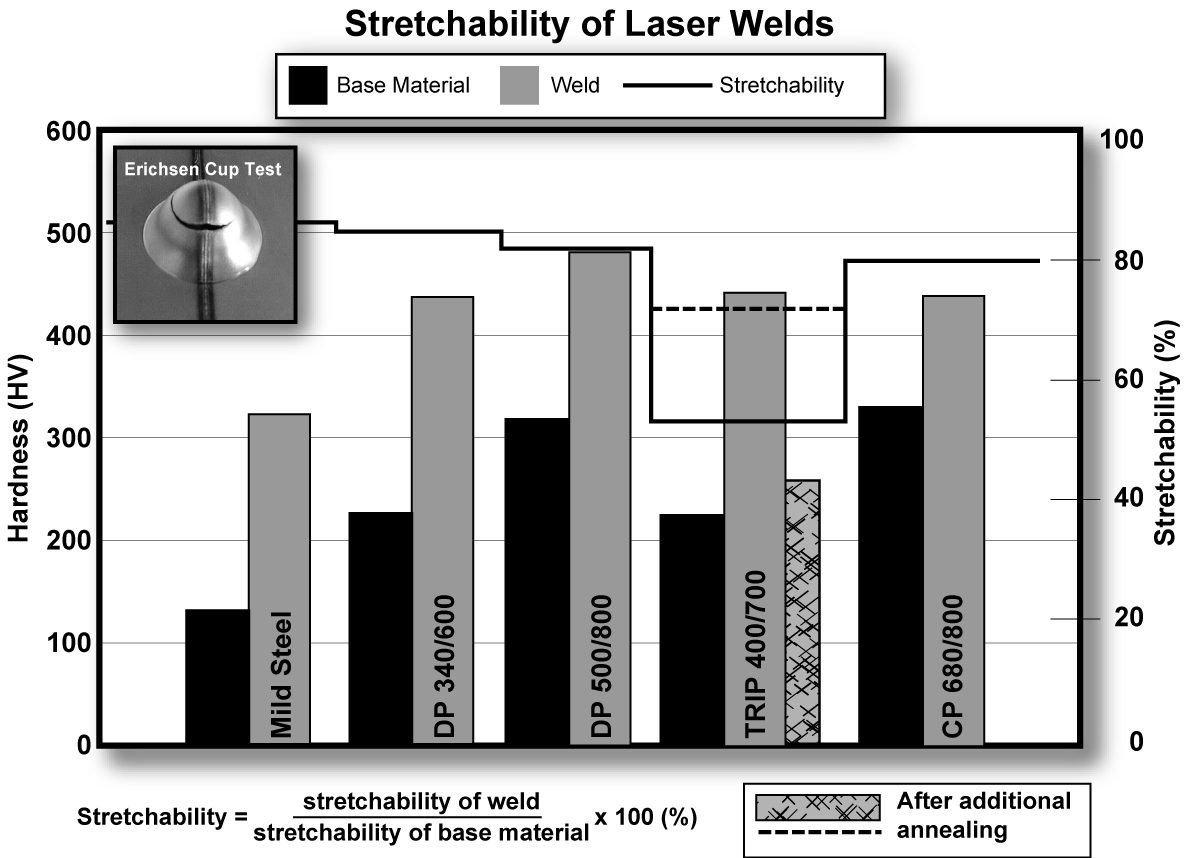

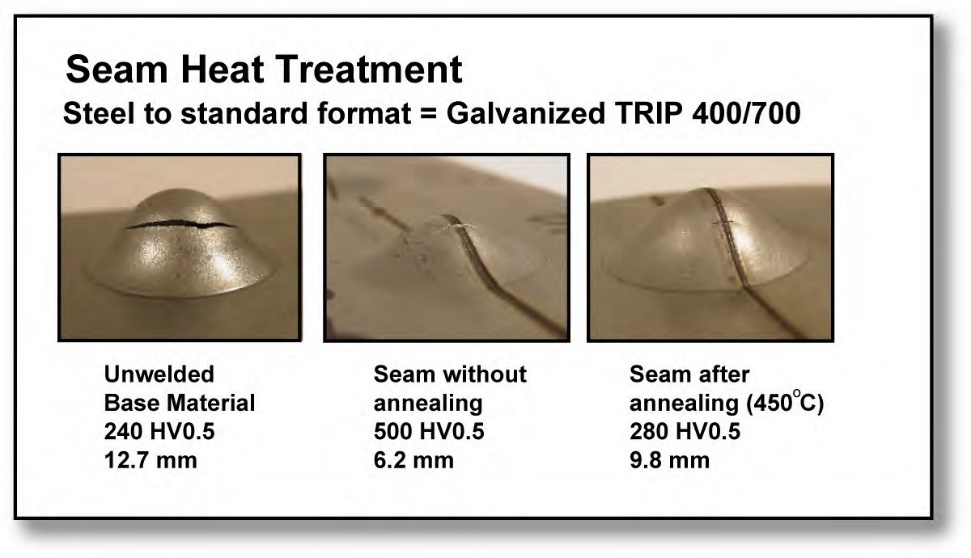

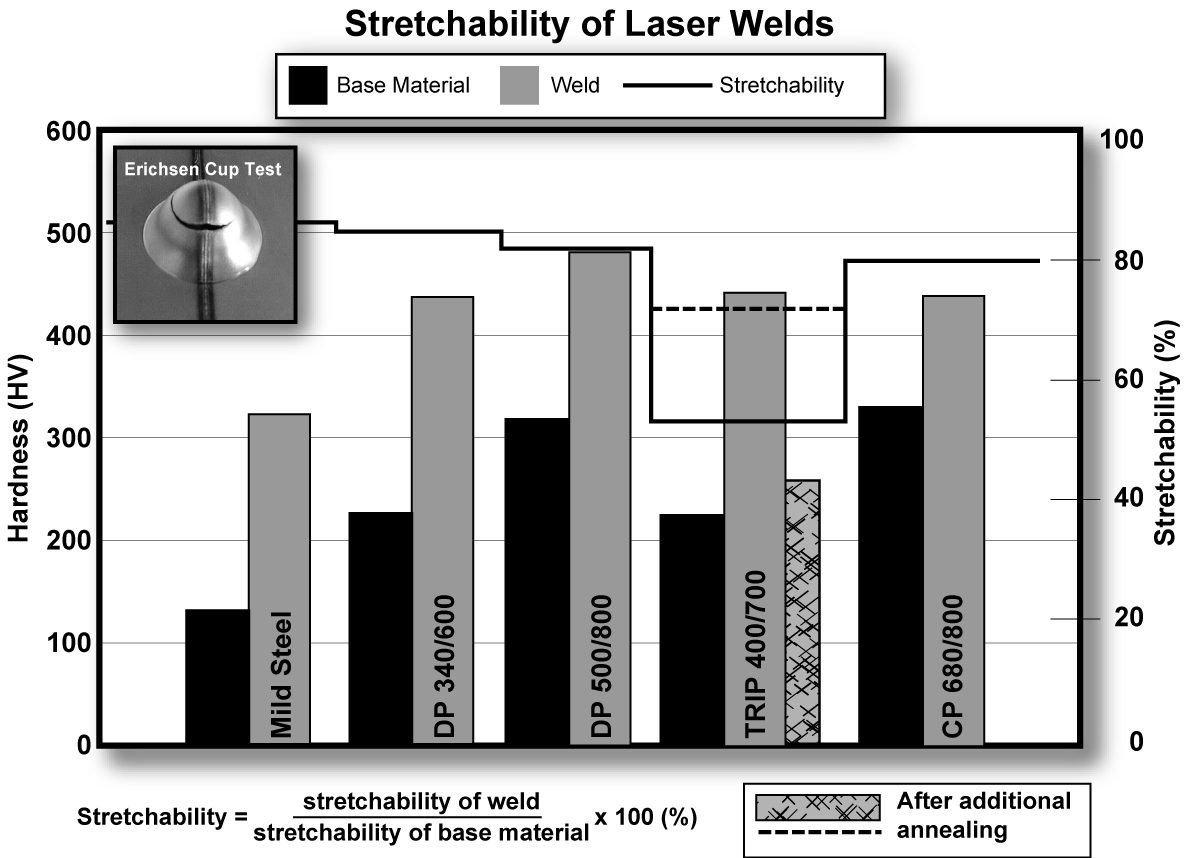

If a tailored product is intended for use in a forming operation, a general stretchability test such as the Erichsen (Olsen) cup test can be used for assessment of the formability of the laser weld. AHSS with tensile strengths up to 800 MPa show good Erichsen test values (Figure 2). The percent stretchability in the Erichsen test = 100 × the ratio of stretchability of weld to stretchability of BM.

Figure 2: Hardness and stretchability of laser butt welds with two AHSS sheets of the same thickness (Erichsen test values describe the stretchability.B-1)

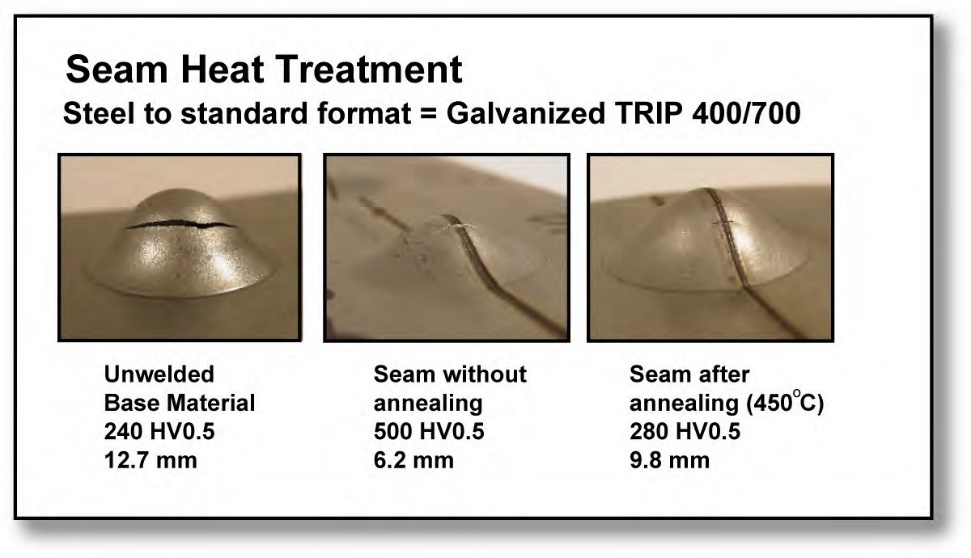

The hardness of the laser welds for AHSS is higher than for mild steels (Figure 3). However, good stretchability ratios in the Erichsen test can be achieved when the difference in hardness between weld metal and BM is only slightly higher for AHSS compared to mild steels. If the hardness of the weld is too high, a post-annealing treatment (using HF-equipment or a second laser scan) may be used to reduce the hardness and improve the stretchability of the weld.

Figure 3: Improved stretchability of AHSS laser welds with an induction heating post-Heat treatment (Testing performed with Erichsen cup test.T-3)

Laser butt-welded AHSS of very high strength (for example Martensite steels) have higher strength than GMAW [LINK TO 3.2.1] welded joints. The reason is that the high CR in the laser welding process prompts the formation of hard martensite and the lower heat input reduces the soft zone of the HAZ.

Laser butt-welding is also used for welding tubes in roll-forming production lines as an alternative method for HF induction welding.

Assembly Laser Welding

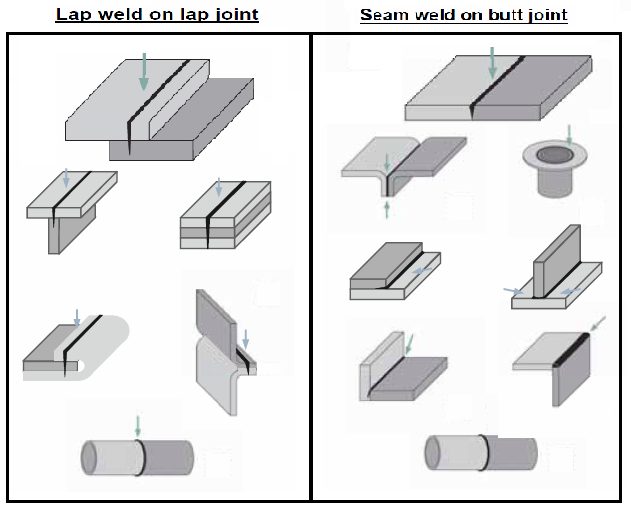

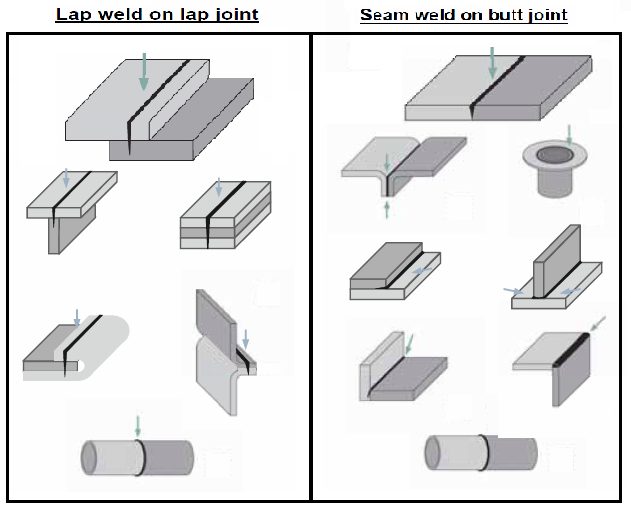

Automotive applications use a variety of welding joint designs for laser welding in both lap joint and seam butt joint configurations as shown in Figure 4. Lap joints and seam butt joint configurations use different characteristics. Seam welds on butt joints need less power from the machine than lap joints due to the smaller weld fusion area, producing less distortion and a smaller HAZ. Butt joint configurations are more cost efficient. However, the fit up for seam welds can be more difficult to obtain than those of lap joints. Also, lap joints tend to provide a larger process window.

Figure 4: Common seam and joint types for laser welding of automotive applications.T-9

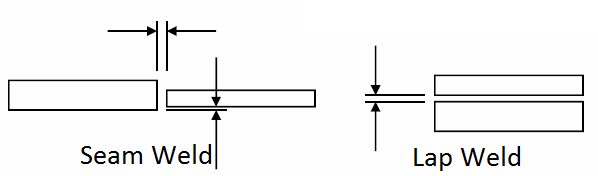

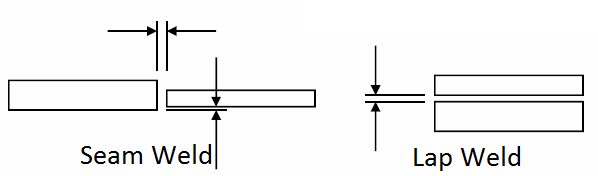

When seam welding butt joint configurations, a general guideline for fit-up requirements include a gap of 3-10% the thickness of the thinnest sheet being welding and an offset of 5-12% thickness of the thinnest sheet. A guideline for lap joints can require a gap of 5-10% the thickness of the top sheet being welded (Figure 5). These general guidelines are not absolute values due to the change of variables such as the focus spot size, the edge geometry for butt welds, strength requirements, etc.

Figure 5: Fit-up requirements for butt joint and lap joint configurations in laser welding.T-9

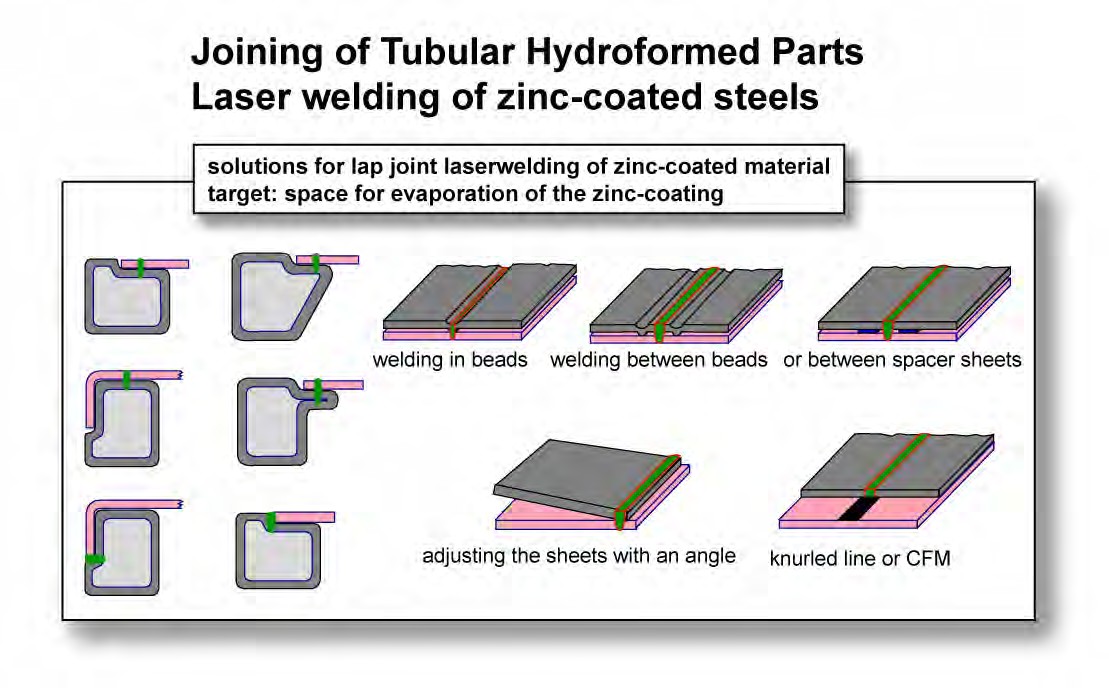

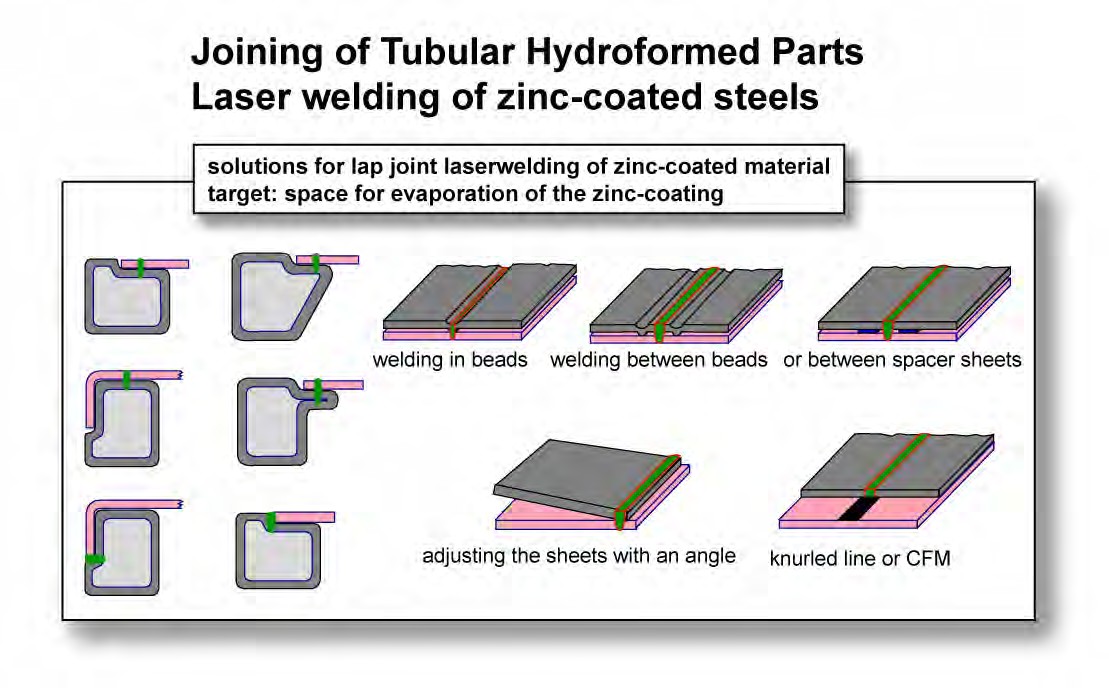

Laser welding is often used for AHSS overlap joints. This type of weld is either a conventional weld with approximately 50% penetration in the bottom sheet or an edge weld. Welding is performed in the same way as for mild steels, but the clamping forces needed for a good joint fit-up are often higher with AHSS than for mild steels. To achieve good laser-welded overlap joints for Zn-coated AHSS, a small intermittent gap (0.1-0.2 mm) between the sheets is recommended, which is identical to Zn-coated mild steels. In this way, the Zn does not get trapped in the melt, avoiding pores and other imperfections. An excessive gap can create an undesirable underfill on the topside of the weld. Some solutions for lap joint laser welding Zn- coated material are shown in Figure 6.

Figure 6: Laser welding of Zn-coated steels to tubular hydroformed parts.L-3

StudiesL-59 have shown welding Zn-coated steels can be done without using a gap between the overlapped sheets. This is accomplished using dual laser beams. While the first beam is used to heat and evaporate the Zn coating, the second beam performs the welding. The dual laser beam configuration combines two laser-focusing heads using custom-designed fixtures.

Remote Laser Welding

Remote scanner welding is used for many automotive applications, including seating (recliners, frames, tracks, and panels), BIW (trunks, rear panels, doors I hang on parts, side walls, and pillars) and interior (IP beams, rear shelfIhat rack) (Figure 7). Compared to conventional laser welding, remote scanner welding has several advantages. Those include a reduced cycle time (via reduction of index time), programmable weld shapes (ability to customize weld shape to optimize component strength), large stand-off (longer protection glass life), and reduced number of clamping fixtures (via reduced number of stations).

Remote laser welding, or “welding on the fly”, combines a robot and scanner optics to position the focused laser beam on the workpiece on the fly. The robot arm guides the scanner optics along a smooth path about half a meter over the workpiece. Extremely nimble scanning mirrors direct the focal point in fractions of a second from weld seam to weld seam. A fiber-delivered, solid-state laser is the source of the joining power far away from the processing station. The scanning optic or Programmable Focusing Optic (PFO) at the end of the laser’s fiber-optic cable is the central element for precise positioning of the laser’s focus point on the component to be welded. Inside the PFO, two scanner mirrors direct the beam through a “flat field” optic, which focuses the beam onto a common focus plane no matter where it is in the work envelope of the PFO. The PFO is also equipped with a motorized lens that allows the focus plane to be moved up and down in the Z-axis. The repositioning of the focused laser beam from one end of the entire work envelope to the other takes about 30 ms.T-9

Figure 7: Remote laser welding of automotive applications.T-9

There are three basic preconditions for welding on the fly. First, a solid-state laser is needed as the beam source. Solid-state lasers enable delivery of the laser beam through a highly flexible fiber optic cable, which is required when joining components in 3D space with a multi-axis robot. Second, a laser with excellent beam quality and the appropriate power is required. Beam quality is the measure of focus-ability of a laser, and the long focal lengths required for remote welding necessitate superior beam quality (i.e., 4 to 8 mm-mrad) to achieve the appropriate focused spot size (i.e., about 0.6 mm) at the workpiece. For remote welding in automotive body production, typically about 4 to 6 kW of laser power is used. The third essential precondition is precise positioning of the weld seams, which requires axis synchronization between the robot and the scanner control. This allows the weld shape programmed in the scanner control for a specific shape weld to have proper shape with the robot moving at various speeds over the part to be welded. Some control architectures use “time” synchronization. The problem here is that if the robot speed is changed for any reason, the weld shape will also change because the axes are not synchronized.T-9

Body-in-White (BIW) Joining

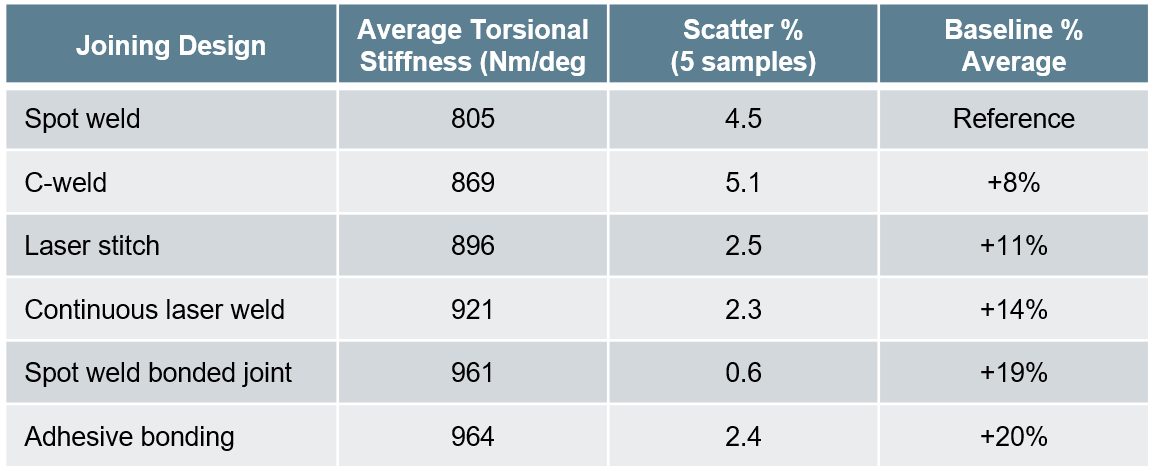

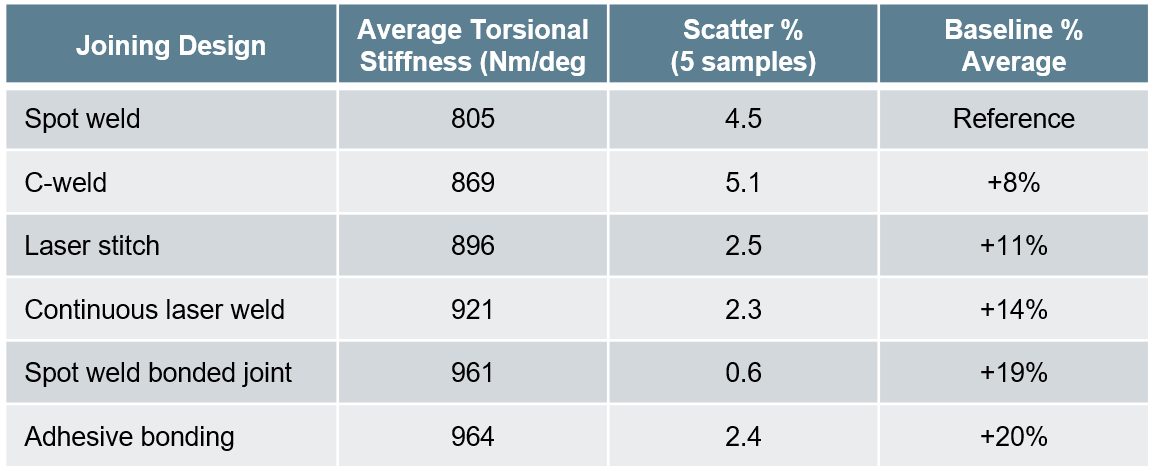

Laser-based solutions can offer a high- and cost-effective improvement potential for steel-based BIW joining. The laser joining design’s stiffness increases in direct relation to the laser weld length. Also, at low process time, there is up to a +14% torsional stiffness increase without any additional joining technique, shown in Table 1.

Table 1: Stiffness performances comparison for several joining designs.A-16

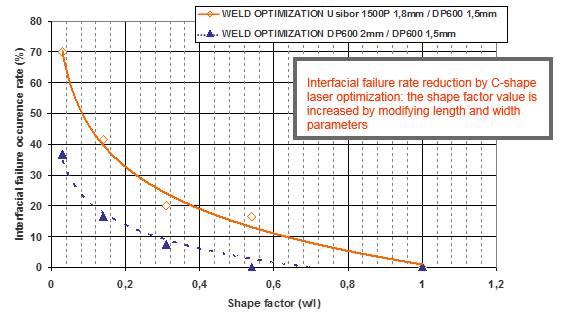

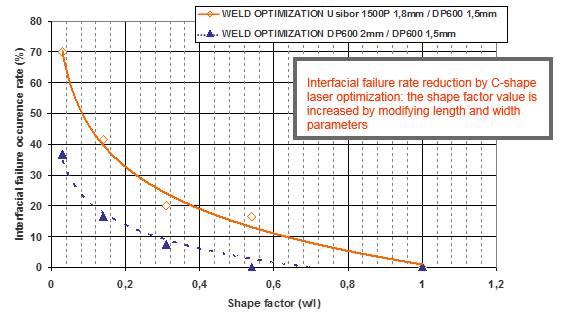

Laser weld shape optimization can help to homogenize performances and increasing the laser weld shape factor leads to a signification reduction of IF fracture risk (Figure 8).

Figure 8: Impact of laser weld design optimization on fracture type.A-16

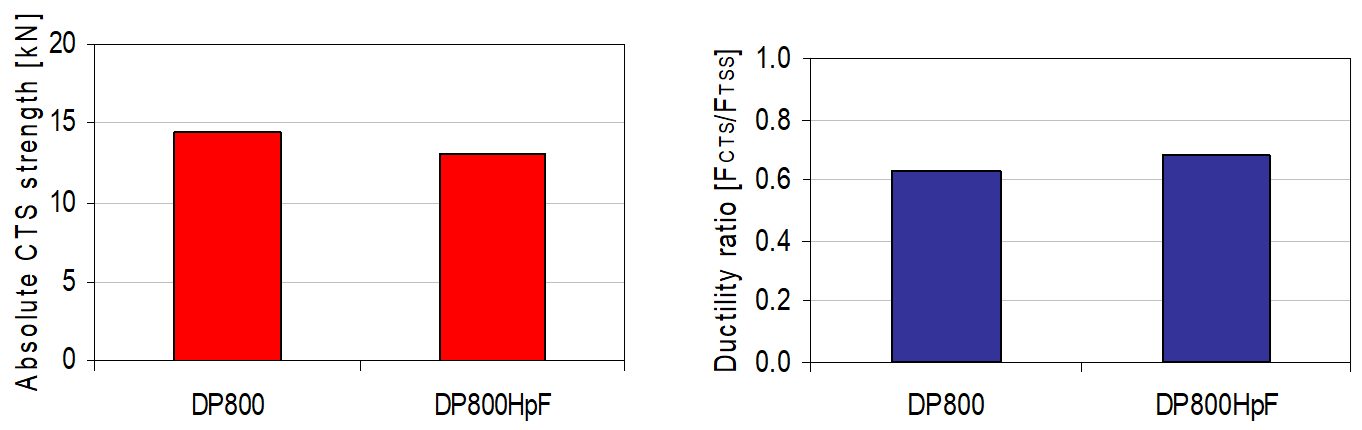

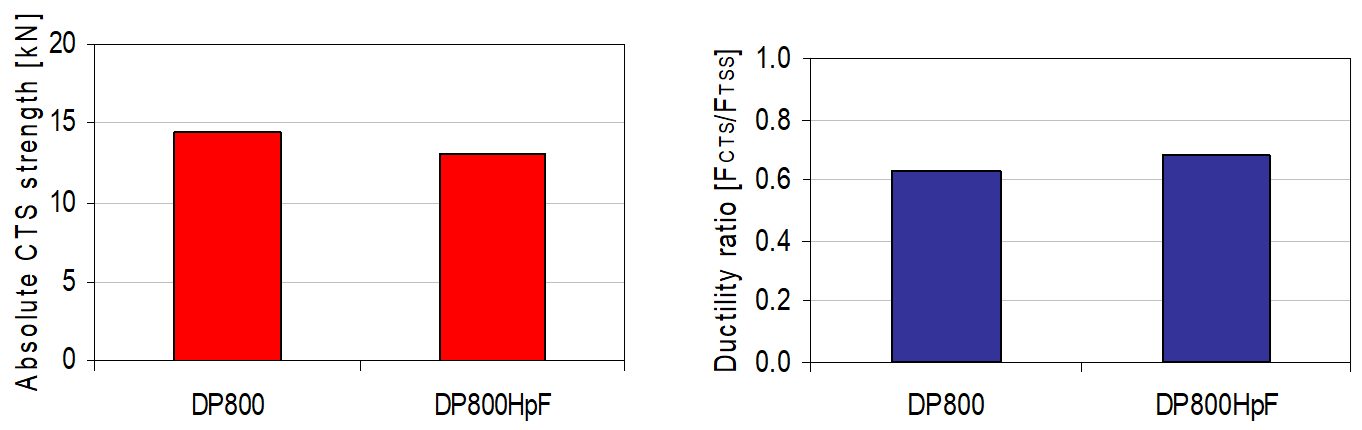

DP 800 (with additional retained austenite and associated bainite) has the advantage of weight reduction and equally good properties when laser welding as the DP 800. The absolute strength of DP 800 is slightly higher, but the ductility for the DP 800 is greater, shown in Figure 9.

Figure 9: Absolute strength and ductility of DP 800 and DP 800.T-10

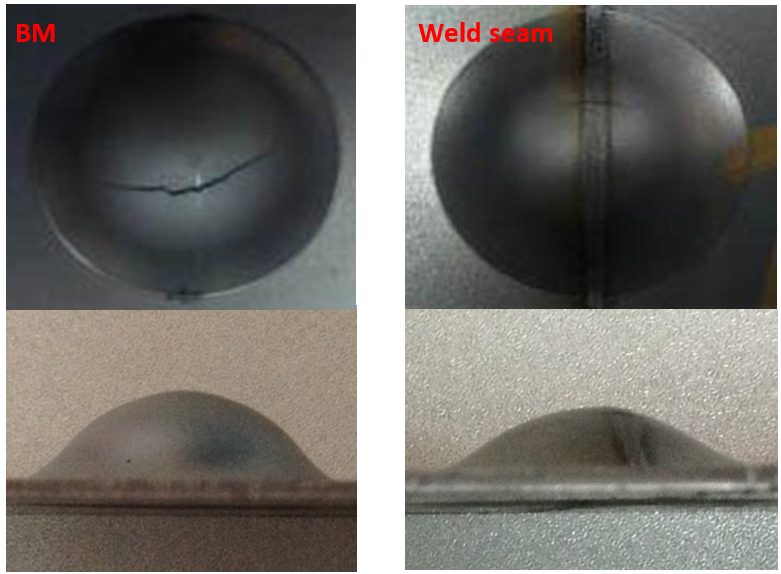

Figure 10 shows a cross-tension test in which both materials fail outside the weld zone, DP 800 failing entirely in the HAZ and DP 800 failing partly in the HAZ and partly in the BM.

Figure 10: Cross-tension testing of DP 800 and DP 800.T-10

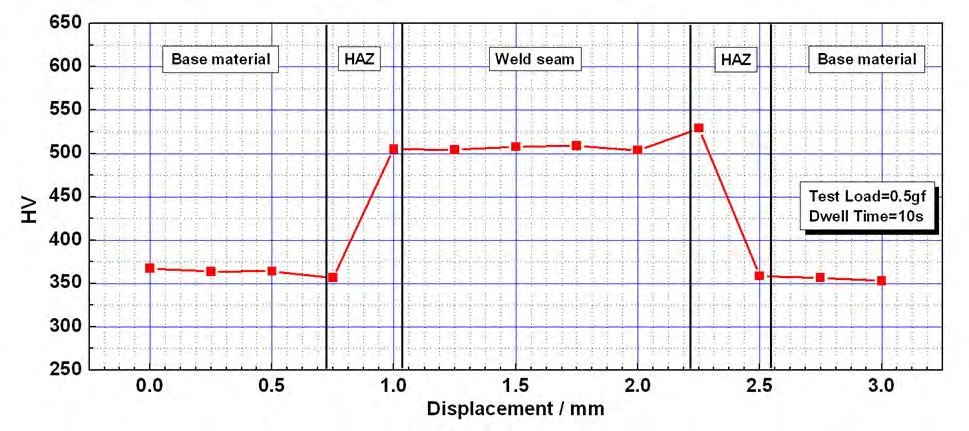

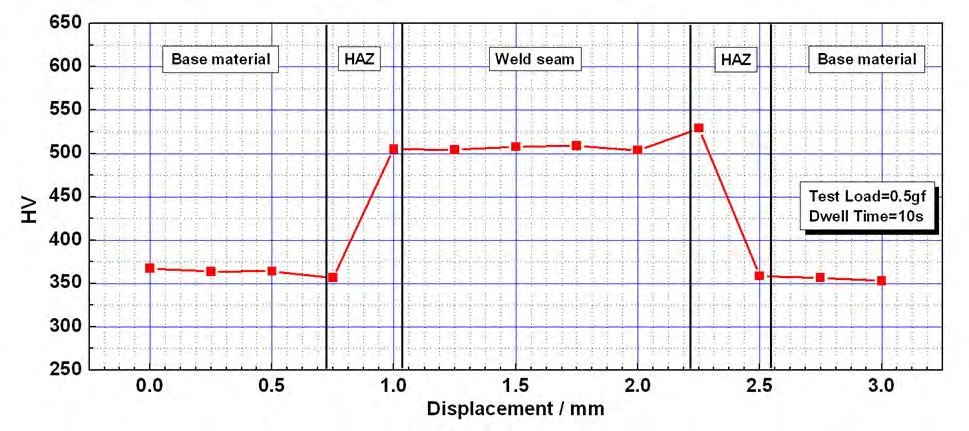

Figure 11 is the microhardness profile of 1.6-mm Q&P 980’s laser weld joint. Microhardness of both welded seam and HAZ are all higher than BM, and there is no obvious softened zone in HAZ.

Figure 11: Microhardness profile of 1.6-mm Q&P 980’s laser weld joint.B-4

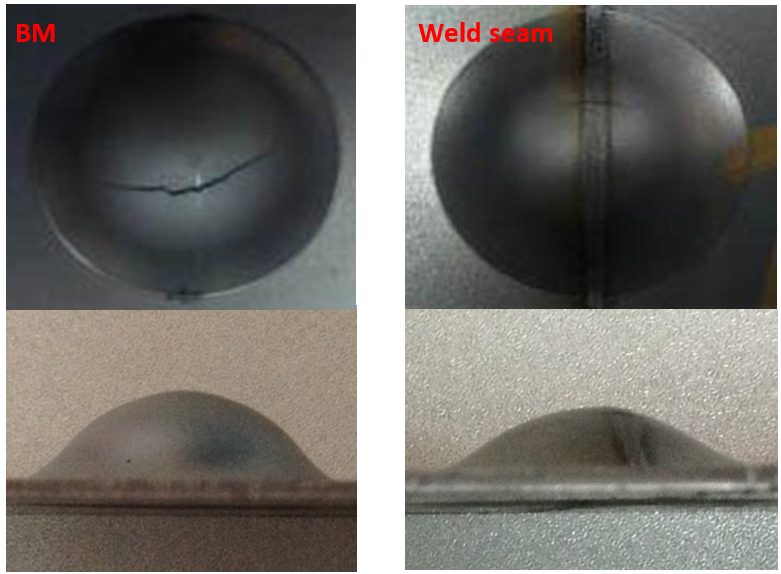

Figure 12 is Erichsen test result for the BM and weld seam of 1.6-mm Q&P 980, showing good stretchability.

Figure 12: Erichsen test result of 1.6-mm Q&P 980, laser welded.B-4

Hybrid Laser and GMAW Welding

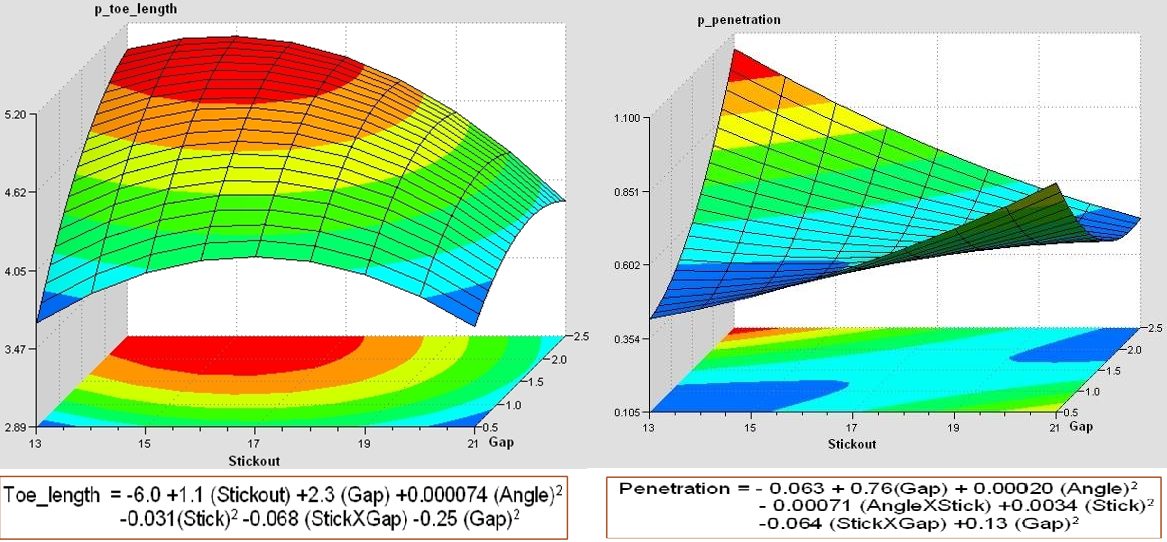

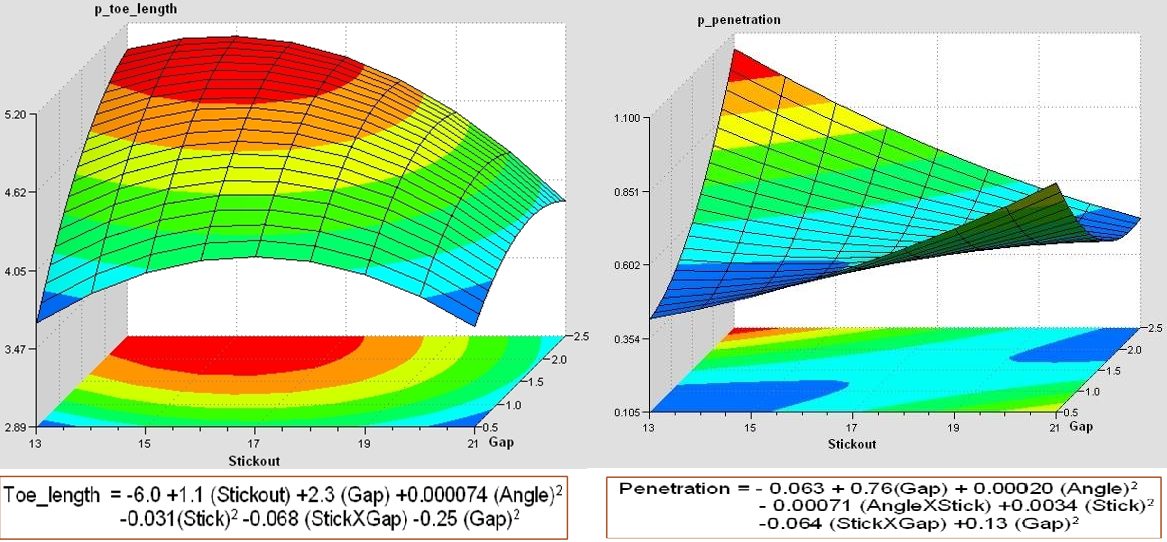

In hybrid welding process parameters such as stick out and torch angle are very important to decide overall joint performance. A model has been developed to predict the penetration and toe length under similar heat input conditions, shown in Figure 13. The gap, stickout and angle shows synergic agreement with penetration and toe length but the interactions among them can show disagreement.

Figure 13: Effects of toe length and penetration.T-10

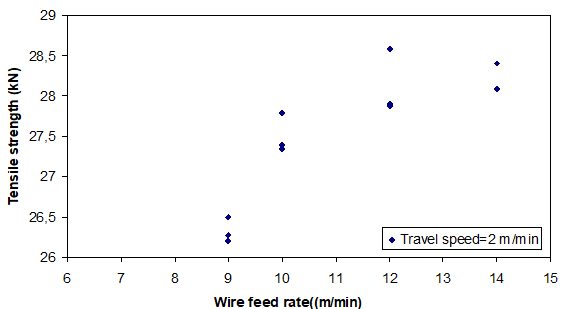

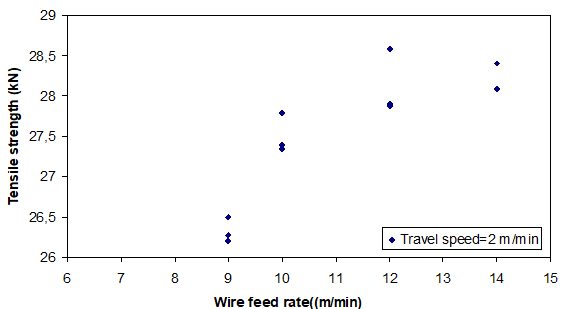

The weld joint strength increases with the increase in wire feed rate for a given laser power shown in Figure 14.

Figure 14: Wire feed rate versus tensile strength of hybrid laser and MIG welds.T-10

Back To Top

Adhesive Joining

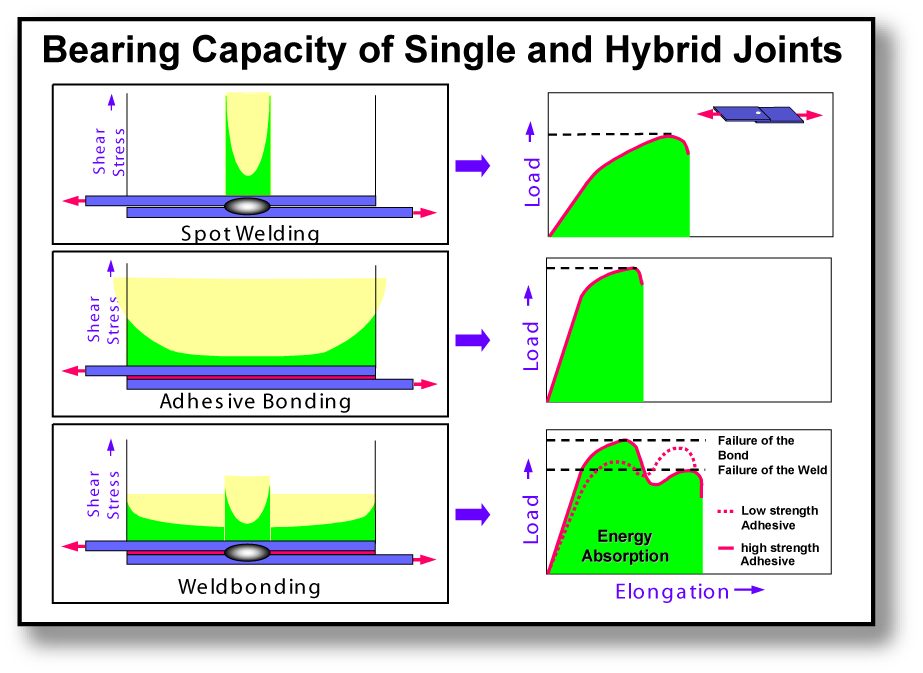

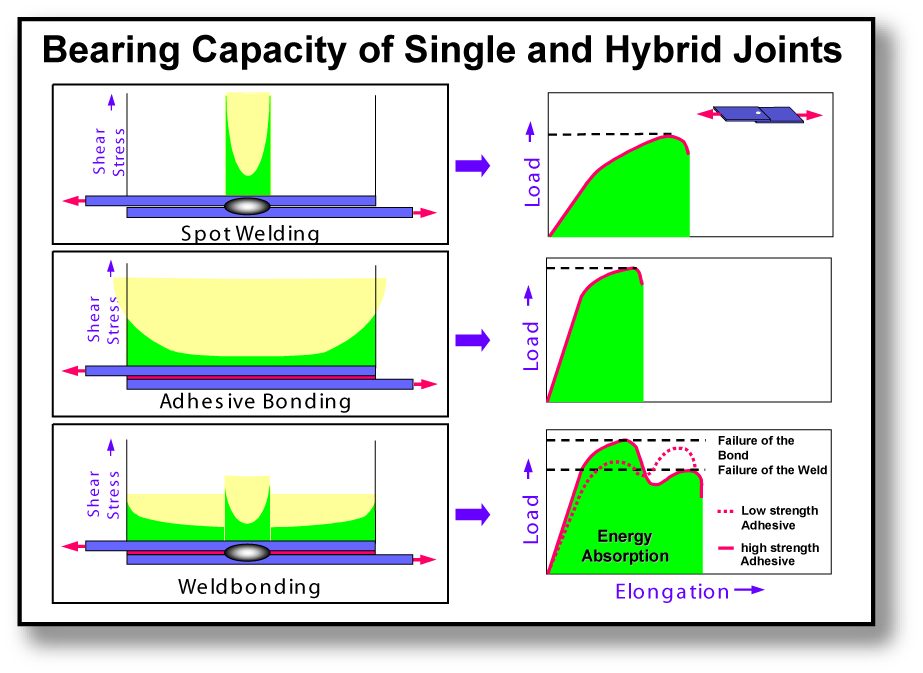

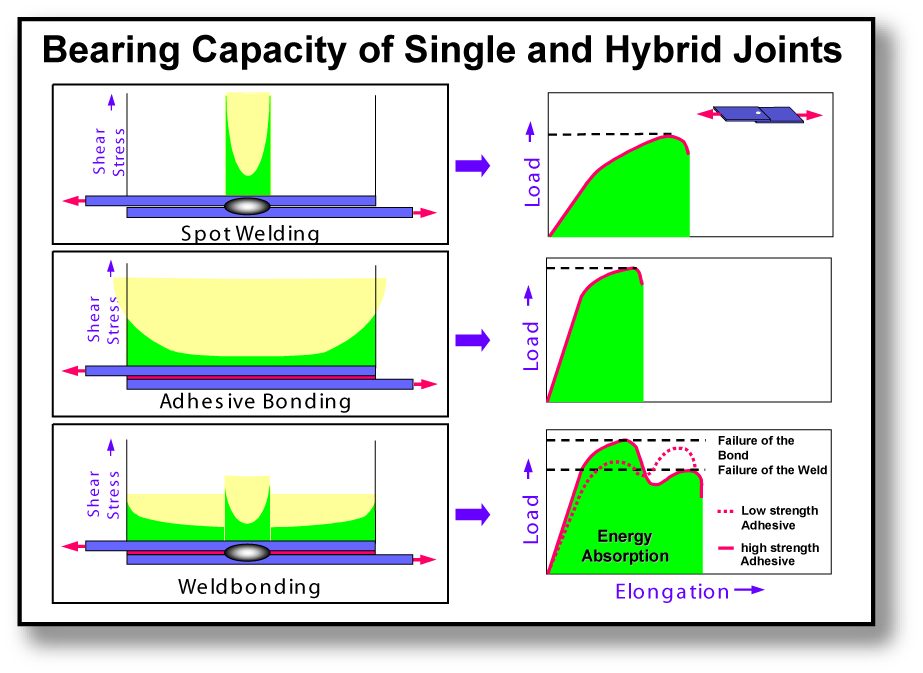

As with mild steels, AHSS-hybrid joints can be made by combining adhesive bonding with RSW, clinching, or self-piercing riveting. These hybrid joints result in higher strength values (static, fatigue, and crash) than the spot welding alone (Figure 1). If local deformation and buckling can be avoided during in-service applications of weld bonding/adhesive hybrid joining, the potential for component performance is enhanced.

Figure 1: Comparison of bearing capacity for single and hybrid Joints.B-3

Hybrid RSW and Adhesives

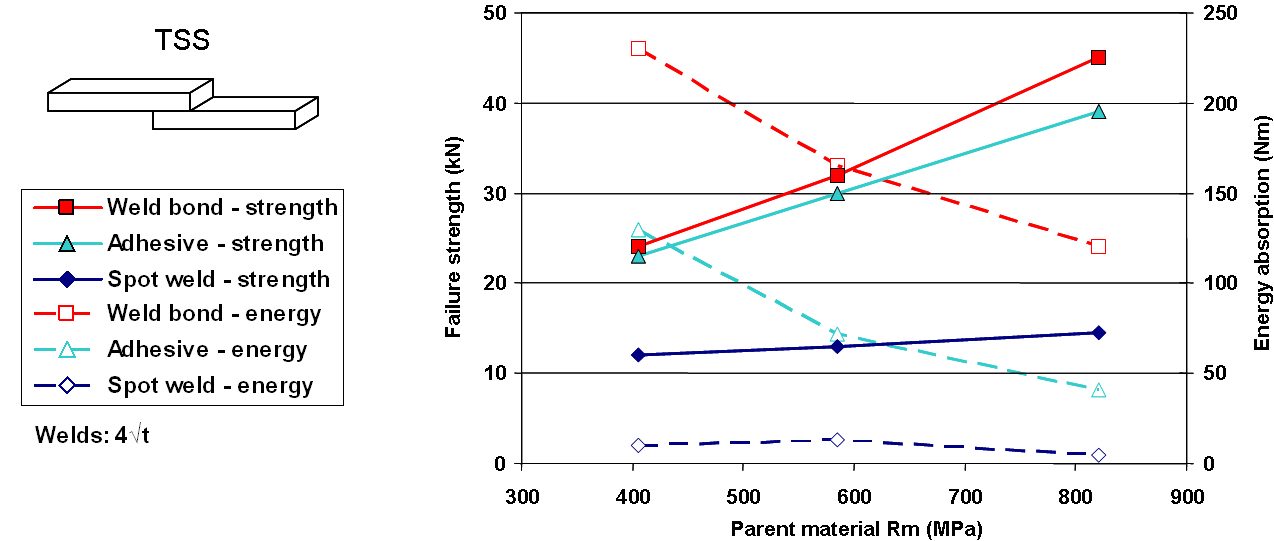

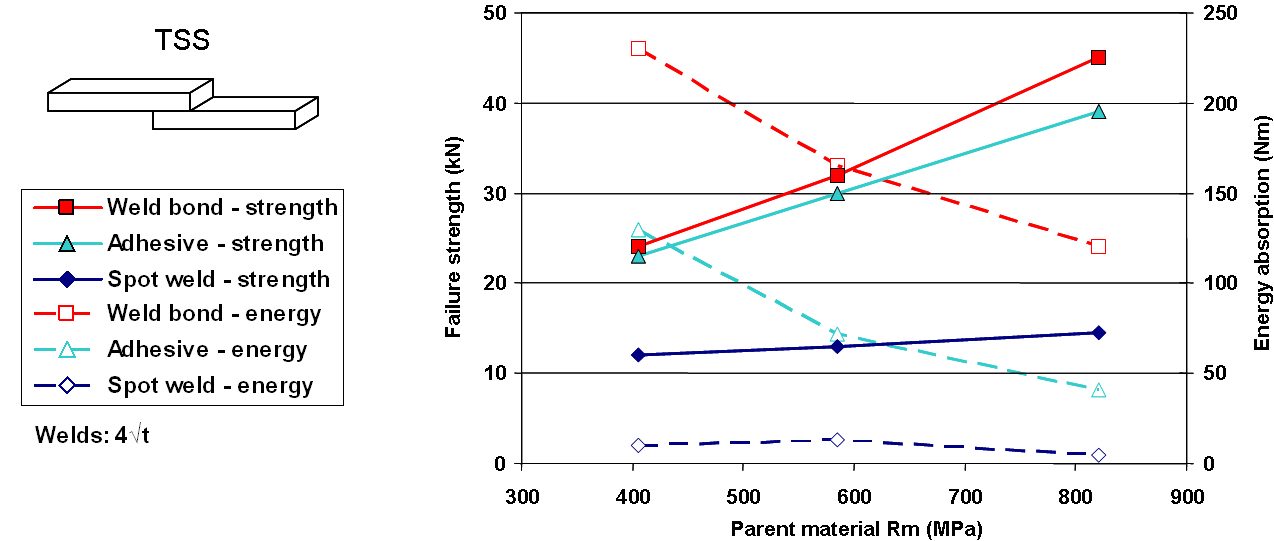

Many automotive joining BIW applications are using the combination of RSW together with adhesives to obtain superior joint performance. This combination is referred to as WB. Figure 2 shows a tensile shear test for resistance spot welds, adhesives, and weld bonds. There were trends of fracture strength increasing slightly with material strength with the spot welds. Also, the fracture strength was very high, increasing significantly with increasing material strength for adhesive bonds. The fracture strength was the highest for welded bonds and increased significantly with increasing material strength.

Figure 2: TSS failure strength and energy absorption for all joints and materials.T-10

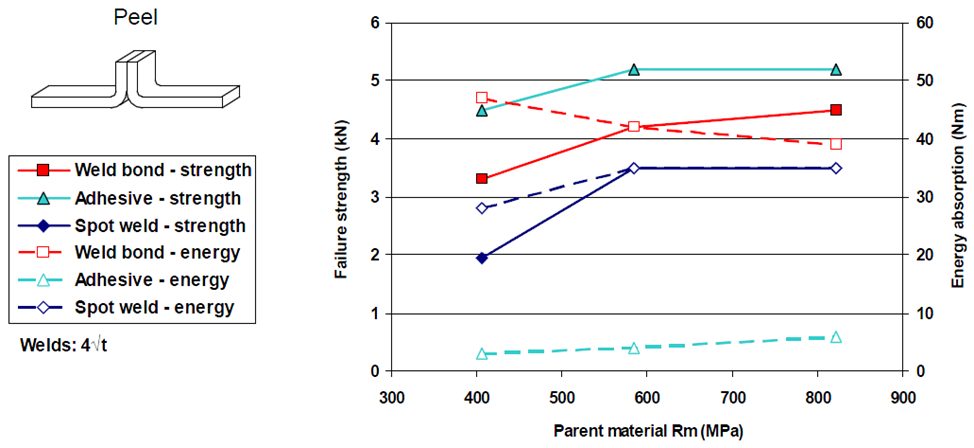

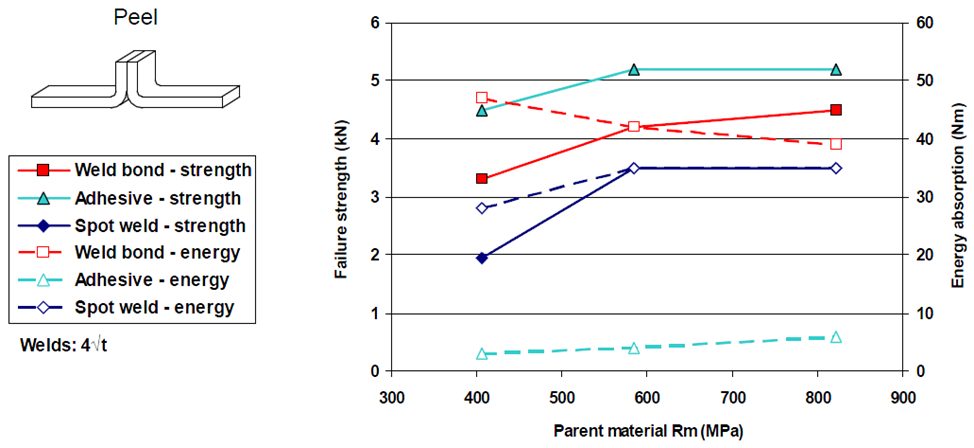

Figure 3 represents a peel test for the same samples. Trends observed were fracture strength increasing slightly with material strength but is lower than the other joining methods for spot welds. Fracture strength for adhesive bonding is greater than Weld Bonding (WB) and spot welding. Energy absorption was not very sensitive to material strength. The bond using adhesive alone had poor failure strength as well as poor energy absorption.

Figure 3: Peel strength data for all joint types.T-10

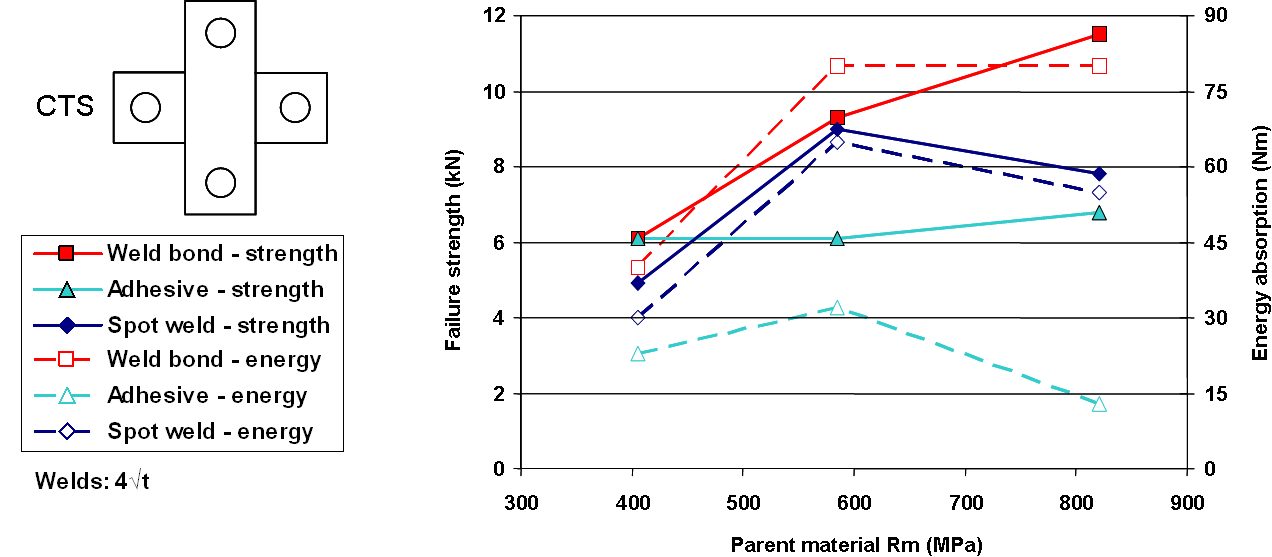

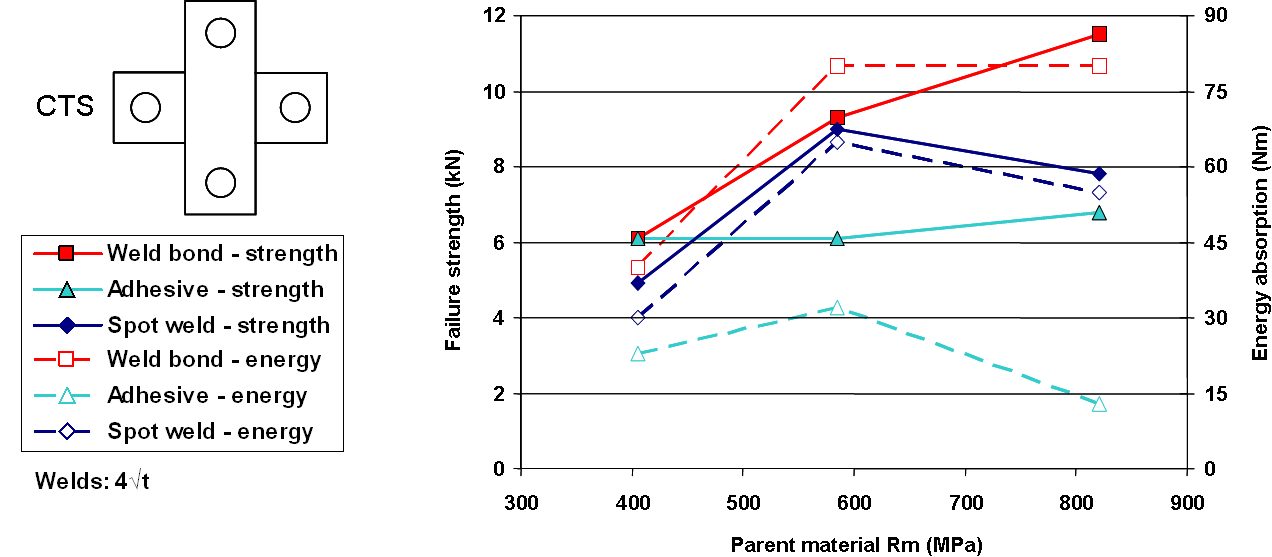

Figure 4 shows cross tensile results for the three samples. Spot welds showed fracture strength reaching a maximum for DP 600. Adhesive fracture strength increased slightly with increasing material strength. The welded bond’s fracture strength was greater than the other joint types and increased significantly with increasing material strength.

Figure 4: CTS fracture strength and energy absorption for all joints and materials.T-10

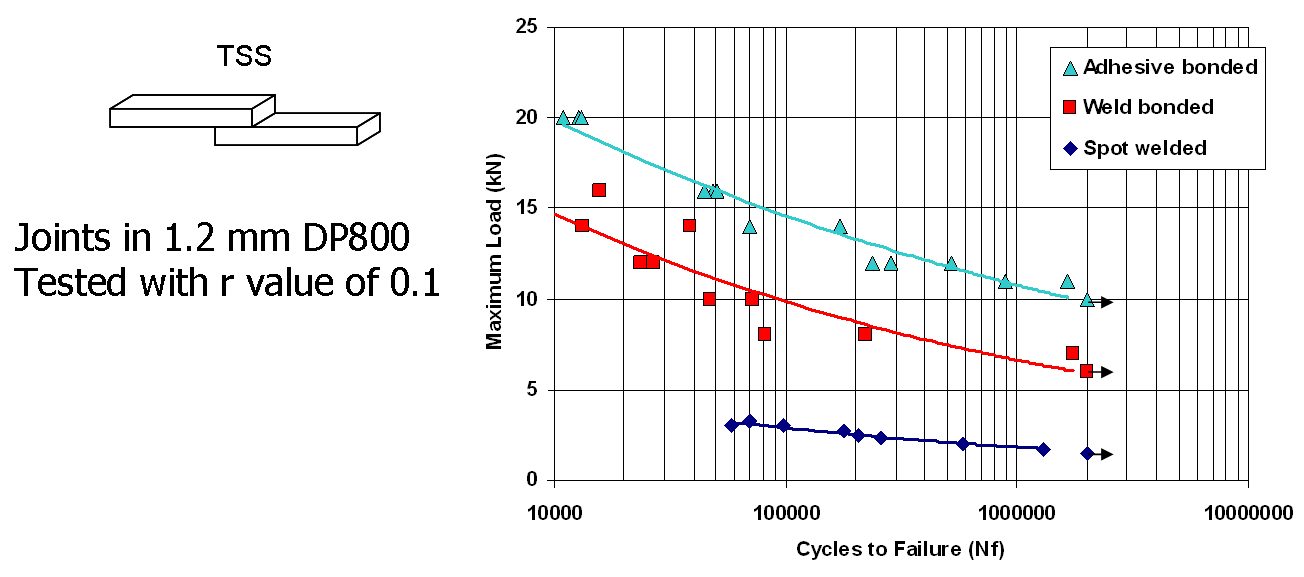

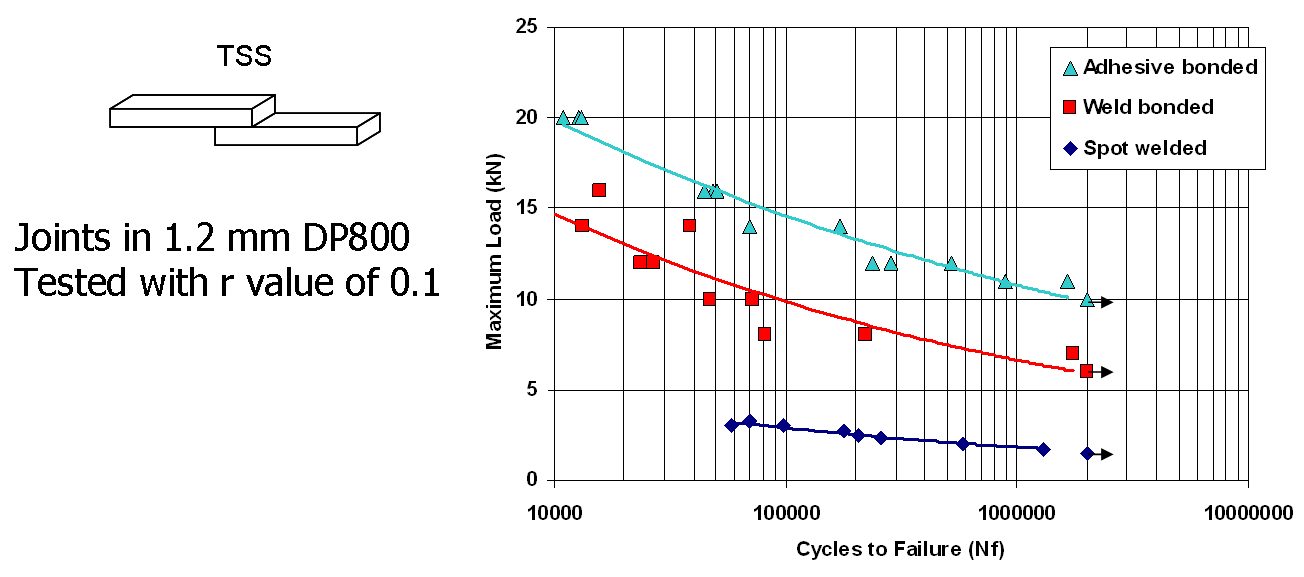

Figure 5 shows the fatigue testing performed in tensile shear mode on DP 800 [LINK TO DP steel page in Metallurgy] material (1.2-mm gage). Spot welds showed the lowest fatigue properties of the test samples. While the weld-bonded samples performed much better than conventional spot welds, they were still weaker than the adhesive joints. Adhesive had the best fatigue performance. The parent material properties had little influence upon the fatigue properties of spot welds because the spot weld itself acts as a fatigue crack initiator.

Figure 5: DP 800 fatigue results.T-10

Adhesive Joining

Fundamentals and Principles of Adhesive Joining

Adhesive bonding is a joining process for metals and non-metals that uses and adhesive or glue, typically in the form of a liquid or a paste. It offers the major advantage of being able to join a wide array of materials, but is limited by joint strength and applicable service conditions. Many of the fundamentals are similar to brazing and soldering, in particular the need for wetting and capillary action, and overlapping joint designs that rely on joint area for strength. Adhesives are categorized as thermosetting or thermoplastic. Thermosetting adhesives require a chemical reaction to cure and cannot be remelted once cured. They are the most common adhesives for structural applications. Thermoplastic adhesives soften when heated and harden when cooled, a process that can be continually repeated. They are generally not used for structural applications because of their poor mechanical properties (in particular, creep) and decomposition that can occur at relatively low temperatures.

Surface preparation is usually a very important and time-consuming step prior to applying the adhesive, and typically includes cleaning and deoxidizing procedures. Further steps may be taken such as the application of a coating. Adhesives may be applied a variety of ways, including caulking and spray guns, dipping, rollers, and brushes. Curing may be accelerated by heating or some other energy source. In addition to joining, adhesives may be used for many other reasons including sealing, electrical insulation, and sound suppression. Some of the larger users of adhesive bonding include the automotive, appliance, and electrical/electronics industry sectors.

Adhesive Joining Procedures

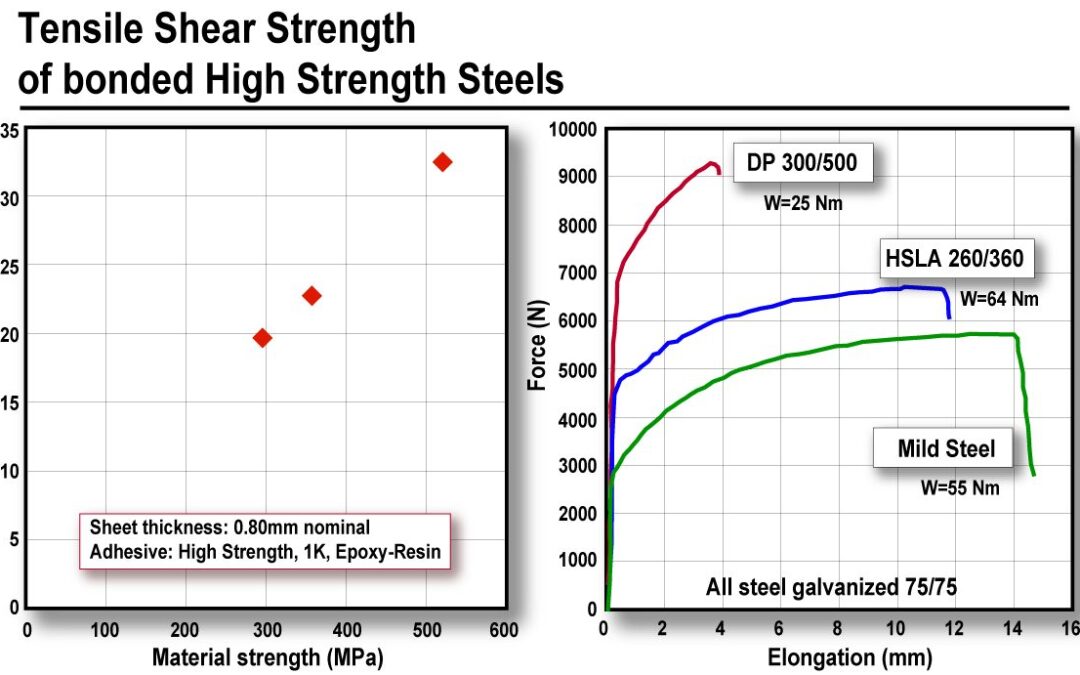

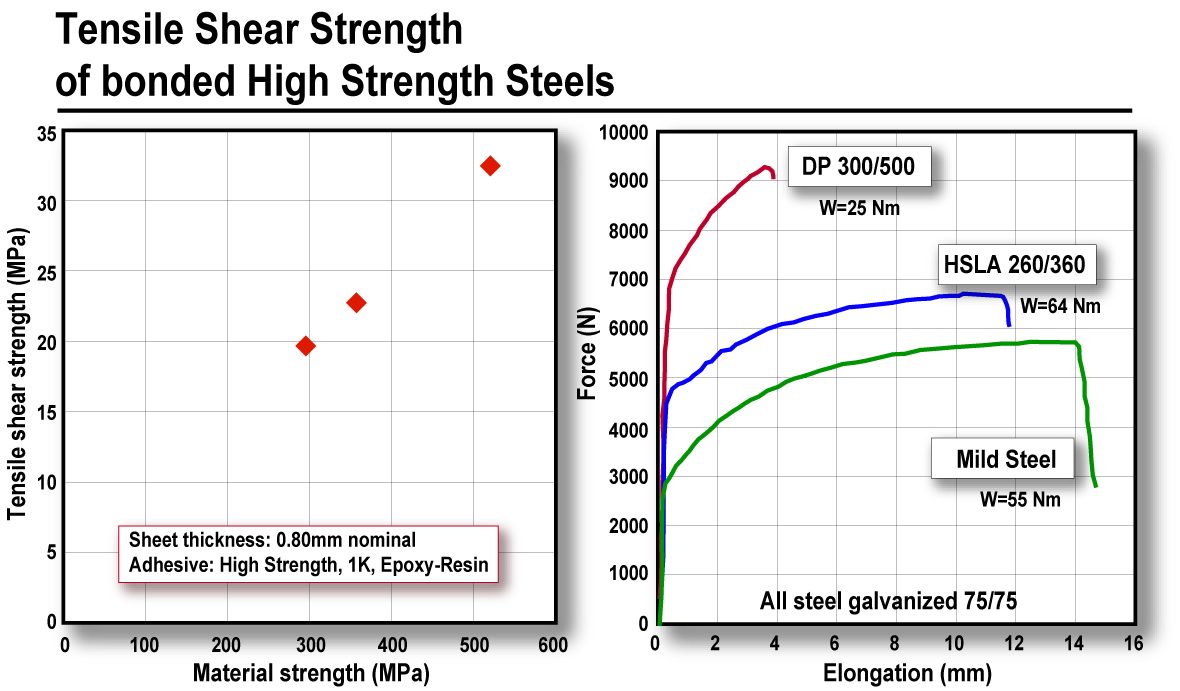

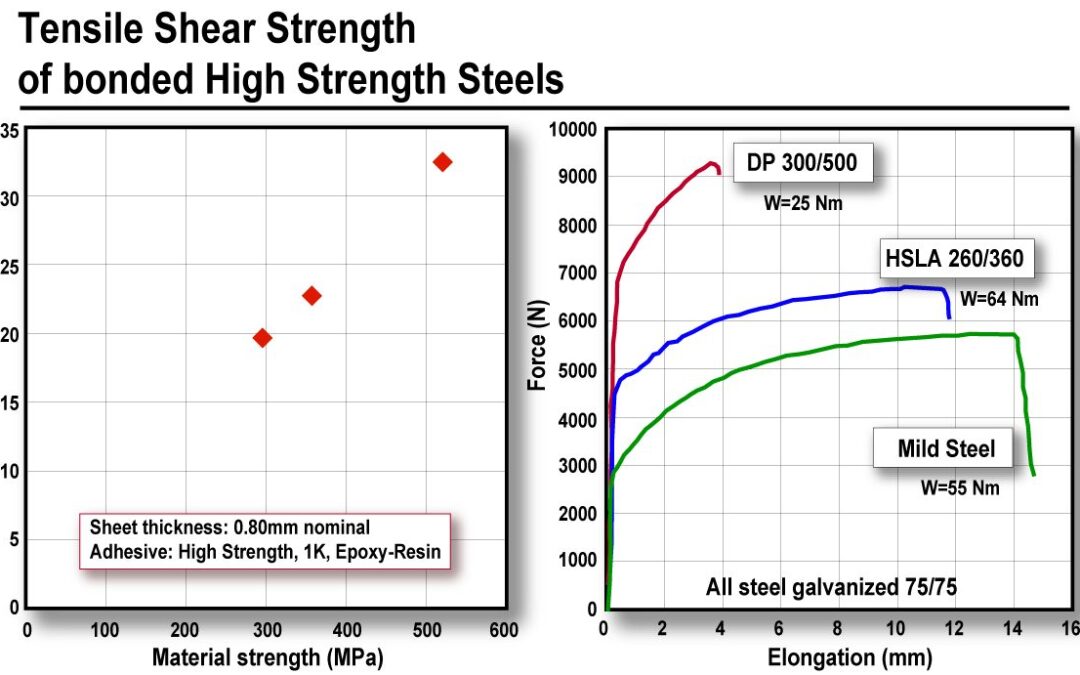

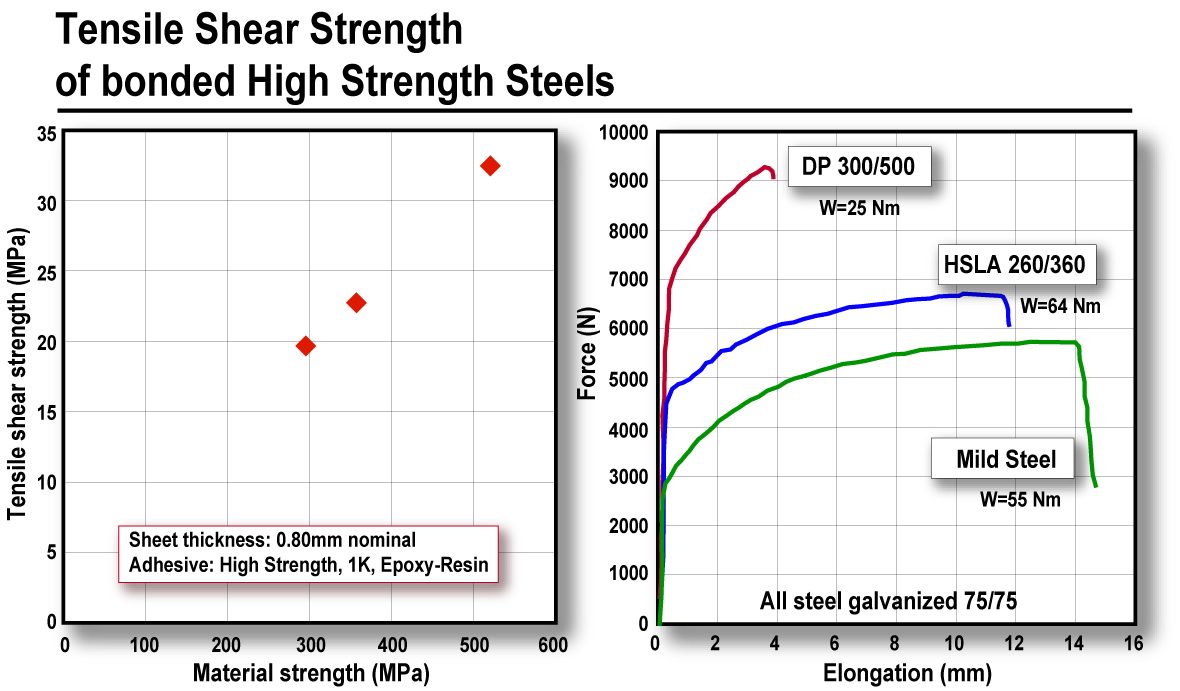

The bond strength of an adhesive is constant, and in design applications, is proportional to the area covered by the adhesive. The adhesive joint strength will be unchanged and analysis of the joint should be comprehensive. In general, the use of AHSS with high-strength structural adhesives will result in higher bond strength than for mild steel if the same sheet thickness is applied (Figure 1). Reduction of sheet thickness will decrease the strength because more peel load will occur. The true mechanical load in the component part must be considered. If higher joint strengths are needed, the overlapped area may be enlarged. Adhesives with even higher strength are under development.

Figure 1: Effect of material strength on bond strength (W is the integral of the force/elongation curve.B-2).

Joining of AHSS with adhesive bonding is a good method to improve stiffness and fatigue strength in comparison to other joining methods (spot welding, mechanical joining, arc welding, and laser welding). Due to the larger bonding area with adhesive bonding, the local stresses can be reduced and therefore the fatigue strength is increased. These improvements in stiffness and fatigue strength are important factors to consider at the design stage, especially in those cases when AHSS is used to decrease the weight of a component.

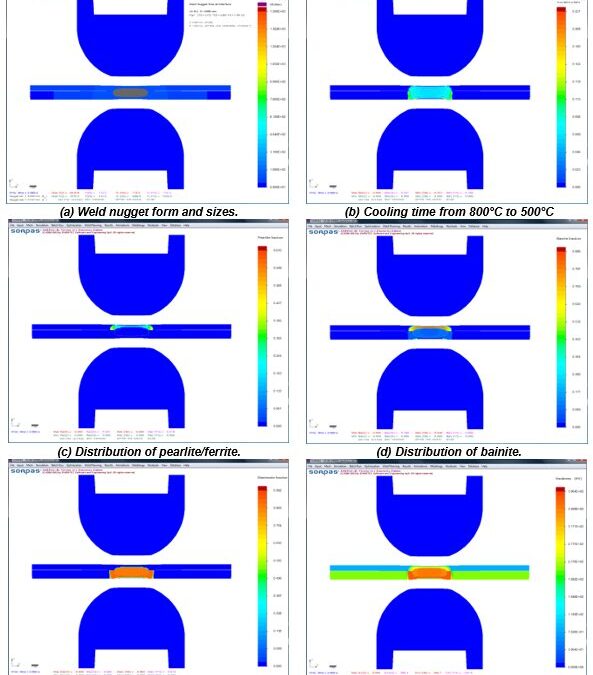

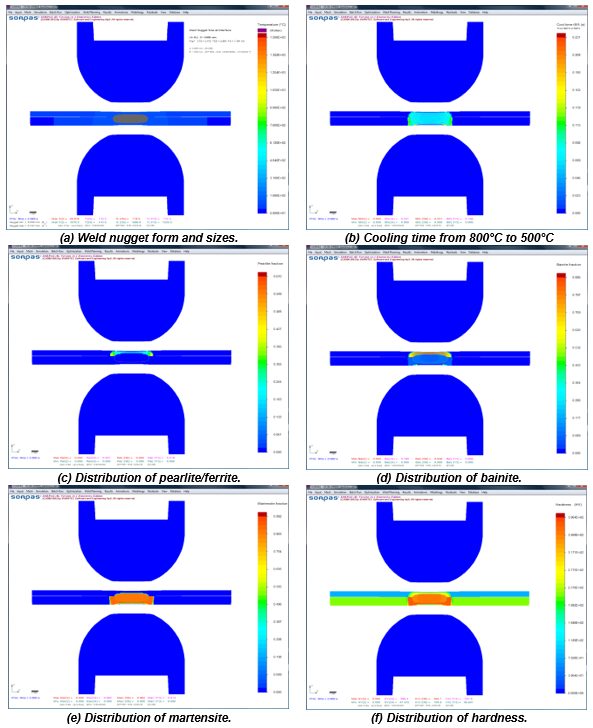

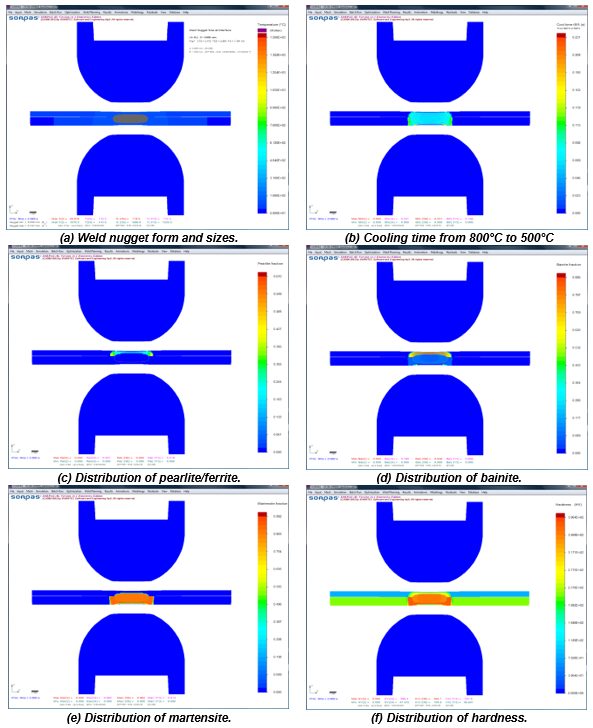

RSW Modelling and Performance

The advantages of numerical simulations for resistance welding are obvious for saving time and reducing costs in product developments and process optimizations. Today’s modeling techniques can predict temperature, microstructure, stress, and hardness distribution in the weld and Heat Affected Zone (HAZ) after welding. Commercial modeling software is available which considers material type, various current modes, machine characteristics, electrode geometry, etc. An example of process simulation results for spot welding of 0.8-mm DC 06 low-carbon steel to 1.2-mm DP 600 steel is shown in Figure 1. Obviously, this technique can apply to dissimilar thicknesses, material types, and geometries. Application of adhesives is also being used with these simulations. This simulation techniques are found to be very beneficial to predict vehicle crashworthiness as it can dramatically reduce the cost of crash evaluations.

You will find several articles in this section describing RSW modelling studies and procedures.

Figure 1: Simulation results with microstructures and hardness distribution for spot welding of 0.8-mm DC06 low-carbon steel to 1.2-mm DP 600 steel.Z-1