Joining, Projection Welding

As with resistance spot welding in automotive applications, projection welding also is used to join two overlapping sheets of relatively thin metal. The process involves pressing a projection or number of projections in one of the plates and welding the two plates together at the projection locations.

The method can also be used for welding metal sheet to the ends of bars, rods or pipes, or for welding bolts, nuts, and other attachments to sheets. Such attachments are being used widely in the automotive industry. Wire grids (i.e. the crossing points of the wires) are also particularly suitable for projection welding (it is also called cross wire welding).

A modern car body may contains some 300 welded and punched fasteners, such as bolts, nuts, and studs. The quality of the attachment of these fasteners to the stamped body components is critical for the final product’s safety and reliability. Crucial components such as the front and rear axles are mounted to such fasteners, the seat belts and steering column are anchored to them, and they provide grounding for electrical wires.L-25

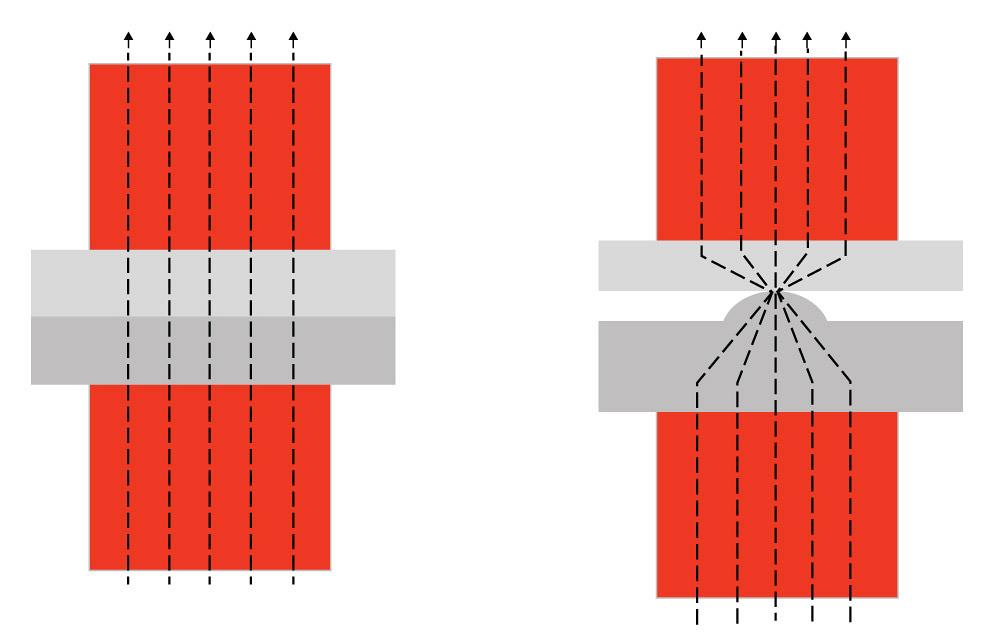

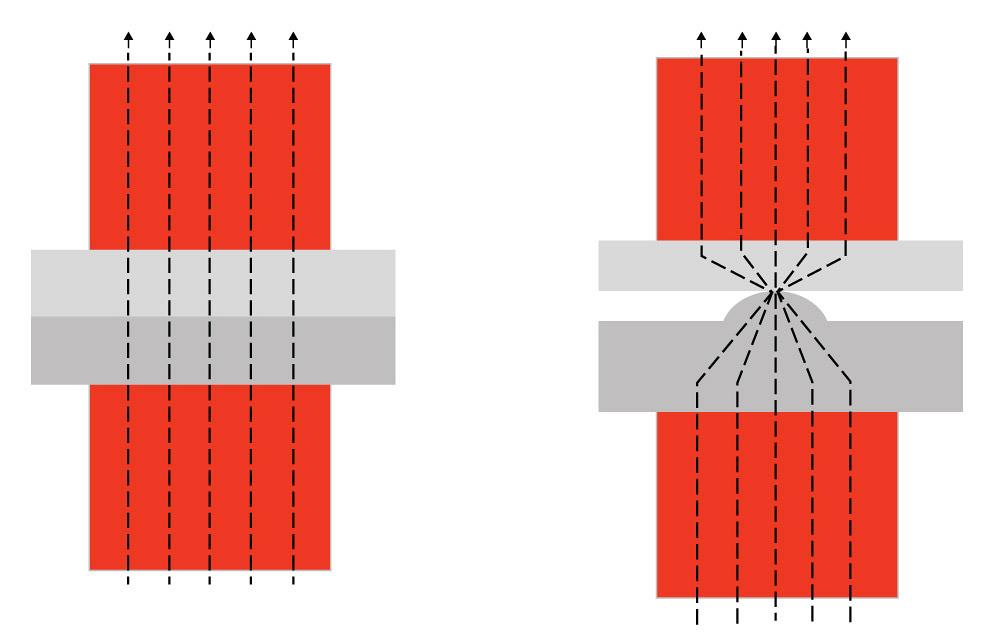

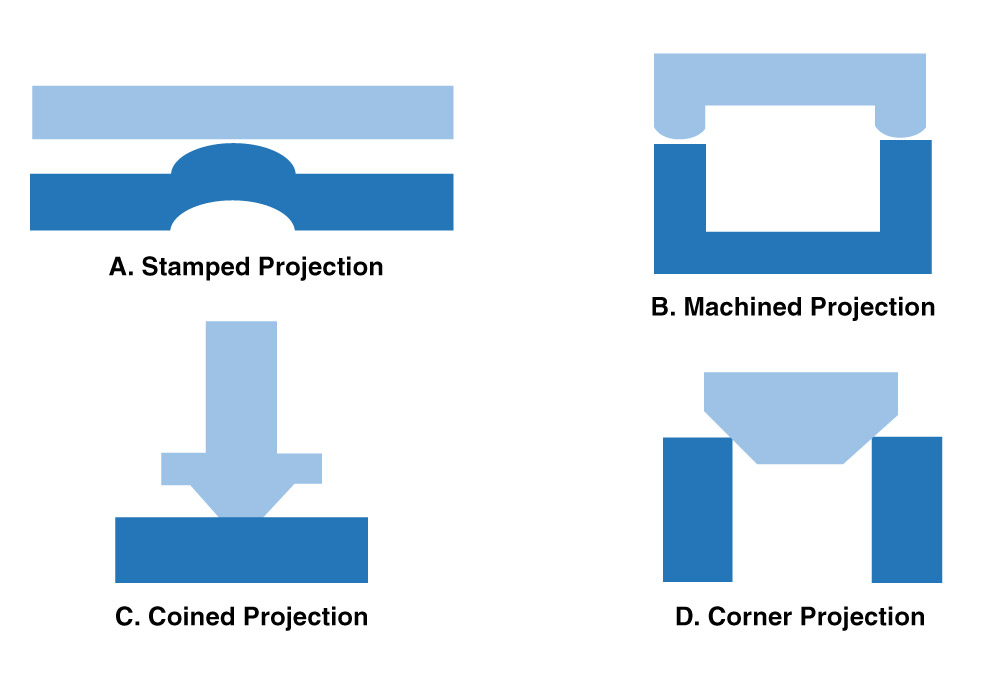

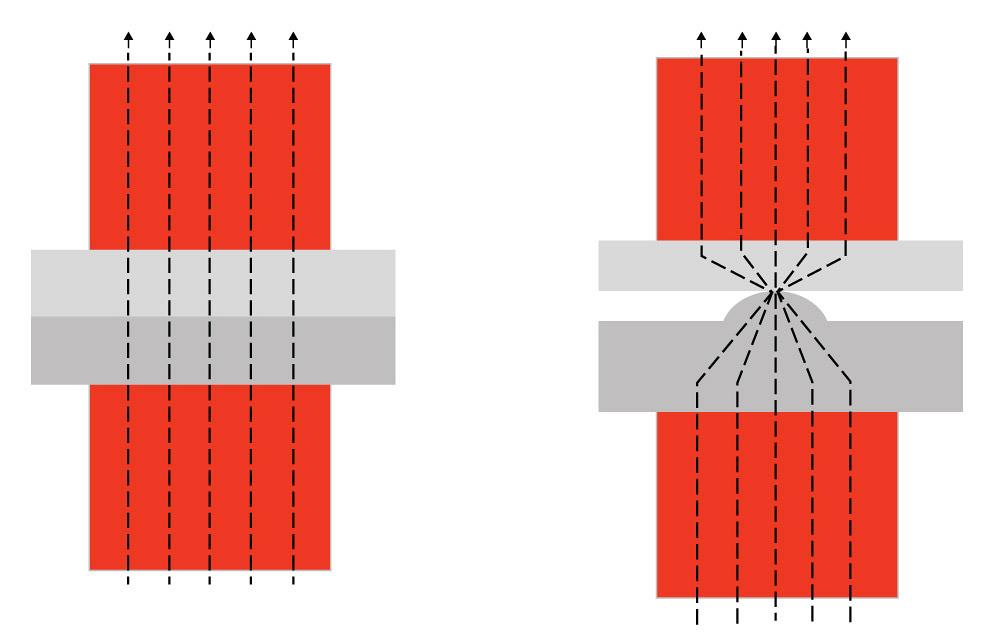

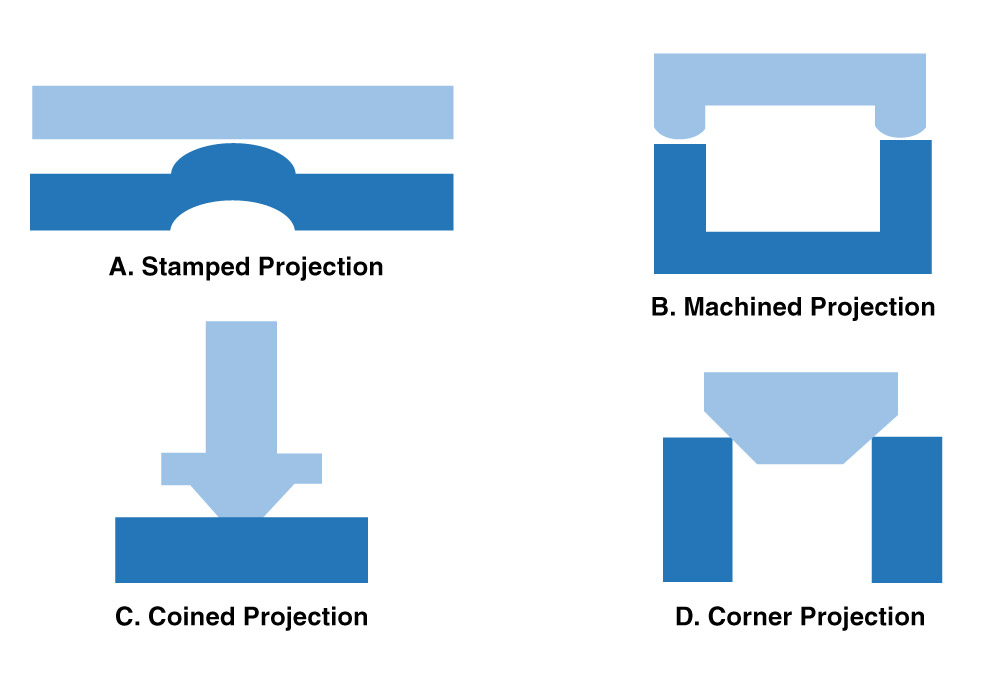

As noted, projection welding is similar to resistance spot welding. However, in the Resistance Spot Welding process, the size of the contact surface of the electrode cap tip determines the current flow, whereas in projection welding, the current flow is constricted to the embossed or machined projection as shown in Figure 1. Both AC and DC power sources are suitable for fastener welding. The heat balance for projection welding is affected by the following factorsA-11:

- Projection design and location

- Thickness of the sheet to which the fastener is attached

- Thermal and electrical conductivities of the metals being welded

- Heating rate

- Electrode alloy type

As compared to Resistance Spot and Seam Welding, Resistance Projection Welding is capable of welding much thicker parts, as well as parts with a significant thickness mismatch. As a result, it is often considered as a potential replacement for arc welding processes such as GMAW. One of the reasons for this is the drastic reduction in welding time that can be achieved. For example, a typical automotive part that might require several minutes or more of welding with the GMAW process may have the potential to be welded in less than a few seconds with the Resistance Projection Welding process. This is because the entire weld or multiple welds can be made at the same time in a single fixture. Another advantage of the process, relative to spot welding, is that there is less wear and tear on the electrodes.

Different types of projections made by different methods are shown in Figure 2. It is important to note that the types of projections that are extensions of the part are known as solid projections (2-B and 2-D) and can only be produced by a machining or forging process, whereas the other projections are more easily produced by stamping with a punch and die. Projections produced with a punch and die usually involve the formation of a molten nugget during welding but not always. The solid projection designs mostly result in solid‐state welds that occur via a forging action as the projection is heated and pressure applied. A common Projection Welding application that uses solid projections involves the attachment of a wide variety of nuts, bolts, and fasteners. Many fasteners used on automobiles are attached this way.

Figure 1: Welding current flow concentration due to projection geometry.

Figure 2: Typical projection types and designs.

Solid State Welding Steel to Aluminium

Introduction

Multi material design approach is the most common trend being followed by various industries including the automotive and aerospace industry. The main motive behind the concept is to attain weight reduction and increase the overall efficiency of the system.G-13 Once such desirable combination in the automotive industry is aluminum and steel. Resistance spot welding is one of the most common method used for the joining of aluminum and steel, however, is associated with challenges due to differences in physical properties, mechanical properties, and metallurgical incompatibilities. The inherent aluminum oxide layer creates uncertainties during the process and reduce the electrode life.P-10 Recent trends have shown an increase in the usage of the solid-state processes to attain better weldability between aluminum and steel. Solid state joining processes can be classified into two main categories i.e. mechanical joining processes and solid-state welding.

Mechanical joining involves clinching, clinch riveting, hemming and seaming, blind riveting, self-pierce riveting (SPR), solid pouch riveting, high speed tacking and flow drill screws. Joining is attained via plastic deformation at room temperature. The main advantages of mechanical joining processes involve high tool life, simple equipment, and relative shorter process time. Drawbacks include access required from both sides, bulge and indents, and relatively high amounts of force required during the process.

Solid state welding (SSW) consists of joining processes in which coalescence is attained via pressure or combination of pressure and heat. The peak temperature during the solid-state welding process remains below the melting point and mostly no filler material is required. SSW includes ultrasonic welding, friction welding, and diffusion bonding.

Mechanical Joining

Clinching

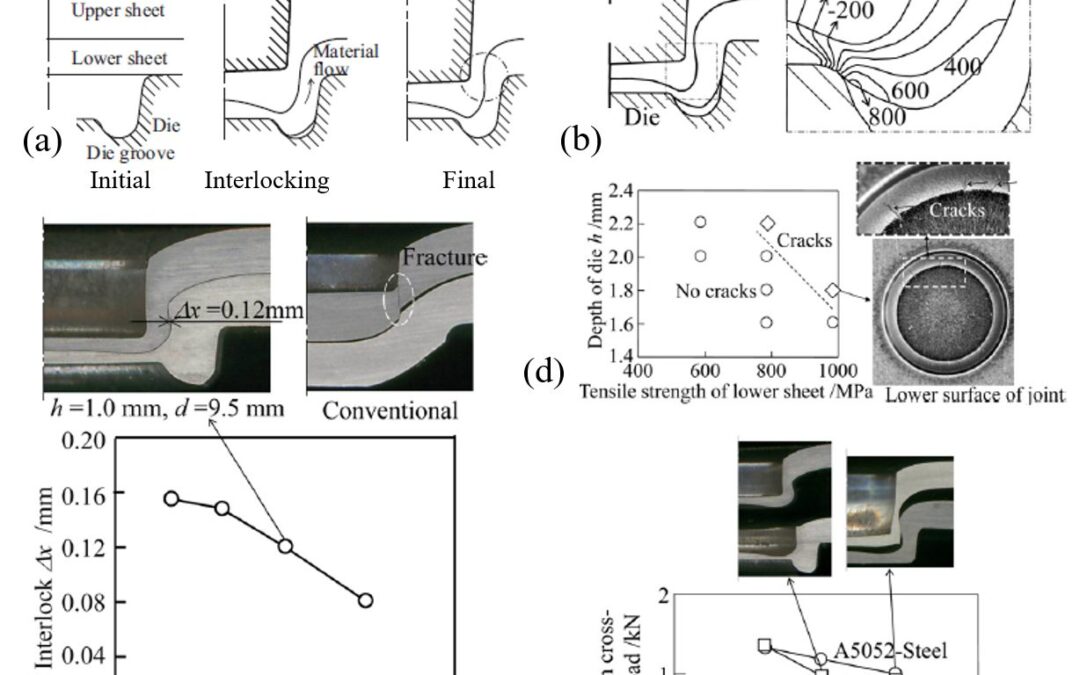

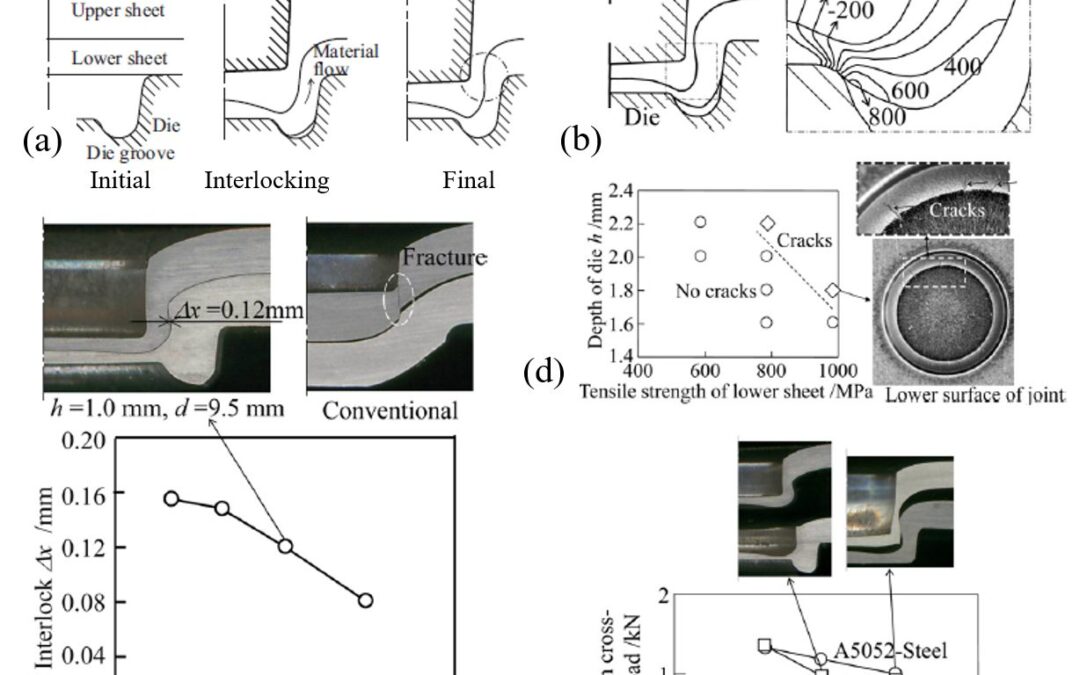

Clinching is a local hemming process that includes offsetting, upsetting and flow pressing. In a work carried out by Abe and coworkers, machinal clinching process is investigated for the joining between aluminum and sheets.A-34 Punch and dies with various depths were used to control the material flow and interlocking distance. The main objective was to attain mechanical interlocking without rupture in the sheets. Figure 1a shows the clinching process steps and Figure 1b shows the stress distribution of the formed joint after the clinching process. Figure 1c shows the relationship between interlocking distance and tensile strength of the sheets. Higher strength steel sheets have shown less interlocking due to more resistance to deformation. At higher tool depth the cracks can be seen in the bottom sheets due to excessive plastic deformation (Figure 1d). For all the tests between aluminum and steels, joint was fractured on the aluminum side. Higher strength steels sheets have shown lower cross tension strength due to reduction in the interlocking. Cracks formed during the process can be minimized by eliminating the groove of the die.

Figure 1: (a) Joining of sheets by mechanical clinching. (b) calculated hydrostatic stress. (c) Relationship between interlock and tensile strength of upper high strength steel obtained from experiment. (d) Occurrence of cracks for lower high strength steel sheets obtained from experiment for d = 8 mm. (e) Maximum load measured from cross-tension test of joined high strength steel and aluminum alloy sheets.A-34

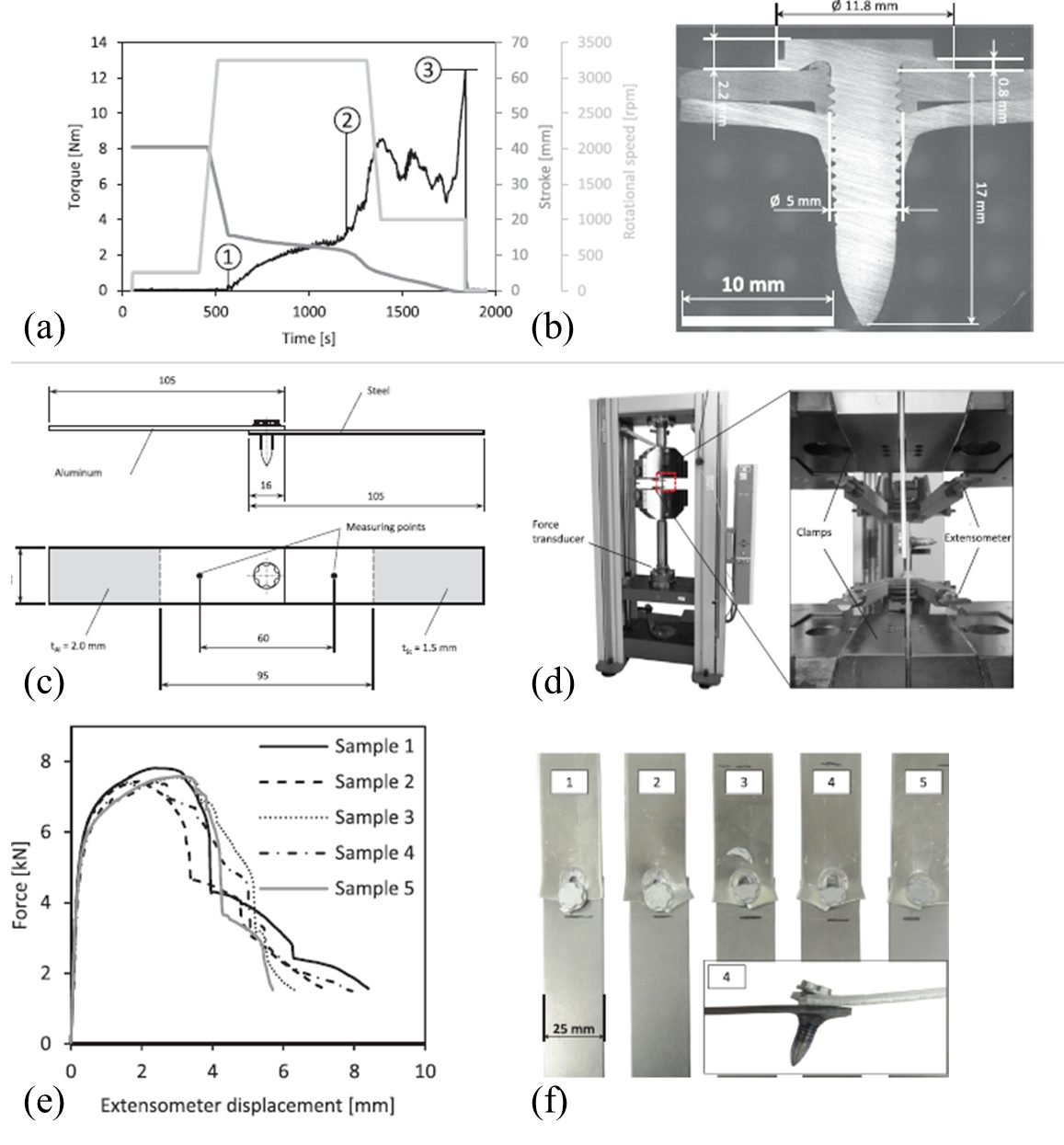

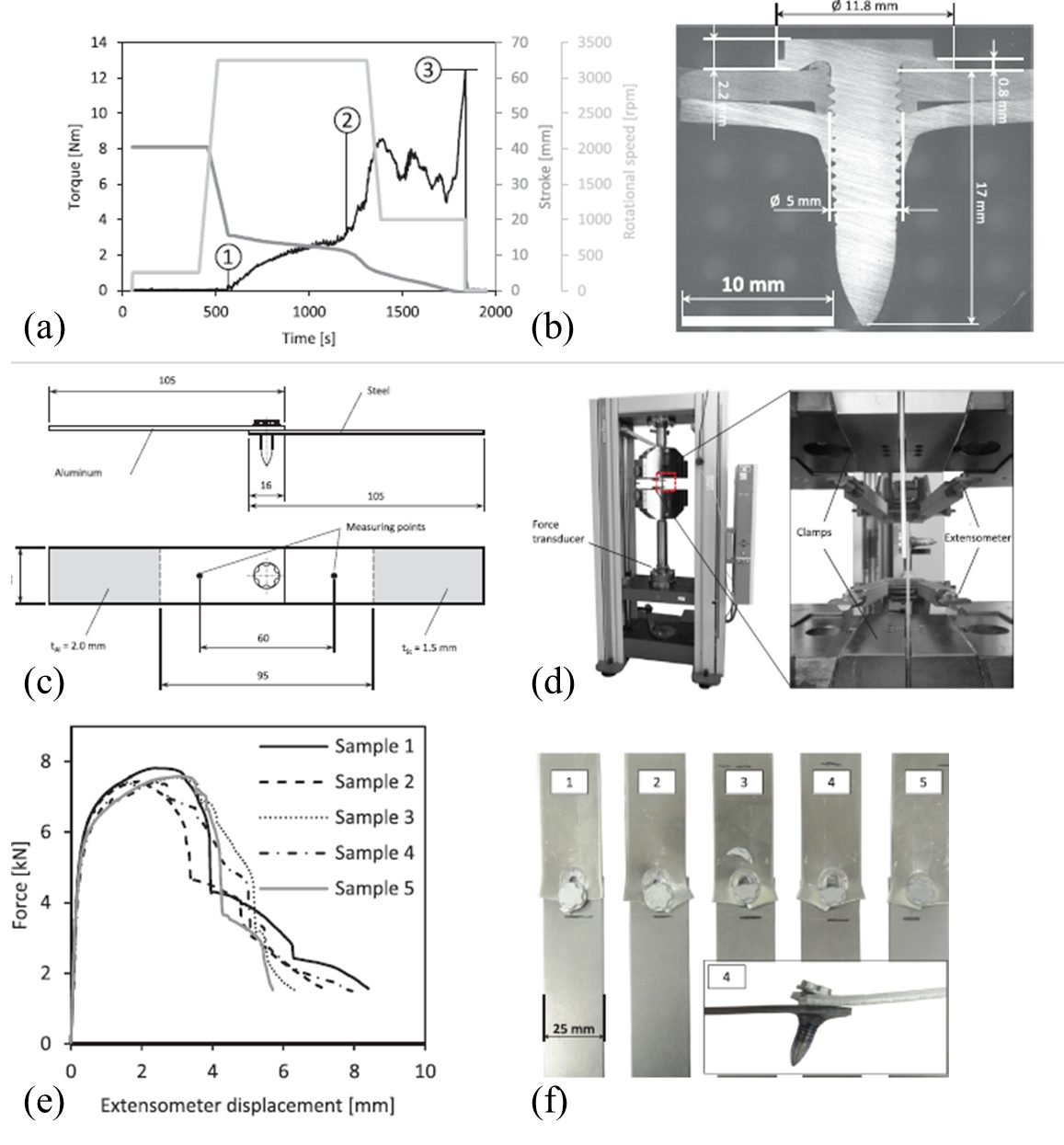

Self-Pierce Riveting

Self-pierce riveting (SPR) is a cold joining process in which two or more sheets are joined via inserting rivet from the top sheets towards bottom sheets and is locked by a die shape. It is one of the most widely used mechanical joining process for the dissimilar materials combination i.e. steel and aluminum. Main advantages include no predrilled holes, no spark, no fumes, and no surface treatment. It comprises of four stages clamping, piercing, flaring, and releasing as shown in Figure 2 (a & b). Figure 2c shows the semi tubular and full tubular rivet through the multi materials stacks. The use of tubular or semi tubular rivet depends upon the material stacks combination. Steel rivets have shown higher mechanical strength compared to aluminum rivets (Figure 2d). The right half of the Figure 2e shows possible defects occur during riveting process.

![Figure 2: (a) A schematic diagram of the four stages of a SPR process, L-16 (b) A typical four-stage force–displacement curve of an SPR process, L-16 (c) Thick stacks with a semitubular SPR rivet and a fully tubular SPR rivet, L-16 (d) Comparison of the single-joint strength between aluminum rivets and a steel rivet with combined shearing and pull-out loading with loading angle α = 45°, H-11 (e) SPR joint quality and some faults [4]& (f) The displacement-load curves of the joints with different stack orientations. S-31](https://ahssinsights.org/wp-content/uploads/2020/09/image003.jpg)

Figure 2: (a) A schematic diagram of the four stages of a SPR process,L-16 (b) A typical four-stage force–displacement curve of an SPR process,L-16 (c) Thick stacks with a semitubular SPR rivet and a fully tubular SPR rivet,L-16 (d) Comparison of the single-joint strength between aluminum rivets and a steel rivet with combined shearing and pull-out loading with loading angle α = 45°,H-11 (e) SPR joint quality and some faults,L-16 and (f) The displacement-load curves of the joints with different stack orientations.S-31

Three main aspects are considered to determine the joint quality i.e. rivet head height, interlock distance and minimum remaining bottom material. Han et al. H-12 concluded that lower head height could result in higher interlocking distance for joining aluminum and steel alloys. Sun et al. S-31 has evaluated different stack configuration for the 5128O aluminum alloy with the HSLA 1350 alloys as shown in Figure 2f. It was concluded in the study that high strength materials such as HSLA 1350 should be on the tail side as it promotes sufficient interlocking especially when it comes to join thicker sheets (>3 mm).

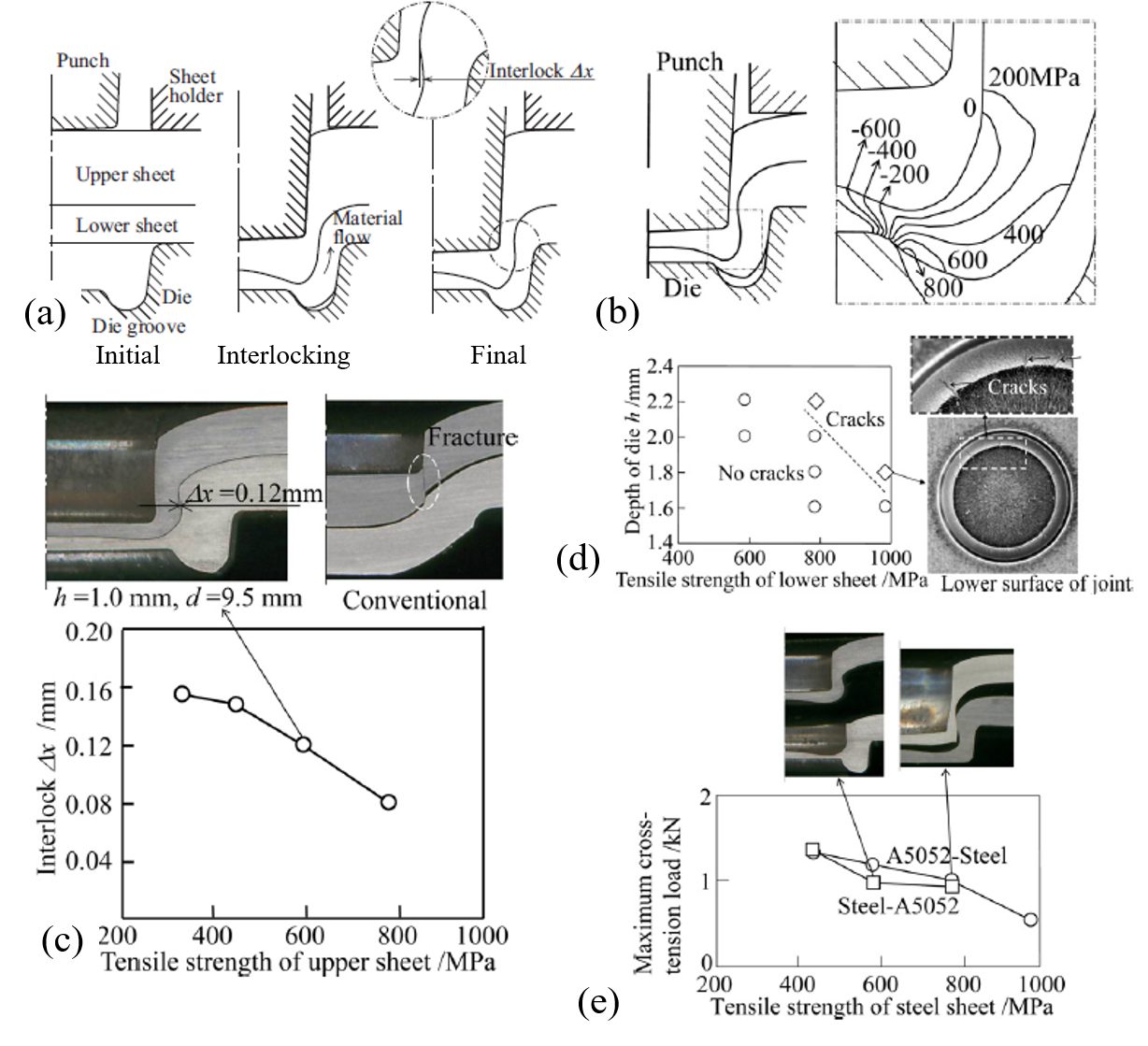

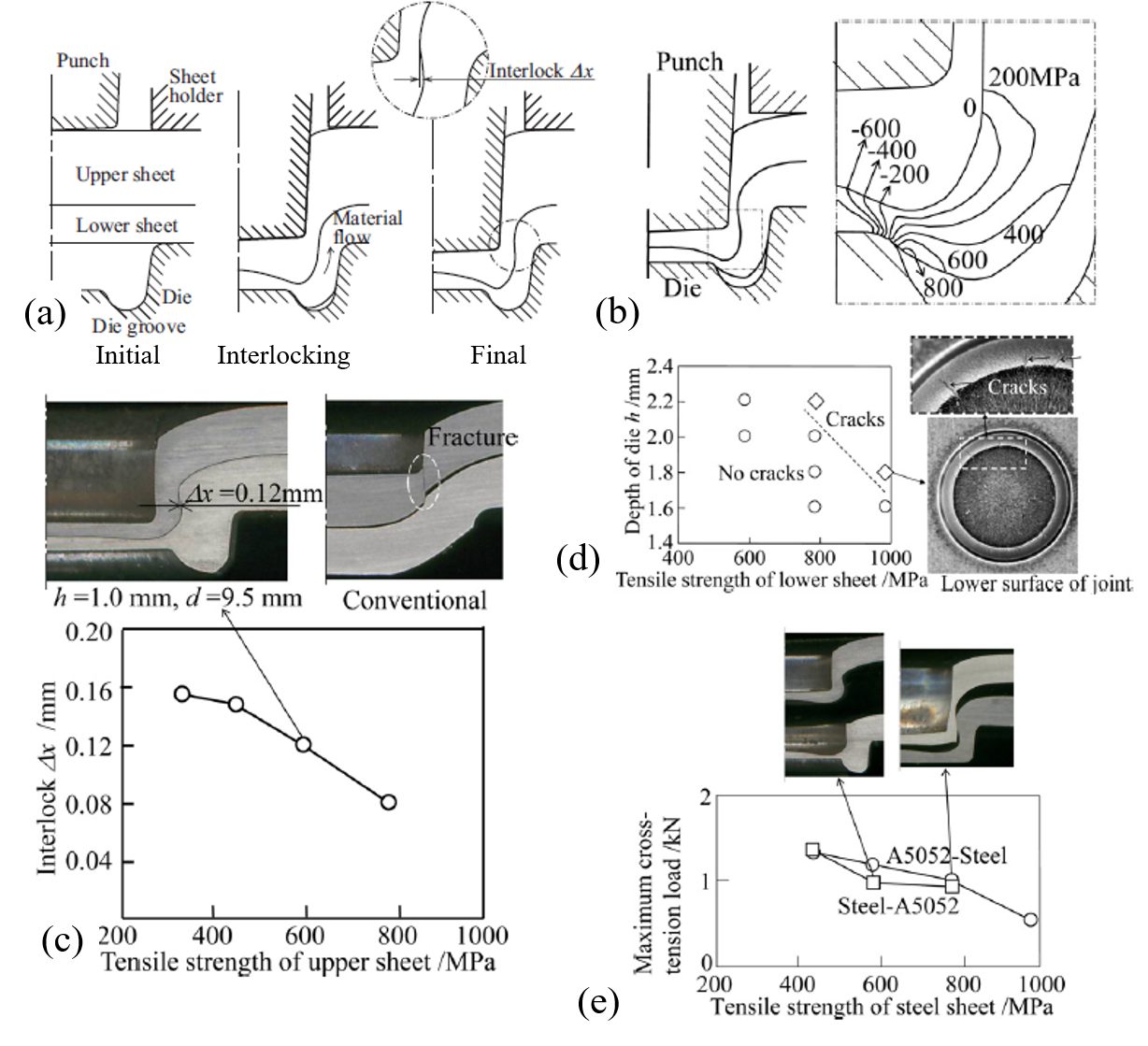

Flow Drill Screw Process

Flow drill screw process is a thermomechanical joining process, combining friction drilling and thread forming process. During the process, screws act as fasteners, drilling and tapping tools. A main advantage is that only single sided access is required for flow drill screw (FDS) process. FDS can be used with or without drilling the hole depending upon the screw material and stack materials.

Figure 3: Joining parameters and cross section of single-lap shear specimen. (a) Relevant screwing parameters over time (representative example): start of warming up and penetration of the substrate material, beginning of thread forming, tightening torque. (b) Cross-section of connection with nominal dimensions. Static single-lap shear test of an aluminum-steel flow drill connection. (c) Geometry of specimen. (d) Experimental setup. (e) Force-displacement curves. (f) Fracture appearance.G-15

Graff and coworkers have evaluated the flow stress during FDS process between aluminum and steel.G-15 A 5083H111 aluminum alloy and HC340LA micro alloyed steel were used in this study. Figure 3a shows the experimental parameters and Figure 3b shows the cross section of the formed joint. Samples were fractured in the aluminum side each time with the peak failure load of 7 kN.

Solid State Welding, Steel to Aluminium

Ultrasonic Welding

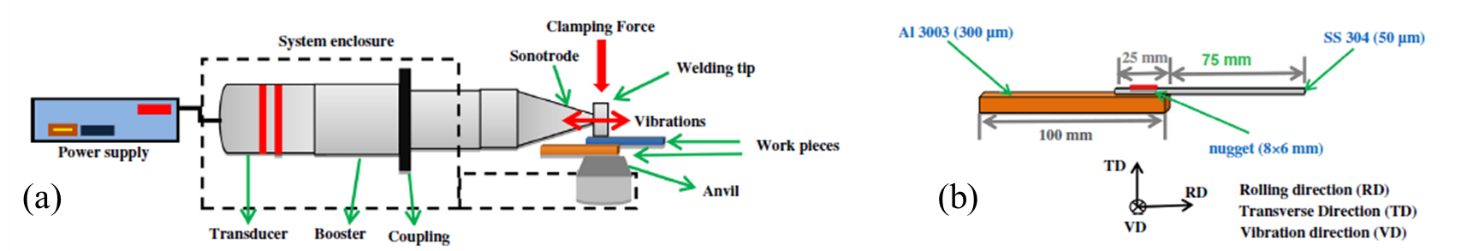

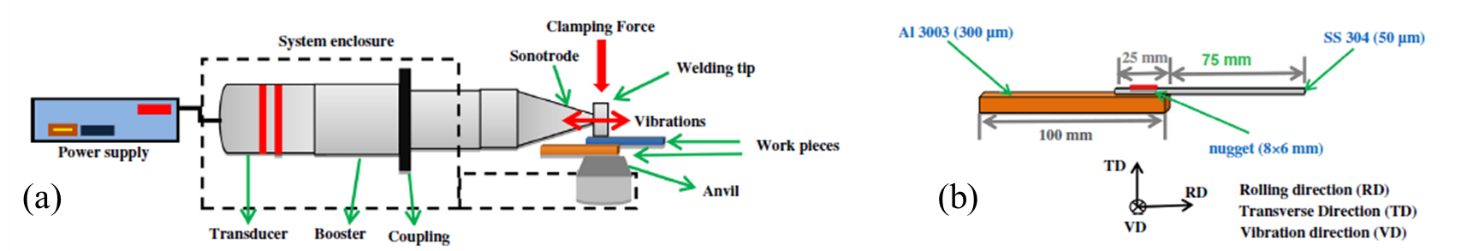

In ultrasonic metal welding process, joining is achieved via shear motion at the faying surfaces of the materials to be joined. It is combination of friction and cold pressure welding. This process is more ideal in joining thinner sheets of aluminum and steel. In a technical report published by Shakil and coworkers, ultrasonic metal welding between 3003 Al alloy (thickness 50 µm) and 304 stainless steel (thickness 300 µm) was evaluated.S-32 Figure 4 shows the schematics of their ultrasonic metal welding process. In this work, a 2.4 kW lateral drive ultrasonic welder with a welding tip of 8 x 6 mm and 25 mm overlapping between the sheets without any surface preparation was utilized. Welding energy was varied between 75 J and 200 J and clamping force of 30, 40, 50, and 60 psi was utilized. It is shown in the studies that increase in the clamping force decreases the weld time. It is attributed to more heat generation due to increased sliding resistance.

Figure 4: (a) Schematic diagram of lateral derive system. (b) Weld sample geometry.S-32

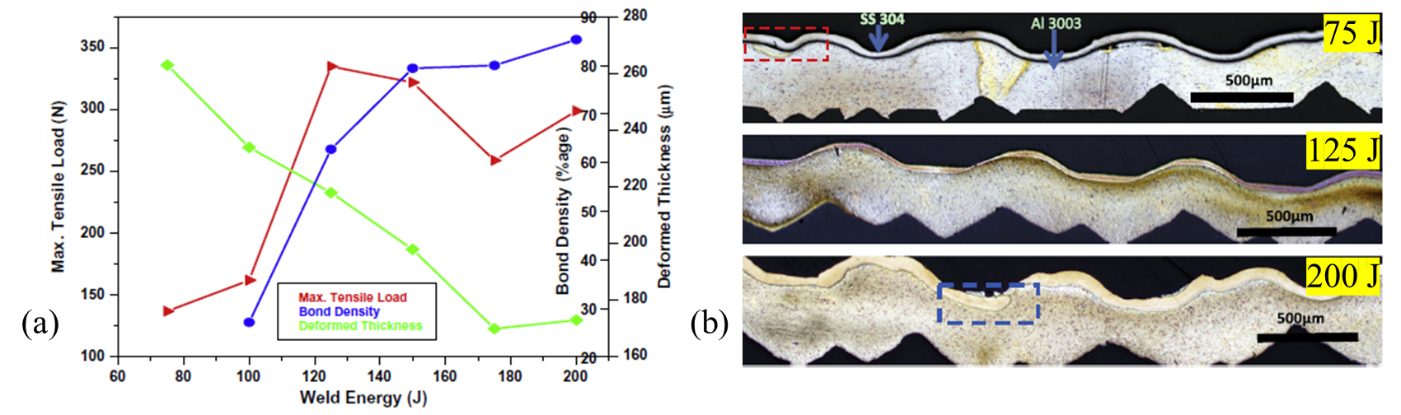

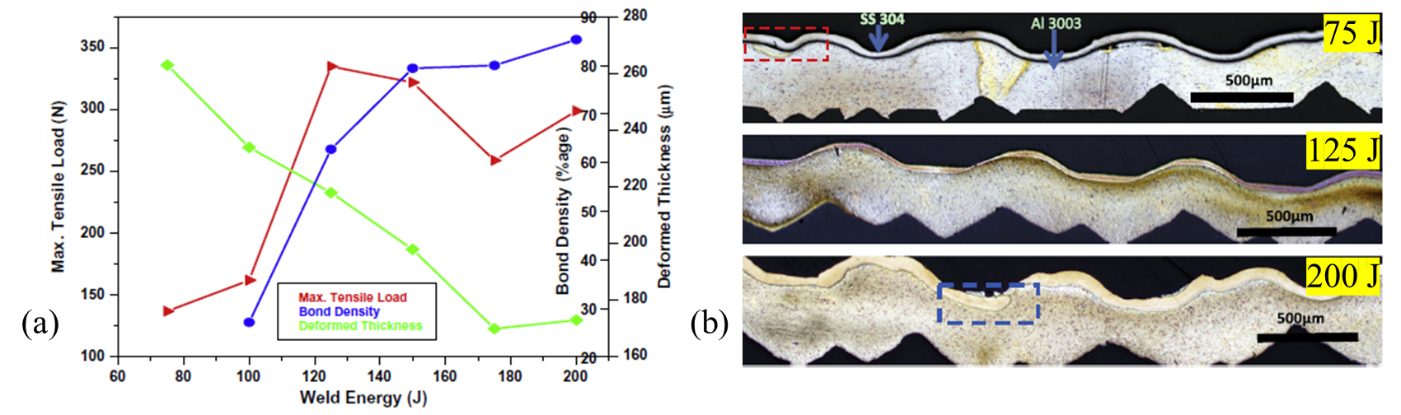

Figure 5: (a) Correlation of weld performance with bond density and deformed thickness. (b) Optical micrographs of 3003 Al and 304 SS weld cross-section produced with a pressure of 40 psi with increasing weld energies.S-32

A 40 psi maximum peak load to failure is observed at an energy input of 125 J as shown in the Figure 5. Optical micrographs revealed the wave like bonding line at the interface due to continuous shear oscillations. The joining process has been summarized into three steps i.e. formation of the micro bonds at the interface due to expansion followed by continuous deformation due to normal and shear oscillations at the faying surfaces. Lastly, these micro bonds grow and join to form a fully bonded interface. Moreover, it is specified that for a good quality weld, good combination of the bond density and material deformation is required.

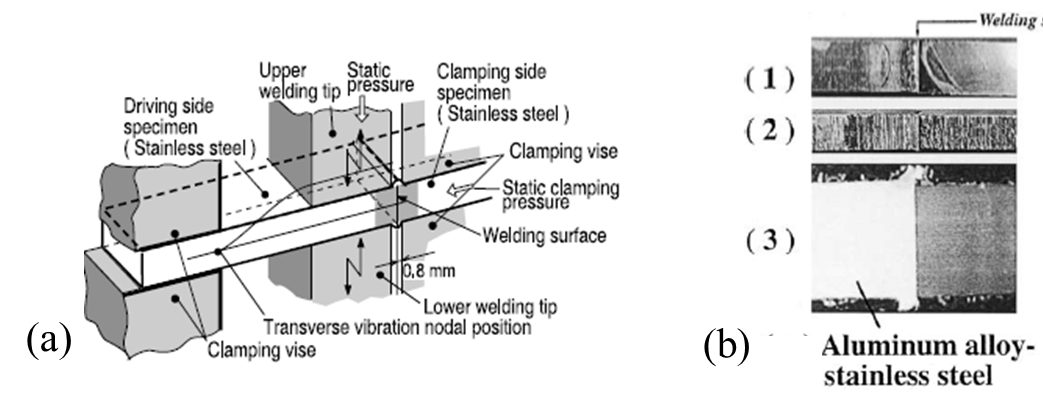

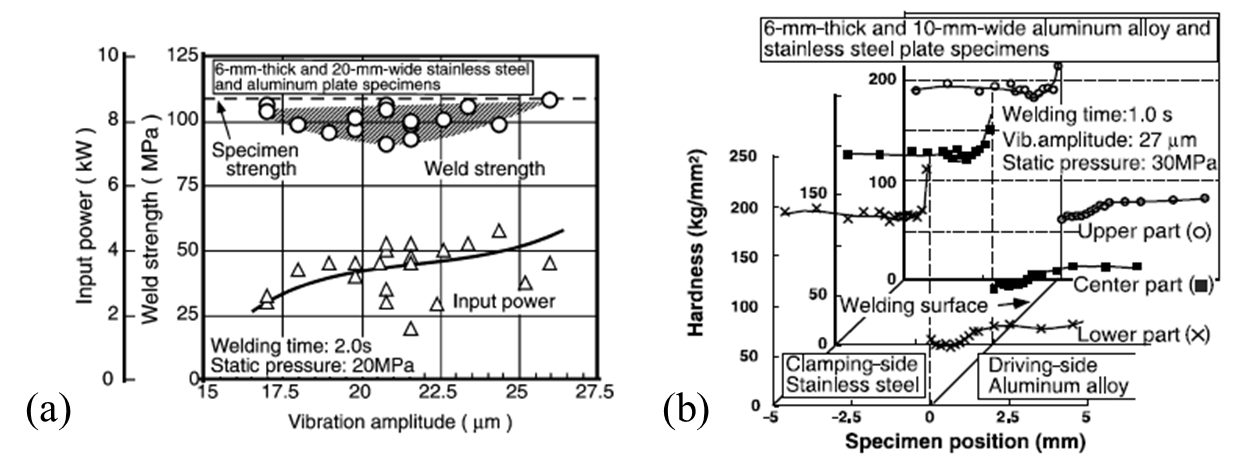

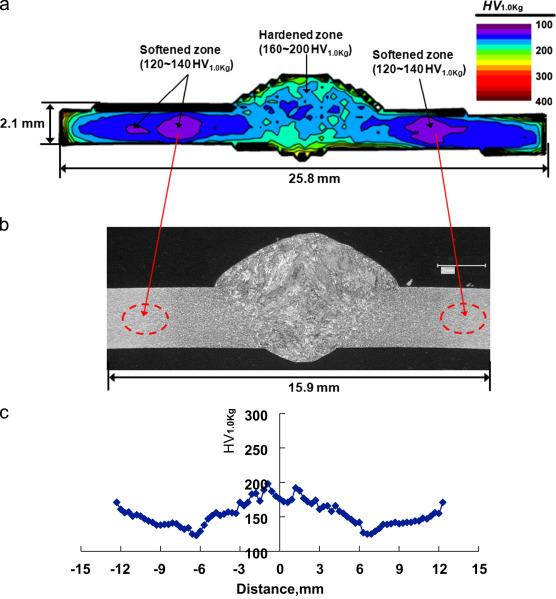

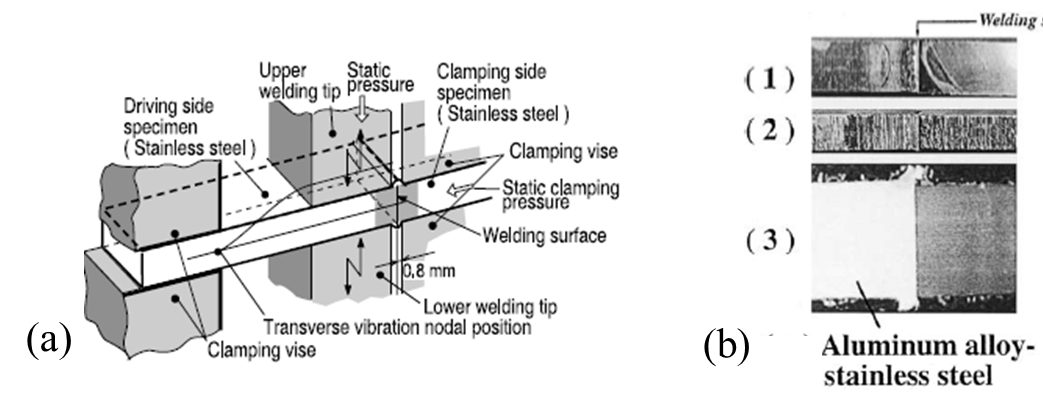

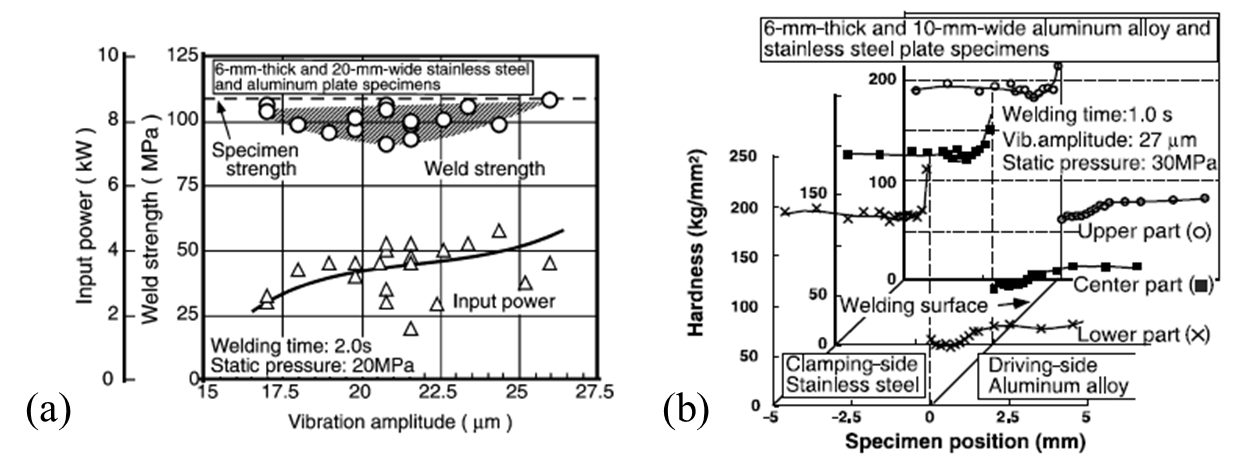

In another work carried out by Jiromaru and coworkers, butt welding of thicker specimens (6 mm thick 5052 Al alloy and 304 stainless steel) via ultrasonic welding system (50 kW) of 15 kHz is evaluated.T-16 Figure 6 shows the schematics of the process. Welds were obtained at various amplitudes i.e. the peak to zero vibration is varied between 17 and 27 µm, static pressure of 20 Mpa and for a duration of 2 seconds. Figure 6 shows the schematics of the ultrasonic butt-welding system. Static and hydraulic pressure were utilized to clamp the welding specimens. Burrs were observed on the aluminum side and is attributed to the lower hardness of the aluminum compared to steel. Maximum strength attained was around 100 MPa at various amplitudes as shown in Figure 7. Significant decrease in the hardness is reported near the aluminum side and increase in the hardness is observed 2 mm away from the weld line on the stainless-steel side. The hardness value is lower in the upper and lower region compared to center region due to conduction. 20 % variation was observed in the hardness profile through the cross section of the welded specimens from top to bottom.

Figure 6: (a)) 15 kHz ultrasonic butt welding equipment using an upper and a lower welding tips, and hydraulic vices for clamping welding specimens and inducing static pressure to welding surface. (b); Welded conditions of 6-mm-thick, 10-mm-wide stainless steel plate specimens. (1) Upper view, (2) side view and (3) cross-section of welded 6-mm-thick, 10-mm.T-16

Figure 7: (a) Relationship between vibration amplitude, input power and weld strength of 6.0-mm-thick and 20-mm-wide pure aluminum and electrolytically polished stainless steel plate specimens. (b) Hardness tributions along a cross-section of a 6.0-mm-thick and 10-mm-wide welded aluminum alloy–stainless steel specimen at upper, center, lower parts. Welding time: 1.0 s.T-16

Friction Welding

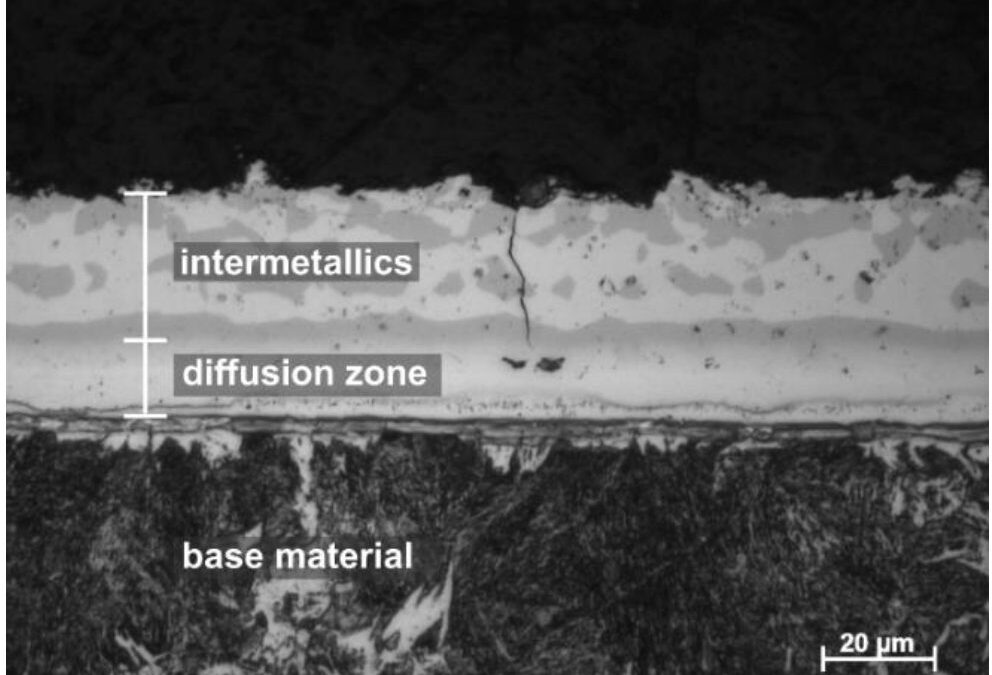

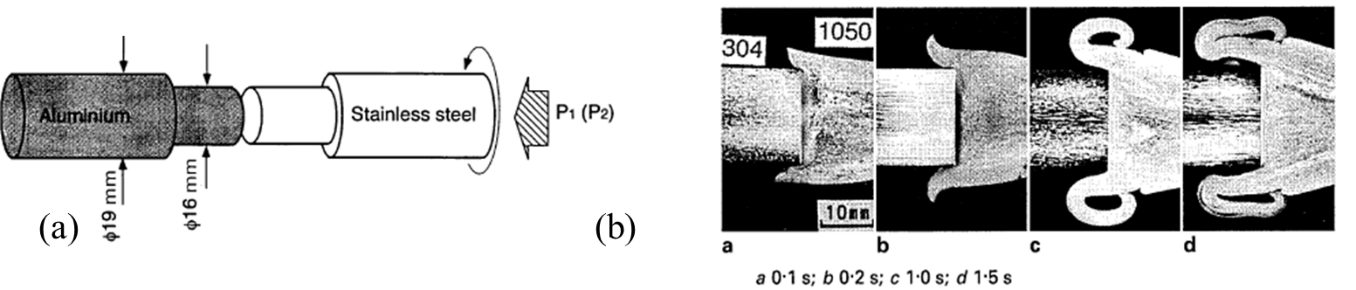

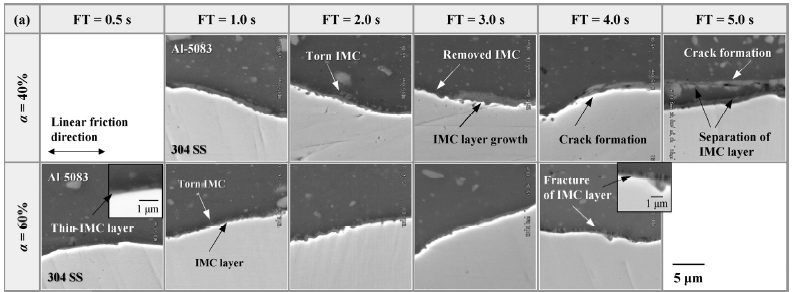

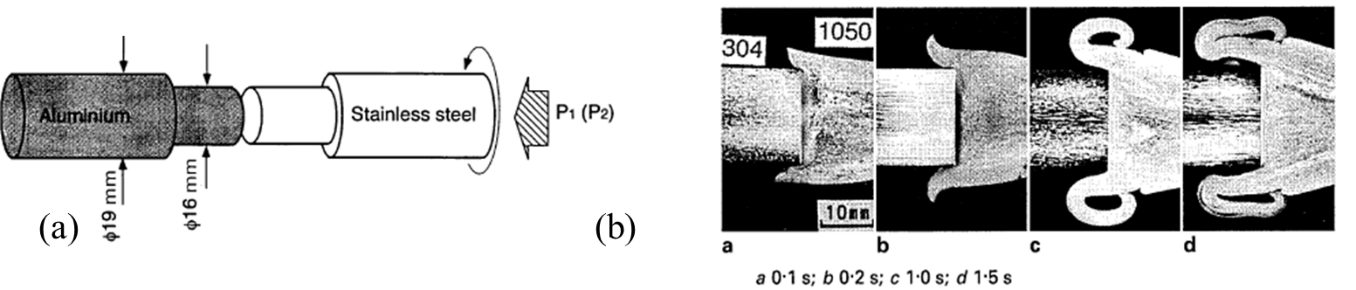

In friction welding, joining is attained under the application of the pressure and rotation i.e. torque is applied and the materials to be joined are pushed against each other. Main advantages include reproducibility, shorter time, no filler material, and high-quality welds. However high capital cost is a limitation of this process. Friction welding processes involve several methods, such as linear friction welding, rotary friction welding and friction stir welding. Fukumoto and coworkers have evaluated the friction welding of 1050 aluminum alloy to austenitic stainless steel.F-8 Figure 8 shows the schematics of the materials to be joined. This study was carried out at constant parameters of 2400 rev/min, frictional pressure of 50 MPa, forging pressure of 150 MPa, and forging time of 6 seconds. However, frictional time was varied between 0.1 to 2 seconds. Flash was found to be symmetrical around the weld. Smaller heat affected zone was observed on the steel side. Intermetallic compounds Fe2Al5, Fe3Al and FeAl were detected in the reaction layer. Reaction layer thickness was found to be around 500 nm as shown in the Figure 9.

Figure 8: (a) Schematic illustration of friction welding procedure. (b) Cross-sectional macrostructures of friction welded joints for given frictional time t.F-8

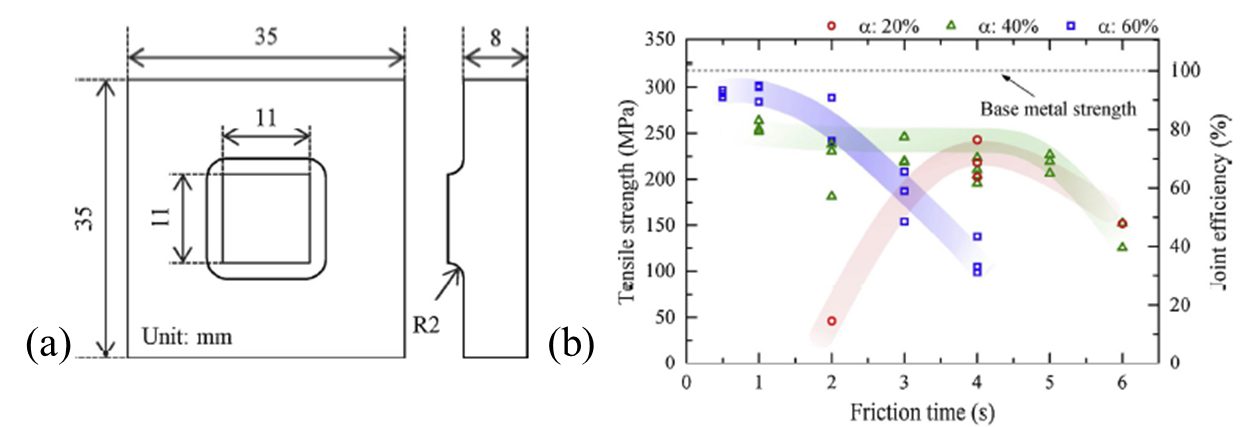

Figure 9: EDS analysis along line along the interface between aluminum and steel at 1.5 seconds.F-8

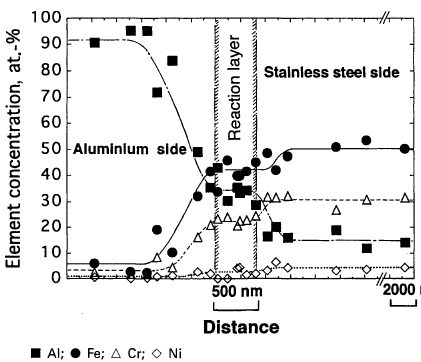

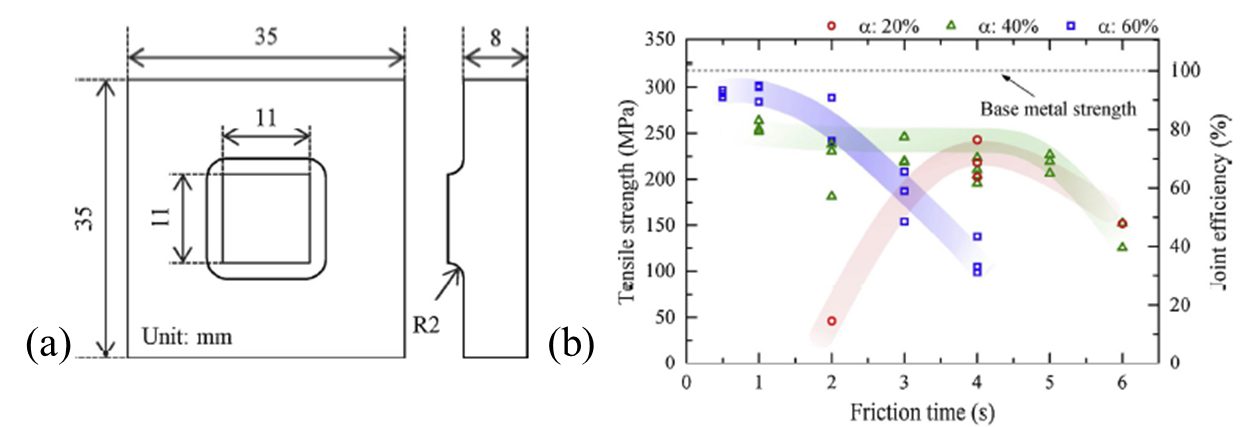

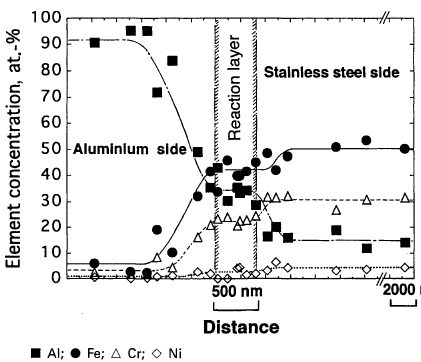

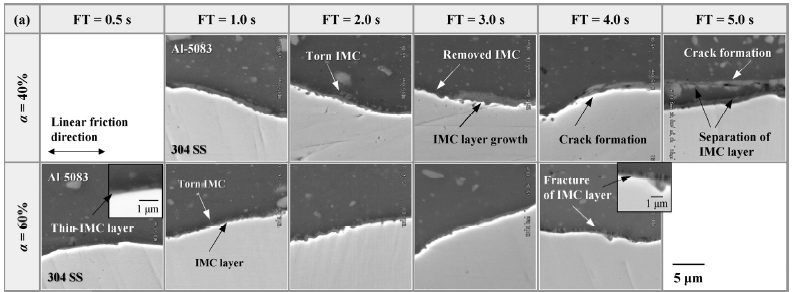

In another work carried out by Matsuda and coworkers, high frequency linear friction welding between aluminum alloys (5083 & 6063) and 304 stainless steel alloys was evaluated.M-14 The friction frequency was 245 Hz with an amplitude of 1.8 mm. It can be seen in the Figure 10 that loading ratio and friction time influences the tensile strength of the joints. Loading ratio was calculated as a function of proof stress with respect to aluminum alloys and was found to be 145 MPa. Maximum strength was reported at 60 % loading ratio at a friction time of 1 second i.e. 300 MPa.

Figure 10: (a) Schematic illustration of the specimen. (b) Influence of loading ratio α and friction time on the tensile strength of Al-5083/304 SS.M-14

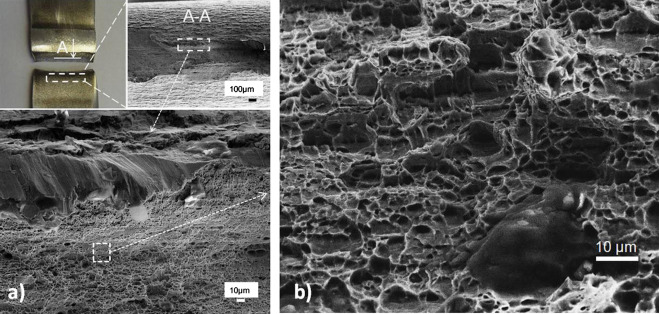

Tensile strength of these joints decreases with the increase in the friction time. Longer time promotes to wider reaction layer that is detrimental for the weld quality. Figure 11 shows the cross-sectional SEM images between Al5083/SS304 at 40 % and 60 % loading ratio. At longer friction times, cracks and fractures were observed at the interface. No reaction layer was seen at 20 % loading ratio. Reaction layer between Al5083/SS304 decreases below 500 nm at higher pressure and at longer time cracks were observed due to fracture of the intermetallic compounds (Figure 11).

Figure 11: Cross-sectional SEM images of (a) Al-5083/304 SS joints showing the temporal evolution of their interfacial structures (FT=friction time)M-14

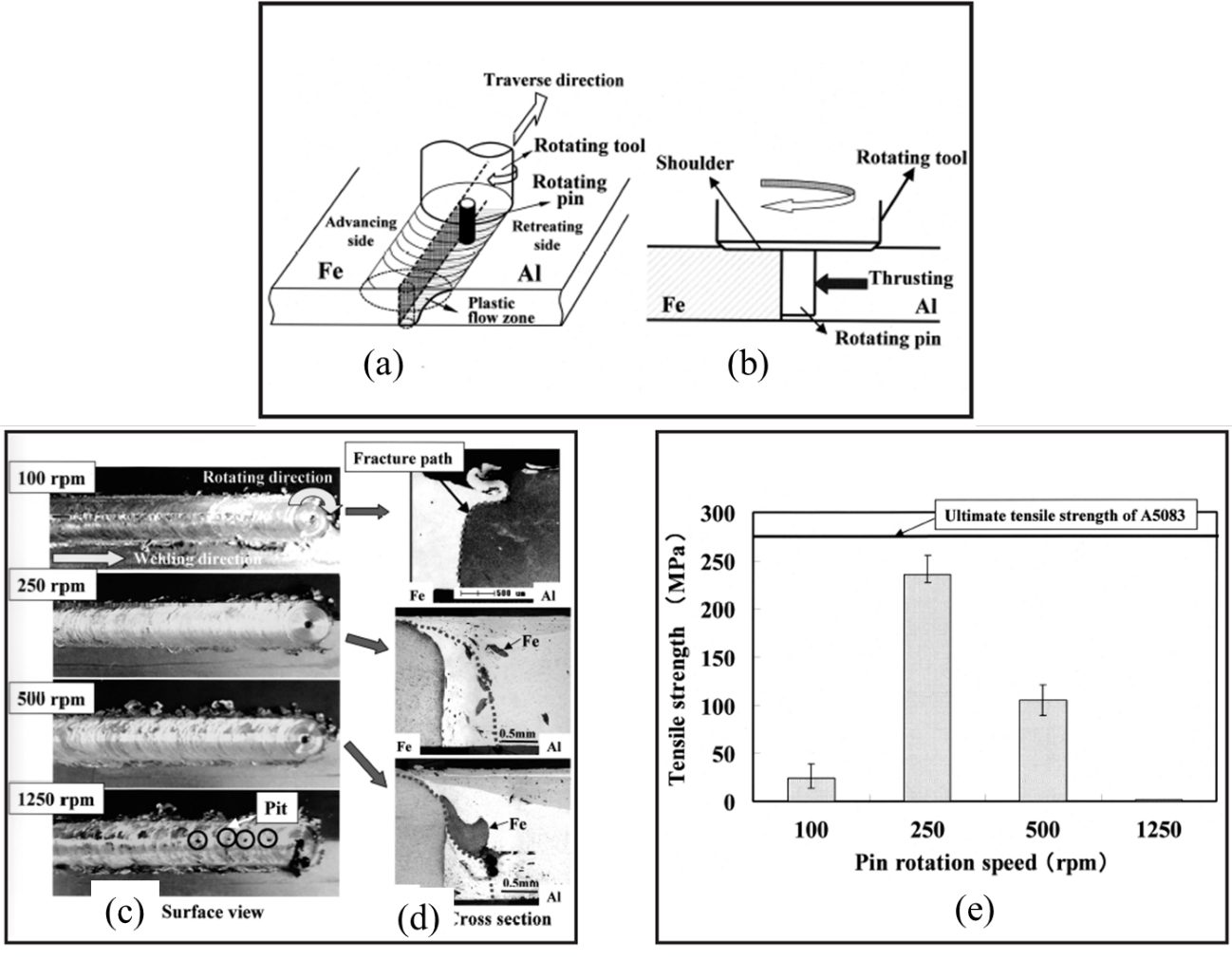

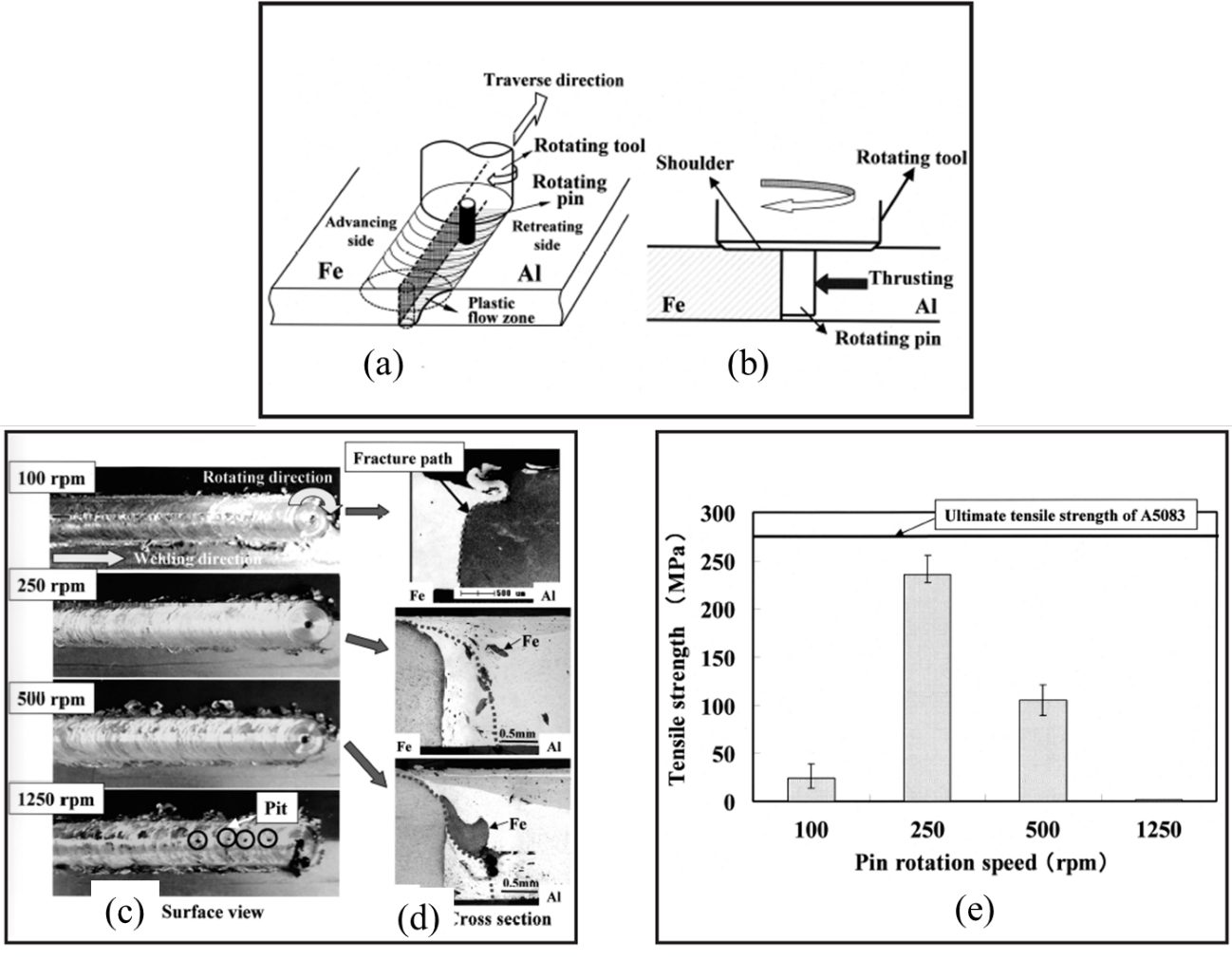

Kimapong and T. Watanabe reported butt joint of an aluminum alloy and mild steel via friction stir welding process.W-17 Up to 86 % of the joint strength is attained compared to aluminum alloy. SS400 mild steel plates A5083 plates having a thickness of 2 mm was used in this study. Figure 12a shows the schematics of the experimental procedure. A high-speed steel tools with 15 mm shoulder and 2 mm threaded pin diameter was used in this study. Rotational speed was varied from 100 to 1250 rpm. The pin traverse speed was 25 mm/min. Figure 12 (c&d) shows the effect of the rotating speed on the weldability of the friction stir welding process. Figure 12e shows the tensile strength of 240 MPa at a rotation speed of 250 rpm. At lower rotational speeds, the pin wore out due to inadequate heat generation and at higher rotational speed oxidation occurred due to the presence of aluminum and magnesium. Lower rotation speeds do not generate enough heat required for plasticization whereas higher rotational speeds lead to higher temperature that promotes the oxidation of the aluminum and magnesium, hence decrease the quality of the weld. It is therefore important to select right rotational speed for the sound weld.

Figure 12: Schematic of the rotating pin position in this study: (a) Bird’s eye view of the method; (b) view of the cross section perpendicular to the weld interface. Effects of pin rotation speed; (c) surface view; (d) cross-sectional structure with the fracture path indicated by a dashed line in the welds. (e) Relation between pin rotation speed and joint tensile strength.W-17

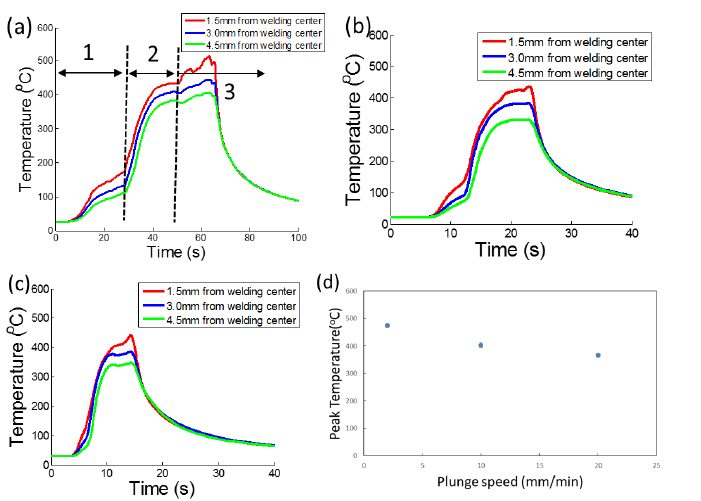

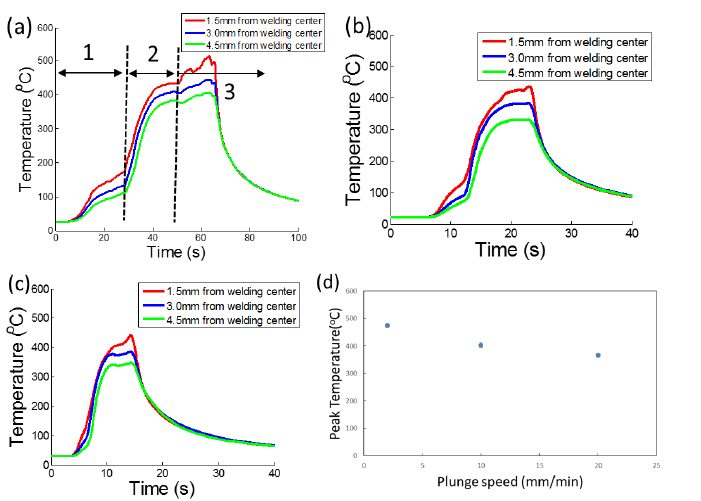

In an investigation carried out by K. Chen, the relationship between axial plunge force and process temperature during friction stir spot welding of the Al6061 with TRIP 780/800 steel is evaluated.C-12 It was reported that increase in the plunge speed leads to larger reaction forces and lower peak temperature as shown in Figure 13. The bonding mechanisms during the process involve, mechanical interlock and chemical bonding. Moreover, it was reported that Zn coating can enhance the joint quality during friction stir spot welding process.

Figure 13: Temperature profile with different plunge speeds: (a) 2 mm/min, (b) 10 mm/min, (c) 20 mm/min, and (d) peak temperature with different plunge speeds).C-12

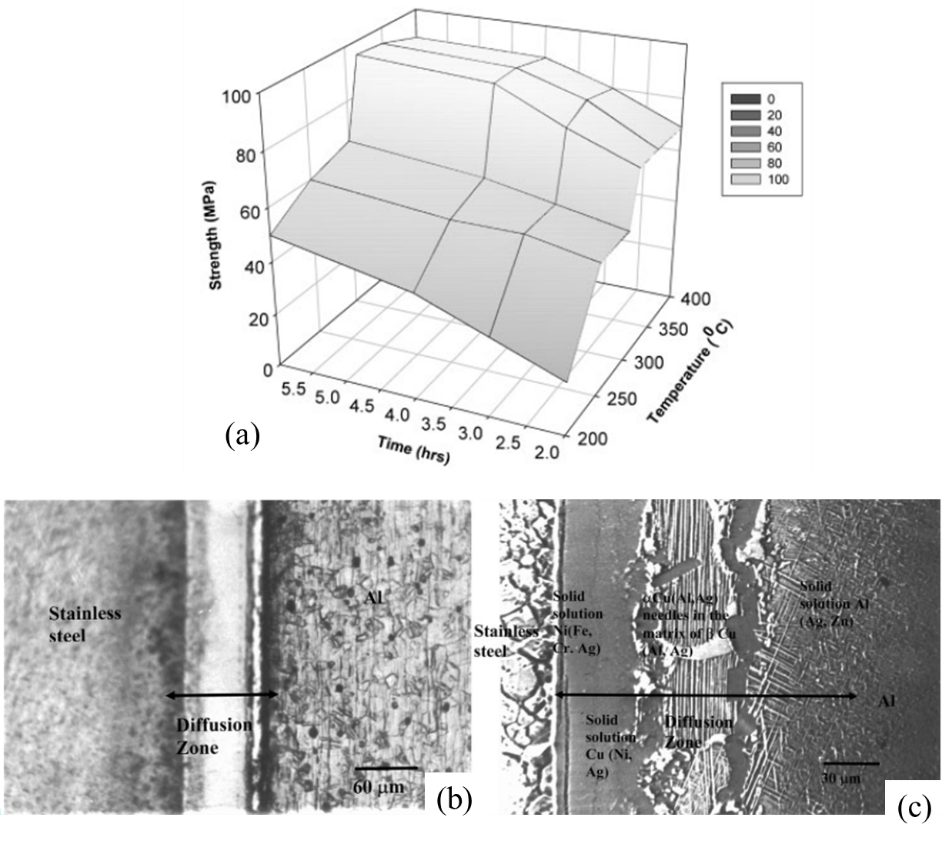

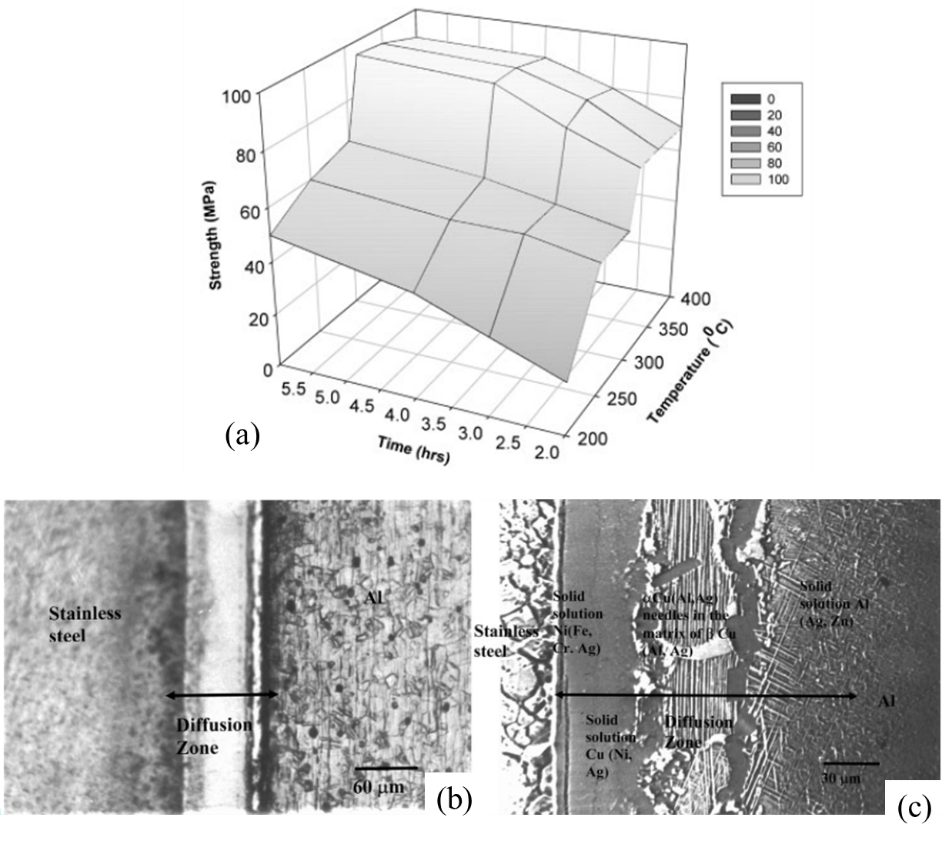

Diffusion Bonding

In diffusion bonding, sheets to be joined are placed against each other under a vacuum or an inert gas. At the faying surfaces, bonding is attained via diffusion due to difference in the chemical concentration. Diffusion bonding process can be accelerated by operating the process at higher temperatures. This process is not suitable for the direct joining of the aluminum and steel, however with assistance of interlayer a sound weld can be obtained via this process. Bhanumurthy has used interlayer in the Al/Zn/Cu/Ag–Ag/Cu/Ni/SS interlayer pattern to minimize metallurgical incompatibilities for the joining of the aluminum alloys with the stainless steels.B-7 All the layers were deposited electrochemically. 304 stainless steel and pure aluminum (99.8 & pure) were used in this study (10 x 5 x 4 mm). The whole assembly was placed in vacuum (10‑3 Pa) at a heating rate of 300 k h-1. Temperature range of 250 oC to 550 oC and time duration of 1h to 4h under a pressure of 50 MPa was evaluated in this study.

Figure 14: (a) Bond strength data for cylindrical specimens with variation in bonding time and temperature. Optical micrograph for specimen bonded at (b) 450 oC and (c) 550 oC for 4 h. B-7

Diffusion bonding done at 315 oC for 4 h have shown maximum strength of ~90 MPa. Specimens bonded at 300 oC failed at the Ag/Ag interface. Maximum diffusion width was 19 µm at 350 oC for 4 hours. Overall, the diffusion bonding process was found to be a strong function of the surface preparation and diffusivities of the bordering species.

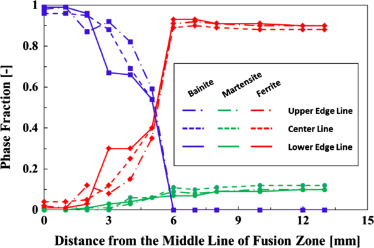

Resistance Spot Welding

In a comprehensive analysis carried out by Sigler and Carlson, hindrances occurred between the joining of aluminum and steel alloys via resistance spot welding process and approaches were established to overcome those challenges.S-33 Main challenges include, the difference in the melting temperature, formation of intermetallic compounds and natural oxide layers. 1.2-mm 6022T4 aluminum alloy, 1.0, 1.5- & 2.0-mm low carbon steel sheets were evaluated in this study. Configuration of lap shear test and couch peel test is shown in Figure 15A. Multiring doom electrode patented by General Motors were used in this study. Figure 15B shows the joint formed between 1.2-mm Al6062 aluminum alloy and 1.5 mm steel sheet at 3.6 kN and 14 kA current. Welding times were 200, 400, 600 and 800ms, with 45ms pulse and cool time of 5ms between pulses. Weld performed at 200ms are not shown in this report due to insufficient strength. Both shrinkage and gas porosities were observed at each time condition. At higher time, porosities join together to form bigger porosities and these was no increase in the bond length form 600ms to 800ms.

![Figure 15: (A) Configuration of Lap-Shear and Coach-Peel Mechanical Test Specimens ,(B) Weld Microstructures for a 1.2-mm AA6022-T4 (top sheet) to 1.5-mm HDG LCS (bottom sheet) Stack-Up Welded using MRD Electrodes at 800 lb and 14 kA , (C) Secondary and Back-Scattered Electron Image (BEI) Micrographs [secondary electron images (SEI) left and BEI right] of the Al-Side Weld Fracture Surfaces for 1.2-mm AA6022-T4 to 1.5-mm HDG LCS Stack-Up Welded at 800-lb Clamping Force and 14-kA Welding Current, (D) Coach-Peel and Lap-Shear Mechanical Properties for (a) 1.2-mm AA6022-T4 Welded to 1.0-mm HDG LCS and (b) 1.2-mm AA6022-T4 Welded to 2.0-mm HDG LCS [, & (E) Coach-Peel and Lap-Shear Mechanical Properties for Coupons of Zn-Coated 1.2-mm AA6022-T4 to 1.0-mm HDG LCS Stack-Up Welded at 800 lb, 250 ms, and 16 kA.S-33](https://ahssinsights.org/wp-content/uploads/2020/09/image029.jpg)

Figure 15: (A) Configuration of Lap-Shear and Coach-Peel Mechanical Test Specimens ,(B) Weld Microstructures for a 1.2-mm AA6022-T4 (top sheet) to 1.5-mm HDG LCS (bottom sheet) Stack-Up Welded using MRD Electrodes at 800 lb and 14 kA , (C) Secondary and Back-Scattered Electron Image (BEI) Micrographs [secondary electron images (SEI) left and BEI right] of the Al-Side Weld Fracture Surfaces for 1.2-mm AA6022-T4 to 1.5-mm HDG LCS Stack-Up Welded at 800-lb Clamping Force and 14-kA Welding Current, (D) Coach-Peel and Lap-Shear Mechanical Properties for (a) 1.2-mm AA6022-T4 Welded to 1.0-mm HDG LCS and (b) 1.2-mm AA6022-T4 Welded to 2.0-mm HDG LCS, and (E) Coach-Peel and Lap-Shear Mechanical Properties for Coupons of Zn-Coated 1.2-mm AA6022-T4 to 1.0-mm HDG LCS Stack-Up Welded at 800 lb, 250 ms, and 16 kA.S-33

Figure 15C shows the SEM of the fractured surfaces. At 200ms porosities were star shaped with arms extending towards periphery of the nugget. Increasing time leads to shorter thicker and fewer porosities. It is an indication of the consolidation of porosities towards the center. Here dark grey features are an indication of the aluminum. Figure 15D shows the comparison of lap shear strength at various conditions. Maximum lap shear strength is observed between 1.2-mm aluminum sheet and 2-mm steel sheet i.e. 64% higher than that of aluminum spot welds. Lower mechanical strength is attributed to discontinuities that could be gas and shrinkage porosities. Moreover Figure 15E shows the effect of the Zn coating on the aluminum. Higher peel strength was observed in the presence of the Zinc coatings. It was summarized in this study that the main reason for the poor mechanical properties is shrinkage and gas porosities. Removing aluminum oxide layer and replacing it with zinc layer can help in the elimination of the defects. Moreover, using multiple weld schedules can also improve weld joint quality.

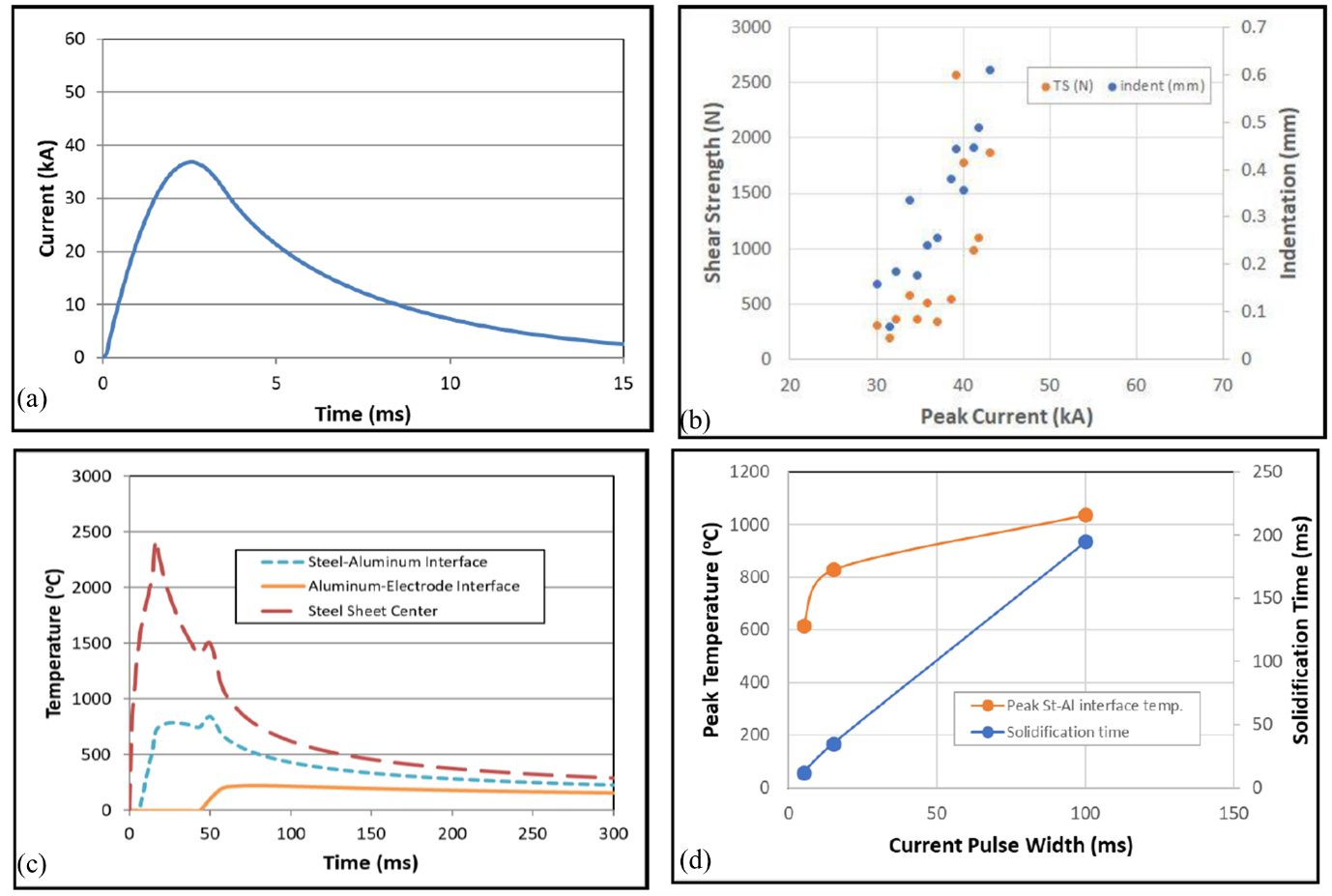

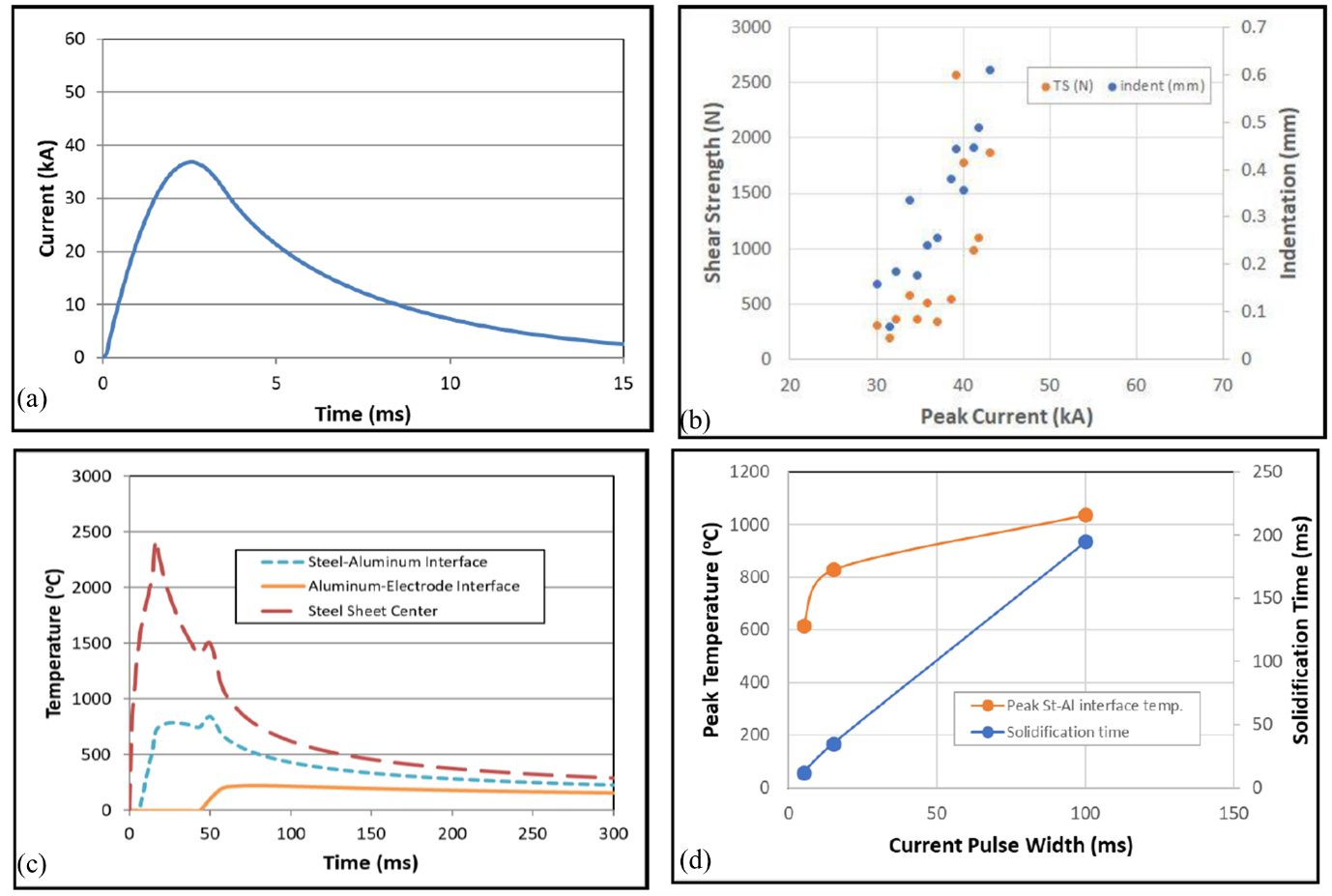

Other investigations carried out at The Ohio State University and Edison Welding Institute, researchers have utilized capacitor discharge power for creating resistance spot welds between aluminum and steel.G-16 The main objective is to minimize the time through which the current is delivered in the sheets to minimize the growth of the intermetallic layer. Figure 16a shows the shape of the current waveform delivered in 15ms. Figure 16b shows the increase in the mechanical strength as a function of increasing current value.

Figure 16: (a) Current waveform for a weld made with the 75:1 turns ratio, (b) Current-range curve for welding with the 75:1 turns ratio ,(c) Estimated thermal profiles for an al-to-steel spot weld made with a 15-ms pulse width & (d) Peak temperature and solidification time for the al weld nuggets as a function of pulse width.G-16

Thermal profiles were measured at multiple interfaces (Figure 16c) and Figure 16d show the variation in the peak temperature as the function of the current pulse width, which increases in direct proportion. Overall, using capacitor discharge power resulted in separate nuggets and narrower pulse widths. At 5ms, 3-5% weld indentation was observed on the aluminum side with no weld discontinuities. Longer weld time takes more solidification time and wider pulse widths resulted in thicker intermetallics layer.

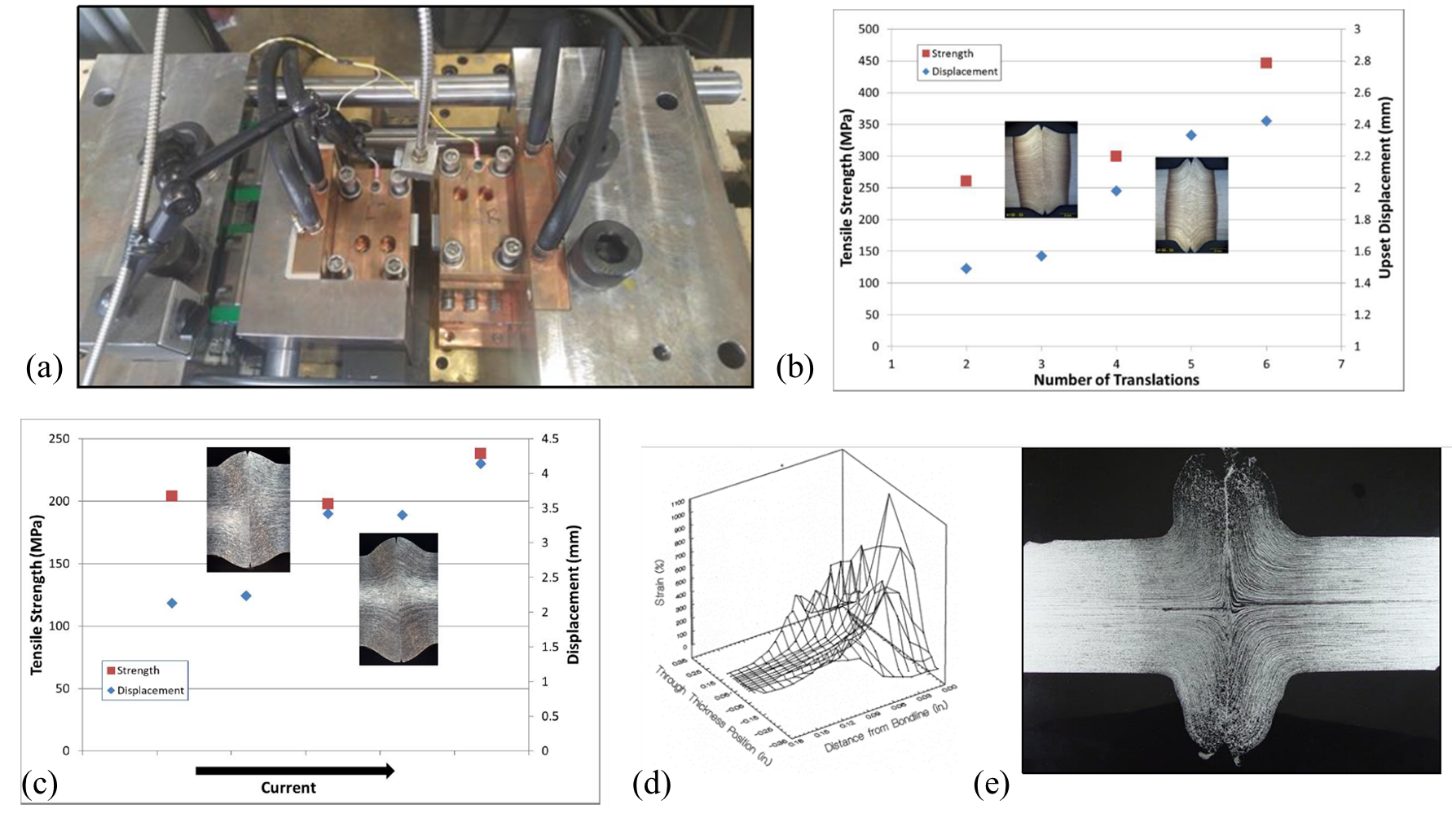

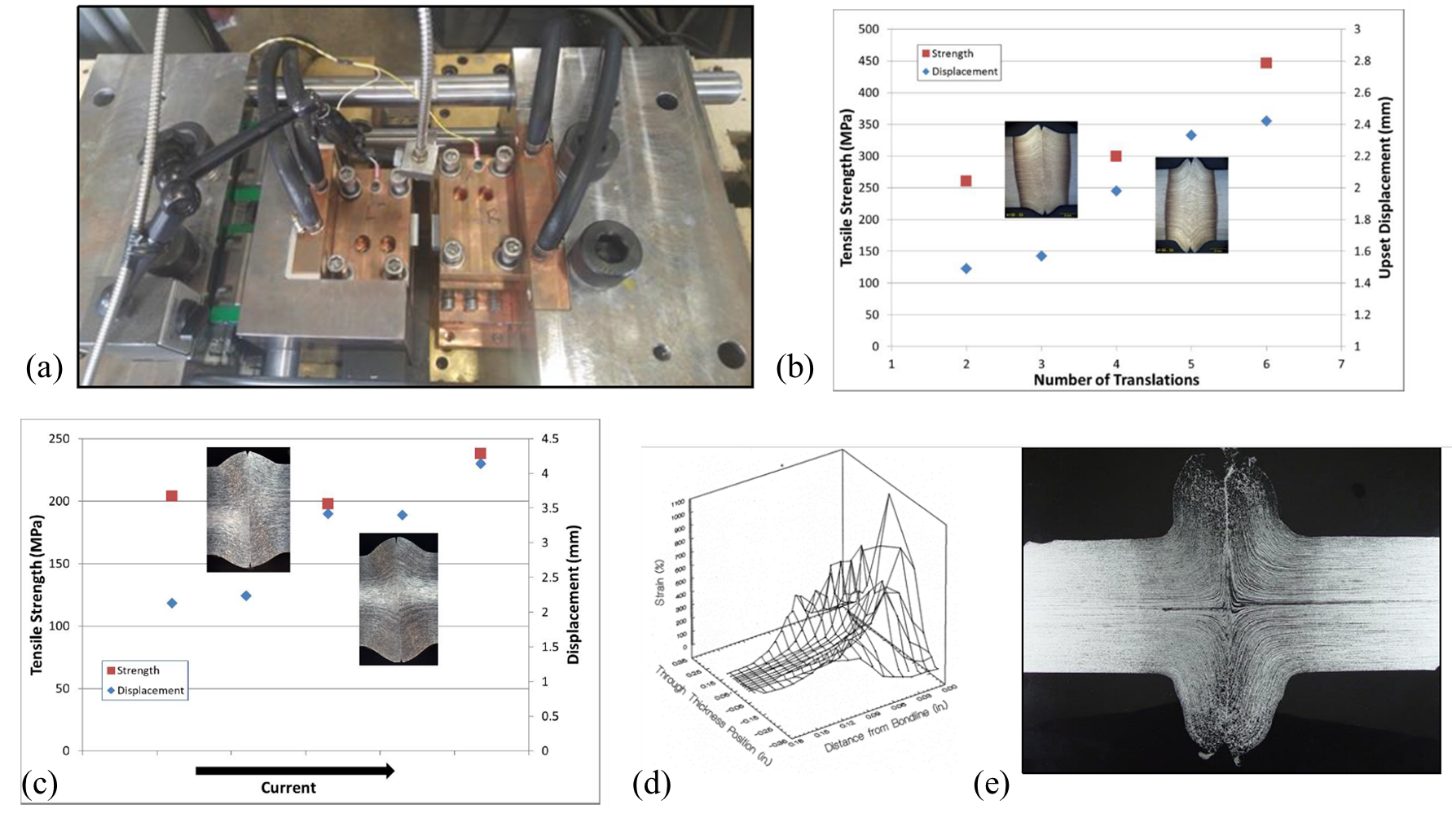

Hybrid Welding Processes

To improve the dissimilar material joining processes, some studies have reported hybrid welding processes. One such work is carried out by J. Gould from Edison Welding Institute, during which resistance welding and linear friction welding process is utilized.G-17 Low force friction welding process is reported and configuration of the setup is based upon the resistance butt welding frame coupled with hydraulic systems to provide linear motion during the process (Figure 17). Figure 17b shows the tensile results carried out at 30 kA and peak strength was observed near 450 MPa with highest number of translations and upset distance (4130-4130 steel sheets). No melting was observed at any of these parameters. For Al6061 aluminum alloy welding parameters were modified as shown in Figure 17c. Linear motion was varied from 2 mm to 4 mm. Peak strength was observed at 4 mm displacement. Strain map was developed for a steel sheet and it shows that to achieve the required amount of strains, significant upset is required during the process. Using this competitive process, less than 1/5 contact pressure without melting is reported compared to conventional process. This hybrid process reduces the frequency and translation required during friction welding process.

Figure 17: (a) Details of the tooling pack used to accomplish low-force friction welding. (b) Sample process window plot for steel joints made using increasing numbers of translational actions. (c) Process window plot showing variations in aluminum joints made using increasing current. (d) Two-dimensional strain map taken from a flash-butt weld on 6-mm-thick steel. (e) Flash-butt weld cross section corresponding to the strain map.G-17

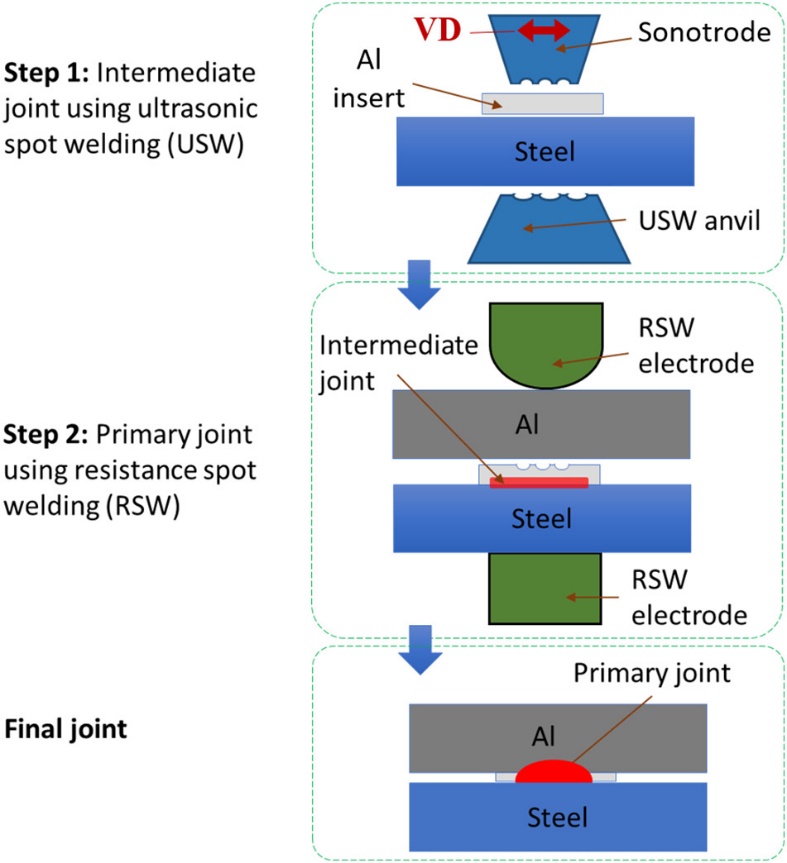

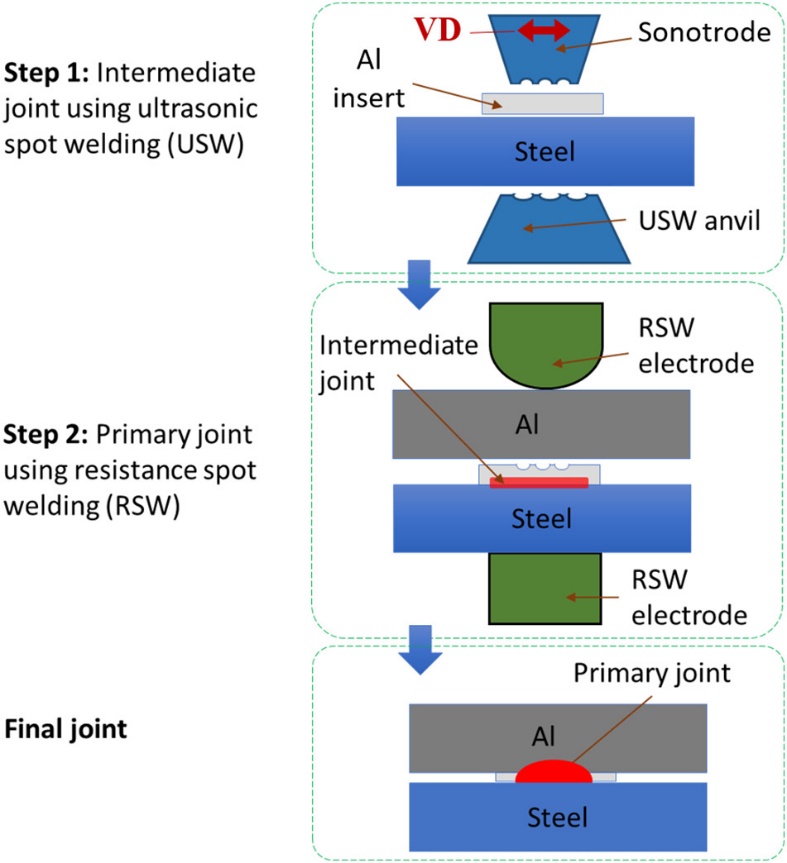

Y. Lu and co-workers L-17 developed the ultrasonic plus resistance spot welding process (U+RSW). In this process, a thin aluminum sheet was joined with a steel sheet via ultrasonic welding, followed by the RSW between the aluminum side of previously sheet and an additional aluminum sheet as shown in Figure 18. In this study they have used 1-mm-thick AA6061-T6 to 0.9-mm-thick AISI 1008 steel with 0.4-mm-thick AA6061-T6 as the insert.

Figure 18: Schematic diagram of U + RSW process. VD is the sonotrode’s vibration direction for USW of intermediate joint.L-17

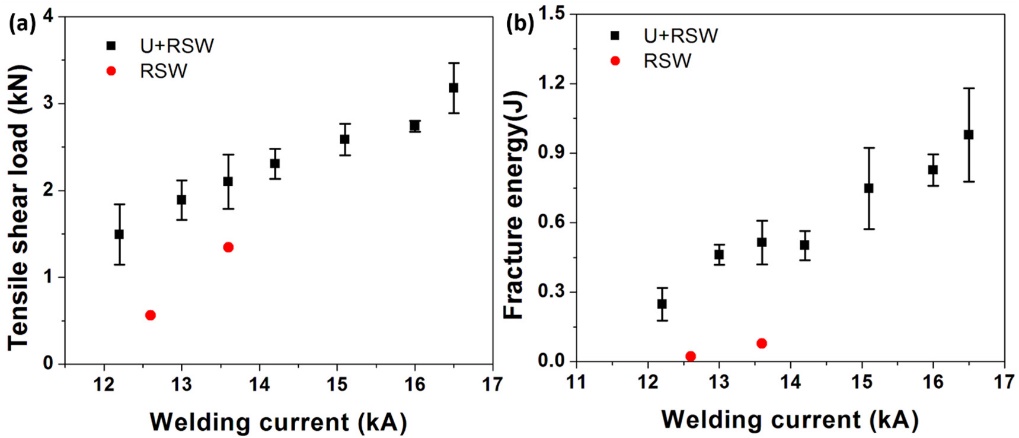

U+RSW method has shown improved mechanical properties, (Figure 19) tensile shear strength and, energy absorbed prior to failure. It has shown relatively thin intermetallic layer.

Figure 19. Effect of welding current on tensile shear strength and fracture energy of welded dissimilar joints of AA6061 to AISI 1008 steel. The welding time and the electrode force for RSW were kept constant at 0.083 s and 3.56 kN, respectively.L-17

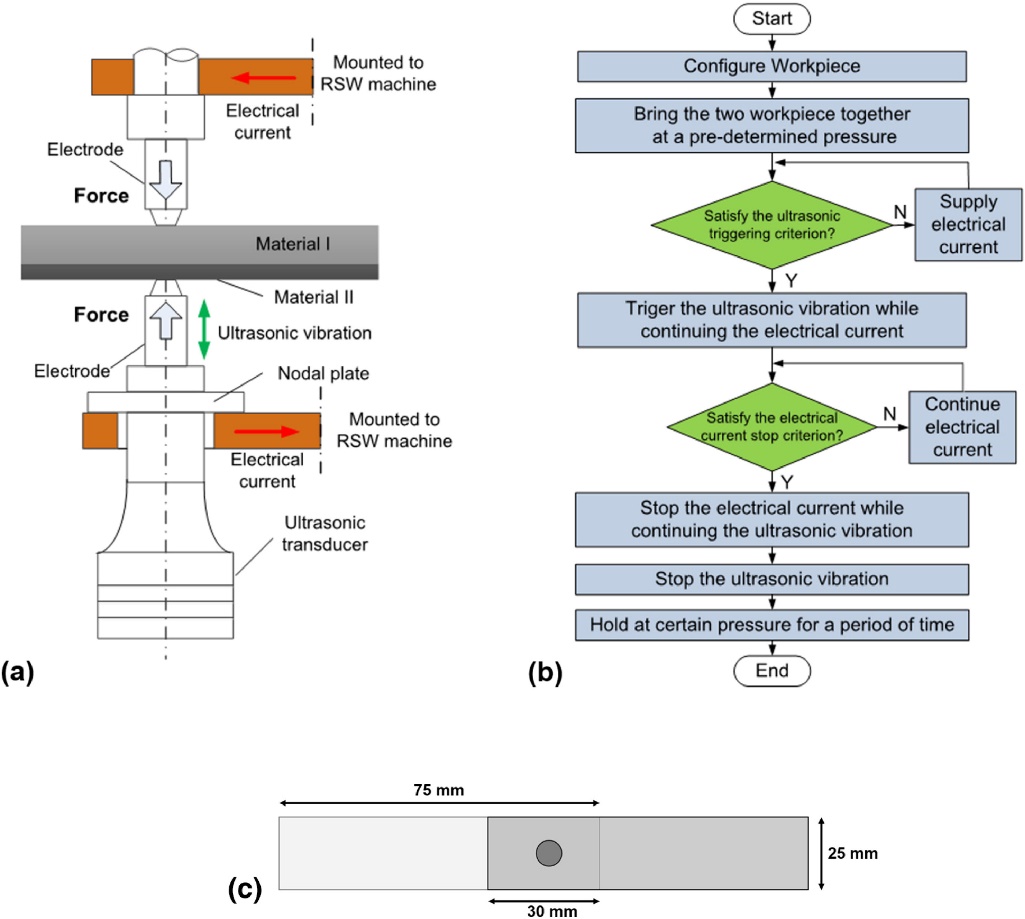

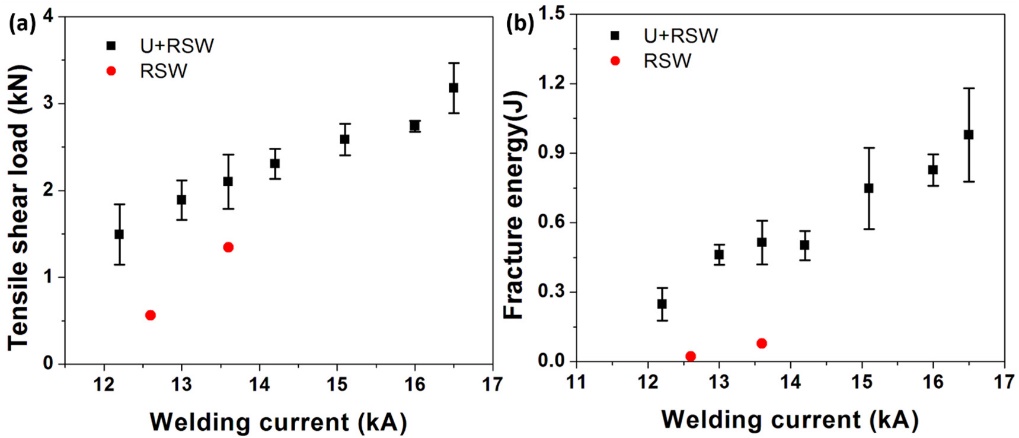

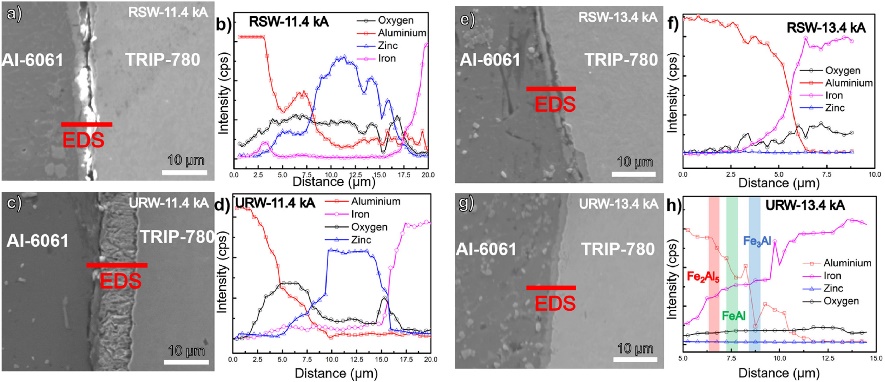

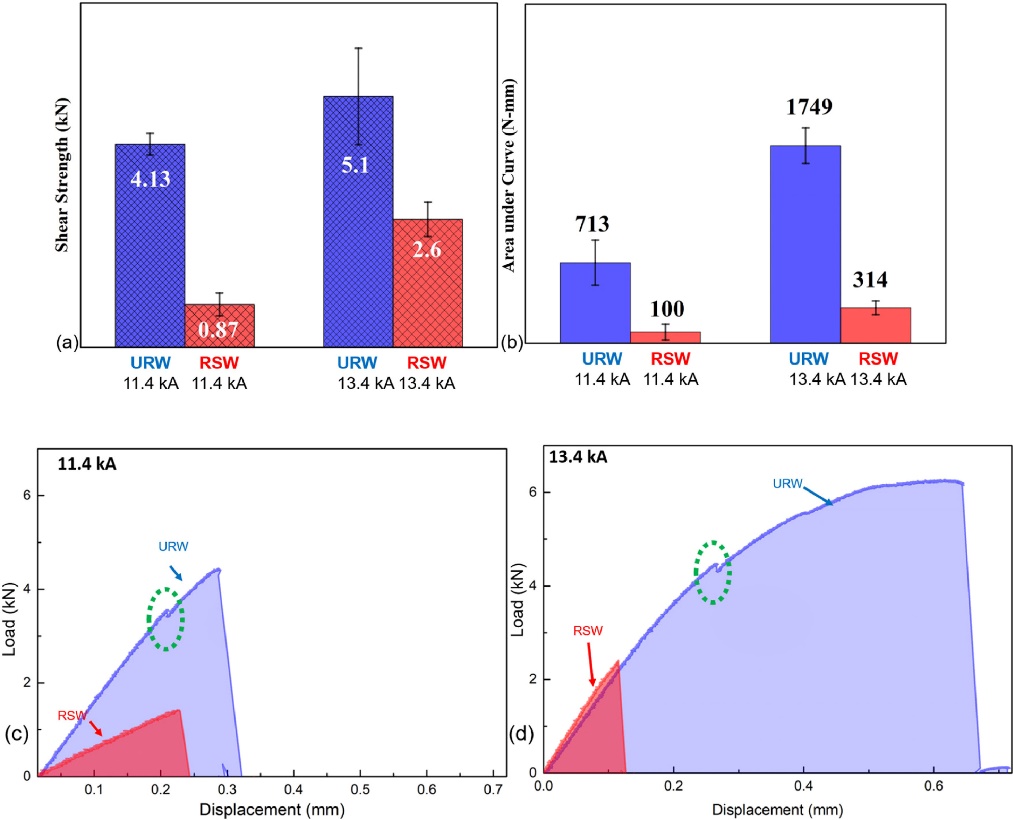

Another research group has developed ultrasonic resistance welding process (URW), that apply in situ ultrasonic waves during the resistance spot welding process. S-17 The schematics of the process is shown in the Figure 20. Al-6061T6 and electrogalvanized TRIP-780 with dimensions of 70Lx25Wx1.6T mm3 and 70Lx25Wx1.3T mm3 respectively were used in this study.

Figure 20. URW Setup (a) Schematic illustration; (b) Flowchart of the URW process.S-17

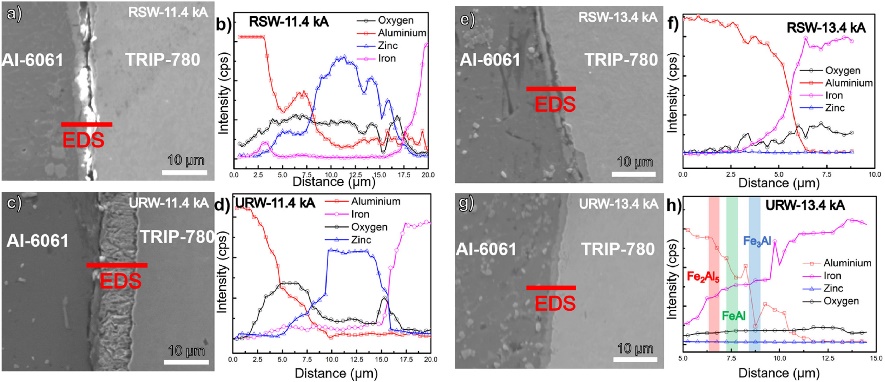

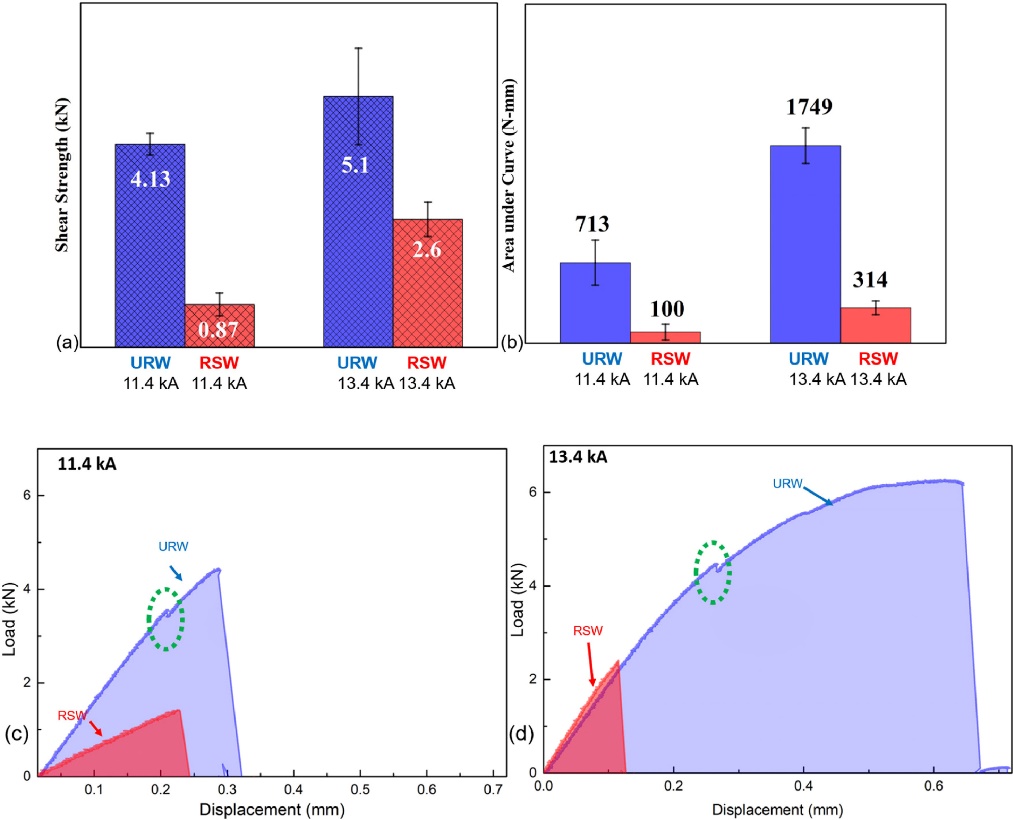

URW process have shown improved mechanical properties and defect free interface compared to RSW process. In situ ultrasonic vibration facilitated the breakdown of the surface oxide and contaminants, which modifies contact resistance and heat generation rate accordingly. If melting occurs, ultrasonic vibration promoted wetting of the molten aluminum over the steel interface and resulted in the formation defect free fully bonded interface as shown in Figure 22 compares the mechanical properties between the RSW & URW process. Comparing URW with traditional RSW, up to 300% increase in strength and more than 150% increase in displacement to failure is reported. SEM images of the fractured surface revealed that ultrasonic waves eliminated the eggcrate morphology generally observed in RSW welds fractured surface, which is a typical representative of solidification cracking.

Figure 21. EDS line Scan of Al-6061 & TRIP 780 across interface for RSW at 11.4 kA (a-b) & at 13.4 kA (e-f) and for URW at 11.4 kA (c-d) & at 13.4 kA (g-h).S-17

Figure 22: Tensile test results (a) Joint shear strength from 11.4 kA (30 cycles) & 13.4 kA (20 cycles); (b) Energy absorption calculated via area under load-displacement curve for 11.4 kA (30 cycles) & 13.4 kA (20 cycles); (c-d) load-displacement curve for 11.4.S-17

Back To Top

RSW Parameter Guidelines

This article summarizes a paper entitled, “RSW of 22MnB5 at Overlaps with Gaps-Effects, Causes, and Countermeasures”, by J. Kaars, et al.K-12

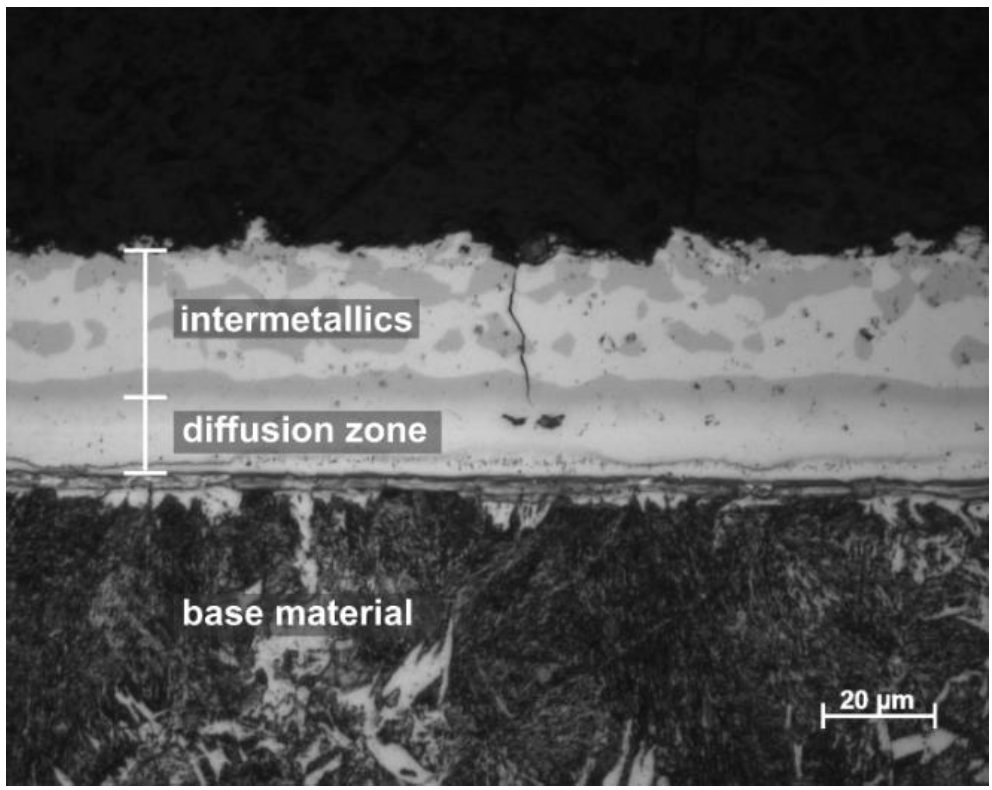

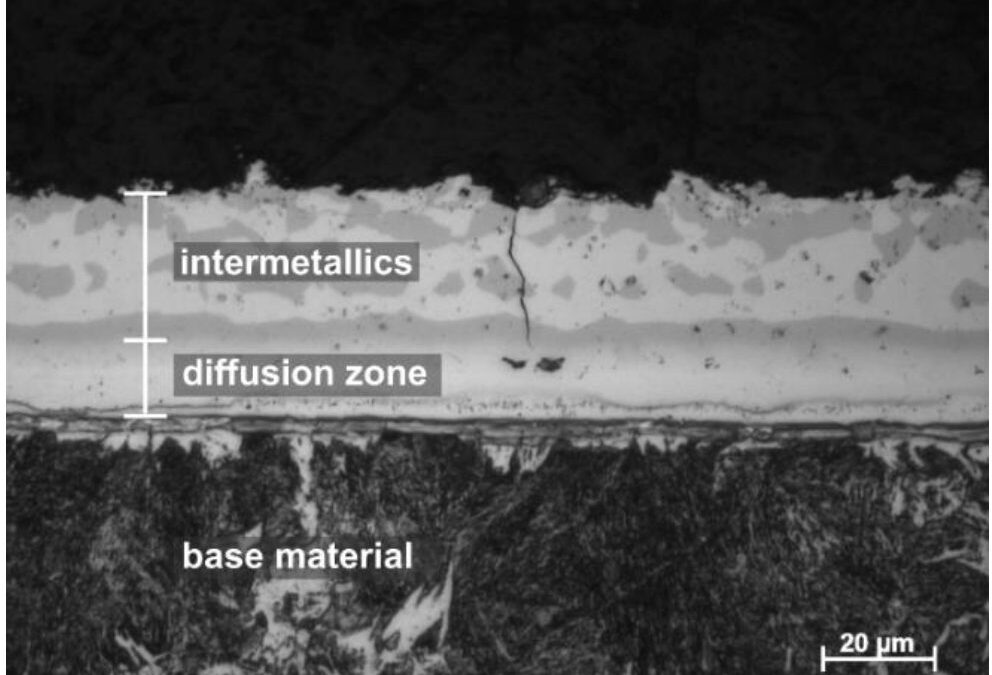

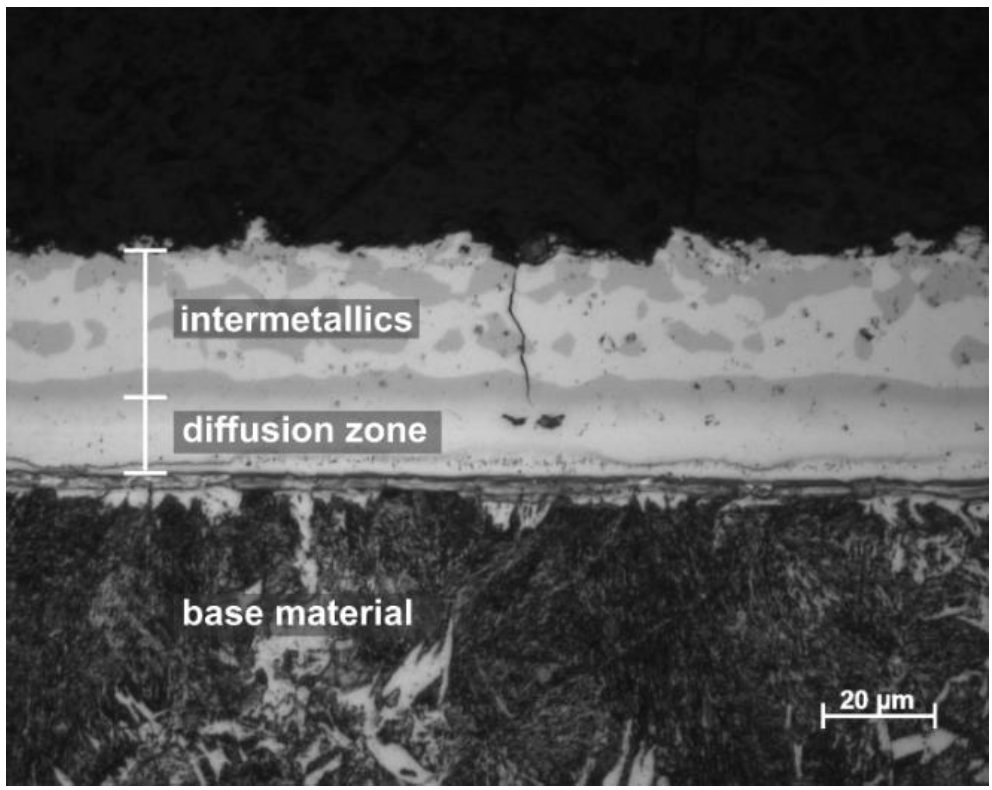

This study aims to elaborate on the influencing mechanisms of gaps on the welding result. Welding experiments at artificial gaps and finite element analysis (FEA) of the welding process have been used to investigate the matter. In both methods, the same configuration of two 1.5-mm-thick 22MnB5+AS150 welded with electrodes of the type ISO 5821 B0-16-20-40-6-30 was considered. Tensile tests yielded an ultimate tensile strength (UTS) of the press-hardened material of 1481 ± 53 MPa with a strain to fracture of 7.5 ± 0.26%. A microsection of the coating morphology after heat treatment can be found in Figure 1.

Figure 1: Morphology of the Aluminum-Silicon Coating.K-12

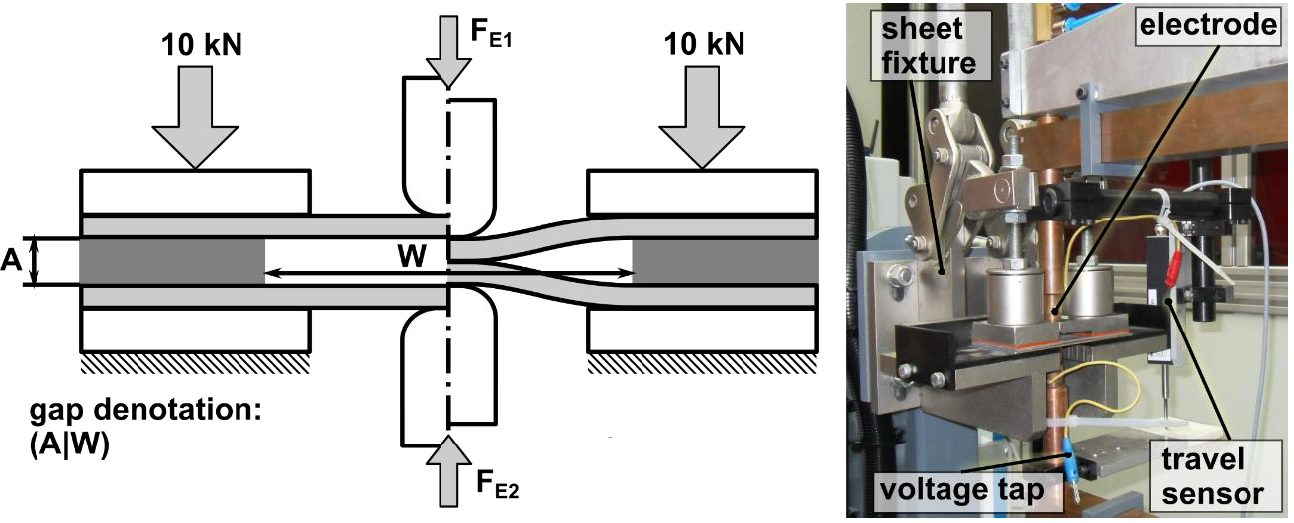

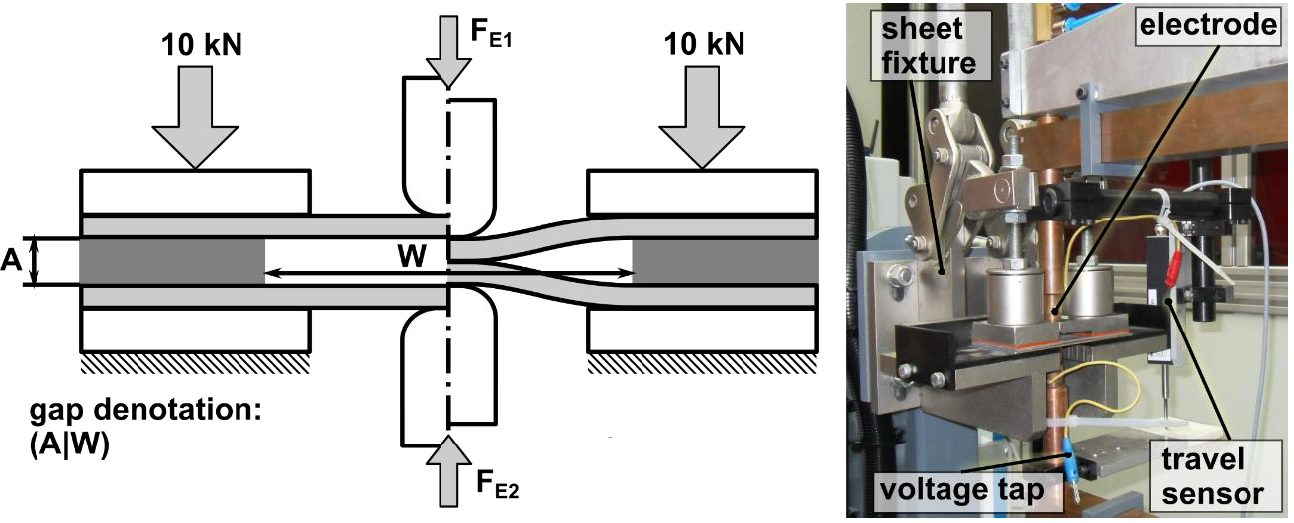

To set up an artificial and reproducible gap between the sheets, a dedicated fixture was used. It is displayed in Figure 2. All welding experiments were carried out with a 6-kN electrode force.

Figure 2: Fixture for Welding at Artificial Gaps, Definition of Quantities.K-12

In Table 1, the parameter variations of the gaps investigated in this work are presented.

Table 1: List of Gap Parameters Investigated.K-12

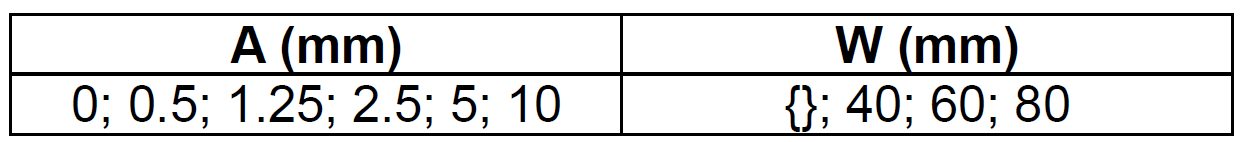

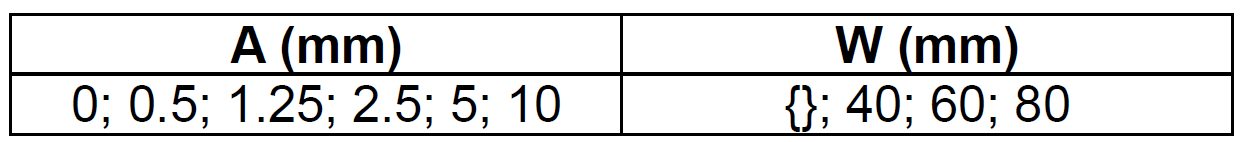

A 7-kN maximum denting force was observed at the gap (10|60). With a gap of (10|40) the gap could not be closed with the machines’ 8-kN clamping force capacity. In comparative tests on mild steel for deep drawing a clamping force of about 2 kN was required to overcome the gap (10|60) (see Figure 3). The main effects diagram of the denting force clearly shows that the average denting force gets smaller with increasing support width and becomes larger with increasing gap clearance.

Figure 3: Main Effects Diagram of the Denting Force.K-12

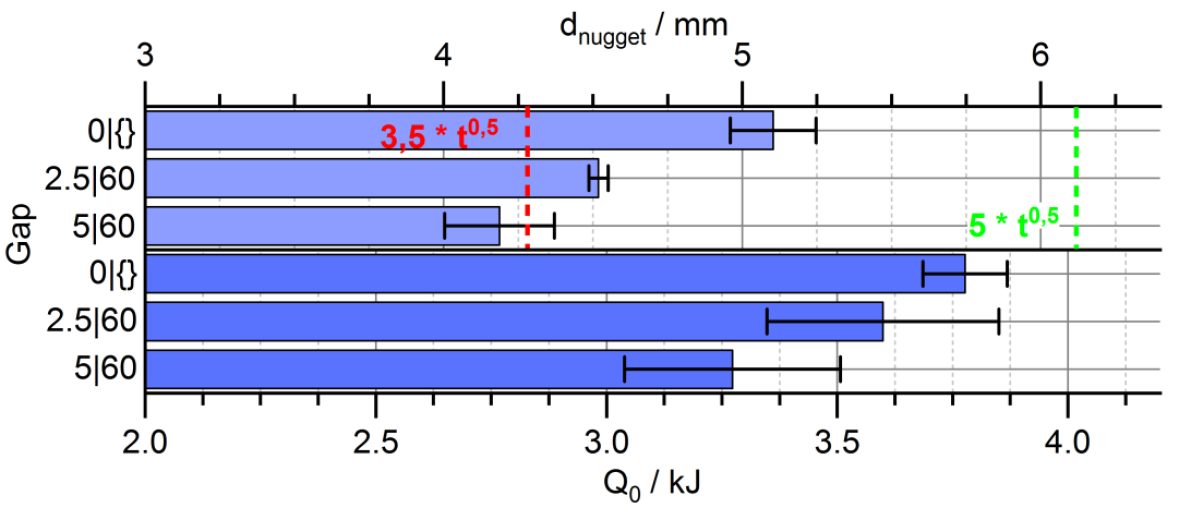

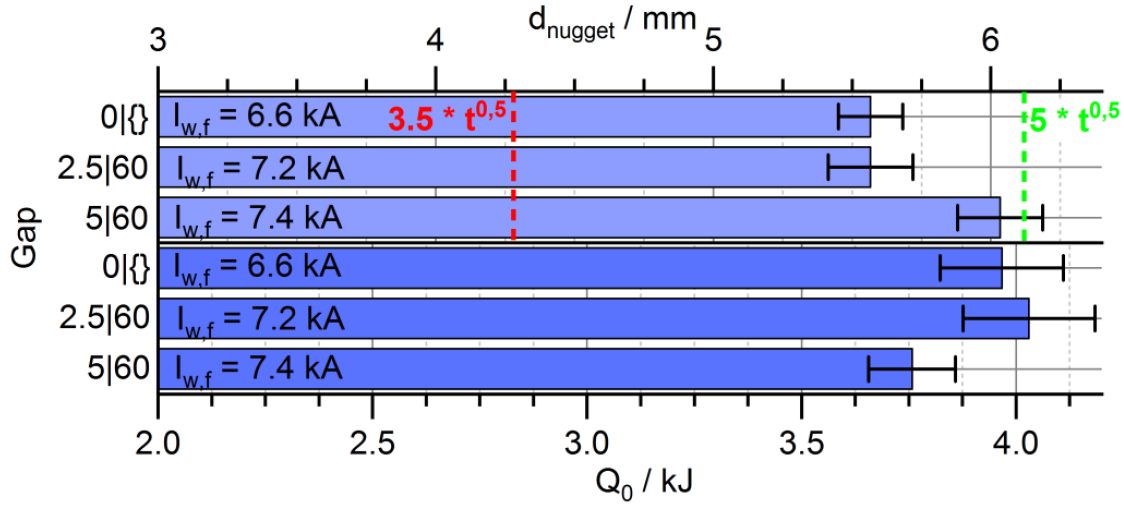

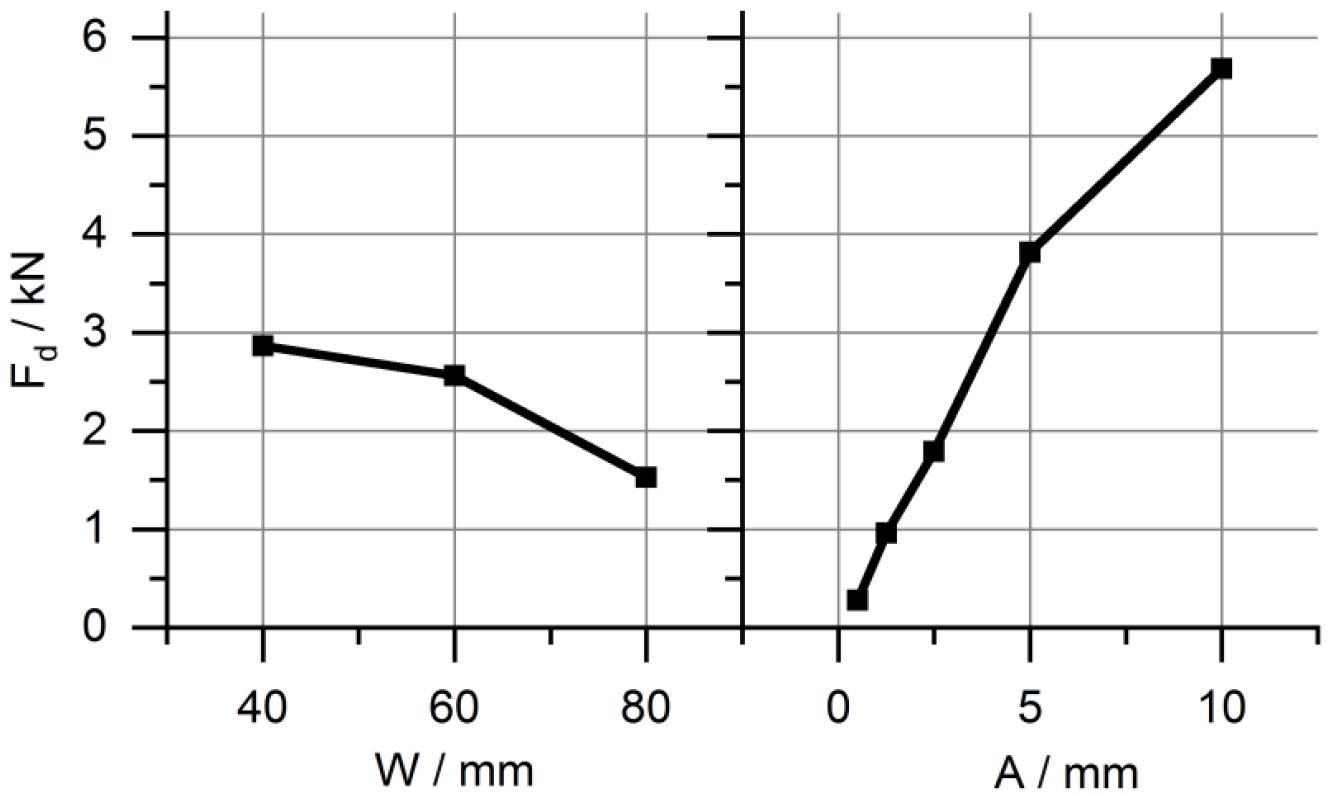

In Figure 4, the achieved nugget diameters at different gaps using a constant machine setting of Iw,f = 6.4 kA are displayed.

Figure 4: Effect of Gaps on Nugget Diameter, Absolute and Relative Results.K-12

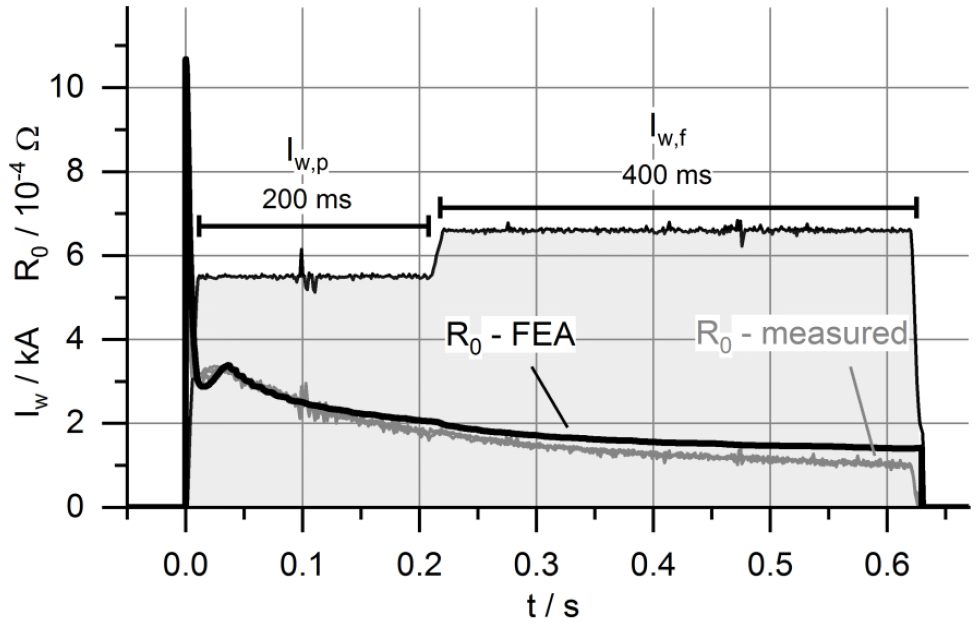

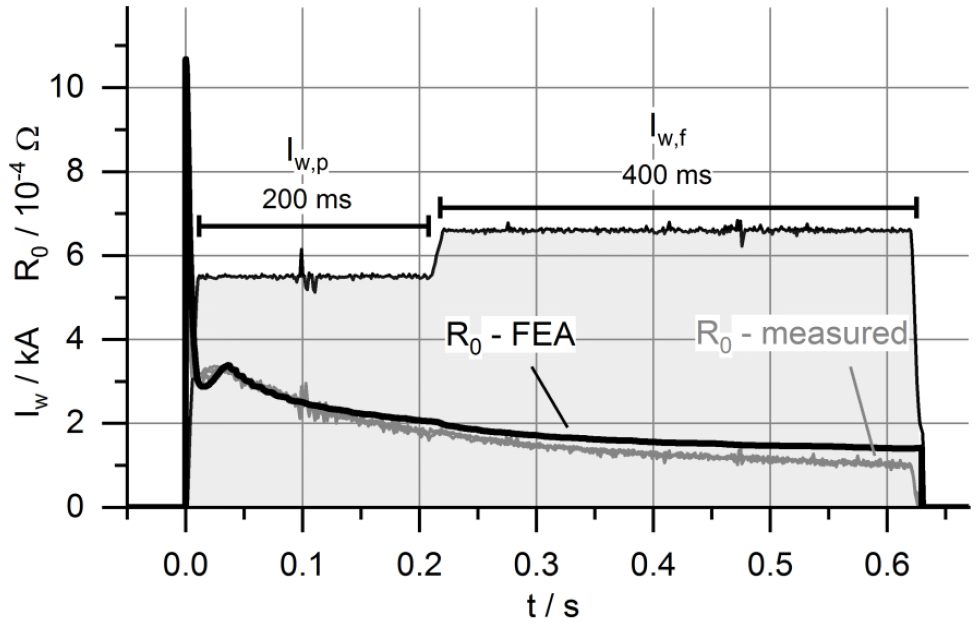

A two-staged welding program, starting with a preheat current followed by a larger finishing current proved to yield the best welding results with the material used, cf., Figure 5. In Figure 5, the applied welding current program along with the measured and computed total resistance curve is displayed.

Figure 5: Exemplary Total Resistance Curve of a Weld without Gap, Measured and Computed Results.K-12

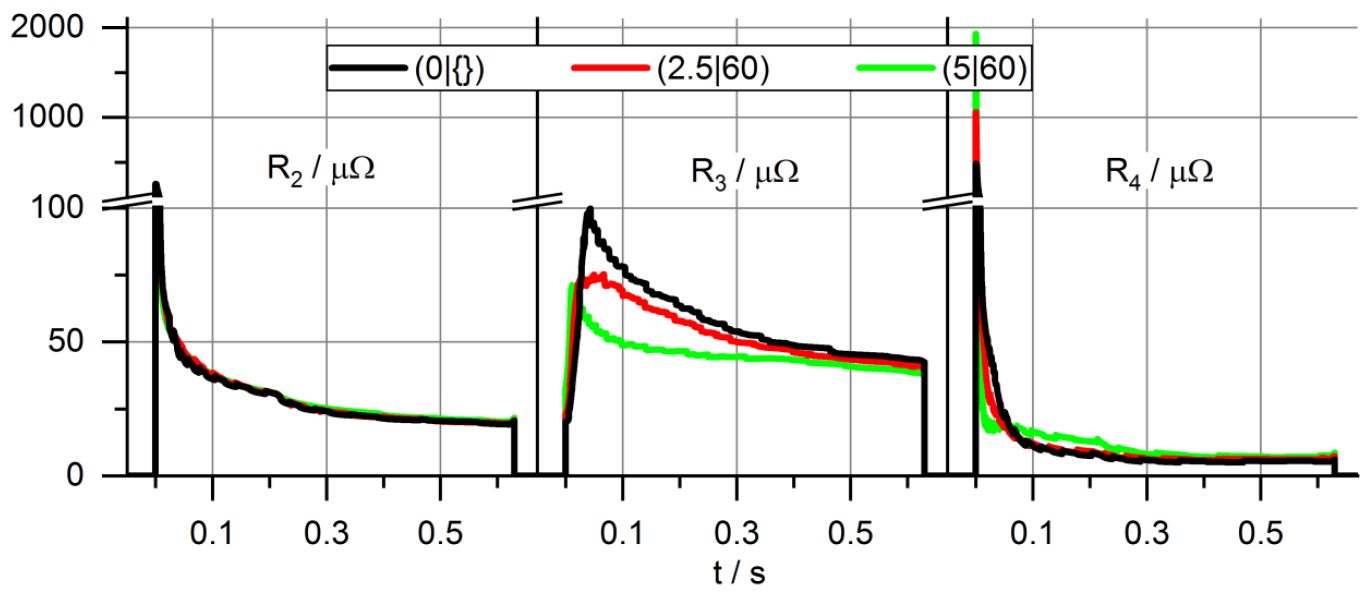

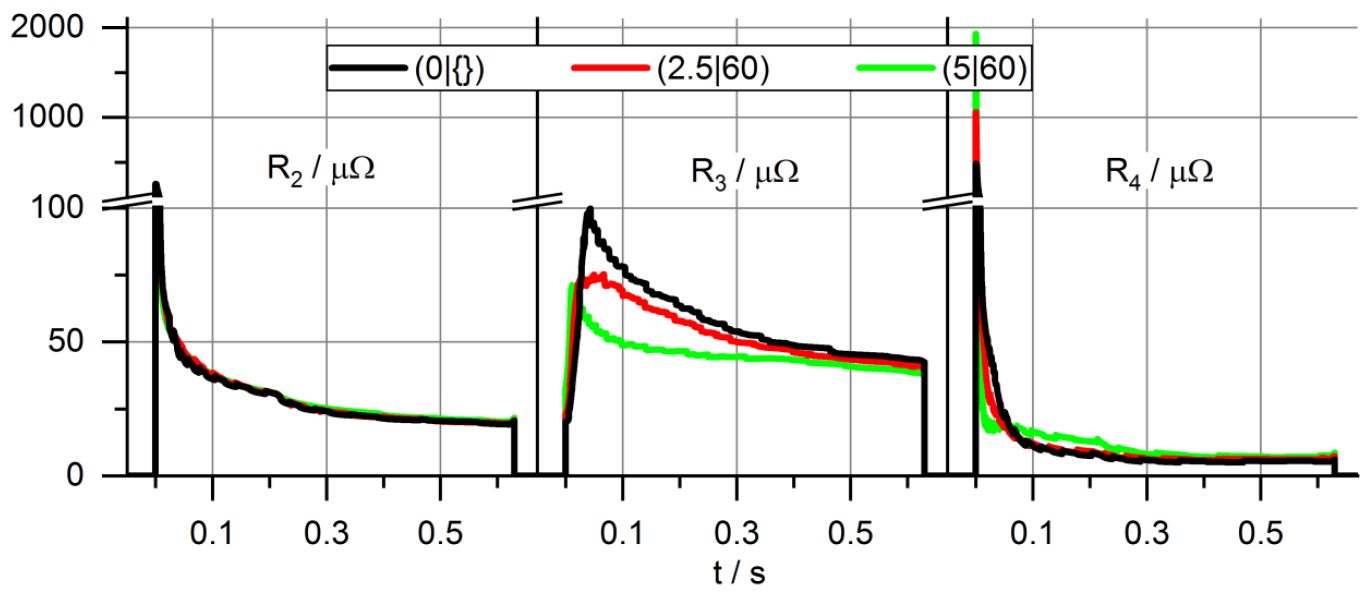

The FEA model can represent the welding process in terms of nugget diameter, dynamic resistance curve, and total electric energy with great accuracy. In Figure 6, the partial resistances of the weld as computed by FEA are composed.

Figure 6: Partial Electrical Resistances at Different Gap Configurations.K-12

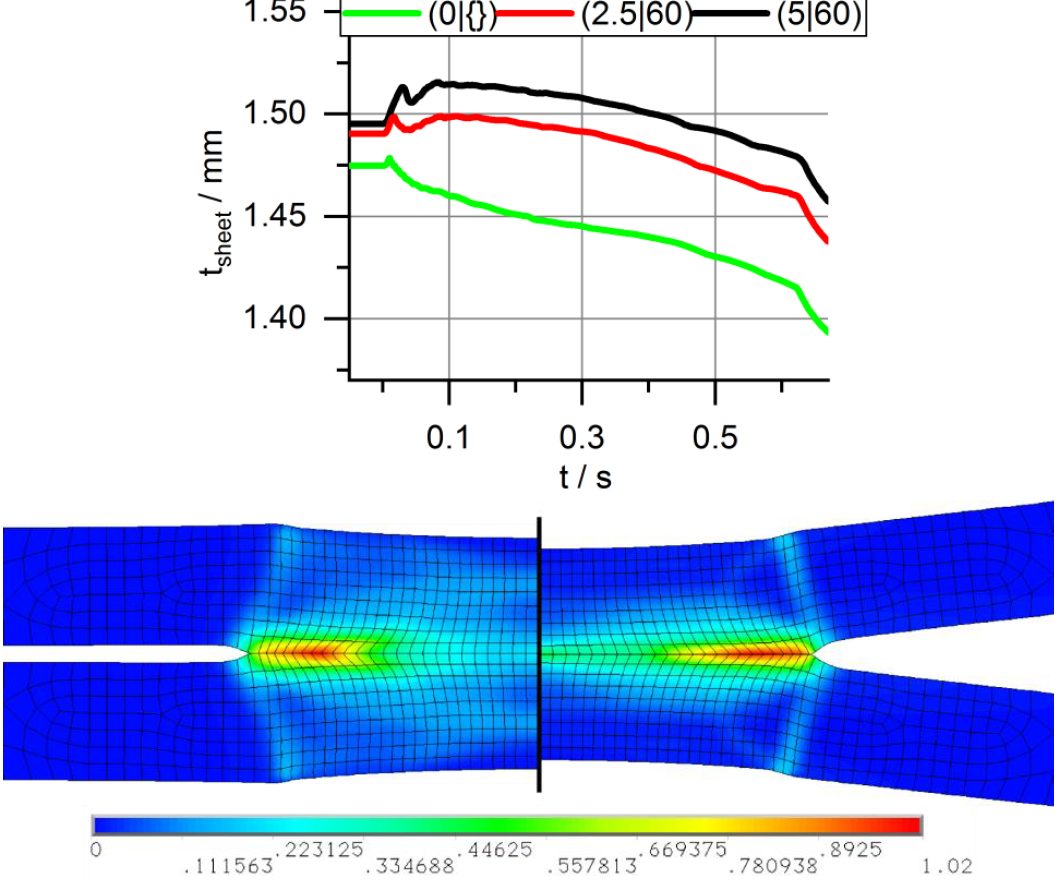

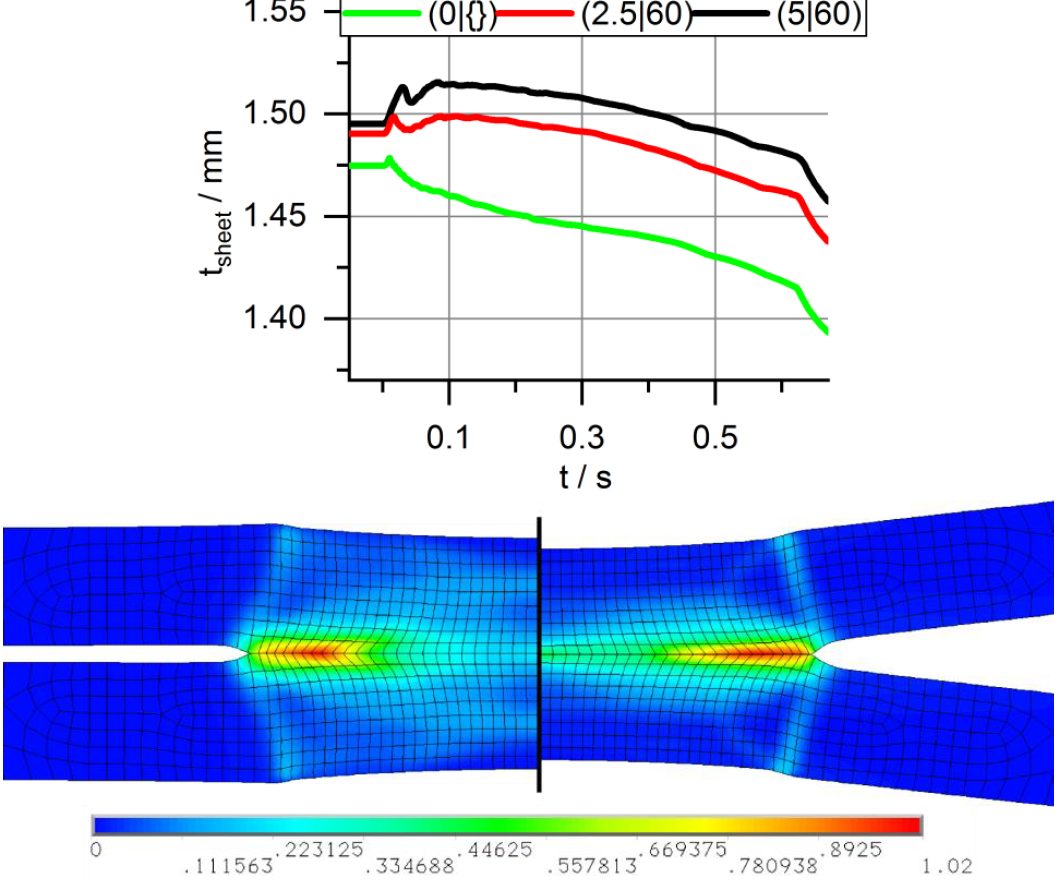

In the top section of Figure 7, the computed sheet thickness curve during the process for different gaps is presented. Increased electrode indentation during welding at gaps is the reason for reduced resistance and, therefore, results in reduced nugget diameters. The lower section of Figure 7 shows the plastic strains in the sheets along with a visibly reduced sheet thickness.

Figure 7: Dynamic Sheet Thickness (up) and Plastic Strain in millimeters at Different Gaps (low, to scale).K-12

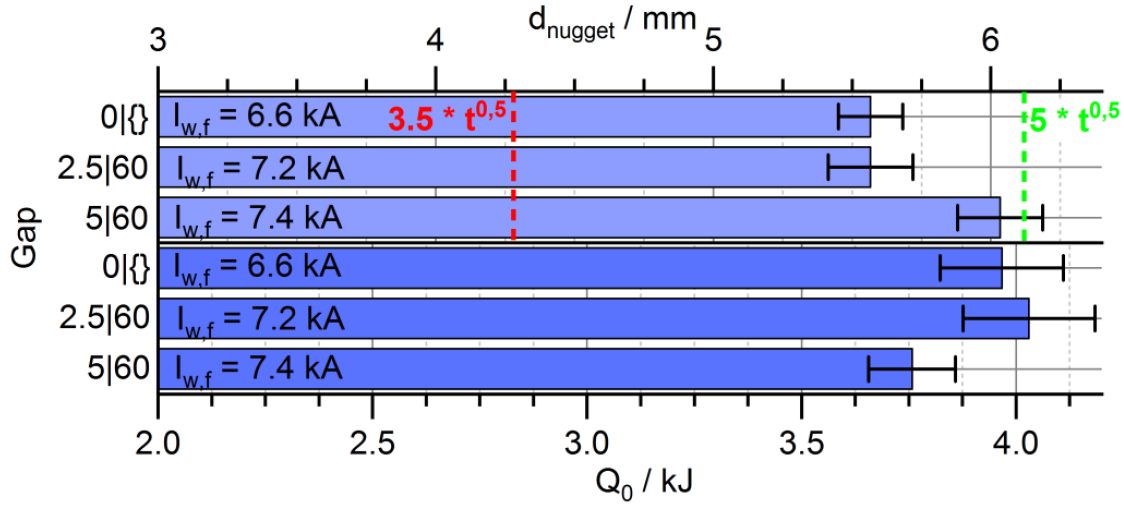

Additional welding experiments were performed to clarify, if increased welding current can counter the gap effect and maintain the energy level of the weld. The results are shown in Figure 8. They prove that increased weld current is sufficient to not only maintain the nugget diameter at gaps, but moreover increase it.

Figure 8: Nugget Diameter and Energy of Spot Welds near the Splash Limit at Overlaps with Gap.K-12

Results of further investigations on the weldability lobe of the joint are composed in Figure 9.. It is visible that with increasing gap the current range shifts toward larger currents and gets narrower.

Friction Stir Welding

This article summarizes a paper entitled, “An Evaluation of Friction Stir Spot Welding as a Method for Joining Ultra-thin Steel Sheet,” by Y. Hovansk, et al.H-10

The study analyzes Friction Stir Spot Welding (FSSW) as a process for assembly of two sheet stack ups. The steel sheet used for this study is CR4-GI, a hot dip galvanized ultra-low carbon interstitial free steel with a tensile strength of 280 MPa. Thicknesses of both 0.45 and 1.2 mm were used to create dissimilar thickness, two-sheet stack-ups. Preparation for joining via FSSW did not alter the zinc coating. FSSW joints were evaluated in lap shear tensile, T-peel, and cross tension.

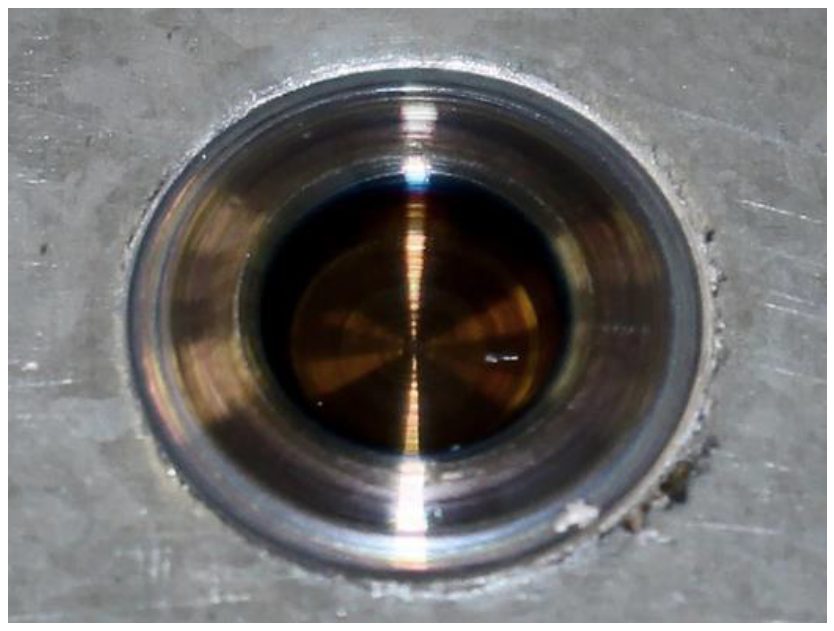

FSSW welds were welded with an EKasin injection molded, silicon nitride tool shown in Figure 1. All welds were performed at 1600 rpm.

Figure 1: Representative Picture of a Silicon-Nitride FSSW Tool with a 10-mm-diameter Shoulder and a 1.15-mm Probe Length.H-10

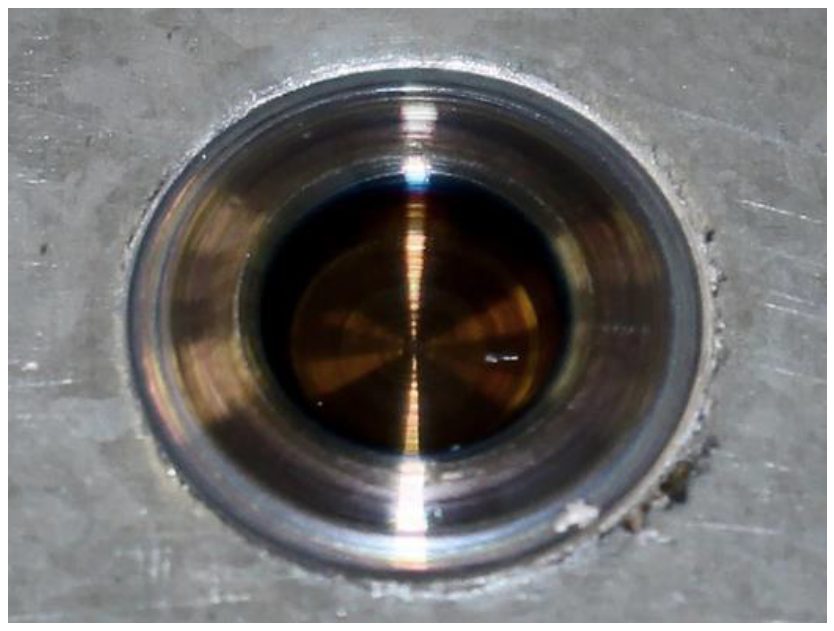

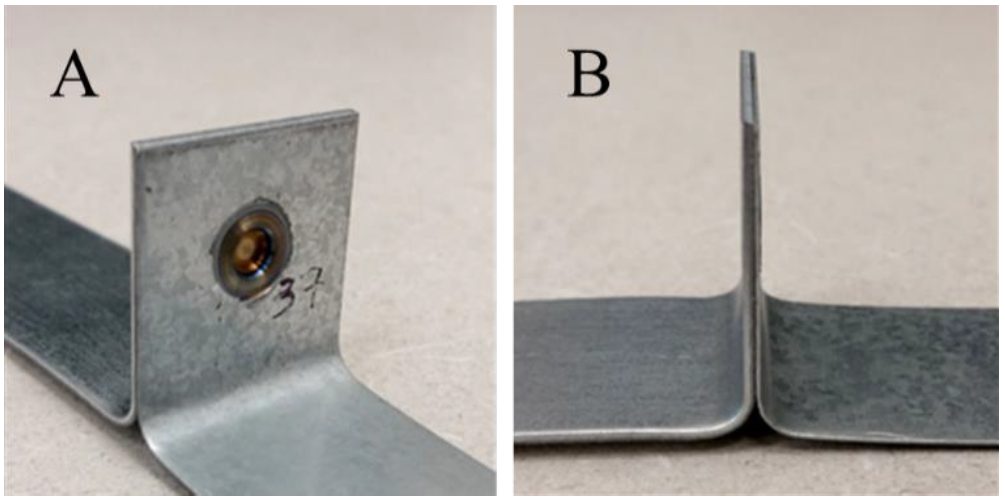

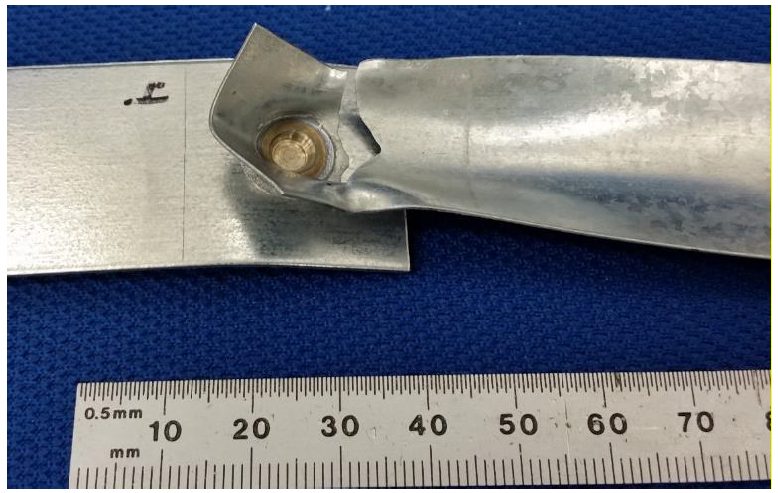

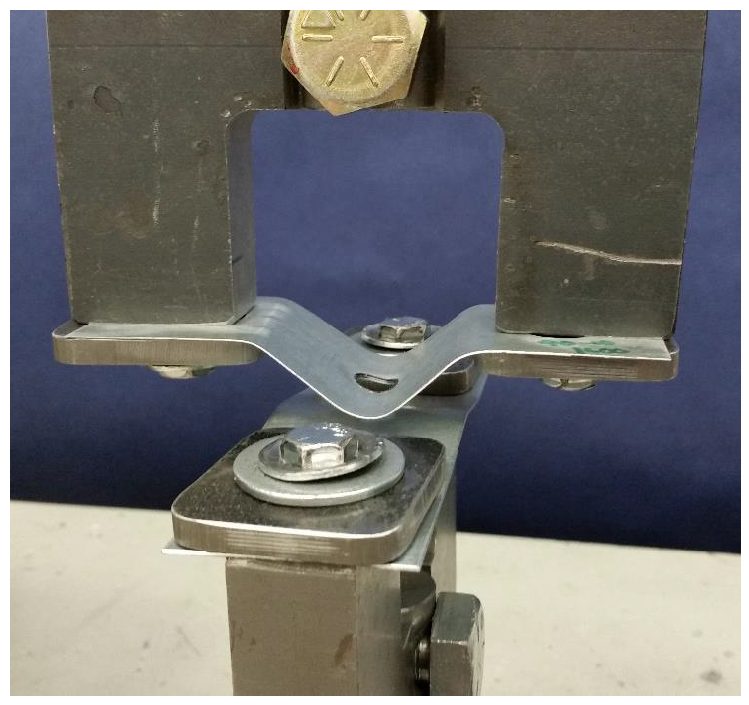

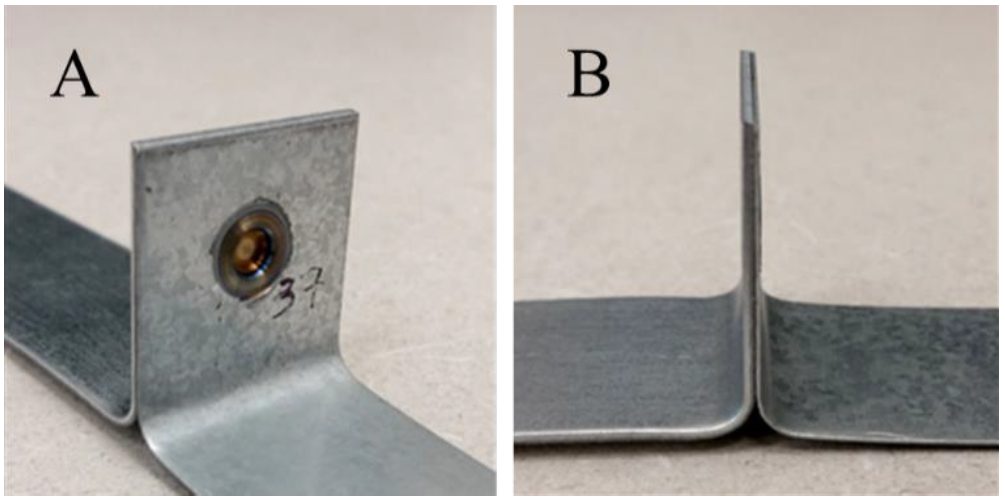

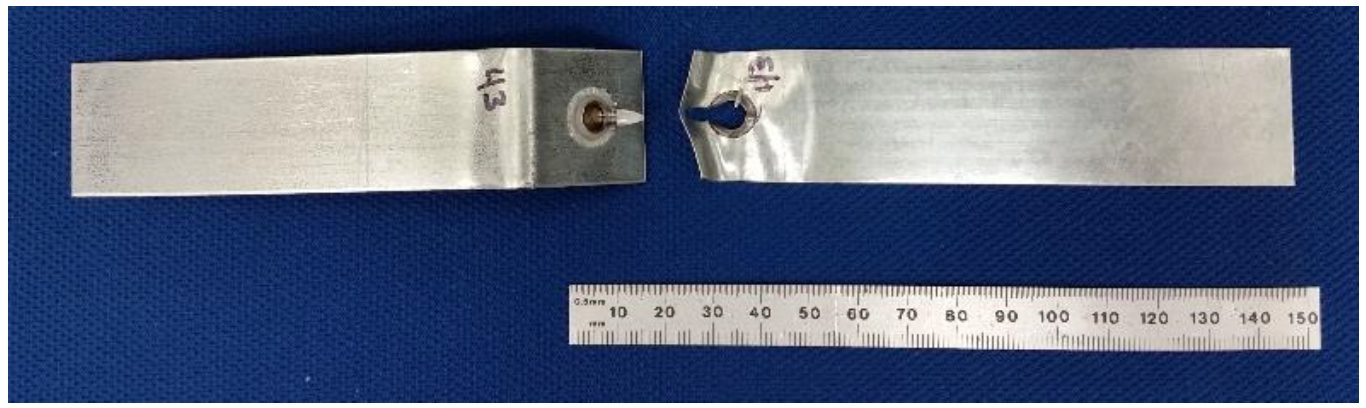

The zinc coating that originally covered the sheet surface was extruded beneath the FSSW tool to the outer edges of the weld as seen in Figure 2. Figure 3 shows a representative weld on a T-peel specimen.

Figure 2: Optical Image of the Top Surface of a Friction Stir Spot Weld in CR4-GI.H-10

Figure 3: A T-Peel Specimen Produced on a 25-mm-wide Strips with FSSW 0.45- to 1.2-mm-thick CR4-GI.H-10

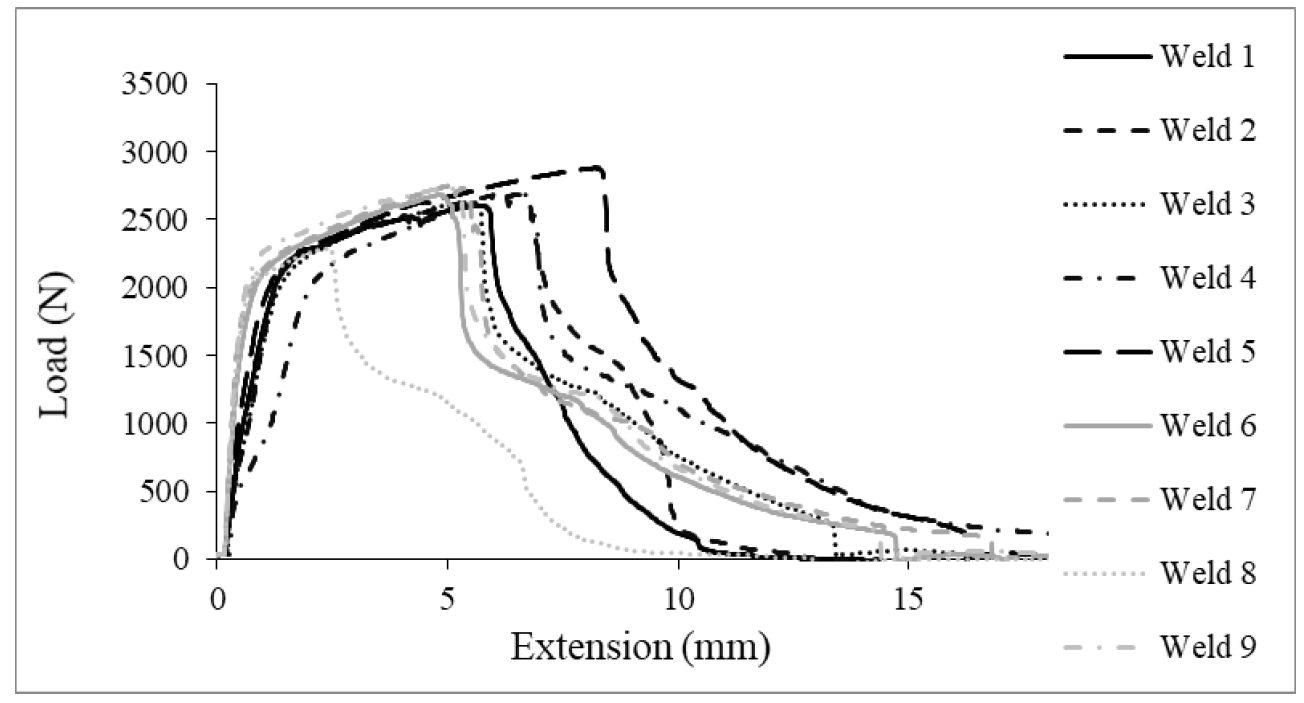

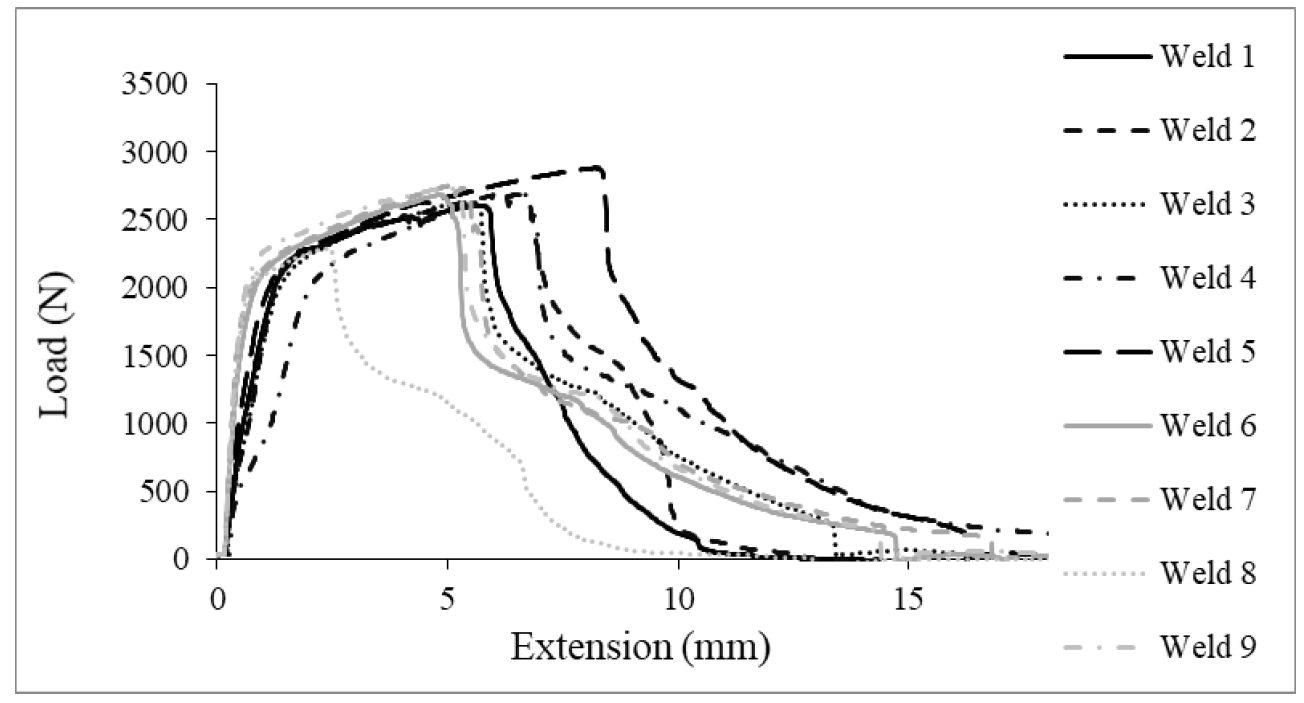

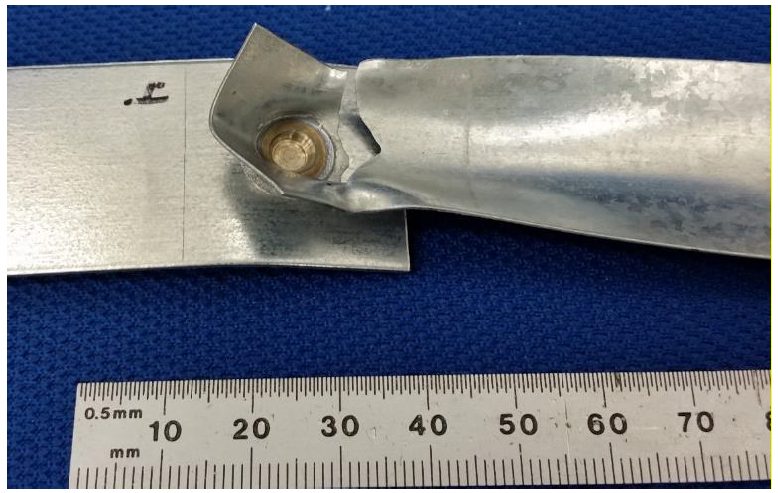

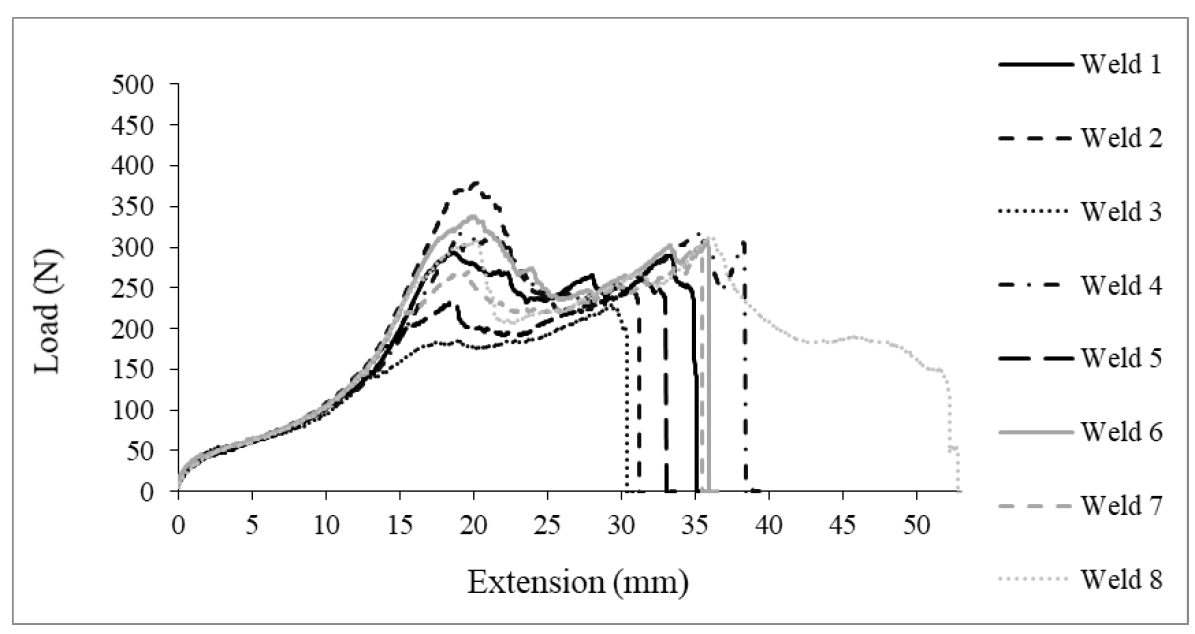

A minimum of 25 specimens were produced for each geometry tested, however, these specimens were performed at various times throughout weld development and data is shown below. Figure 4 shows the load-extension curves for a set of nine friction stir spot welds. Figure 5 shows a representative fracture of lap-shear tensile specimen.

Figure 4: Test Results for Lap-Shear Tensile Data of Friction Stir Spot Welds in 0.45-mm CR4-GI.H-10

Figure 5: Friction Stir Spot Weld in 0.45-mm CR4-GI Fractured in Lap-Shear Tensile.H-10

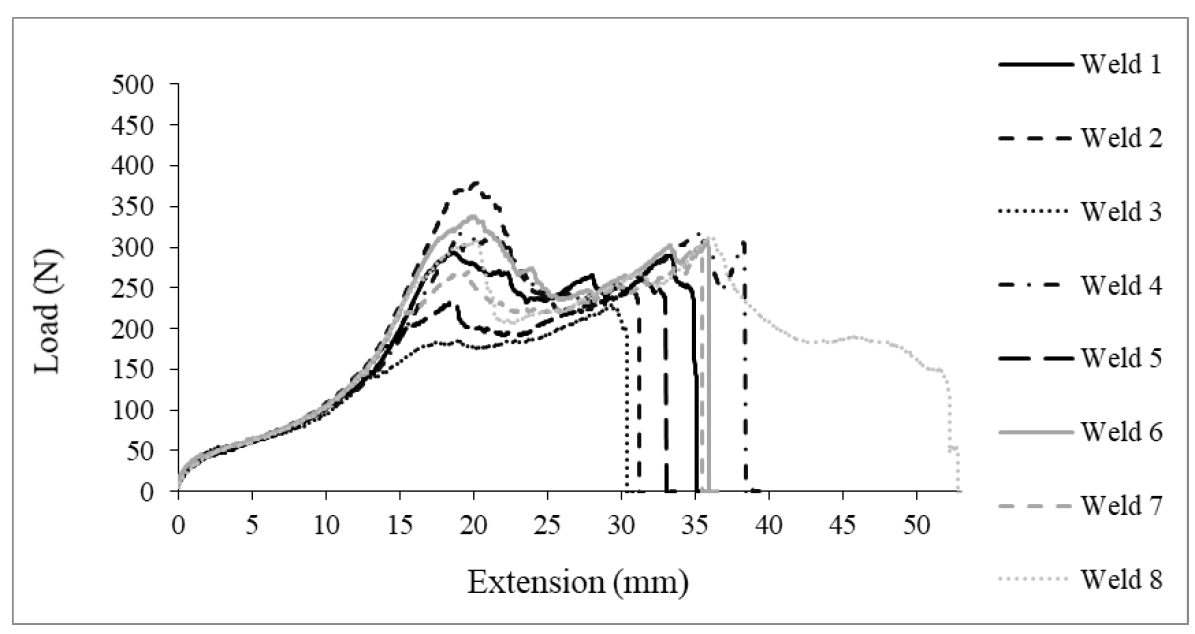

Figure 6 shows the load-extension curves for a set of eight friction stir spot welds tests in T-peel. A representative fracture of T-peel specimen is shown in Figure 7.

Figure 6: Test Results for T-Peel Data of Friction Stir Spot Welds in 0.45-mm CR4-GI.H-10

Figure 7: Friction Stir Spot Weld in 0.45-mm CR4-GI Fractured in T-Peel.H-10

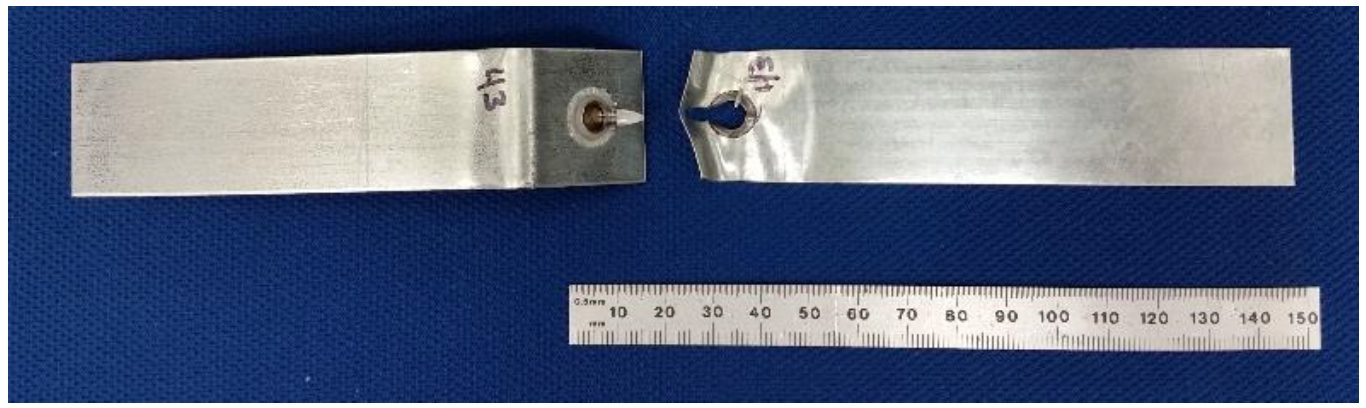

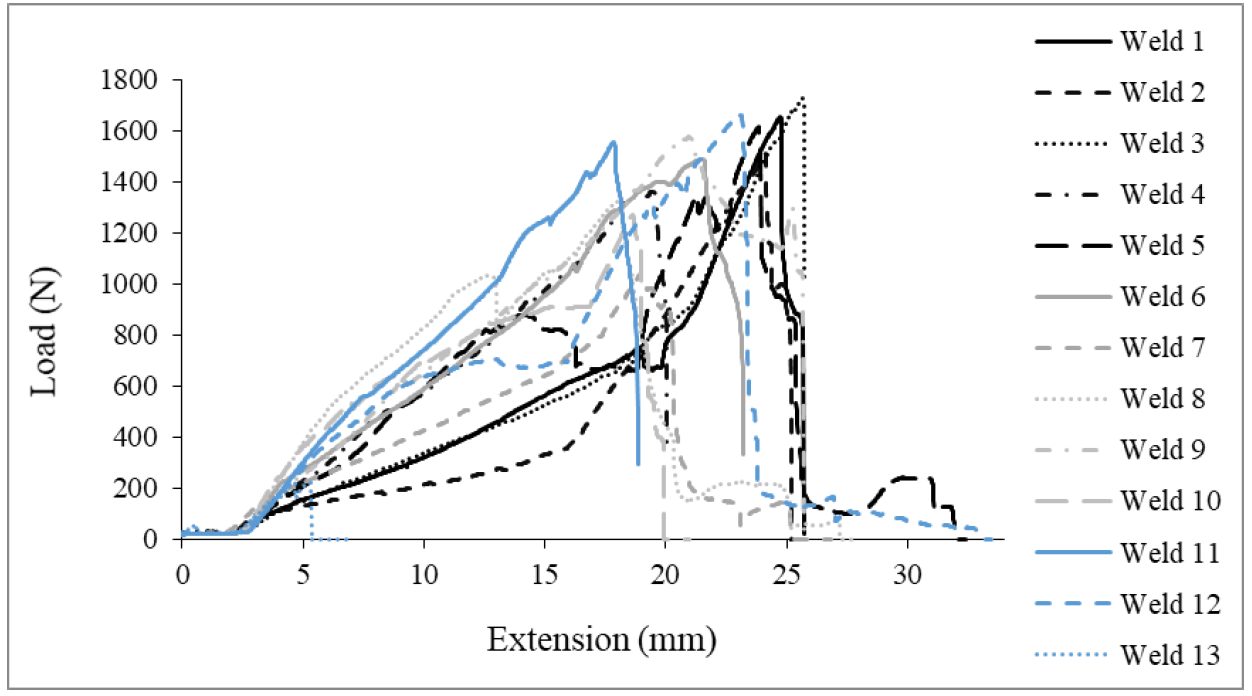

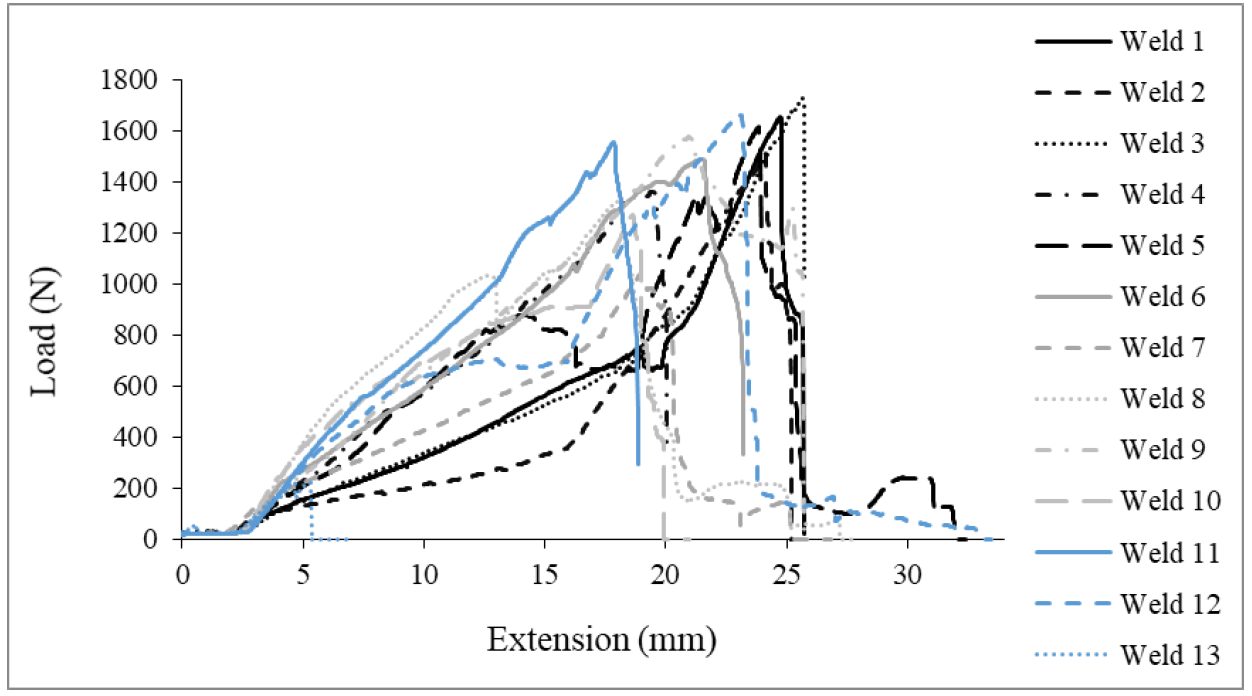

Figure 8 shows the load extension curves for a set of 13 friction stir spot welds tested in cross tension. Representative geometry and fracture of cross tension specimen are shown in Figure 9.

Figure 8: Test Results for Cross-Tension Data of Friction Stir Spot Welds in 0.45-mm CR4-GI.H-10

Figure 9: Friction Stir Spot Weld in 0.45-mm CR4-GI Fractured in Cross-Tension.H-10

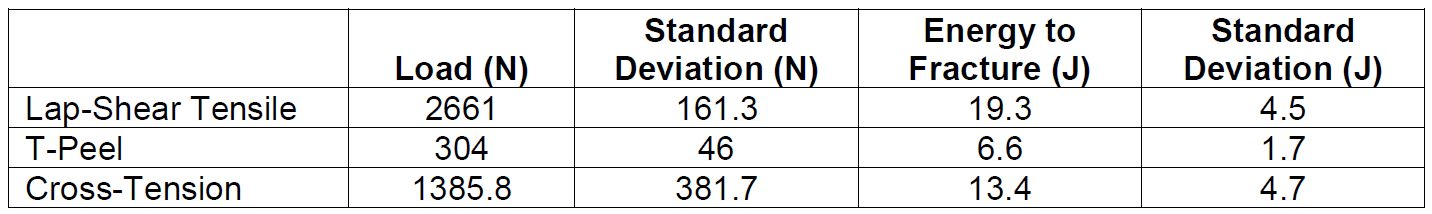

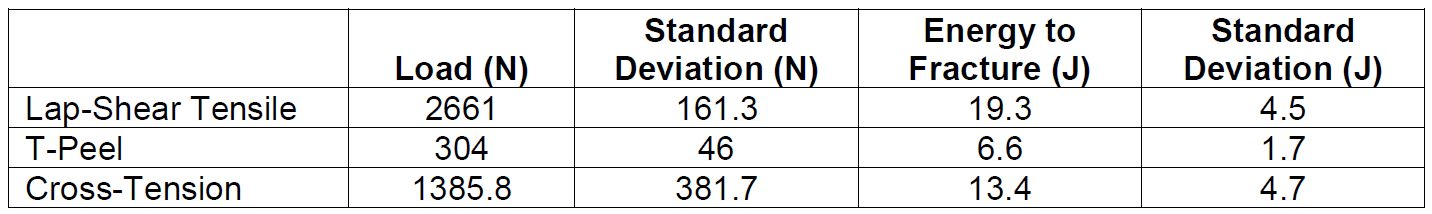

A table showing the overall results for the FSSW joints produced herein are shown in Table 1 below:

Table 1: Summary of Fracture Loads and Energies from Friction Stir Spot Welds made in Ultra-Thin CR4-GI for Three Unique Test Configurations.H-10

While each specific test orientation demonstrated the ability for the weld nugget to pull out of the ultra-thin top sheet and remain with the lower 1.2-mm-thick sheet, the overall ratios between fracture loads suggest there is an area for improvement with respect to T-peel.

Arc Welding

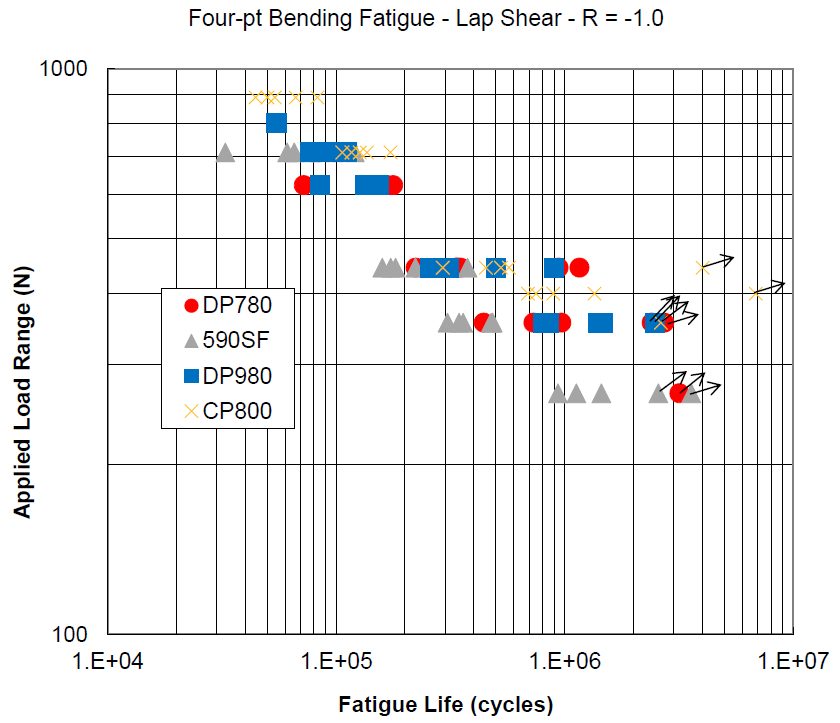

This article summarizes a paper by W. Mohr and N. Kapustka, EWI, entitled, “Fatigue of GMAW-P Lap Joints in Advanced High-Strength Steels.”M-13

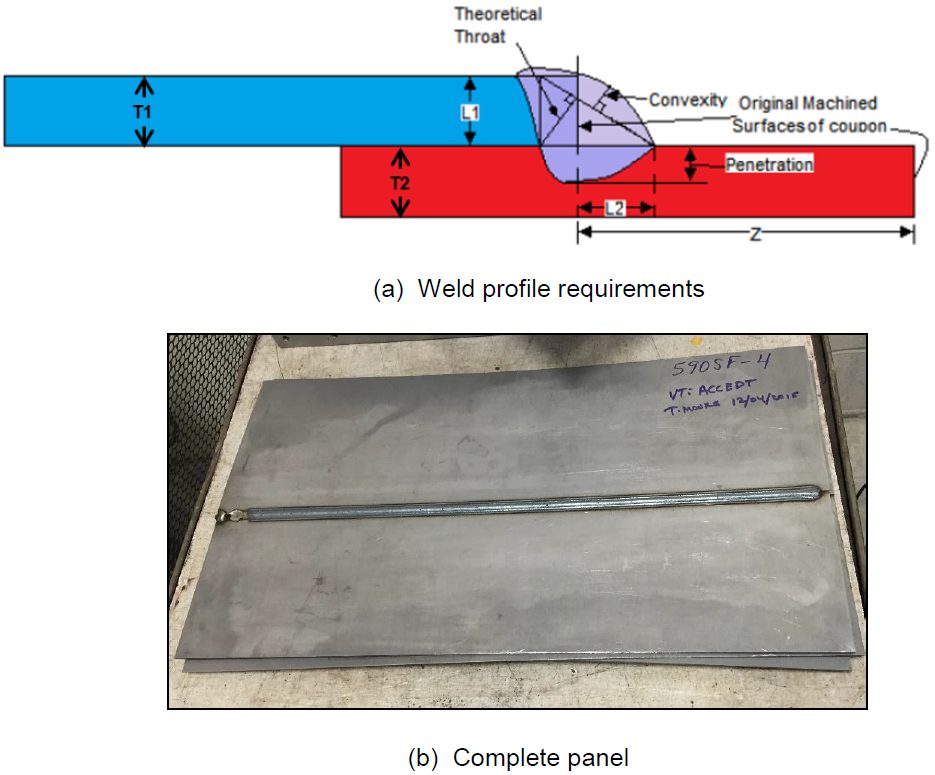

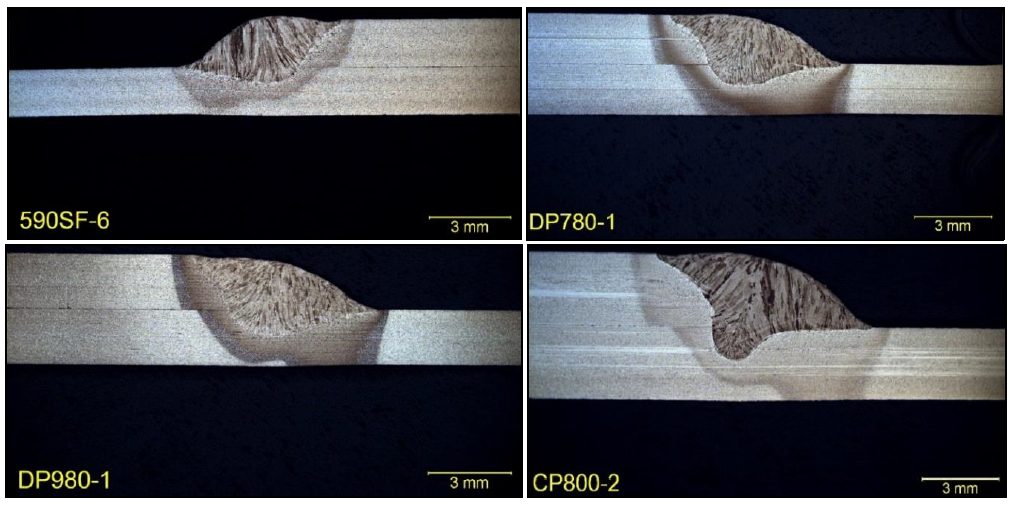

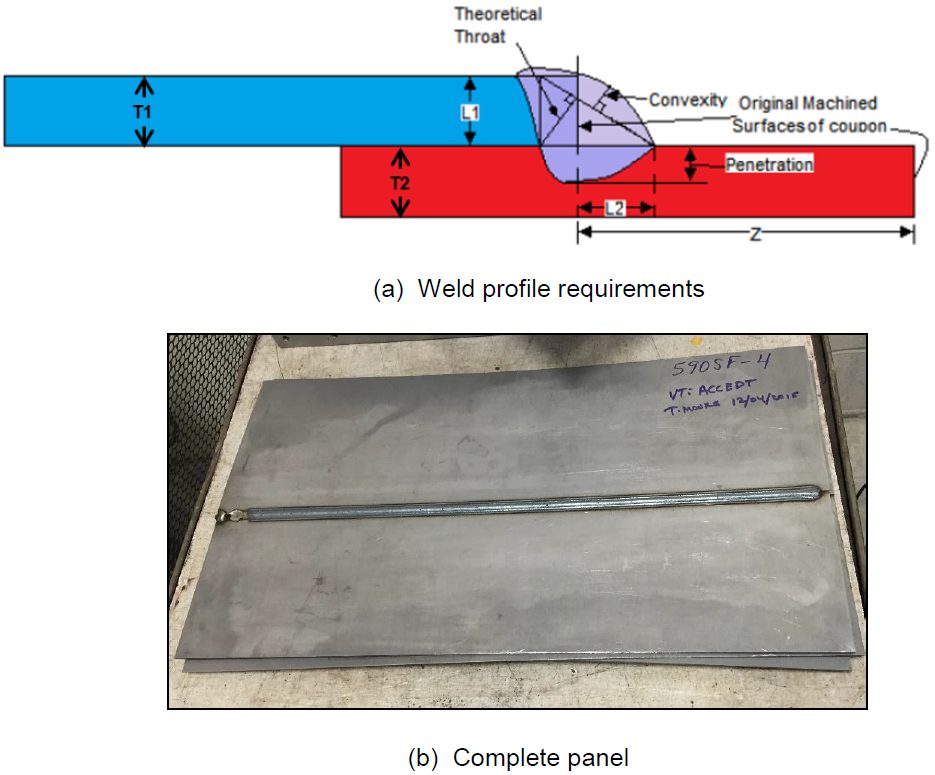

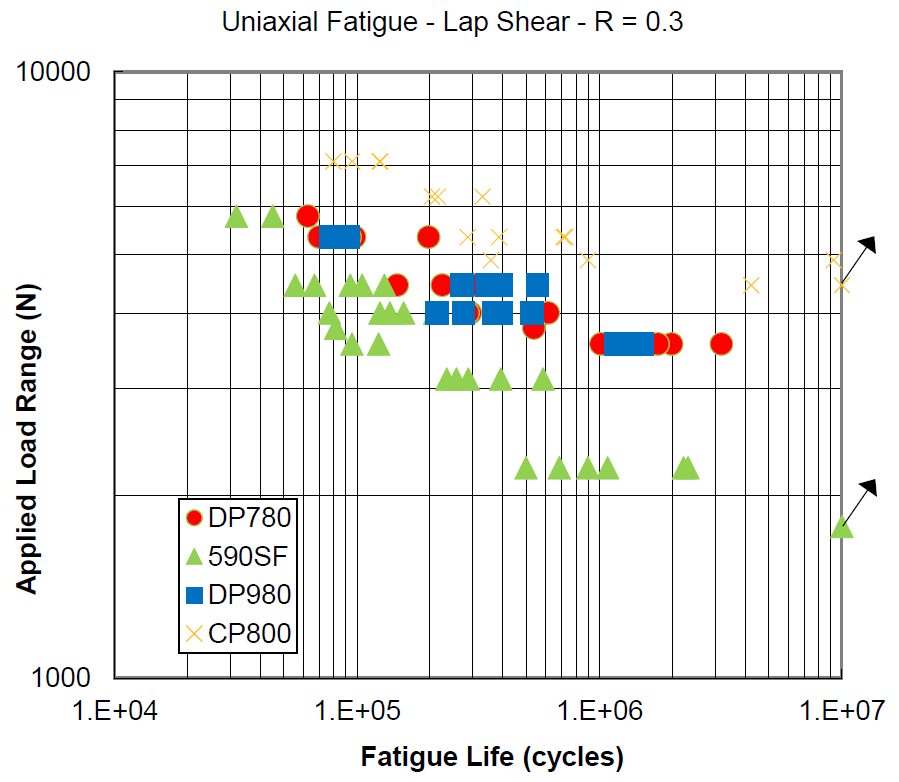

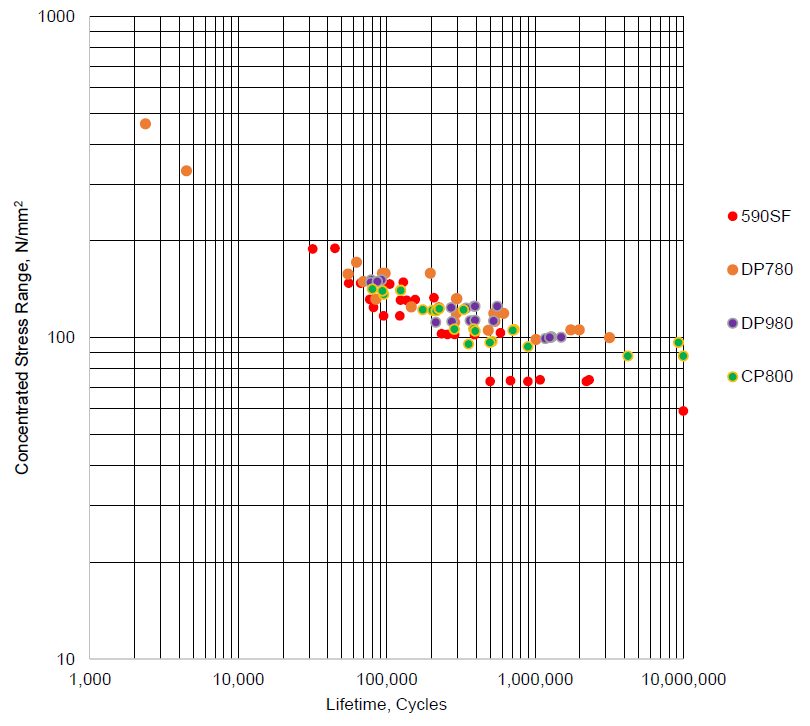

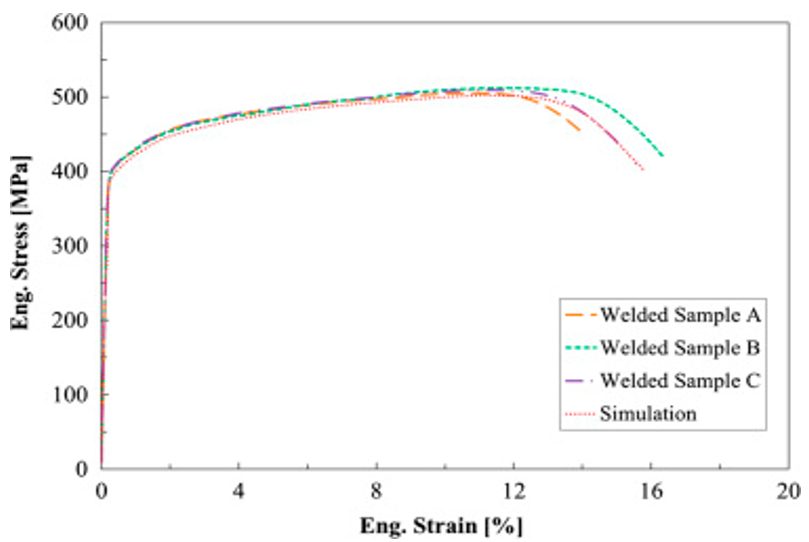

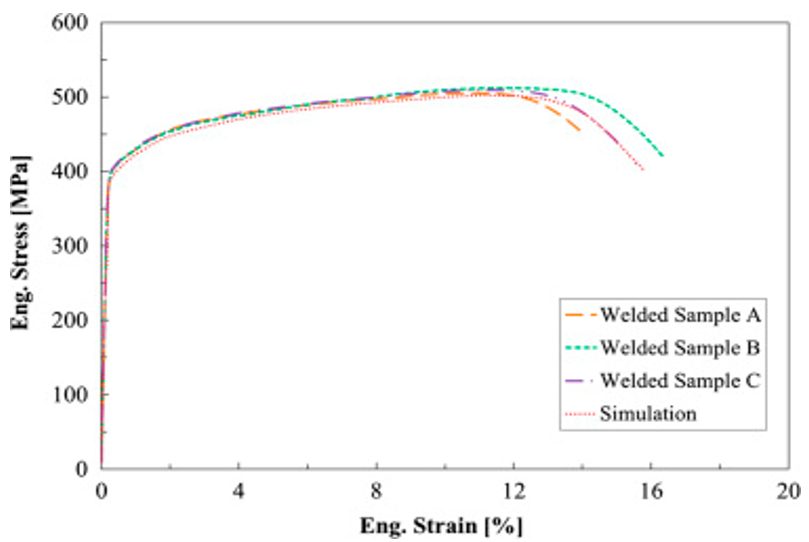

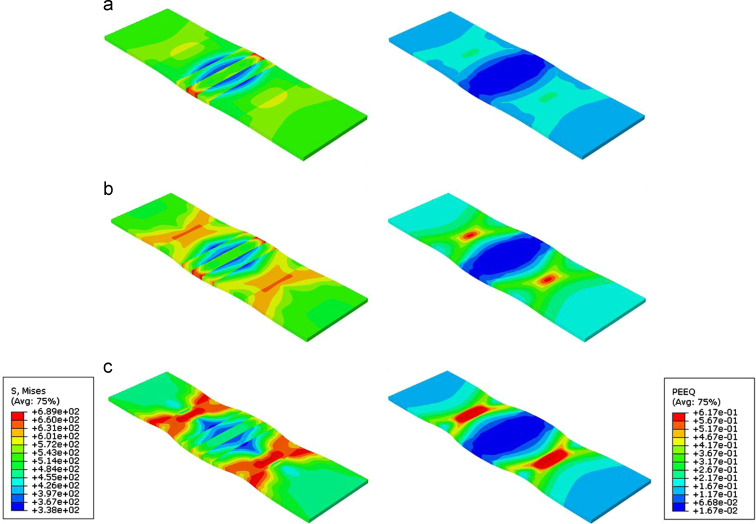

EWI has performed fatigue tests on welds from four Advanced High-Strength Steels (AHSS) in the uncoated condition. The materials were provided in three thicknesses as follows, 2.0-mm DP 780, 1.8-mm 590 SF, 2.0-mm DP 980, and 2.8-mm CP 800. Referring to Figure 1(a), welding parameters were selected to meet the weld profile requirements listed below:

The travel speed to achieve such combinations was 23 mm/s for three of the sheets and 13 mm/s for the 2.8-mm-thick CP 800. Figure 1 shows a completed panel.

Figure 1: Completed Panel.M-13

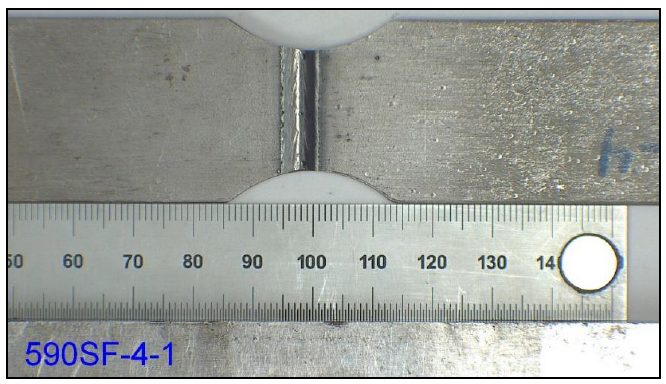

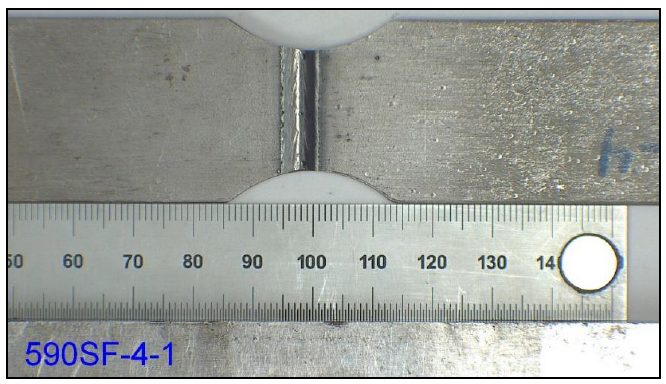

Specimens were cut from the lap-welded panels in a configuration recommended by Z 2275, with minimum reduced sections of 20-mm wide, with 20-mm radii on both sides to a full width of 30 mm, as shown in Figure 2.

Figure 2: Specimen Design.M-13

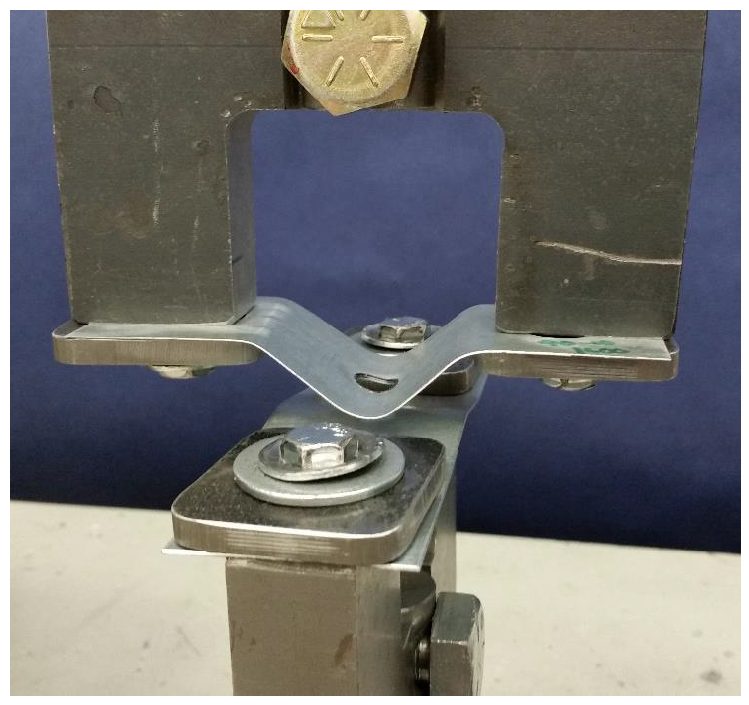

Fixtures for the bend testing had eight, 6.3-mm radius rollers, four on top and four on the bottom, with offsets of the roller centers to accommodate the lap-joint configuration and the differing sheet thicknesses. The interior span was 120 mm, while the exterior span was 210 mm. The full bending fixture, with a specimen inserted, is shown in Figure 3.

Figure 3: Bending Test Fixture.M-13

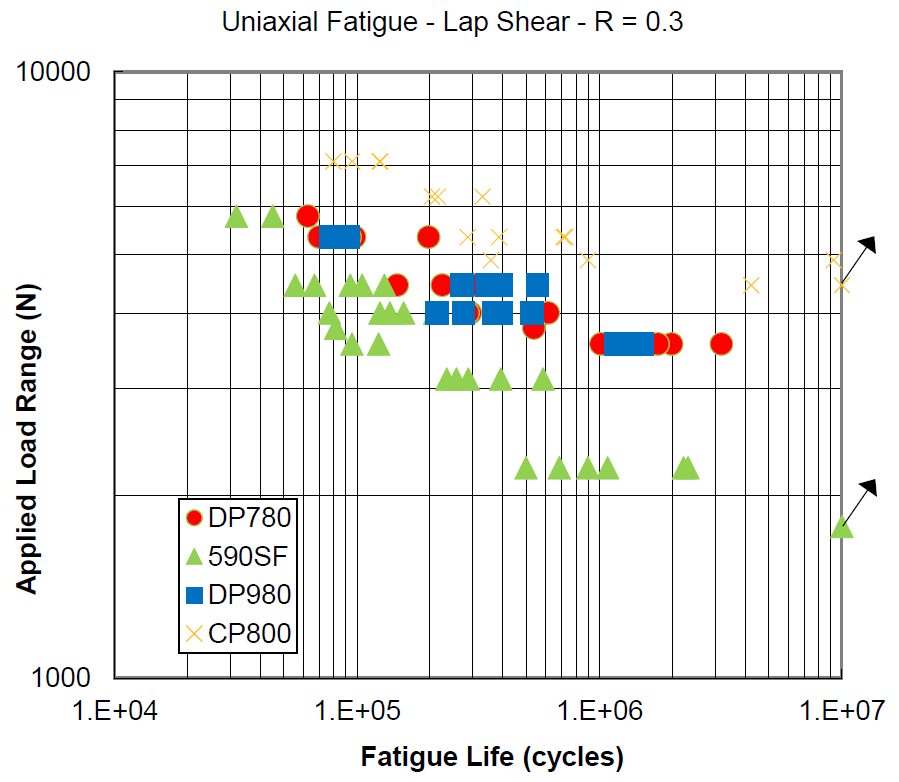

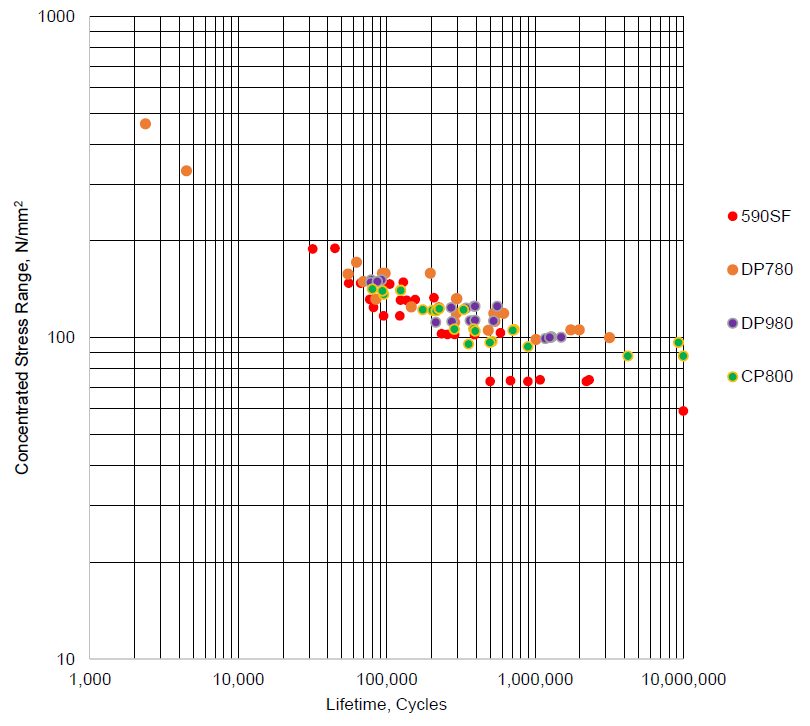

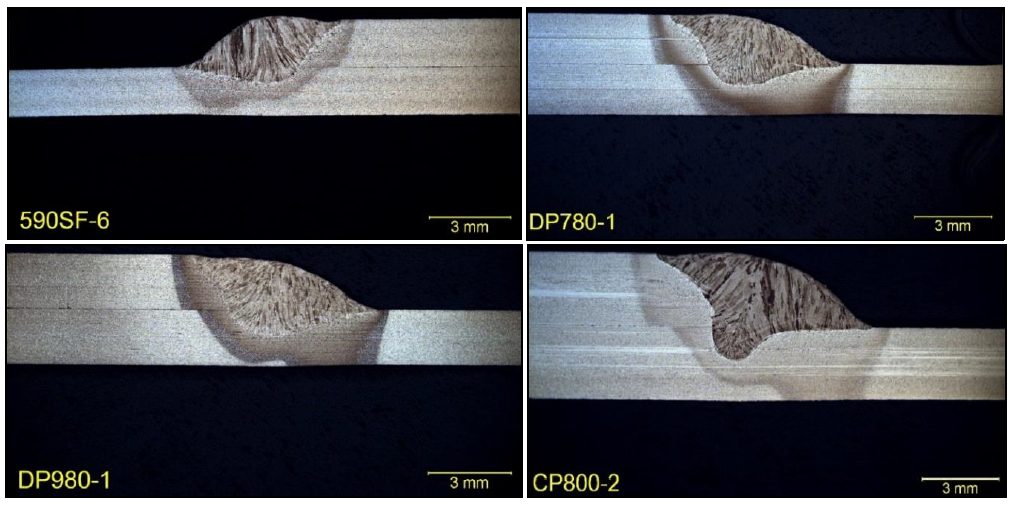

Weld profiles were achieved that met the weld profile requirements for each sheet material type. These weld profiles are shown for the four sheet materials in Figure 4. Fatigue testing results in tension at R = 0.3 gave lifetimes between 30,000 and 9 million cycles, with run-outs at 10 million cycles, as shown in Figure 5.

Figure 4: Cross Sections of Lap Joints (etched with 2% Nital).M-13

Figure 5: Results of Fatigue Testing in Tension at R= 0.3.M-13

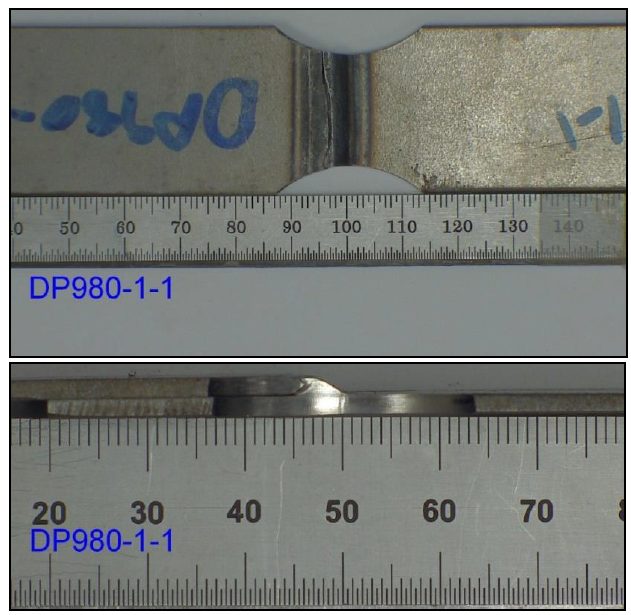

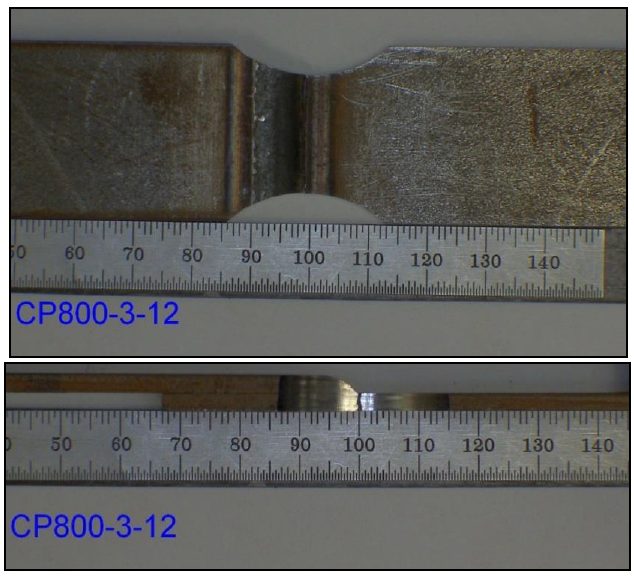

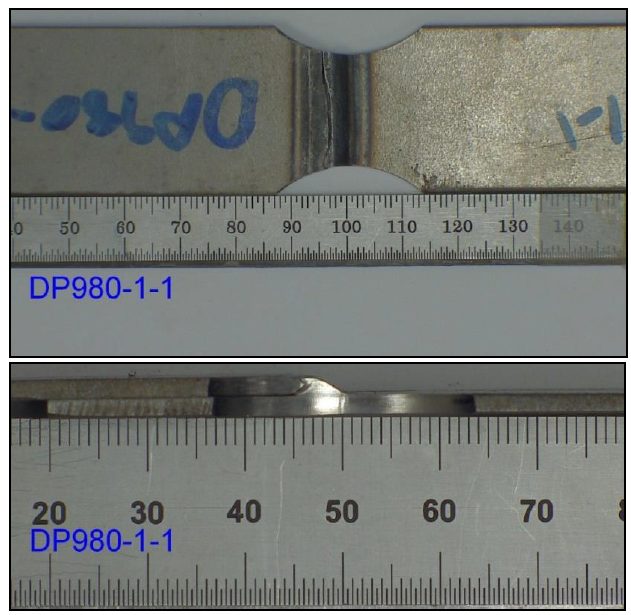

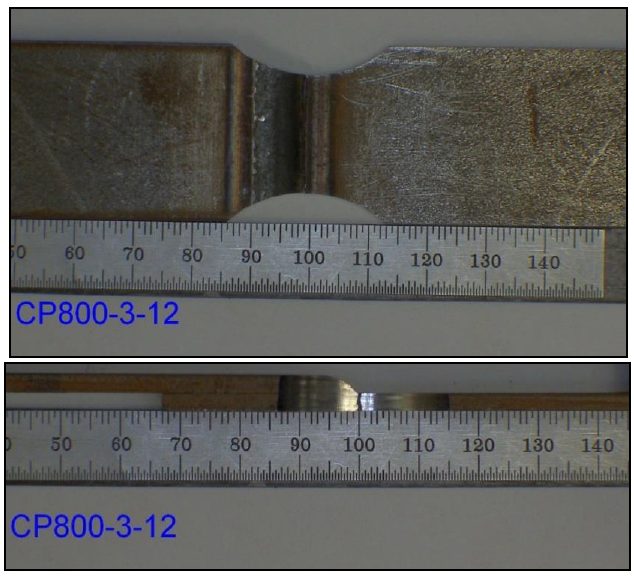

Weld root cracking dominated in the 590 SF, as well as the DP 780 and DP 980, with an example shown in Figure 6. Weld toe cracking was observed on the 2.8-mm-thick CP 800, with an example shown in Figure 7.

Figure 6: Example for a Root Crack Breaking Through the Weld Metal on DP 980.M-13

Figure 7: Example of a Toe Crack Breaking Through the Base Metal.M-13

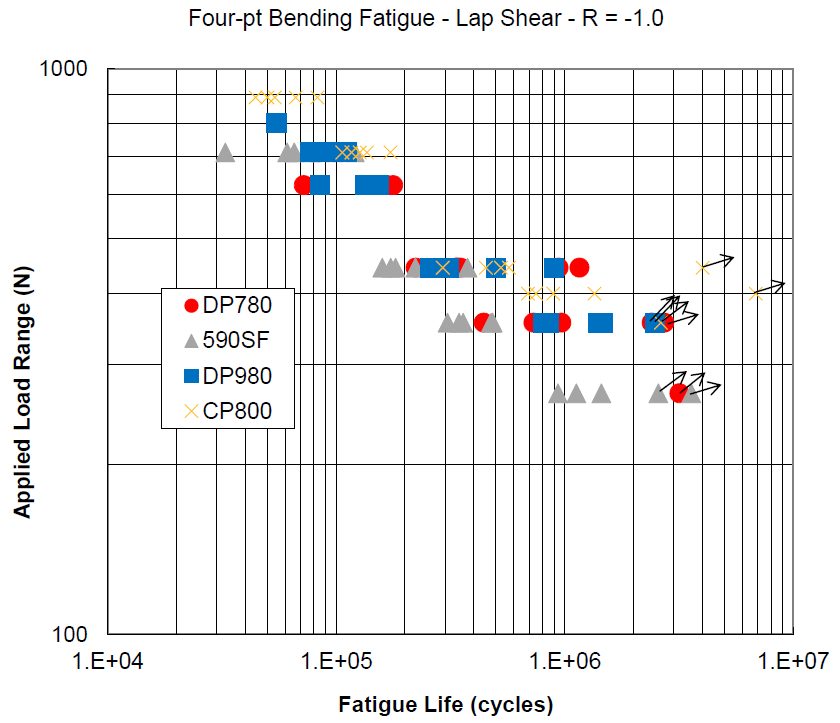

Fatigue testing in bending at R = -1 gave lifetimes between 30,000 and 2 million cycles, with run-outs on tests that continued to up to 7 million cycles, as shown in Figure 8.

Figure 8: Four-Point Bending Tests at R = -1.M-13

Taking the differing thicknesses, minor variations in minimum width, and the stress concentrations from the radii into account, the concentrated stress range was calculated to compare the four materials on a common basis, as shown in Figure 9.

Figure 9: Concentrated Stress Range versus Lifetime for Tension Tests.M-13

The fatigue cracks initiated at the root for the 1.8-mm 590 SF on both tension and bending testing. The fatigue cracks initiated at the weld toe for the 2.8-mm CP 800 on both tension and bending testing. The fatigue cracks initiated from the weld root in the tension testing and from primarily the weld cap in bending testing, for the 2.0-mm-thick DP 780 and 2.0-mm-thick DP 980.

![Figure 2: (a) A schematic diagram of the four stages of a SPR process, L-16 (b) A typical four-stage force–displacement curve of an SPR process, L-16 (c) Thick stacks with a semitubular SPR rivet and a fully tubular SPR rivet, L-16 (d) Comparison of the single-joint strength between aluminum rivets and a steel rivet with combined shearing and pull-out loading with loading angle α = 45°, H-11 (e) SPR joint quality and some faults [4]& (f) The displacement-load curves of the joints with different stack orientations. S-31](https://ahssinsights.org/wp-content/uploads/2020/09/image003.jpg)

![Figure 15: (A) Configuration of Lap-Shear and Coach-Peel Mechanical Test Specimens ,(B) Weld Microstructures for a 1.2-mm AA6022-T4 (top sheet) to 1.5-mm HDG LCS (bottom sheet) Stack-Up Welded using MRD Electrodes at 800 lb and 14 kA , (C) Secondary and Back-Scattered Electron Image (BEI) Micrographs [secondary electron images (SEI) left and BEI right] of the Al-Side Weld Fracture Surfaces for 1.2-mm AA6022-T4 to 1.5-mm HDG LCS Stack-Up Welded at 800-lb Clamping Force and 14-kA Welding Current, (D) Coach-Peel and Lap-Shear Mechanical Properties for (a) 1.2-mm AA6022-T4 Welded to 1.0-mm HDG LCS and (b) 1.2-mm AA6022-T4 Welded to 2.0-mm HDG LCS [, & (E) Coach-Peel and Lap-Shear Mechanical Properties for Coupons of Zn-Coated 1.2-mm AA6022-T4 to 1.0-mm HDG LCS Stack-Up Welded at 800 lb, 250 ms, and 16 kA.S-33](https://ahssinsights.org/wp-content/uploads/2020/09/image029.jpg)