Adhesive Joining

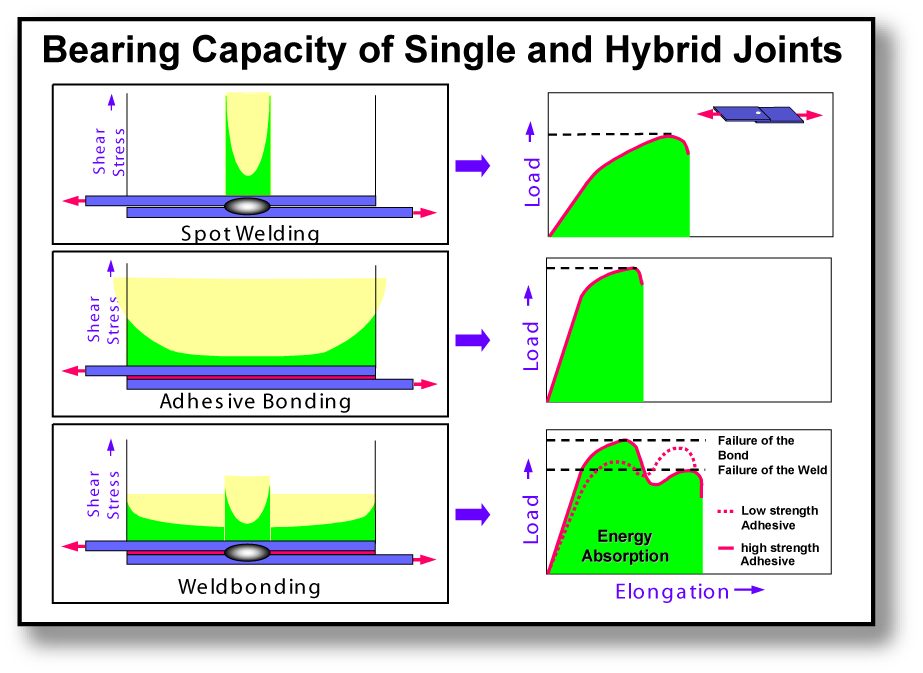

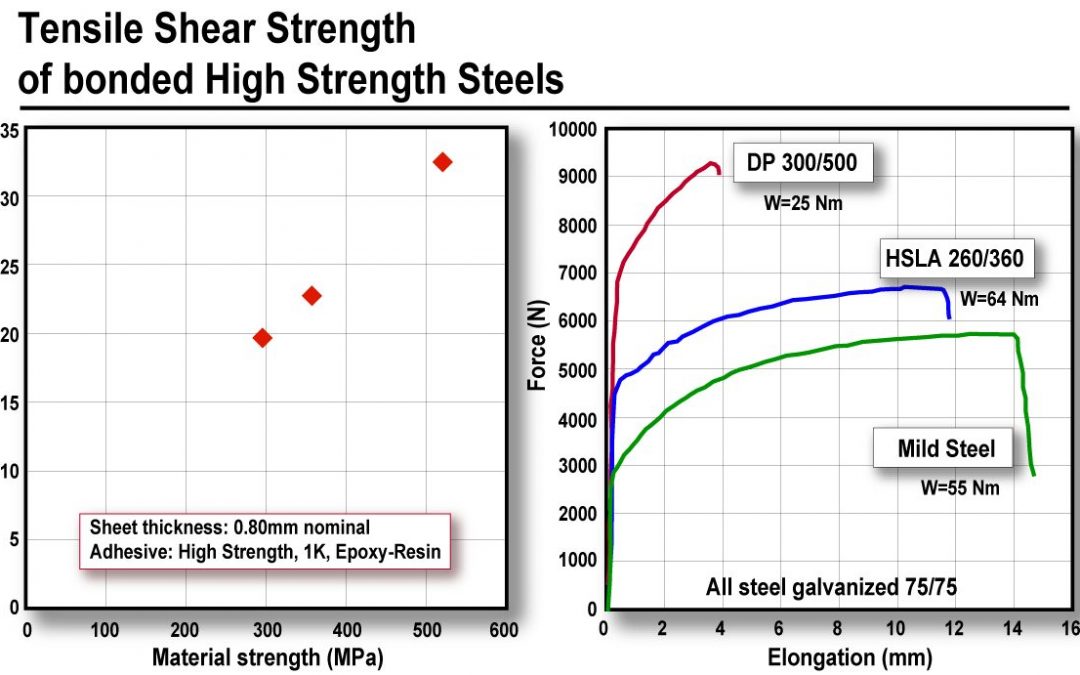

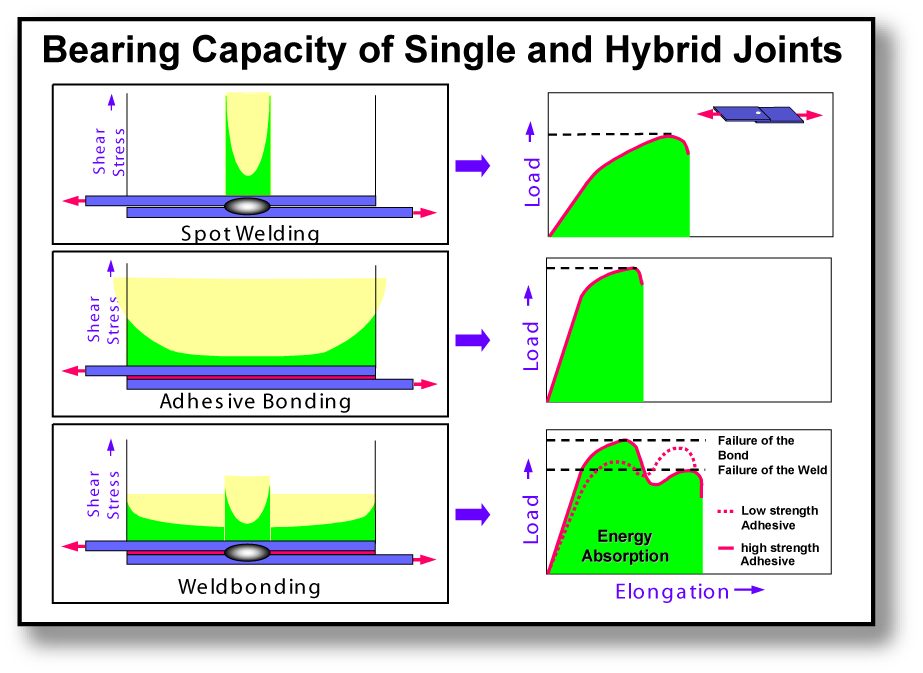

As with mild steels, AHSS-hybrid joints can be made by combining adhesive bonding with RSW, clinching, or self-piercing riveting. These hybrid joints result in higher strength values (static, fatigue, and crash) than the spot welding alone (Figure 1). If local deformation and buckling can be avoided during in-service applications of weld bonding/adhesive hybrid joining, the potential for component performance is enhanced.

Figure 1: Comparison of bearing capacity for single and hybrid Joints.B-3

Hybrid RSW and Adhesives

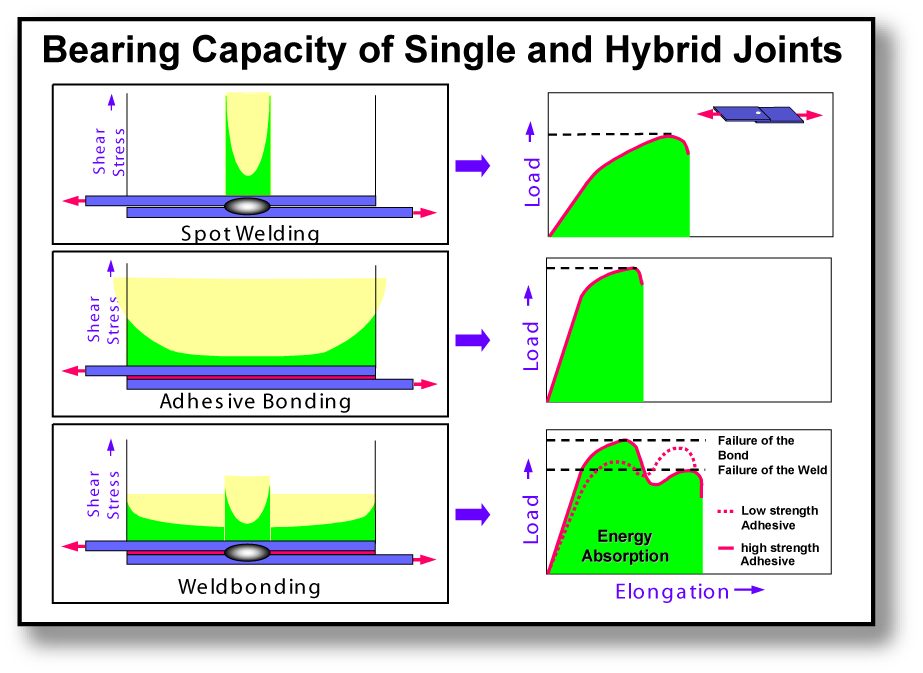

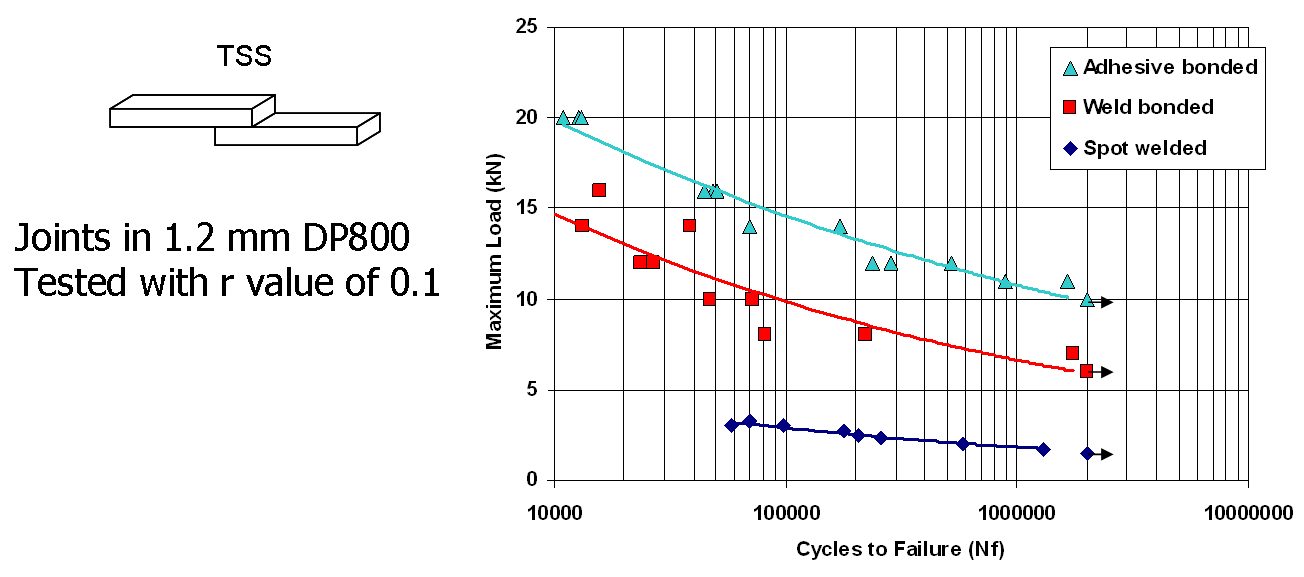

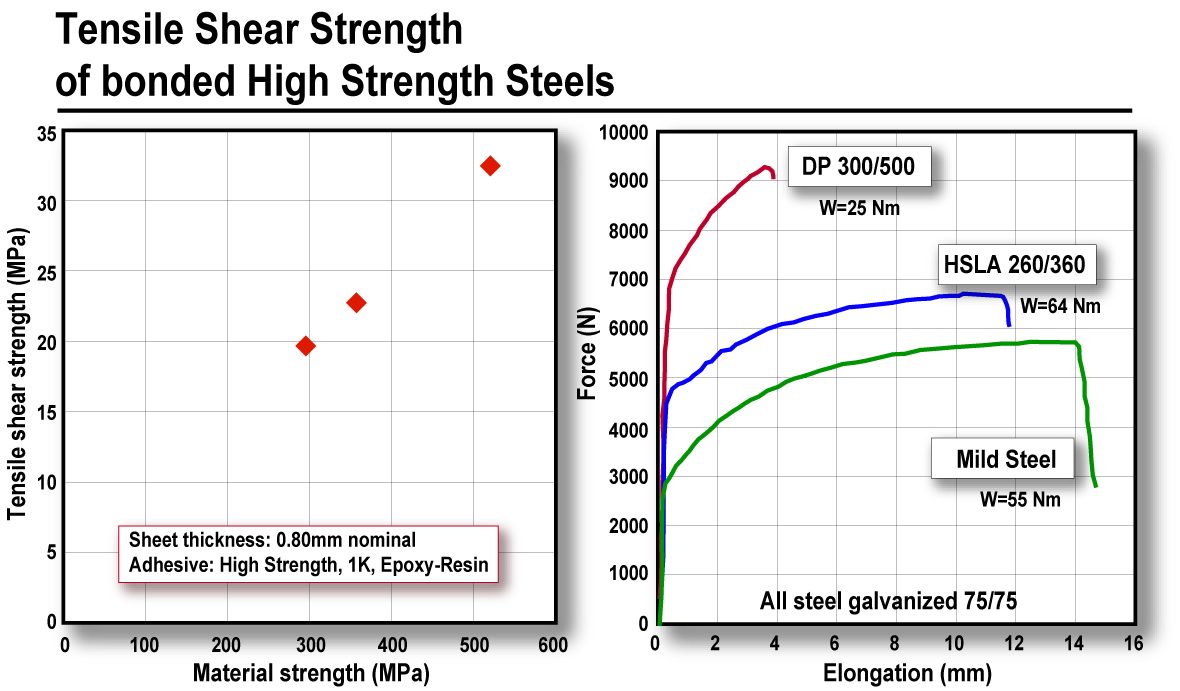

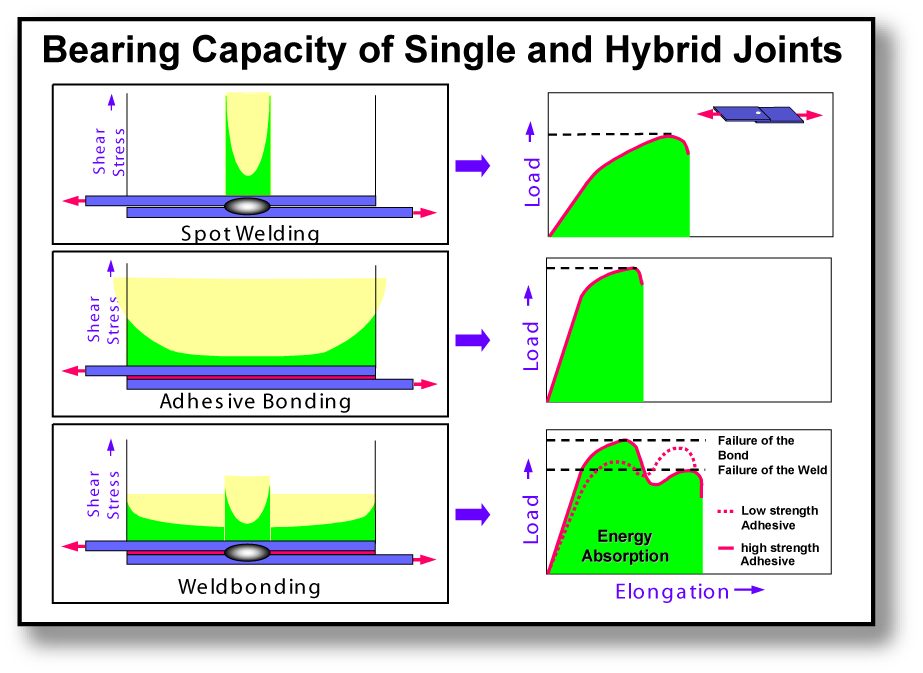

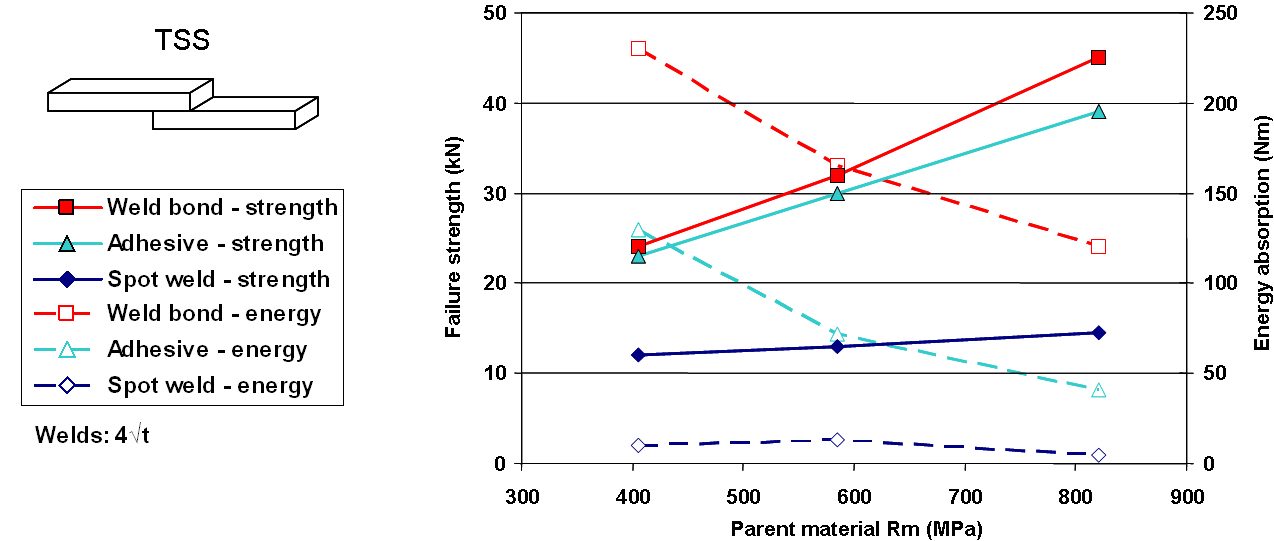

Many automotive joining BIW applications are using the combination of RSW together with adhesives to obtain superior joint performance. This combination is referred to as WB. Figure 2 shows a tensile shear test for resistance spot welds, adhesives, and weld bonds. There were trends of fracture strength increasing slightly with material strength with the spot welds. Also, the fracture strength was very high, increasing significantly with increasing material strength for adhesive bonds. The fracture strength was the highest for welded bonds and increased significantly with increasing material strength.

Figure 2: TSS failure strength and energy absorption for all joints and materials.T-10

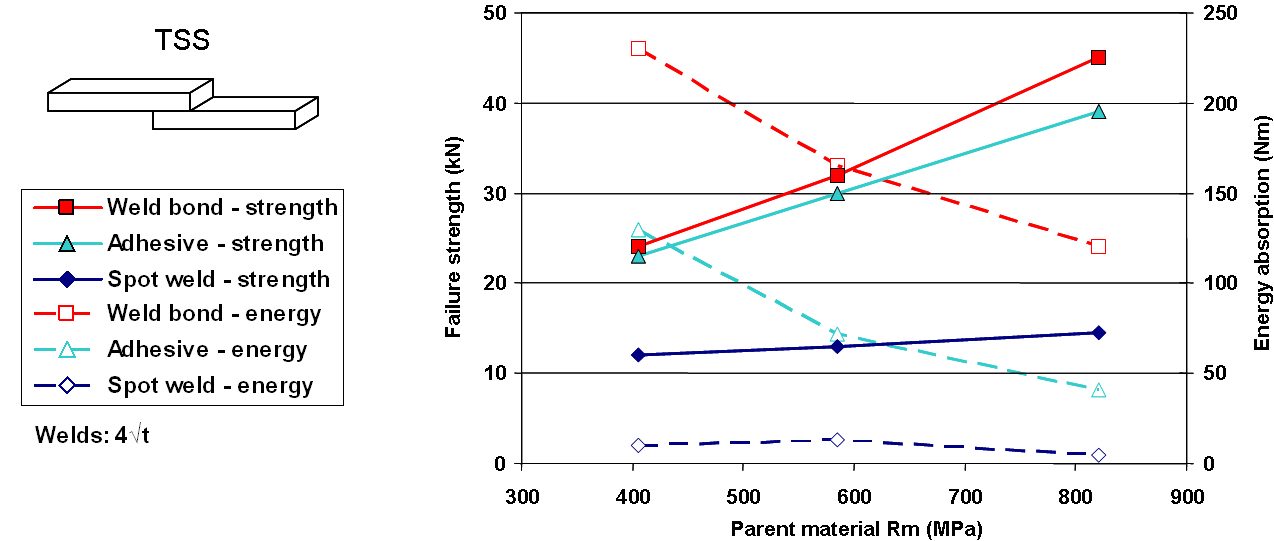

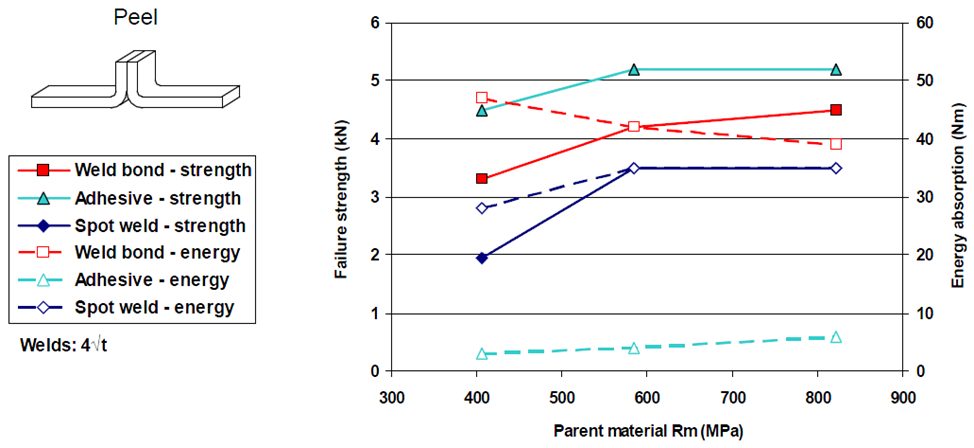

Figure 3 represents a peel test for the same samples. Trends observed were fracture strength increasing slightly with material strength but is lower than the other joining methods for spot welds. Fracture strength for adhesive bonding is greater than Weld Bonding (WB) and spot welding. Energy absorption was not very sensitive to material strength. The bond using adhesive alone had poor failure strength as well as poor energy absorption.

Figure 3: Peel strength data for all joint types.T-10

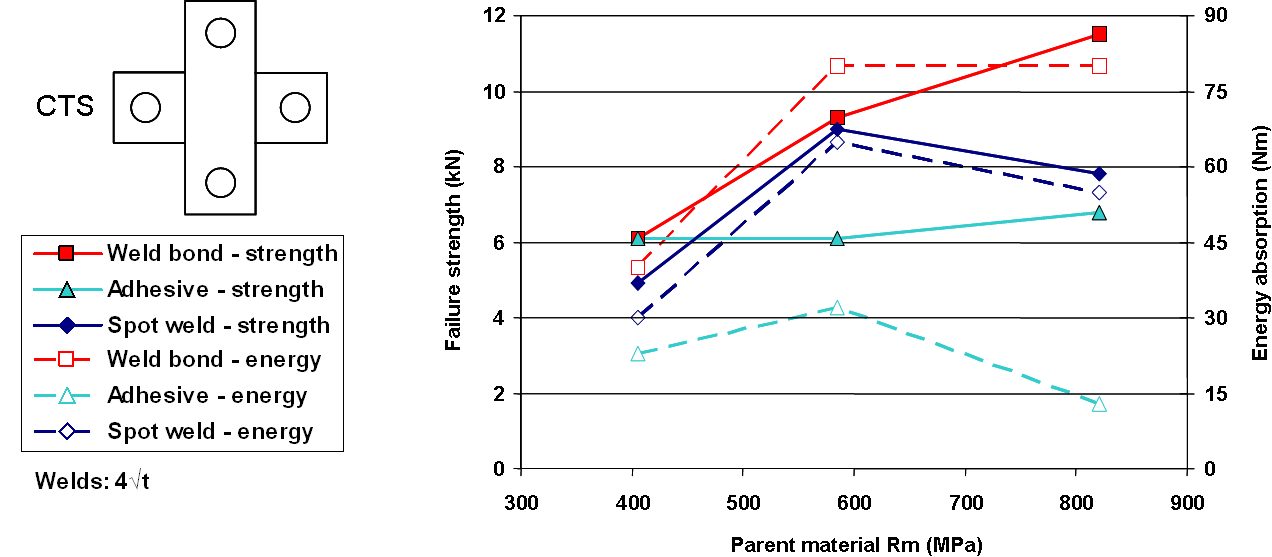

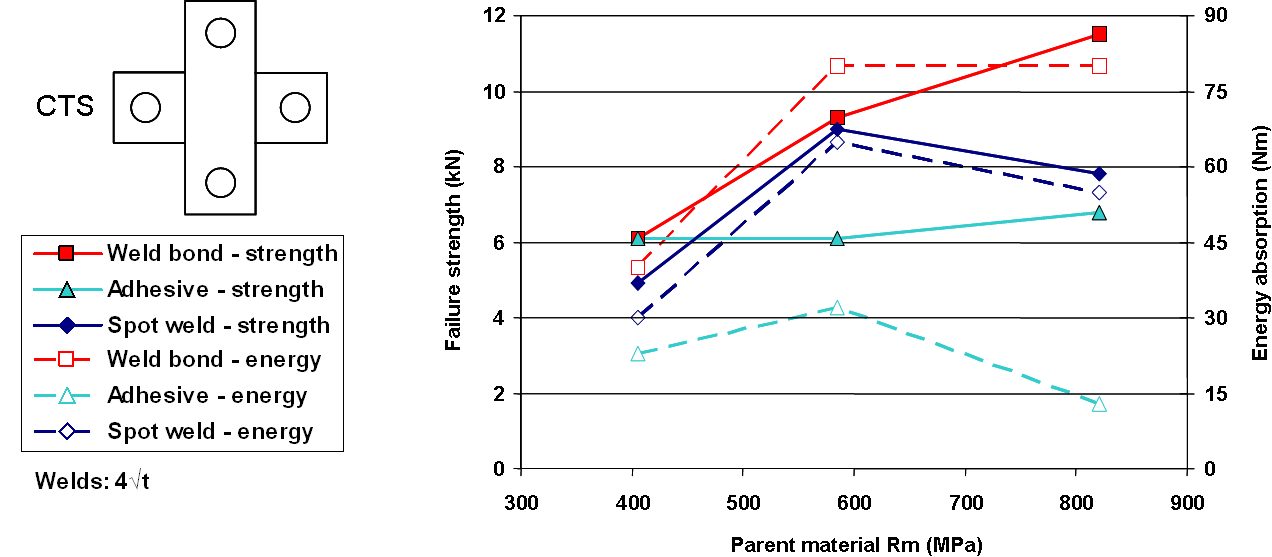

Figure 4 shows cross tensile results for the three samples. Spot welds showed fracture strength reaching a maximum for DP 600. Adhesive fracture strength increased slightly with increasing material strength. The welded bond’s fracture strength was greater than the other joint types and increased significantly with increasing material strength.

Figure 4: CTS fracture strength and energy absorption for all joints and materials.T-10

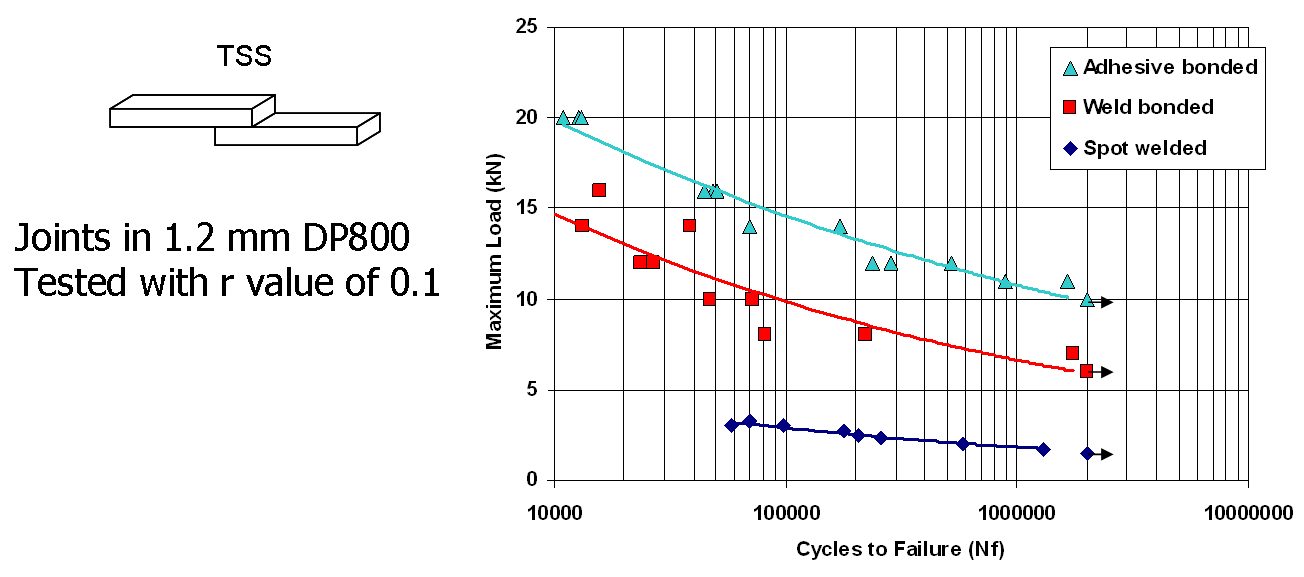

Figure 5 shows the fatigue testing performed in tensile shear mode on DP 800 [LINK TO DP steel page in Metallurgy] material (1.2-mm gage). Spot welds showed the lowest fatigue properties of the test samples. While the weld-bonded samples performed much better than conventional spot welds, they were still weaker than the adhesive joints. Adhesive had the best fatigue performance. The parent material properties had little influence upon the fatigue properties of spot welds because the spot weld itself acts as a fatigue crack initiator.

Figure 5: DP 800 fatigue results.T-10

Adhesive Joining

Fundamentals and Principles of Hybrid Welding

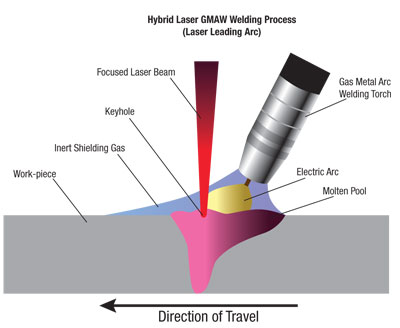

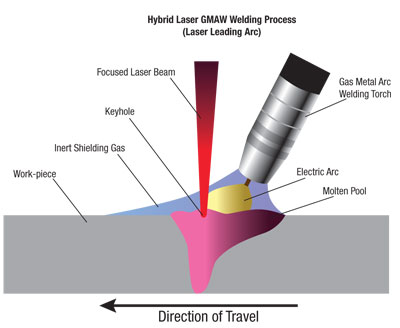

Recent developments in welding include approaches that could be considered novel, as well hybrid, or those that combine more than one established process. A sampling of these unique approaches will be reviewed here. A hybrid process that is being extensively developed known as hybrid laser welding combines both the laser beam and Gas Metal Arc Welding (GMAW) processes (Figure 1). This approach uses a head that carries both the laser focusing optics and the GMAW gun. The laser beam creates a keyhole near the leading edge of the puddle.

Figure 1: Hybrid laser welding.L-11

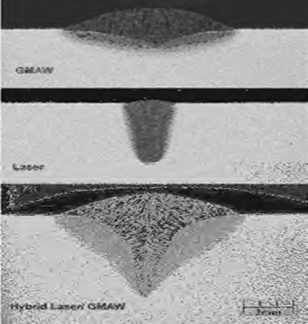

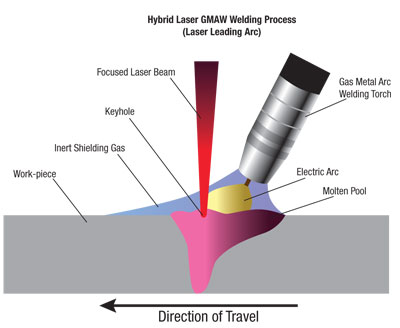

The motivation for this concept is that the best features of each process can be combined (Figure 2) to create an even better process for certain applications. Laser beam welding provides the capability for deep-penetrating single-pass welds at high speeds but requires precise joint fit-up and doesn’t produce weld reinforcement which can add strength to the joint. When combined with GMAW, these limitations are eliminated. The laser beam also helps stabilize the arc, which can be of particular benefit when welding Titanium (Ti).

Figure 2: Hybrid laser welding combines the best features of laser beam and GMAW (top GMAW, middle LBW, bottom hybrid).

PAW, GTAW and GMAW have also been combined into a hybrid process. The benefits are similar to the laser hybrid welding approach, but the equipment has the potential to be much less expensive. The combination of FSW with ultrasonic energy is being explored as an approach to creating friction stir welds with greatly reduced forces, and therefore, smaller machines.

Adhesive Joining

Fundamentals and Principles of Adhesive Joining

Adhesive bonding is a joining process for metals and non-metals that uses and adhesive or glue, typically in the form of a liquid or a paste. It offers the major advantage of being able to join a wide array of materials, but is limited by joint strength and applicable service conditions. Many of the fundamentals are similar to brazing and soldering, in particular the need for wetting and capillary action, and overlapping joint designs that rely on joint area for strength. Adhesives are categorized as thermosetting or thermoplastic. Thermosetting adhesives require a chemical reaction to cure and cannot be remelted once cured. They are the most common adhesives for structural applications. Thermoplastic adhesives soften when heated and harden when cooled, a process that can be continually repeated. They are generally not used for structural applications because of their poor mechanical properties (in particular, creep) and decomposition that can occur at relatively low temperatures.

Surface preparation is usually a very important and time-consuming step prior to applying the adhesive, and typically includes cleaning and deoxidizing procedures. Further steps may be taken such as the application of a coating. Adhesives may be applied a variety of ways, including caulking and spray guns, dipping, rollers, and brushes. Curing may be accelerated by heating or some other energy source. In addition to joining, adhesives may be used for many other reasons including sealing, electrical insulation, and sound suppression. Some of the larger users of adhesive bonding include the automotive, appliance, and electrical/electronics industry sectors.

Adhesive Joining Procedures

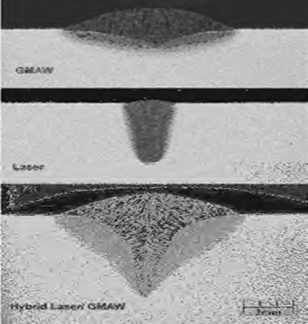

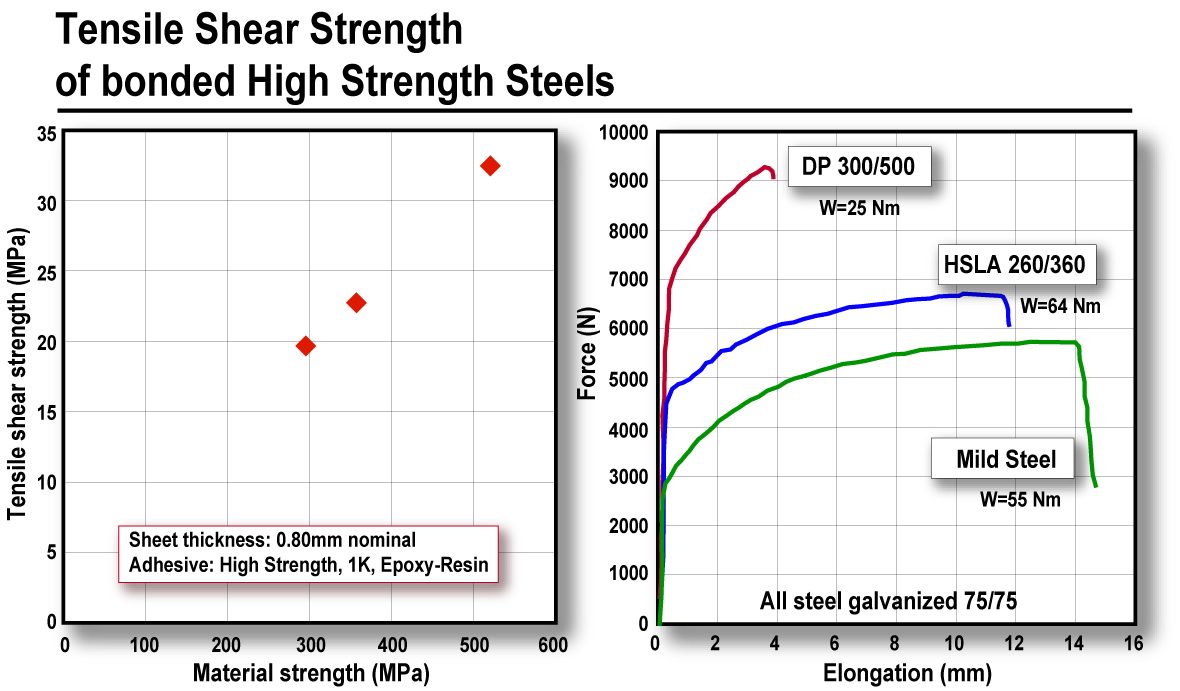

The bond strength of an adhesive is constant, and in design applications, is proportional to the area covered by the adhesive. The adhesive joint strength will be unchanged and analysis of the joint should be comprehensive. In general, the use of AHSS with high-strength structural adhesives will result in higher bond strength than for mild steel if the same sheet thickness is applied (Figure 1). Reduction of sheet thickness will decrease the strength because more peel load will occur. The true mechanical load in the component part must be considered. If higher joint strengths are needed, the overlapped area may be enlarged. Adhesives with even higher strength are under development.

Figure 1: Effect of material strength on bond strength (W is the integral of the force/elongation curve.B-2).

Joining of AHSS with adhesive bonding is a good method to improve stiffness and fatigue strength in comparison to other joining methods (spot welding, mechanical joining, arc welding, and laser welding). Due to the larger bonding area with adhesive bonding, the local stresses can be reduced and therefore the fatigue strength is increased. These improvements in stiffness and fatigue strength are important factors to consider at the design stage, especially in those cases when AHSS is used to decrease the weight of a component.