Laser Welding

The word “laser” is an acronym for “light amplification by stimulated emission of radiation.” Lasers produce a special form of light (electromagnetic energy) consisting of photons that are all of a single coherent wavelength. Light of this form can be focused to extremely small diameters allowing for the creation of the high-energy densities used for welding. The laser beam itself is not useful for welding until it is focused by a focusing lens.

Lasers vary in the quality of the beam produced. A high-quality beam will diffract less when focused, providing for the creation of a smaller spot size. Reflective lenses are important to lasers as well since they are used in the optical cavity where the beam is generated, as well in the beam delivery systems for some lasers. For these reasons, optics play a major role in laser beam welding.

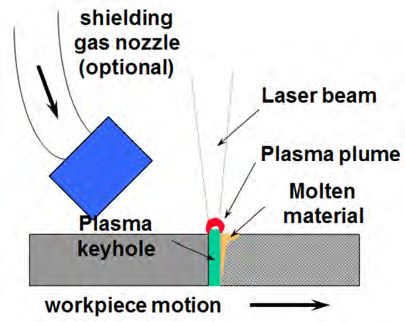

Laser beam welding (Figure 1) does not require additional filler metal and shielding gas is optional. When the beam hits the workpiece, it melts and vaporizes metal atoms, some of which are ionized by the intense beam. This creates what is known as a plume (or plasma) over the weld area that can sometimes interfere with the beam. In these cases, shielding gas may be used to deflect the plume.

The choice of laser type depends on cost, the type and thickness of material to be welded and the required speed and penetration. Lasers are distinguished by the medium used to generate the laser beam, and the wavelength of laser light produced. Although there are many types of lasers, the common lasers for welding include the Nd:YAG, fiber, disk solid-state lasers, and the gas-based CO2 laser. The lasing medium in solid-state lasers are crystals (Nd:YAG and disk lasers) or fibers (fiber laser) that have material added (doped) that will “lase” when exposed to a source of energy, whereas the lasing medium in the CO2 laser is a gas blend consisting of CO2, He, and N2 gas. In all cases, “lasing” occurs when the atoms/molecules of the medium are excited to a higher energy state through the introduction of additional energy (known as pumping). When this occurs, photons are emitted, which, in turn, excite other atoms/molecules. This results in a cascade of photons that travel in coherent waves of a single wavelength, the two properties for which laser light is known.

CO2 lasers produce wavelengths of 10.6 µm, while the wavelength of the solid-state lasers is 1.06 µm. CO2 lasers are generally less expensive, but the longer wavelength of light does not allow its beam to be delivered through fiber optic cables which reduces its versatility. Its light is also more reflective, which limits its use with highly reflective metals such as aluminium. The solid-state lasers are generally more compact and require less maintenance than the CO2 laser. They are more conducive to high-speed production since their beams can be delivered through long lengths of fiber optic cable which can then be attached to a robot. Some of the solid-state lasers such as the fiber laser produce beams of outstanding quality. However, the shorter wavelength of these lasers requires additional safety precautions regarding eye protection.

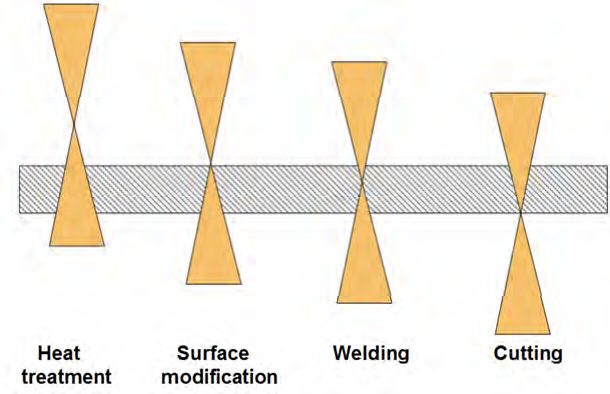

The choices of focus spot size, focus spot location in the joint, and focal length are all important considerations when laser beam welding. Usually, a small focus size is used for cutting and welding, while a larger focus is used for heat treatment or surface modification. As indicated in Figure 2, the location of the beam’s focal point can also be varied based on the application. When welding, it is common to locate the focal point somewhere near the center of the joint. But cutting applications benefit from placing the focal point at the bottom of the joint. Weld spatter onto the focusing lens can sometimes be a problem, especially when there are contaminants on the surface of the parts being welded. Approaches to minimizing the spatter problem include choosing a long focal length lens which keeps the lens a safe distance from the weld area, or the use of an air “knife” to protect the lens. A-11, P-6

In summary, the advantages and limitations of laser beam welding are as follows:

Advantages:

- High energy density process allows for low overall heat input which produces minimal BM degradation, residual stress, and distortion.

- Fast welding speeds.

- No filler metal required.

- Relatively thick (¾ in.) single-pass welds can be made.

- Concentrated heat source allows for the creation of extremely small weld sizes needed for small and intricate components.

- Easily automated, especially with lasers that are conducive to fiber optic delivery.

- Since there is no bulky torch as with most arc welding processes, laser beam welding is capable of welding joints with difficult accessibility.

Limitations:

- Equipment is very expensive

- Portability is usually low

- Requires very tight joint fit-up and accurate positioning of the joint relative to the beam

- Metals that are highly reflective such as Al are difficult to weld with some laser beam welding processes

- High weld CR may create brittle microstructures when welding certain steels

- Laser plume may be a problem

- Energy efficiency of lasers is poor

- Some lasers require special (and expensive) eye protection

- Laser beam welding is complex and requires significant training and knowledge