Laser Blanking

Conventional blanking requires high press forces to shear the sheet metal. As steel strength increases, snap-through tonnage also increases, potentially leading to press and tooling damage. Over time, clearances may change, affecting edge quality. Shearing results in a work-hardened edge, and a shear affected zone know to decrease edge stretchability.

Blanking dies are often among the last dies completed prior to launch. Historically, this led to the use of hand-cut, steel-rule, or laser cut blanks during tryout. When laser cut blanks of AHSS are used during try out, the high hardness in the laser cut edges may damage the blank holder surface. Control the laser cutting parameters to reduce burrs and edge hardness. Deburr the edges of laser cut blanks prior to forming to minimize tool damage, especially when using soft tool materials like kirksite.

Using laser cut blanks during tryout offers product flexibility, since blank dimensions may change as part of the development process. However, upon completion of the blanking die, the dimensions cannot change without costly modifications.

Instead of using a blanking die, some companies are choosing to use laser blanking in production environments. Laser blanking eliminates the cost of blanking die construction and tooling maintenance. A dedicated blanking die for each part is no longer necessary – one laser blanking line can create blanks for multiple parts. Blank shape changes become another way to solve stamping formability problems. This approach also has the flexibility of incorporating blank size optimizations as part of the cost savings efforts targeted through the life of a stamping. Simple programming changes optimize nesting to take advantage of coil width capability improvements made by the sheet metal supplier.

Curved sections on blanking dies present design challenges related to cutting tool steel placement to avoid the creation of a notch at the mating point between two adjacent sections. Maintenance of sharp edges and consistent clearance is another challenge–advanced steel grades damage even the optimal cutting tool steels over time. Laser blanking avoids these concerns.

Multiple heads within the laser blanking system allow for faster processing speeds. According to Citation F-6, typical outer body parts can run 12 to 25 strokes per minute (SPM) on a two-head configuration, while complex body sides tend to run 4 to 6 SPM. Thicker inner structural parts typically run in 6 to 10 SPM area, but configurations with six laser cutting heads increase this rate to 30 to 40 SPM. Daimler achieves the blank production rate of 40 hoods per minute.H-9 On a continuously moving coil, laser heads reach a linear cut speed of 100 meters per minute.S-27 These figures continue to improve with advances in laser technology.

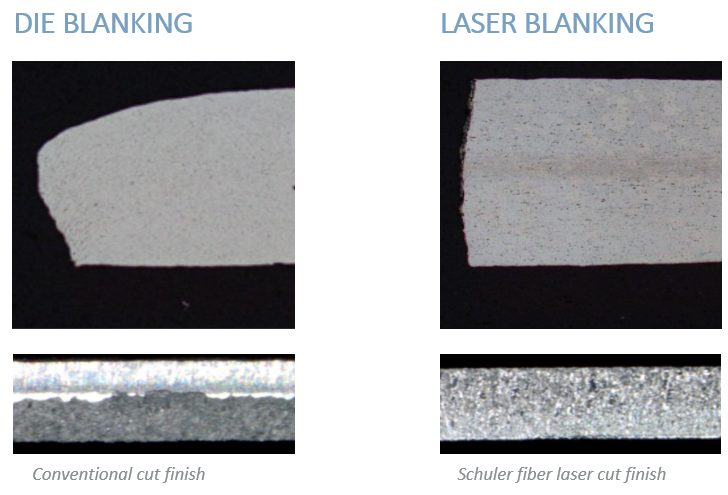

Similar to a shear-affected zone, laser-cut blanks have a heat-affected zone (HAZ) comprising the area from the laser-cut edge into the blank. The typical HAZ distance is under 0.2 mm on steel up to 2 mm thick, which is less than a comparable shear cut edge. In addition, the hardening increase is lower, and edge quality is more consistent than seen in sheared edges.F-6

Note that this discussion relates to the creation of first-operation blanks directly from coil feedstock. For a discussion on Laser Welded Blanks, visit the pages related to Tailor Welded Blanks.

Case Study: Die-Free Blanking of Class A Quality & Structural PartsS-114

Production of Class A quality and structural parts without a blanking die is possible, even for high-volume serial production. Laser blanking enables flexible, cost-effective, and sustainable manufacturing, and is capable of reaching 45 parts per minute.

DynamicFlow Technology (DFT) from Schuler provides highly productive, die-free blanking with lasers—directly from a continuously running steel coil. DFT combines the advantages of flexible laser cutting with the speed of conventional blanking. The video below shows laser blanking with DynamicFlow Technology in action.

Laser blanking technology addresses market challenges such as frequent die changes, the need to increase capacity, and improving plant floor utilization, material utilization, and downstream processes.

Laser Blanking Eliminates Frequent Die Changes

It is important to remember that there are no dies with laser blanking technology, and no dies means no die changes. Overall Equipment Effectiveness (OEE) of up to 80% can be achieved with laser blanking technology. In fact, 4 to 6 million parts per year of various materials are produced with the help of DFT—including mild steel, high-strength steel, and advanced high strength steel. Even processing press hardening steels with an aluminum-silicon coating is possible with laser blanking. Surface and cutting quality can be maintained over this spectrum of steel grades. Laser blanking technology can even achieve effective small batch production of Class A outer body panels and structural parts typically up to 3mm thick.

Laser Blanking Increases Plant Output

Competitive high-speed and high-output results can be achieved in multiple ways with laser blanking technology. The above-ground coil-fed line, optimized to achieve short setup time, can handle coils with material widths up to 2,150 mm, weighing up to 30 tons. The material transport is smooth and controlled, simplifying setup, and leading to uninterrupted processing within the laser cell.

There are three highly dynamic, and simultaneously moving, laser cutting heads within the laser cell of these lines. These laser cutting heads cut the programmed blank contour from a continuously moving material coil. Cutting speeds can exceed 100 meters per minute. The material is protected against any process contamination throughout the cutting process by the custom-designed cutting clearance and material transport.

The blanks and the offal (scrap) must be separated once the cutting process is complete. This occurs through the use of automated systems specially adapted to the individual products. Following the separation, the blanks are cleaned, before moving into the automatic stacking system. This ensures outstanding body shell quality.

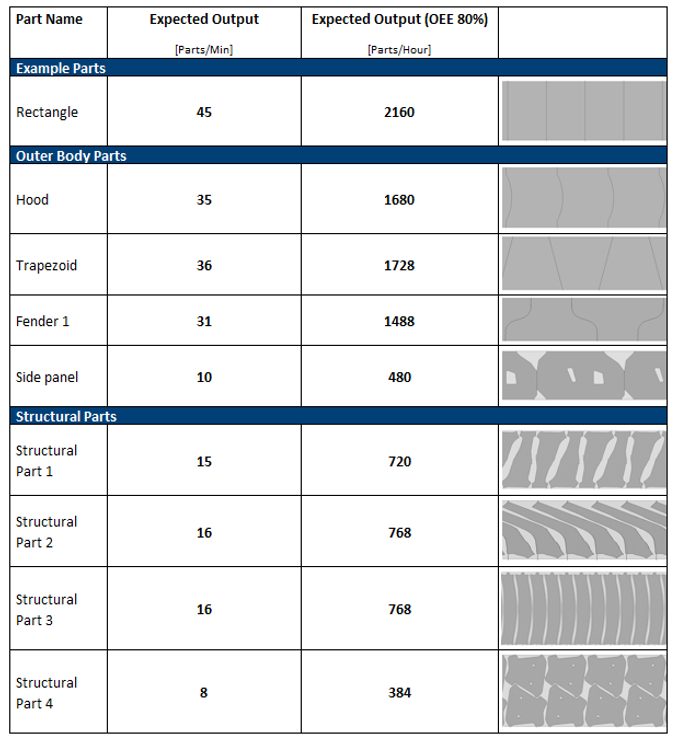

Figure 2 reveals the high-speed and high-output results for outer body parts. Each part is measured by improved output per minute and hour to achieve an OEE of 80%. Significantly, laser blanking lines can achieve up to 45 parts per minute and reduce costs per blank.

Figure 2: High productivity achieved with laser blanking.

Laser Blanking Needs Less Floor Space and Reduces Infrastructure Costs

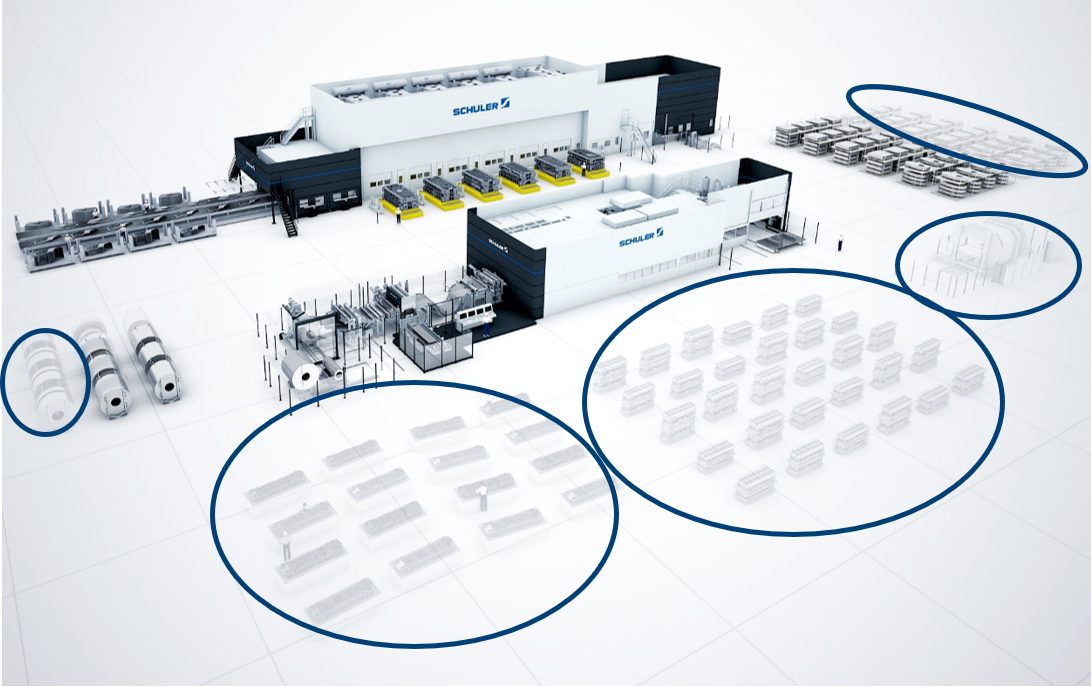

There is a multitude of ways for manufacturers to increase capacity within new or existing facilities when incorporating laser blanking technology into their production process. The clearest example, indicated within the picture below, is that very little floor space is needed in comparison to conventional blanking lines. All the circled areas in Figure 3 can be eliminated when utilizing laser blanking technology.

Figure 3: Circled areas represent freed floor space with laser blanking.

Laser blanking lines are designed to be installed above ground, so they can be used in normal logistics buildings—eliminating the need for special foundations required by press systems.

Capital equipment and operations expenses have drastically increased with supply chain shortages. Laser blanking technology provides cost-effective benefits that can be critical for such challenges.

For new facilities:

- No heavy press foundation or loop pits are needed.

- There are no noise or vibration emissions.

- It is possible to operate next to press lines.

- There is very little floor space required.

- No special infrastructure is needed for die handling.

For existing facilities:

- No heavy press foundations or loop pits are needed, and no special infrastructure is needed for die handling—similar to new facilities.

- There are reduced ground and building costs.

- Other potential benefits include an optimized tryout process, material cost, and weight savings.

Laser blanking lines require no press foundation, loop or press pits, die cranes, or die storage areas. A crane to handle the coils and a forklift to take the blank stacks where they need to go is all manufacturers need. The building and infrastructure costs of a die-based blanking system normally double the costs for capital equipment investment alone. A laser blanking line eliminates a large portion of these costs.

Laser Blanking Improves Material Utilization

Up to 90% of blank costs are determined by the material price. The most significant leverage would be to reduce scrap and save on materials. Schuler conducted research based on the production of 300,000 cars per year, at 350 kg per car and $1,000 USD per ton of steel to provide a realistic inside look at how much cost savings can be achieved with laser blanking. The result was $1 Million USD saved with just 1% of material savings. This is extremely significant as material costs keep increasing.

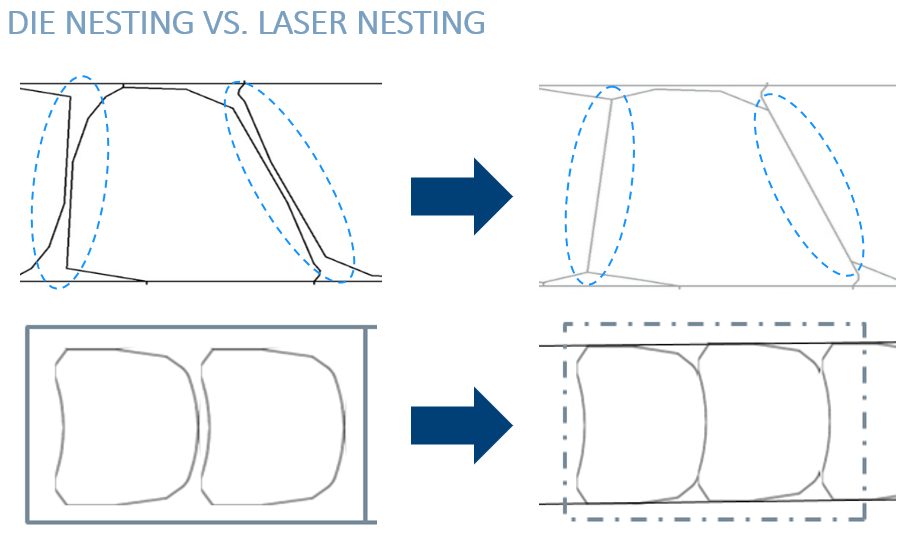

Laser blanking is the digital way to cut blanks. All that’s needed to create a blanking program is a drawing to be loaded and a material to be selected. The part-specific program can be created offline and modified at any time. It is designed to create optimal combinations of material utilization and output—resulting in a high level of flexibility that significantly reduces development time for optimal blanks while also allowing for need-based production. This makes production planning easier, and it also opens the door to continuous contour optimizations for the forming process. Additionally, laser cutting does not require any gaps between individual parts due to smart nesting capabilities that cannot be achieved in comparison to die nesting or flatbed laser nesting. The combined smart, flexible nesting functions unlock new potential for material savings. Manufacturers can optimize individual blanks and eliminate the separating strip or connection bridges. Scrap savings in the forming process can also be achieved as there are no geometric restrictions due to cutting dies, and manufacturers can continuously optimize or adapt parts.

Figure 4 showcases the comparison of die nesting (the two graphics on the left) versus a laser-optimized blank contour and material savings via smart, laser blanking line nesting (the two images on the right).

Figure 4: Die nesting (left) compared with laser-optimized blank contours highlighting potential material savings (right)

Laser blanking technology allows for the conversion of rectangular and trapezoidal blanks into contoured blanks. Blank shapes are no longer restricted to straight lines – programmable laser cutting allows for edges with a sinusoidal or arched contour—improving the material utilization rate or forming characteristics. Adaptations of various geometric shapes can be achieved with optimized nesting of laser blank contours. These images in Figure 4 are just an example, with the possibility of more complex shapes and nesting patterns.

Overall, laser blanking lines can have an equivalent throughput to conventional blanking lines, but laser blanking lines can achieve up to 10% greater material utilization.

Laser Blanking Improves Downstream Processes

High surface quality can be achieved with laser blanking technology as clean blanks are produced with homogeneous and uniform cutting edges—and no burr cleaning is needed during or after the forming process. There is also a reduction in dripping during the hot forming process—which leads to a dramatically increased lifespan of the hot forming rollers—as the laser melts the dripping layer instead of squeezing it into the cutting edge. Figure 5 provides a comparison of the edges produced via die blanking with a conventional cut finish with that produced by laser blanking with a laser fiber cut finish.

Figure 5: Conventional cut edge condition produced from die blanking (left) and laser fiber cut edge condition produced from laser blanking (right).

Laser blanking lines are much more cost-effective for the production of blanks when manufacturers keep these five benefits in mind. The costs for personnel, logistics, buildings, dies, storage areas, repairs, and other additional costs can add up to a pricey amount. Laser blanking lines are the smart manufacturing choice as this technology yields a higher OEE in comparison to conventional blanking lines through the elimination of die-related downtime and lengthy time changes. The system only stops for a short time when the coil needs to be changed.

Schuler will present laser blanking technology, along with a variety of digital tools that create the “Press Shop of the Future” at FABTECH Chicago 2023 (booth # D41306). Tiago Vasconcellos, Sales Director at Schuler North America, will present “How Smart is Your Press Shop?” during FABTECH’s Educational Conference. The presentation will use The Smart Press Shop, a newly formed joint venture between Porsche and Schuler, as an exemplary case study for smart manufacturing standards. Attendees will discover innovative and practical ways to incorporate digitalization into production and become a state-of-the-art stamping facility directly from Schuler.

About Schuler Group

Schuler offers customized cutting-edge technology in all areas of forming—from the networked press to press shop planning. In addition to presses, Schuler’s products include automation, dies, process know-how, and service for the entire metalworking industry. Schuler’s Digital Suite brings together solutions for networking forming technology and is continuously being developed to further improve line productivity and availability. Schuler customers include automotive manufacturers and suppliers, as well as companies in the forging, household appliance, and electrical industries. Schuler presses are minting coins for more than 180 countries. Founded in 1839 at the Göppingen, Germany headquarters, Schuler has approximately 5,000 employees at production sites in Europe, China and the Americas, as well as service companies in more than 40 countries. The company is part of the international technology group ANDRITZ.

Schuler’s global portfolio of world-renowned brands include BCN (Bliss Clearing Niagara) Technical Services, Müller Weingarten, Beutler, Umformtechnik Erfurt, SMG Pressen, Hydrap Pressen, Wilkins & Mitchell, Bêché, Spiertz Presses, Farina Presse, Liebergeld, Peltzer & Ehlers, Schleicher, and Sovema Group.

About Schuler North America

Schuler North America (Schuler), headquartered in Canton, Michigan, is the North American subsidiary of Schuler Group. Schuler provides new equipment, spare parts, and a portfolio of lifecycle services for all press systems—including preventative maintenance, press shop design and optimization, turnkey installations, retrofits for existing systems, and localized production and service. Schuler’s best-in-class position in the metalworking and materials industry serves automotive manufacturers and tier suppliers, as well as home appliance, electronics, forging, and other industries.