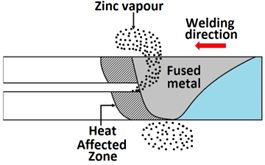

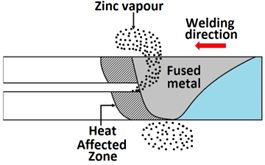

This article focuses on the role of Zinc coatings in causing so-called blowhole defects during gas metal arc welding of automotive body-in-white panels. Blowholes occur when vaporized coating material becomes trapped in the molten weld pool during solidification. This is more prevalent in overlap or T-joint configurations compared to butt joints, where vapors can escape more easily. Random variations can lead to differing pore rates in welded joints, necessitating a statistical approach to evaluation.

Experimental Plan and Methodology

An experimental plan, evaluating the factors contributing to blowhole formation, including heat input, filler wire type, gap distance, and welding conditions was used. Over 1,000 welds were performed to gather sufficient data for statistical analysis. The methodology focused on measuring pore rates and the length of defects through x-ray testing.

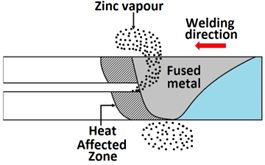

Figure 1: Blowholes are formed by vaporized Zinc escaping through the molten zone.

Solutions

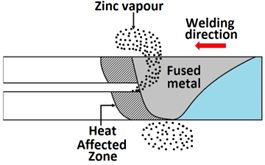

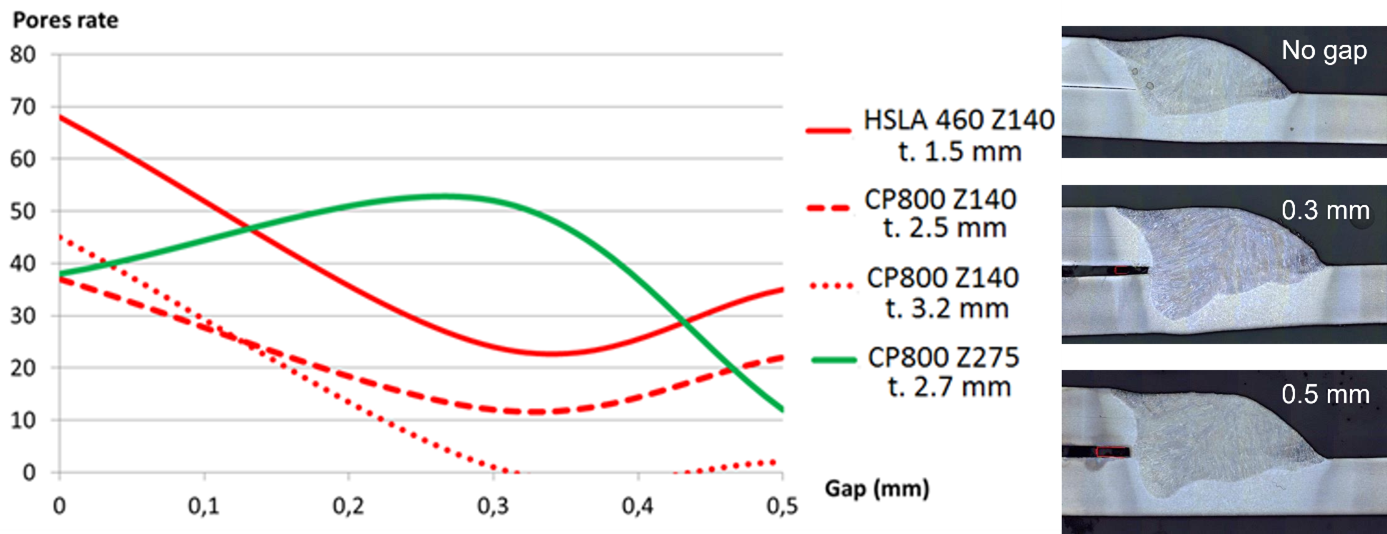

- Introduction of Gaps: A gap greater than 0.3 mm between sheets facilitates vapor extraction during welding, significantly reducing blowhole formation. Controlling the gap between sheets is challenging and costly in automotive assemblies. It may be an adequate solution, when the overlap width cannot be adjusted.

Figure 2: Pore rate in percent for different gap widths and steels (left) and cross-sections with increasing gaps (right). For normal coating level Z140, increasing the gap decreased pore and blowhole formation. Using a steel with significantly increased coating did not show this effect.

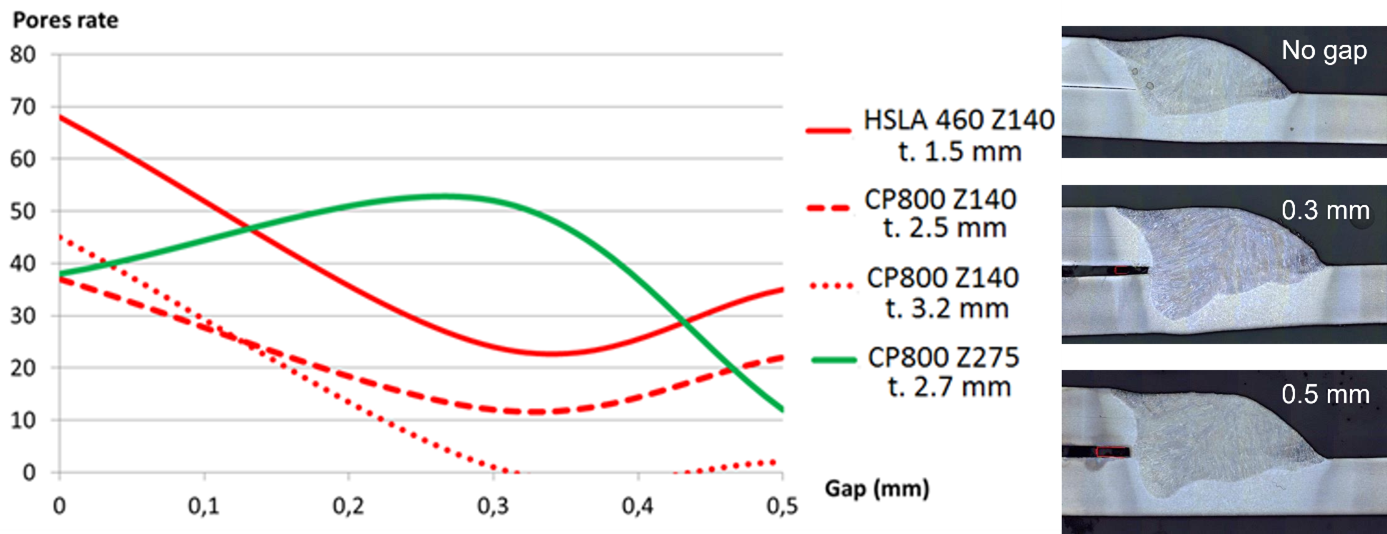

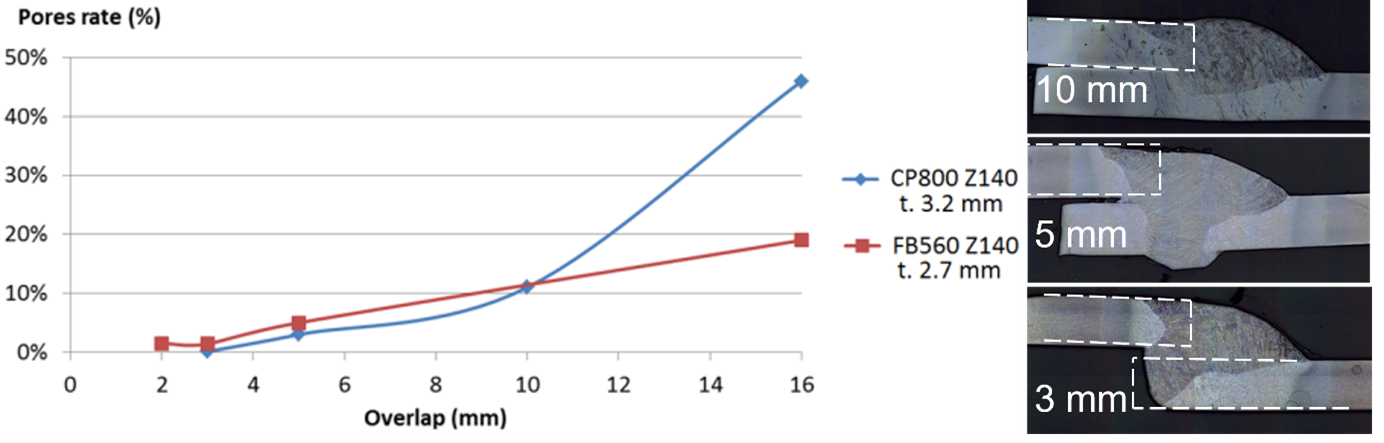

- Reduction of Overlap Width: Decreasing the overlap width not only helps vapors escape more easily but also reduces the overall weight of the assembly, making it the preferable solution

Figure 3: Pore rate in percent for increasing overlaps (left) and cross-sections with increasing overlap (right). Decreasing the overlap decreased pore and blowhole formation.

Effects on Mechanical Properties

Neither the gap nor overlap width significantly affected ultimate tensile strength (UTS) or fatigue performance, if the gap remained below 1 mm. The presence of blowholes did not adversely affect fatigue performance, although they could lead to reduced static strength of the joint if located at critical points within the load path.

Key Messages

- MAG welding of zinc-coated steels can lead to blowholes.

- Utilizing pulsed current may help minimize these defects, but welding parameters have limited effects on blowhole occurrence.

- Introducing a gap or reducing overlap width are effective strategies to mitigate these issues, with no impact on mechanical properties.

Source

J. Haouas, Solutions for improvement of zinc coated steels arc welding, ICWAM conference 2017, Metz

Automotive Welding Process Comparison, Blog, Joining

Car body-in-white (BIW) structures, such as pillars and rails, are increasingly made of complex stack-ups of advanced high-strength steels (AHSS) for vehicle lightweighting to achieve improved fuel efficiency and crashworthiness. Complex stack-ups comprise more than two sheets with similar/dissimilar steels and non-equal sheet thicknesses.

Resistance spot welding (RSW) of complex stack-ups can be challenging, especially when a thin sheet of low-strength steel is attached to multiple thick AHSS sheets with a thickness ratio of five or higher (thickness ratio = total thickness of the stack-up/thickness of the thinnest sheet). In such a case, the heat loss is much faster on the thin sheet side than on the thick sheet side, and consequently, obtaining sufficient penetration into the thin sheet without expulsion on the thick sheet side can be challenging.

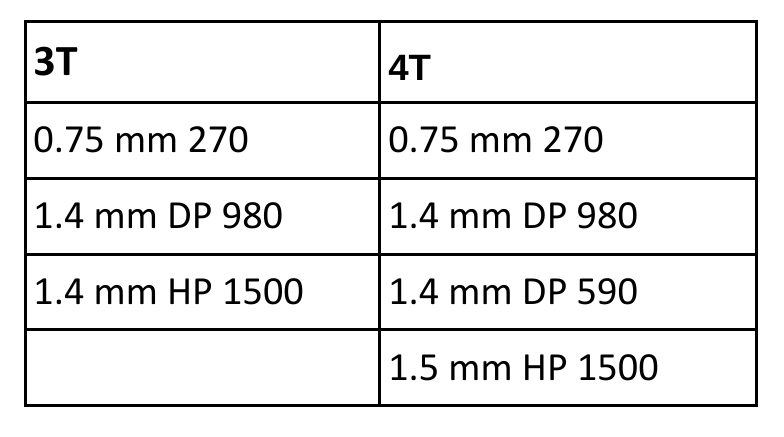

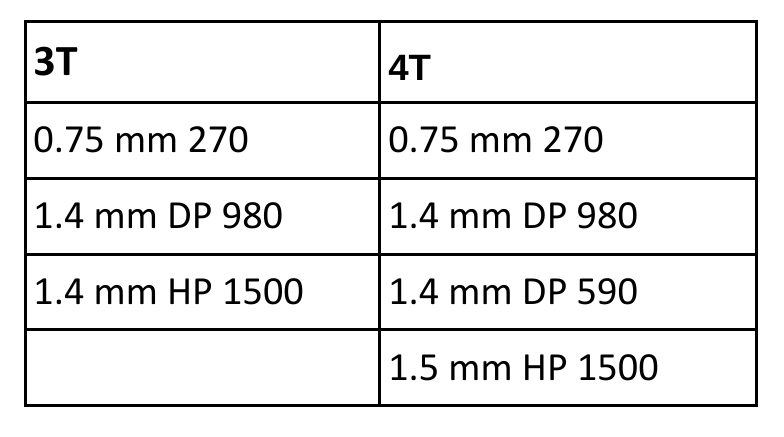

An example of two automotive applications involving complex AHSS steel stack-ups is shown below.

Examples of automotive applications involving complex AHSS steel stack-ups

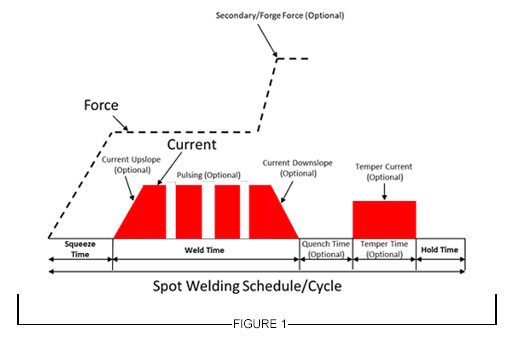

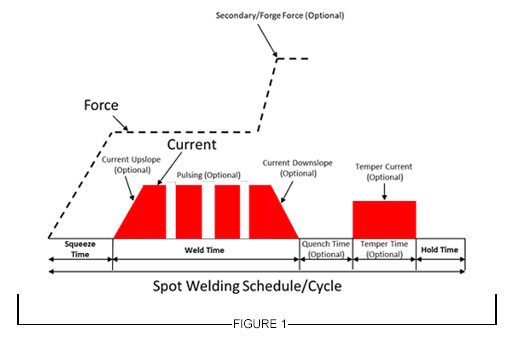

For welding 2T steel stack-ups, the weld schedule may be relatively simple and utilize just one current pulse with a specific weld time. However, typical RSW machines and controllers can customize and precisely control each parameter indicated in Figure 1.

Figure 1: General Description of Resistance Spot Welding Schedule

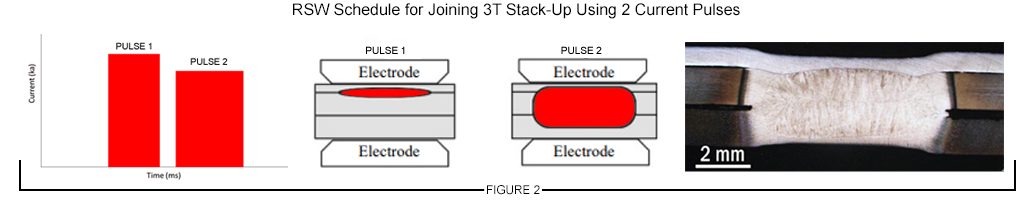

For RSW 3T and 4T applications, more advanced schedules are needed to achieve good weld nugget penetration through all the interfaces in the stack-up. To achieve this objective, the use of multiple current pulses with short cool time in between the pulses showed to be most effective, and in some cases, the application of a secondary force showed to be beneficial.

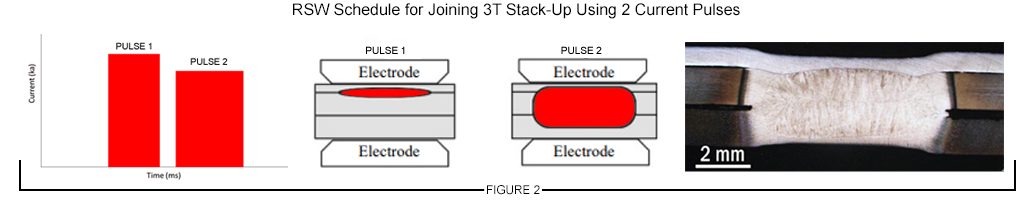

Figure 2 describes a method for joining the 3T stack-up using two current pulses. The first one is a short-time pulse that does not allow enough time for the electrode cooling to dominate at the top sheet, so a weld can easily form between the top and middle sheet. Once that nugget has formed, the second pulse utilizes a lower current and longer time to form the second nugget, which then grows into the first nugget to form a single weld.

This approach can be also used with electrode force variation during the welding cycle to provide additional control of the contact resistances, but of course, it is limited to machines that are capable of varying force during the weld cycle.

Typical pulse times are 50 – 350 ms with cool times of 20 – 35 ms and current levels between 8 – 15 KA, depending on materials type and thickness.

Figure 2: Example of RSW Schedule for Joining 3T Stack-Up Using 2 Current Pulses

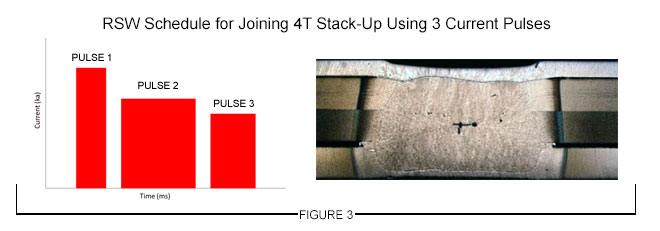

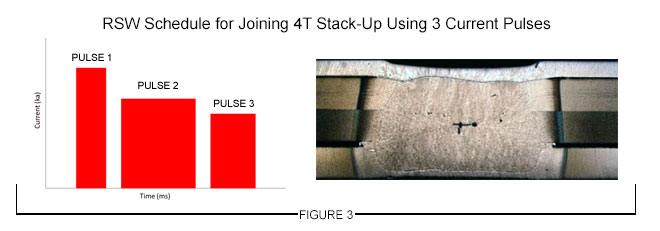

A 4T stack-up example is shown in Figure 3. In this case, a similar approach was used with three current pulses applied during the weld cycle to produce a weld through all interfaces.

The common theme in resistance spot welding all complex stack-ups is using a complex, multi-pulse weld cycle. These more complex schedules should be developed experimentally and potentially with computational modeling. Another consideration that may be beneficial in some cases is to vary the top and bottom electrode face diameter, such as that the smaller electrode face is on the thinner material side of the stack-up.

Figure 3: Example of an RSW Schedule for Joining 4T Stack-Up Using 3 Current Pulses

Thanks is given to Menachem Kimchi, Associate Professor-Practice, Dept of Materials Science, Ohio State University and Technical Editor – Joining, AHSS Application Guidelines, for this article.

Arc Welding, Joining

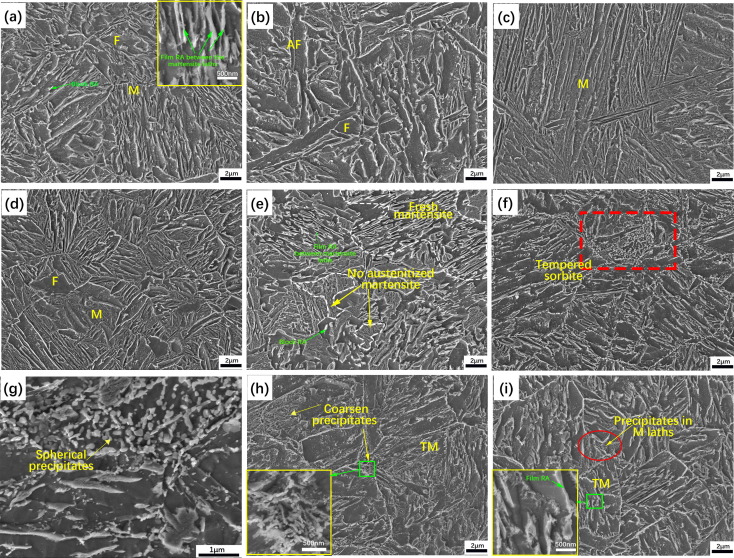

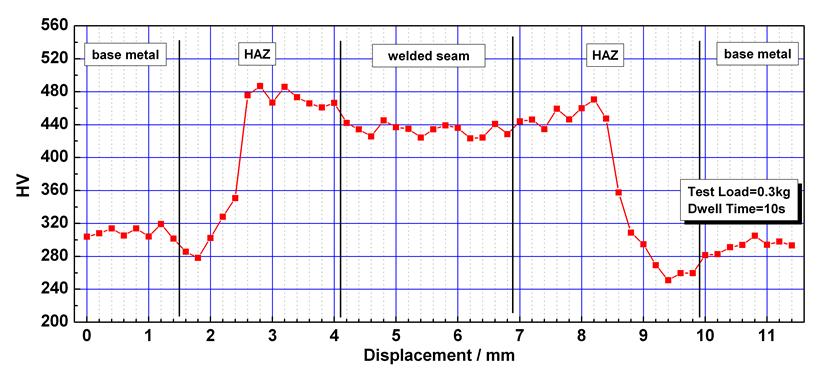

Quenching and partitioning (QP) steels are one of several third generation advanced high strength steel formed by controlled martensite phase fractions and retained austenite. Researchers from the University of Shanghai Jiao Tong tested the effect of HAZ softening in a QP1180 lap joint with the GMAW cold metal transfer (CMT) process.W-1 The steel was welded with ER130s electrode. The fusion zone consisted of chiefly acicular ferrite. The supercritical zone consists of martensite, which is harder than the base metal. There is a drop in hardness (100 HV) in the subcritical zone, and there is a noted lack of retained austenite present in the microstructure. Precipitates are also present in the subcritical zone. The intercritical HAZ only experiences mild softening; where fresh martensite has formed. The softening in the subcritical HAZ presents room for failure that must be accounted for when planning welding using CMT.

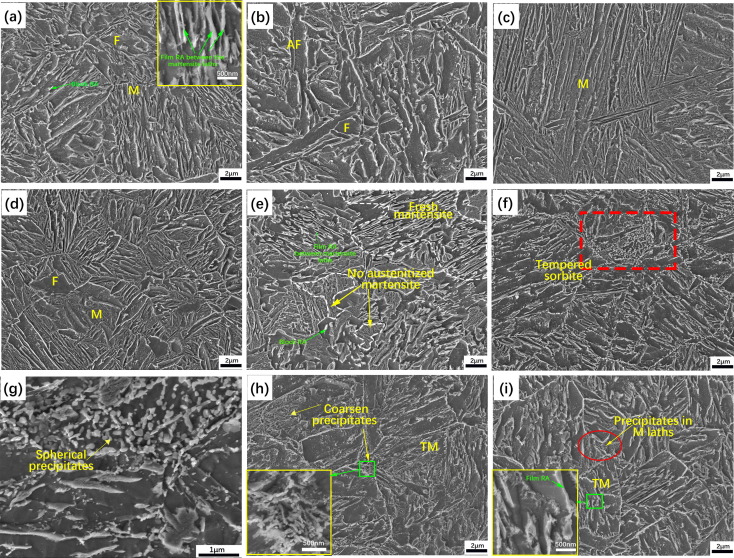

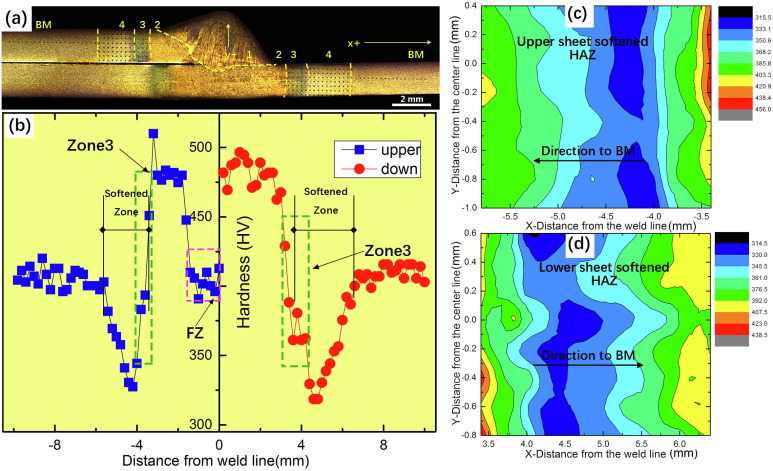

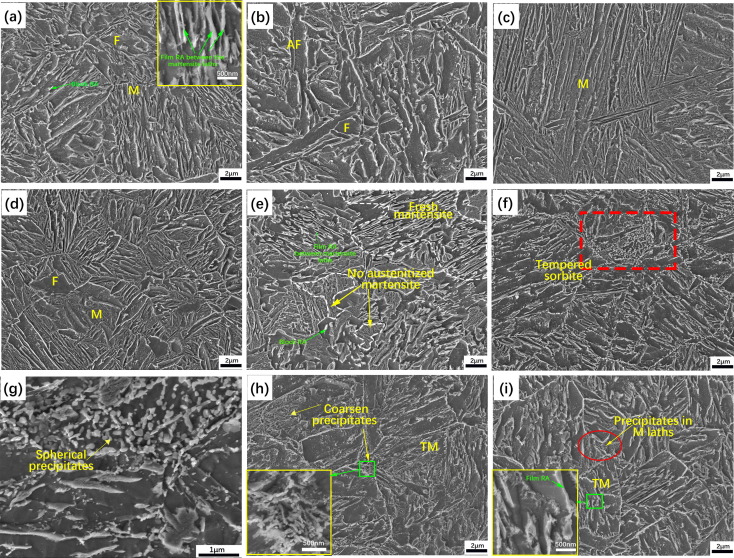

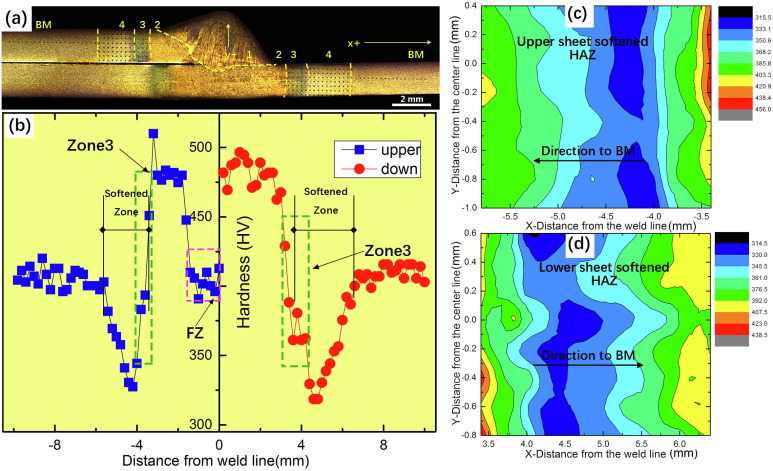

Figure 1 shows the different microstructures in detail throughout the weld and the base metal. In the softening zone shown in Figure 2 correlates to the tempered sorbite region in Figure 1 (part f). The hardness maps shows that the fusion zone is approximately as hard as the base metal, with the supercritical HAZ having the highest hardness values before rapidly softening in the intercritical and subcritical HAZ zones. The softened region must be accounted for in designing CMT or other high heat input welded components.

Figure 1: a) Base metal with retained austenite between martensite lathes, b) fusion zone with acicular ferrite and ferrite, c) coarse martensite grains in supercritical HAZ, d) fine martensite grains and ferrite in supercritical HAZ, e) intercritical HAZ with fresh martensite and untransformed martensite, f) softest region in subcritical HAZ; shows tempered sorbite, g)zoomed in region of subcritical zone with precipitates, h) subcritical HAZ with 350-360HV hardness, i) hardness with 380-390HV.W-1

Figure 2: a) macrostructure of the CMT-welded QP1180 joint, b) hardness chart through joint, c) hardness map in upper sheet, d) hardness map in lower sheet. 1) fusion zone, 2) supercritical HAZ, 3) intercritical HAZ, 4) subcritical HAZ, BM = base metal.W-1

Arc Welding

This article summarizes a paper by W. Mohr and N. Kapustka, EWI, entitled, “Fatigue of GMAW-P Lap Joints in Advanced High-Strength Steels.”M-13

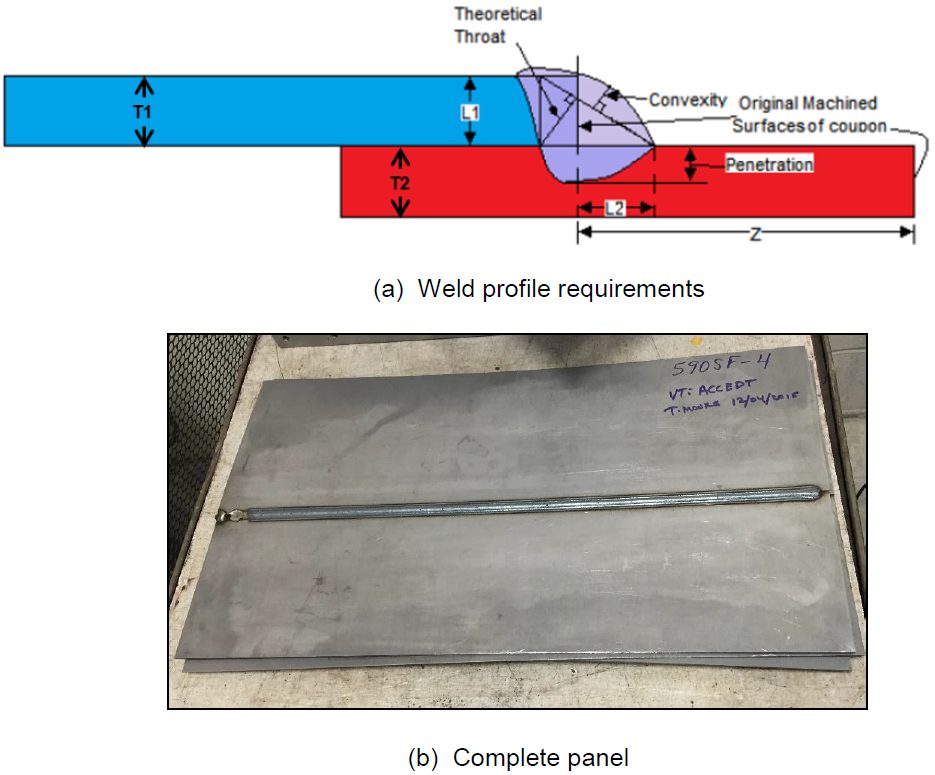

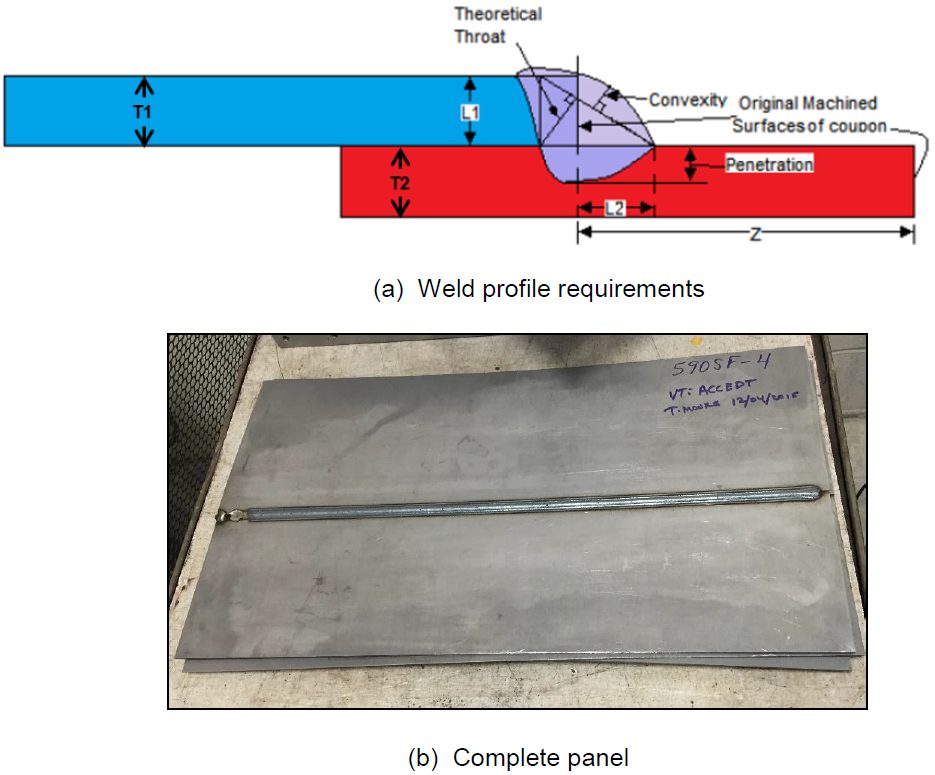

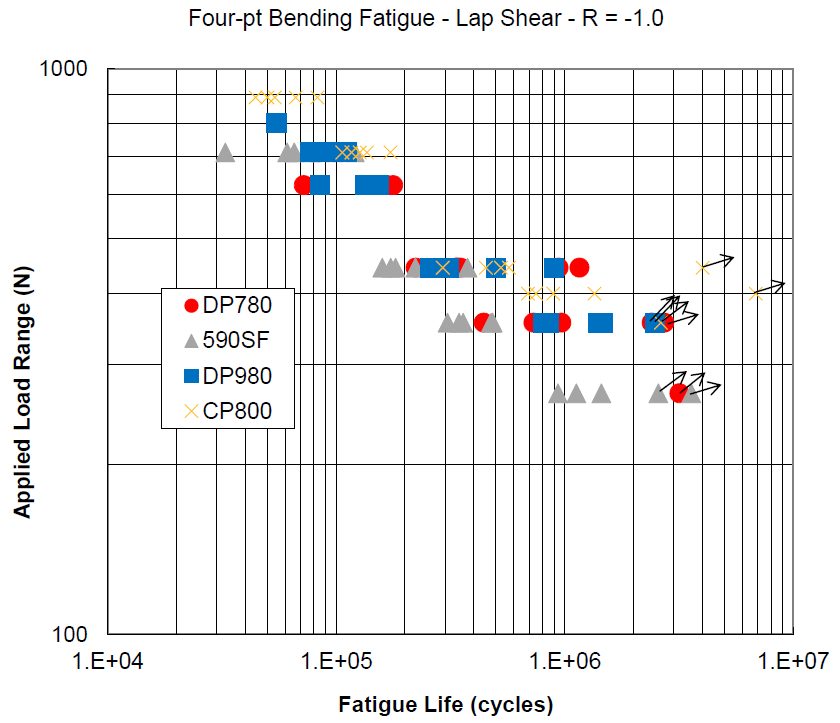

EWI has performed fatigue tests on welds from four Advanced High-Strength Steels (AHSS) in the uncoated condition. The materials were provided in three thicknesses as follows, 2.0-mm DP 780, 1.8-mm 590 SF, 2.0-mm DP 980, and 2.8-mm CP 800. Referring to Figure 1(a), welding parameters were selected to meet the weld profile requirements listed below:

The travel speed to achieve such combinations was 23 mm/s for three of the sheets and 13 mm/s for the 2.8-mm-thick CP 800. Figure 1 shows a completed panel.

Figure 1: Completed Panel.M-13

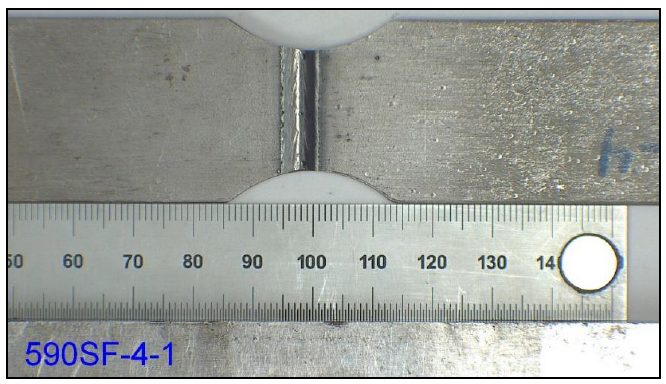

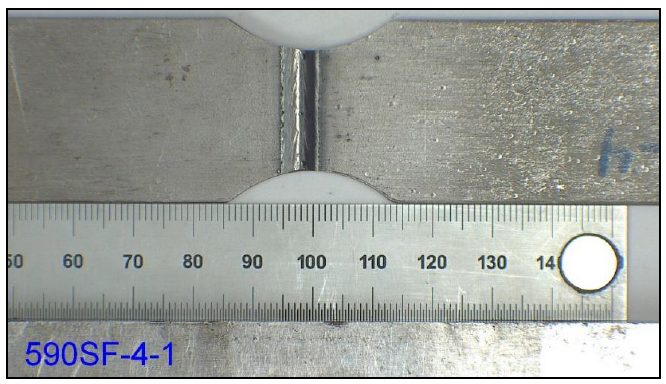

Specimens were cut from the lap-welded panels in a configuration recommended by Z 2275, with minimum reduced sections of 20-mm wide, with 20-mm radii on both sides to a full width of 30 mm, as shown in Figure 2.

Figure 2: Specimen Design.M-13

Fixtures for the bend testing had eight, 6.3-mm radius rollers, four on top and four on the bottom, with offsets of the roller centers to accommodate the lap-joint configuration and the differing sheet thicknesses. The interior span was 120 mm, while the exterior span was 210 mm. The full bending fixture, with a specimen inserted, is shown in Figure 3.

Figure 3: Bending Test Fixture.M-13

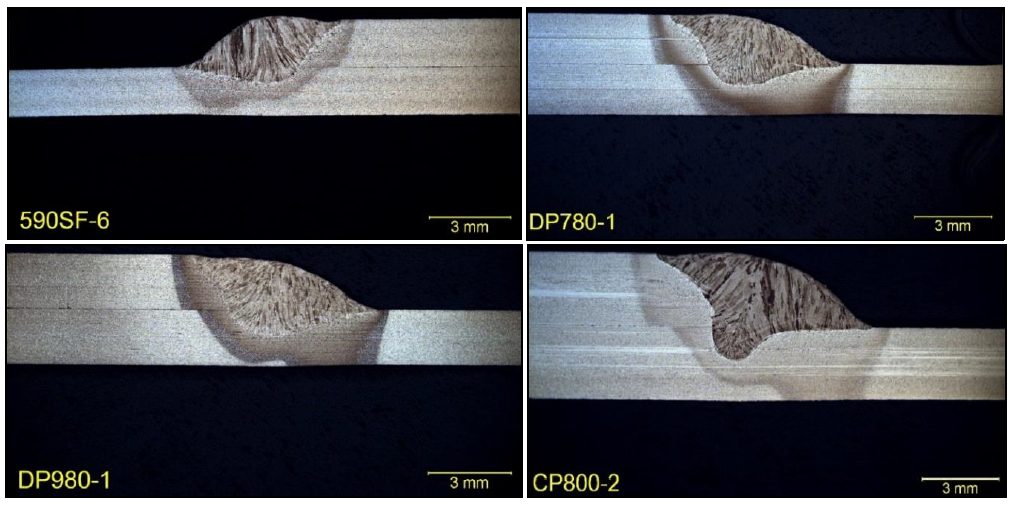

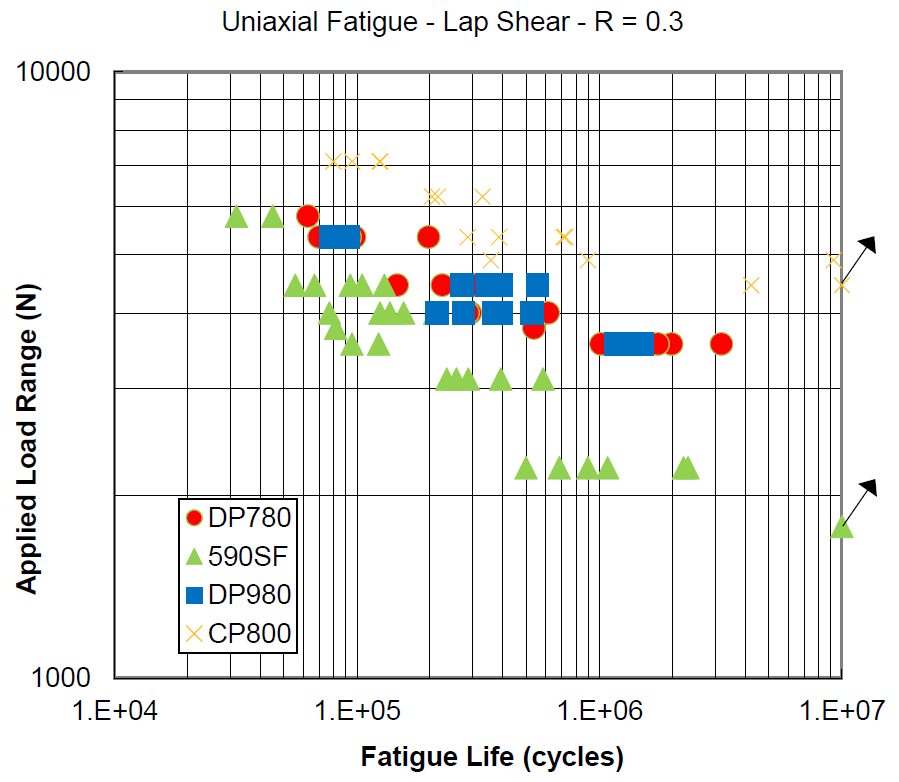

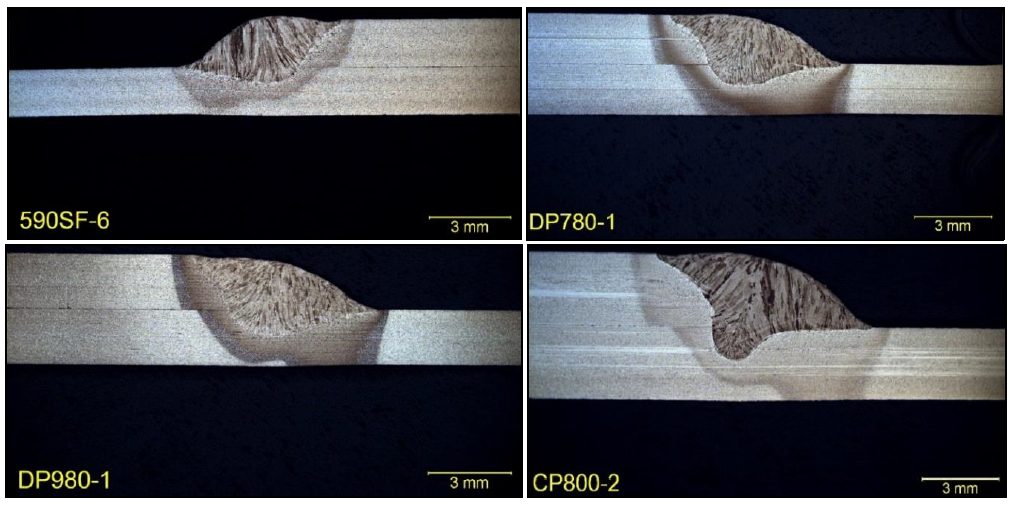

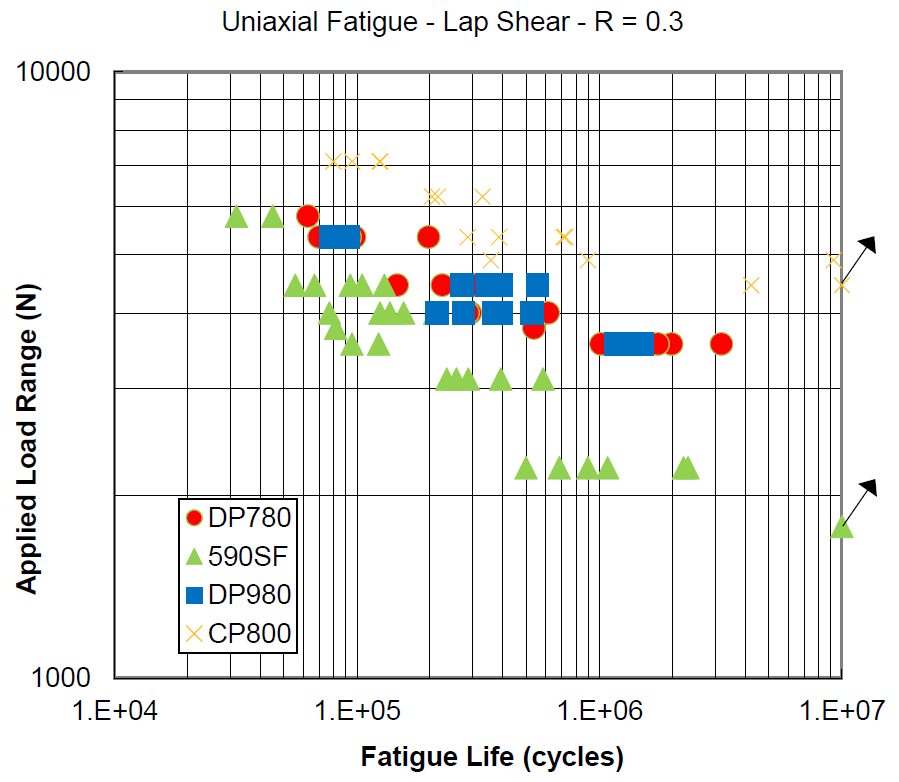

Weld profiles were achieved that met the weld profile requirements for each sheet material type. These weld profiles are shown for the four sheet materials in Figure 4. Fatigue testing results in tension at R = 0.3 gave lifetimes between 30,000 and 9 million cycles, with run-outs at 10 million cycles, as shown in Figure 5.

Figure 4: Cross Sections of Lap Joints (etched with 2% Nital).M-13

Figure 5: Results of Fatigue Testing in Tension at R= 0.3.M-13

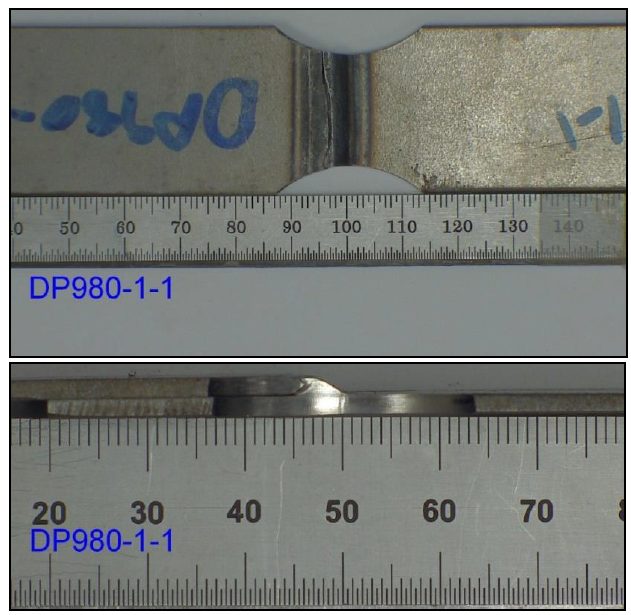

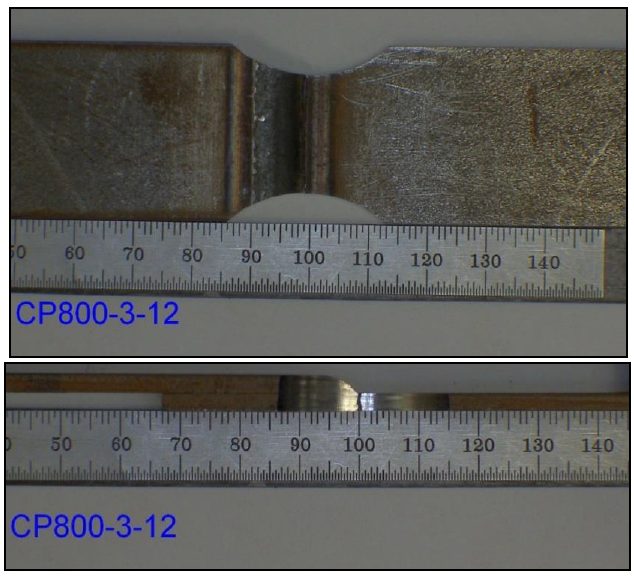

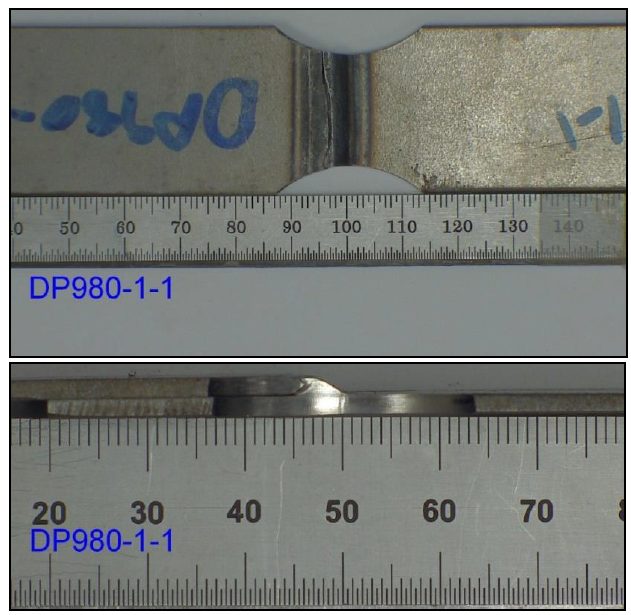

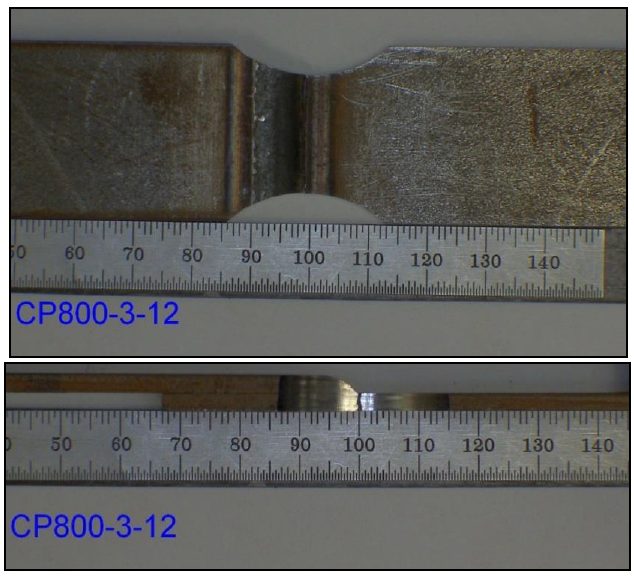

Weld root cracking dominated in the 590 SF, as well as the DP 780 and DP 980, with an example shown in Figure 6. Weld toe cracking was observed on the 2.8-mm-thick CP 800, with an example shown in Figure 7.

Figure 6: Example for a Root Crack Breaking Through the Weld Metal on DP 980.M-13

Figure 7: Example of a Toe Crack Breaking Through the Base Metal.M-13

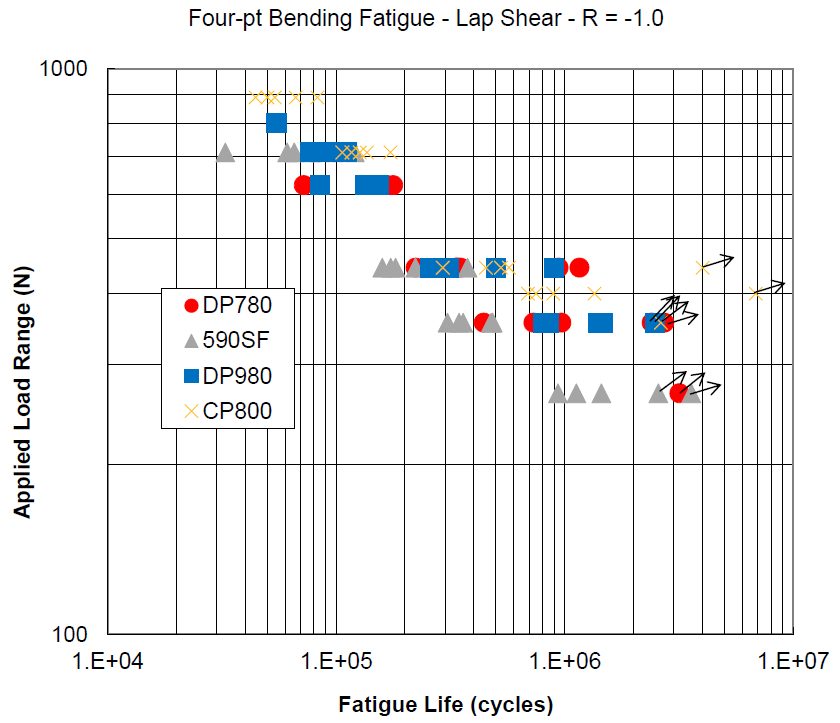

Fatigue testing in bending at R = -1 gave lifetimes between 30,000 and 2 million cycles, with run-outs on tests that continued to up to 7 million cycles, as shown in Figure 8.

Figure 8: Four-Point Bending Tests at R = -1.M-13

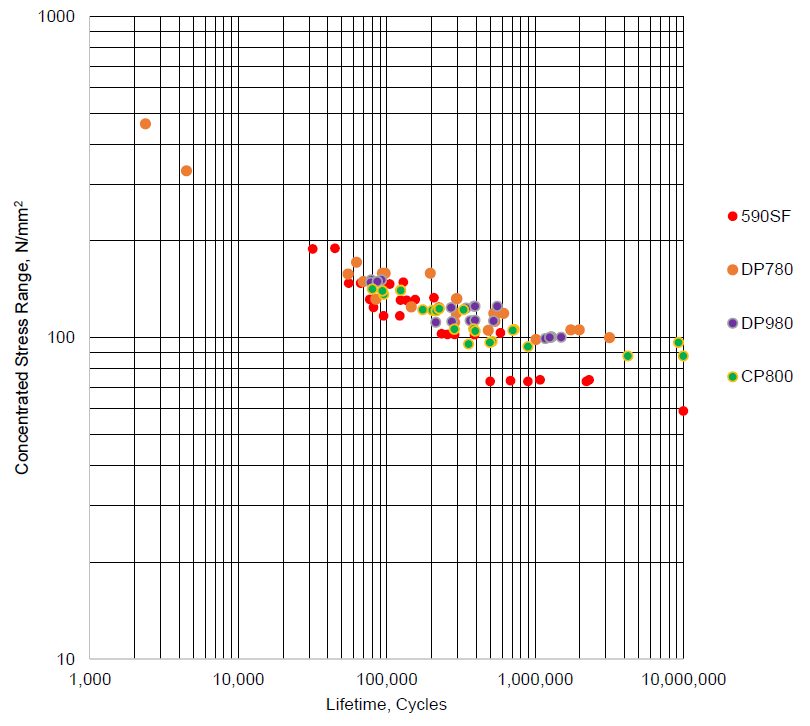

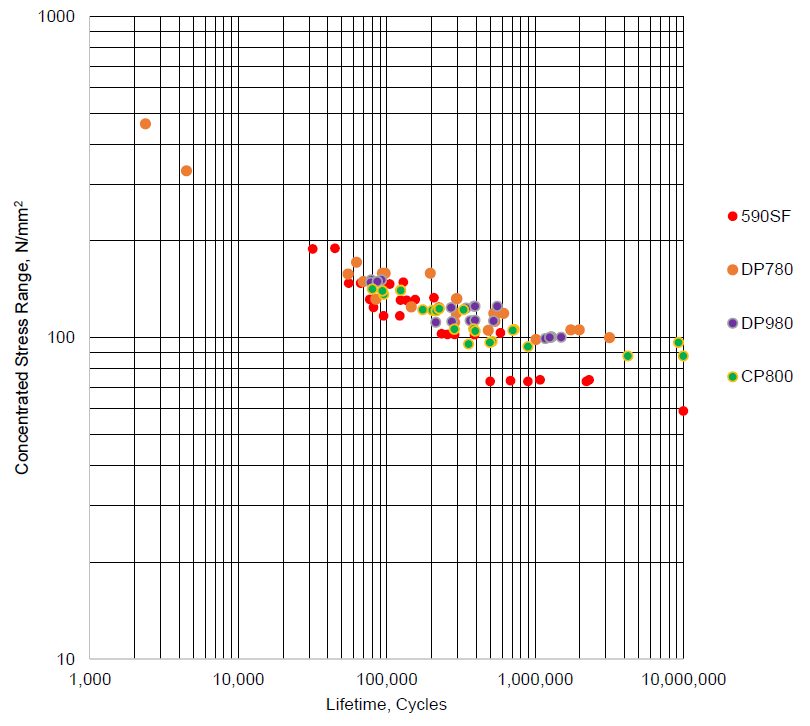

Taking the differing thicknesses, minor variations in minimum width, and the stress concentrations from the radii into account, the concentrated stress range was calculated to compare the four materials on a common basis, as shown in Figure 9.

Figure 9: Concentrated Stress Range versus Lifetime for Tension Tests.M-13

The fatigue cracks initiated at the root for the 1.8-mm 590 SF on both tension and bending testing. The fatigue cracks initiated at the weld toe for the 2.8-mm CP 800 on both tension and bending testing. The fatigue cracks initiated from the weld root in the tension testing and from primarily the weld cap in bending testing, for the 2.0-mm-thick DP 780 and 2.0-mm-thick DP 980.

Arc Welding

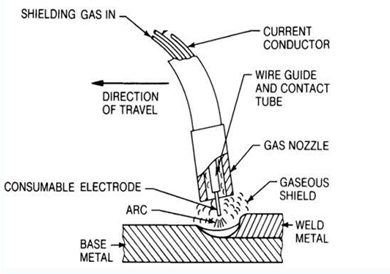

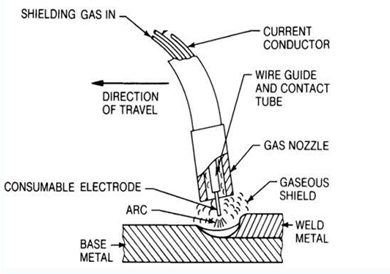

Gas Metal Arc Welding: Introduction

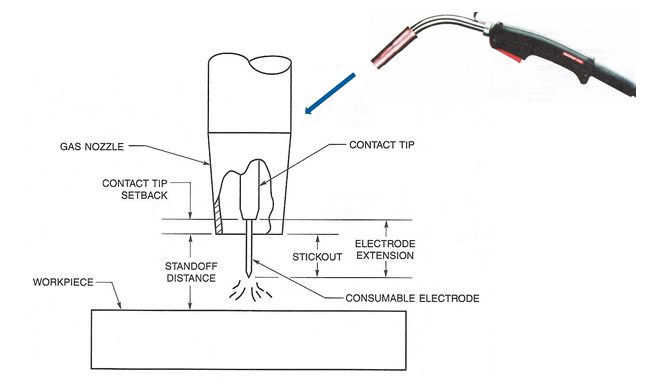

Gas Metal Arc Welding (GMAW) (Figure 1), commonly referred to by its slang name “MIG” (metal inert gas welding) uses a continuously fed bare wire electrode through a nozzle that delivers a proper flow of shielding gas to protect the molten and hot metal as it cools. Because the wire is fed automatically by a wire feed system, GMAW is one of the arc welding processes considered to be semi-automatic. The wire feeder pushes the electrode through the welding torch where it makes electrical contact with the contact tube, which delivers the electrical power from the power supply and through the cable to the electrode. The process requires much less welding skill than Shielded Metal Arc Welding (SMAW) or Gas Tungsten Arc Welding (GTAW) [LINK TO SECTION] and produces higher deposition rates.

Figure 1: GMAW

The basic equipment components are the welding gun and cable assembly, electrode feed unit, power supply, and source of shielding gas. This set up includes a water-cooling system for the welding gun which is typically necessary when welding with high duty cycles and high current.

GMAW became commercially available in the late 1940s offering a significant improvement in deposition rates and making welding more efficient. Deposition rates are much higher than for SMAW and GTAW, and the process is readily adaptable to robotic applications. Because of the fast welding speeds and ability to adapt to automation, it is widely used by automotive and heavy equipment manufacturers, as well as a wide variety of construction and structural welding, pipe and pressure vessel welding, and cladding applications. It is extremely flexible and can be used to weld virtually all metals. Relative to SMAW, GMAW equipment is a bit more expensive due to the additional wire feed mechanism, more complex torch, and the need for shielding gas, but overall it is still relatively inexpensive.

GMAW is “self-regulating”, which refers to the ability of the machine to maintain a constant arc length at all times. This is usually achieved using a constant-voltage power supply, although some modern machines are now capable of achieving self-regulation in other ways. This self-regulation feature results in a process that is ideal for mechanized and robotic applications.

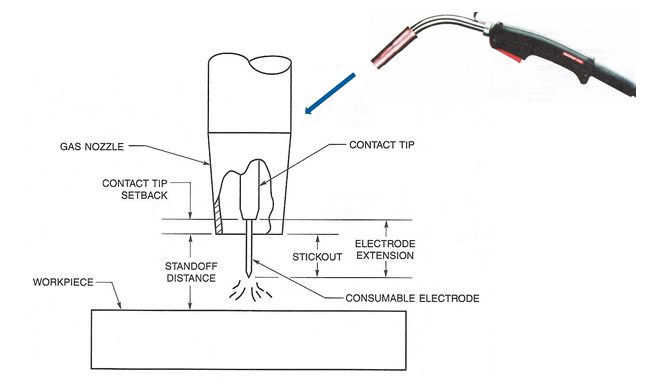

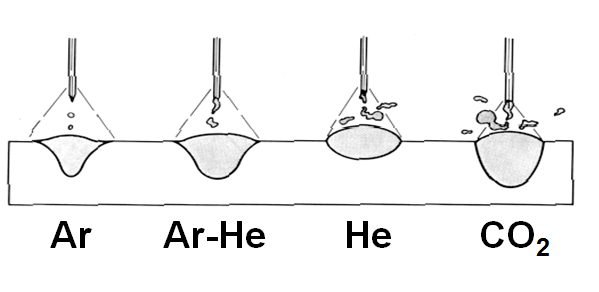

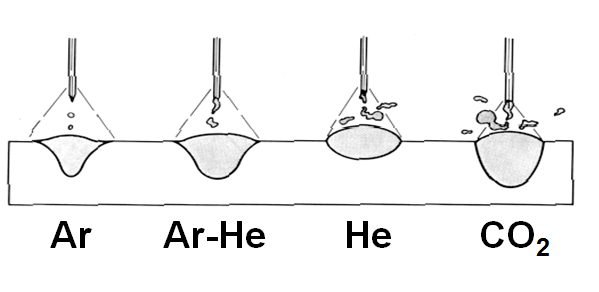

Figure 2 provides important GMAW terminology. Of particular importance is electrode extension. As shown, electrode extension refers to the length of filler wire between the arc and the end of the contact tip. The reason for the importance of electrode extension is that the longer the electrode extension, the greater the amount of resistive (known as I2R) heating that will occur in the wire. Resistive heating occurs because the steel wire is not a good conductor of electricity. This effect can become significant at high currents and/or long extensions, and can result in more of the energy from the power supply being consumed in the heating and melting of the wire, and less in generating arc heating. As a result, significant resistive heating can result in a wider weld profile with less penetration or depth of fusion. The stand-off distance is also an important consideration. Distances that are excessive will adversely affect the ability of the shielding gas to protect the weld. Distances that are too close may result in excessive spatter build-up on the nozzle and contact tip. Various gases are being used for shielding the in GMAW process. The most common ones include argon (Ar), helium (He), and carbon dioxide (CO2) and combinations of these. Figure 3 illustrates the effect of the shielding gas on the weld profile.

Figure 2: Common GMAW terminology

Figure 3: Effect of shielding gas on weld profile

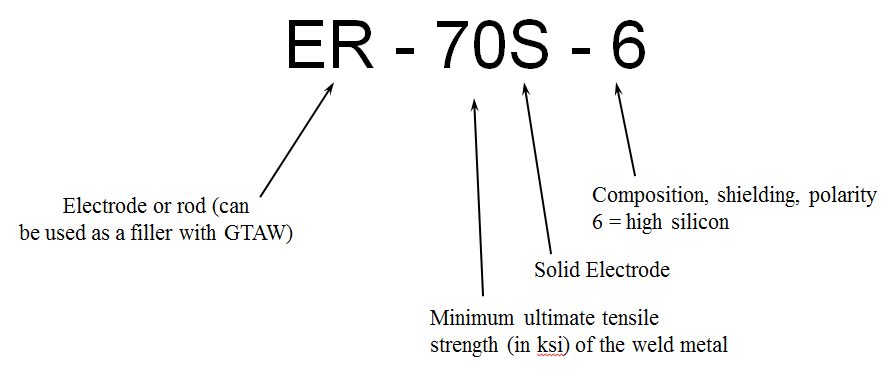

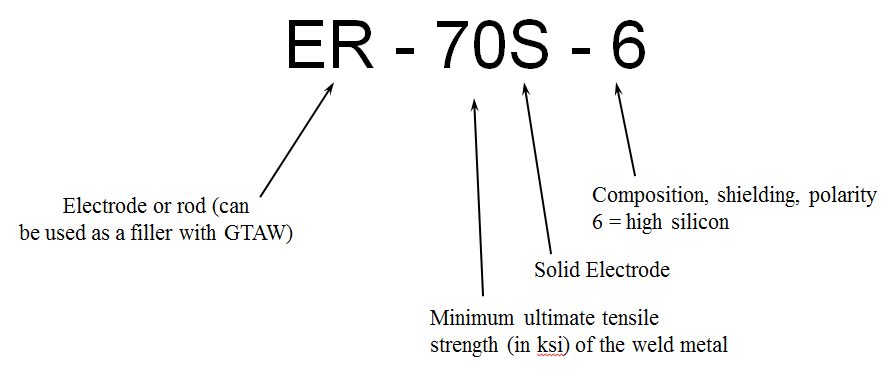

AWS A5.18 is the carbon steel filler metal specification for SMAW, and includes both filler metal for both GMAW and GTAW. A typical electrode is shown on Figure 4. The “E” refers to electrode and the “R” refers to rod which means the filler metal can be used either as a GMAW electrode which carries the current, or as a separate filler metal in the form of a rod that could be used for the GTAW process. The “S” distinguishes this filler metal as solid (vs. the “T” designation which refers to a tubular GCAW electrode or “C” for composite electrode), the number, letter, or number/letter combination which follows the S refers to a variety of information about the filler metal such as composition, recommended shielding gas, and/or polarity.

Figure 4: Typical AWS A5.18 electrode.

In summary, the GMAW process offers the following advantages and limitations:

- Advantages:

- Higher deposition rates than SMAW and GTAW

- Better production efficiency vs. SMAW and GTAW since the electrode or filler wire does need to be continuously replaced

- Since no flux is used there is minimal post-weld cleaning required and no possibility for a slag inclusion

- Requires less welder skill than manual processes

- Easily automated

- Can weld most commercial alloys

- Deep penetration with spray transfer mode

- Depending on the metal transfer mode, all position welding is possible

- Limitations:

- Equipment is more expensive and less portable than SMAW equipment

- Torch is heavy and bulky so joint access might be a problem

- Various metal transfer modes add complexity and limitations

- Susceptible to drafty conditions

GMAW Procedures and Properties

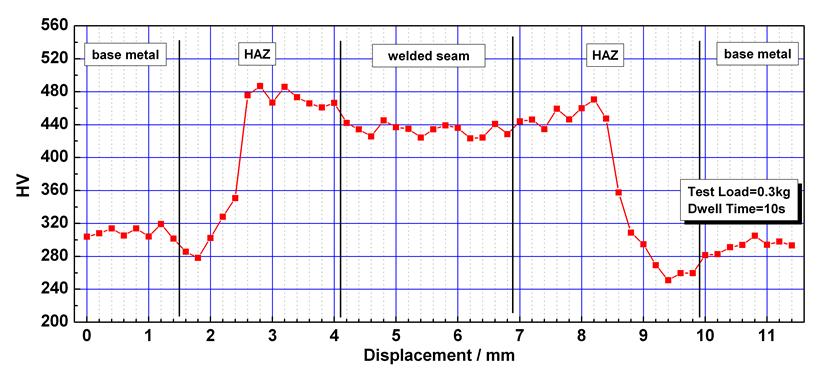

Despite the increase alloying content used for Q&P 980, there is no increased welding defect type or rate compared with mild steel Gas Metal Arc Welding (GMAW) welds. Figure 5 is the microhardness profile of 1.6-mm Q&P 980’s GMAW weld joint. Both welded seam and HAZ are all less than 500 HV, and there is no obvious softened zone in HAZ.B-4

Figure 5: Microhardness profile of 1.6-mm DP 980’s GMAW weld joint. B-4

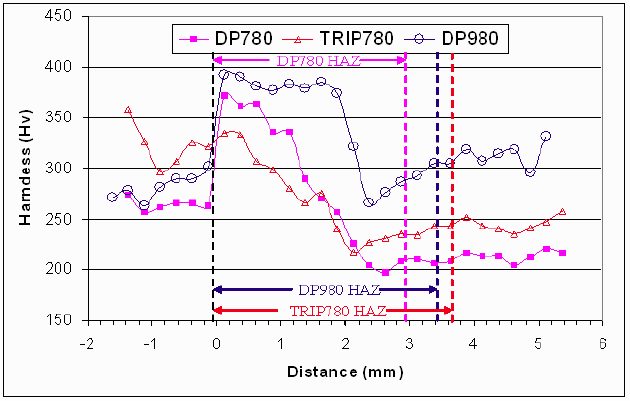

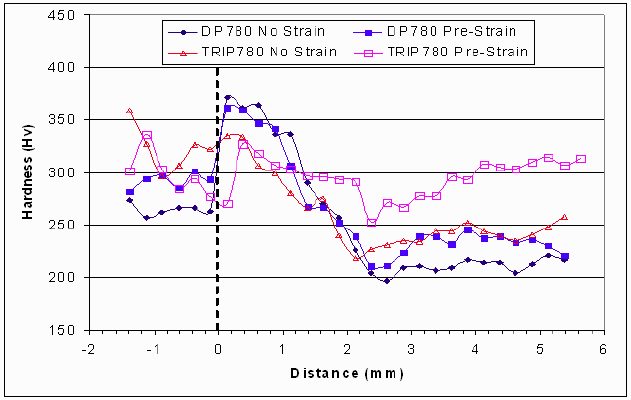

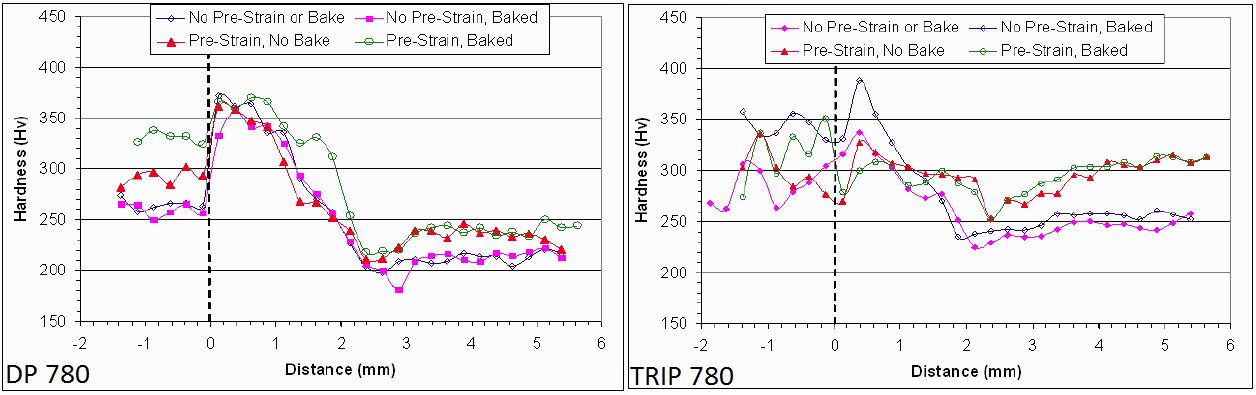

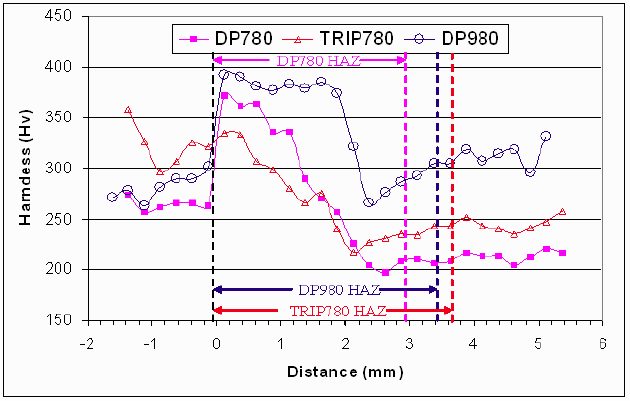

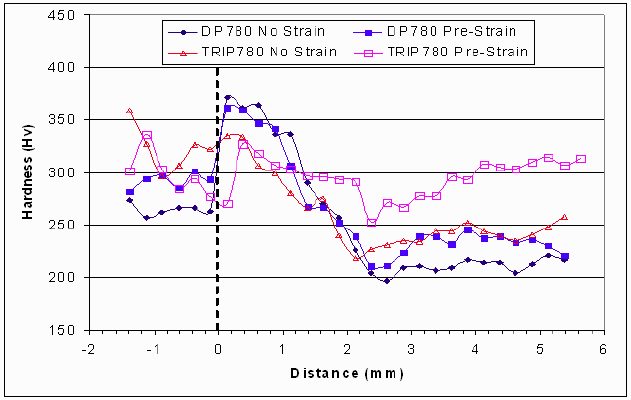

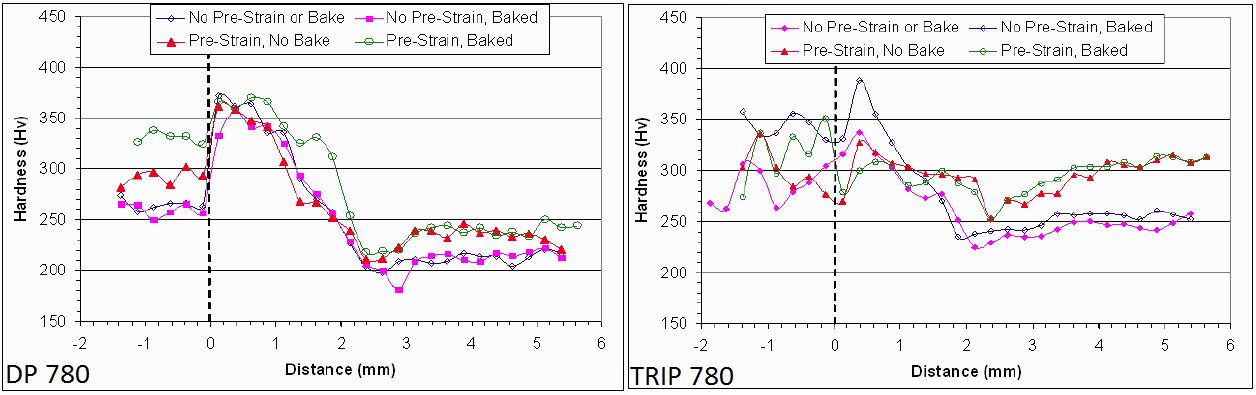

GMAW was used on three steels studied under a range of conditions. The left represents the FZ location and the middle is the HAZ. The figures show various degrees of HAZ hardening and softening depending on material grade and other conditions. The highest hardness occurs in the near HAZ, while the softest point is in the far HAZ. DP 980 [LINK TO THE MATERIAL IN METALLURGY] shows the greatest degree of HAZ hardening and softening. The nominally high CR condition is a combination of low heat input and heat sink. The plots show that CR tends to have the largest effect on the DP steels, with the TRIP steel being somewhat less affected. Pre-strain has the largest effect on the TRIP Base Metal (BM) , increasing the BM hardness by about 25%. The hardness of the softest location of the TRIP 780 HAZ is also increased by pre-strain, although degree of softening (about 20%) is not significantly changed. Pre-straining increased the DP 780 BM hardness by only about 10%. Pre-straining did not affect the peak HAZ hardness for either material. Post-baking did not appear to have a significant influence on the HAZ hardness profiles of the DP 780 material or the TRIP 780 material, regardless of pre-strain condition (Figures 6 through 8).

Figure 6: Hardness profiles of DP 780, TRIP 780, and DP 980 lap welds produced with the nominally high CR, no pre-strain or post-baking.P-7

Figure 7: Hardness profiles of DP 780 and TRIP 780 welds

produced both with and without pre-strain for the high CR condition.E-1

Figure 8: Hardness profiles of DP 780 and TRIP 780 welds produced both

with and without post-baking for both pre-strained sheet and not pre-strained

sheet for the nominally high CR condition.E-1

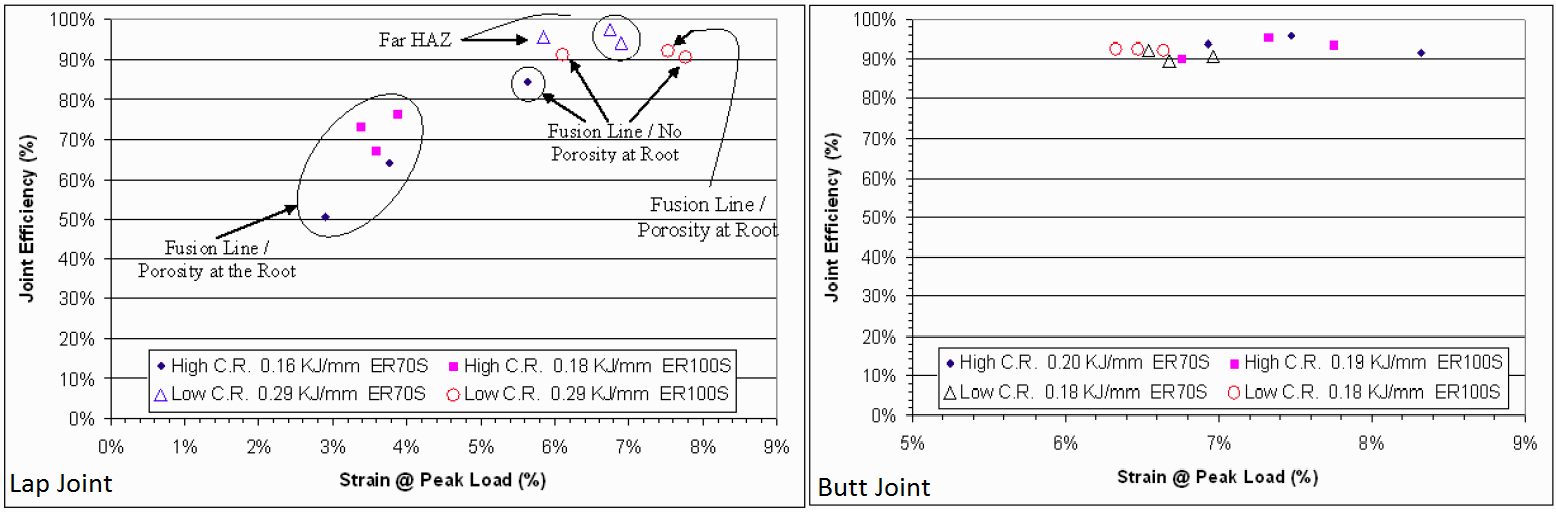

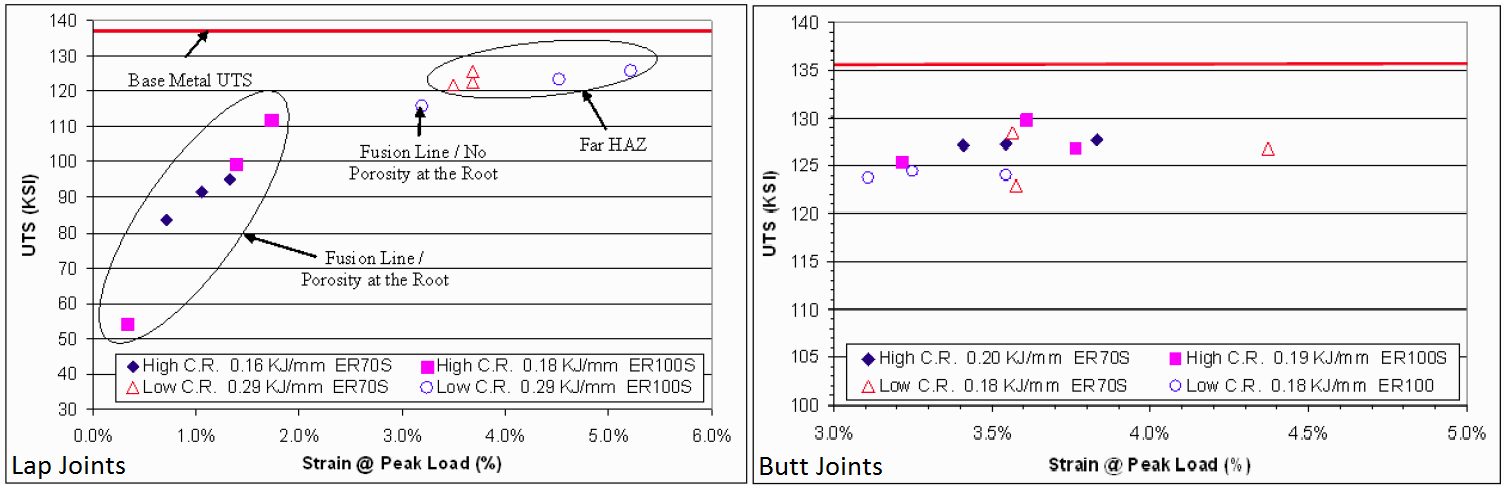

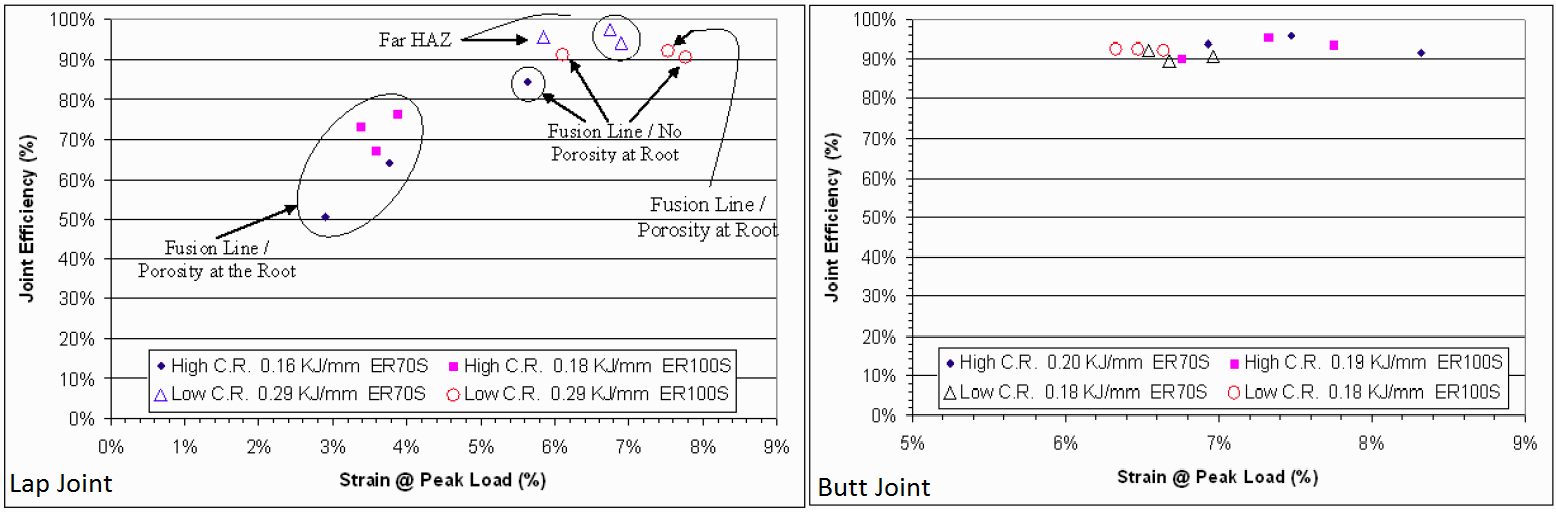

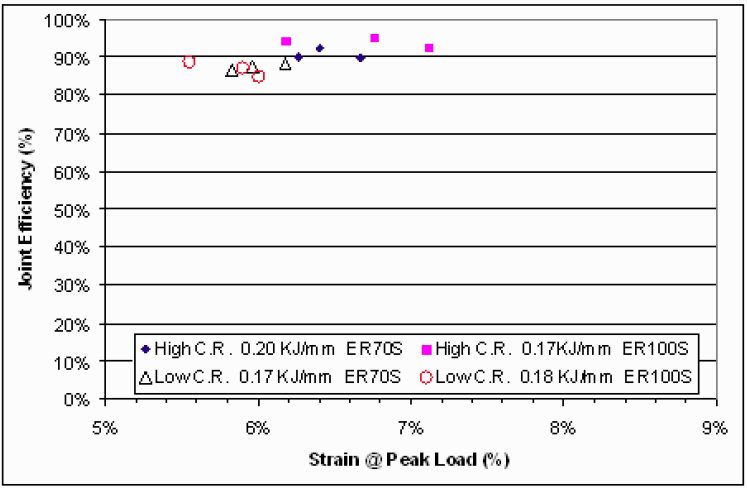

TRIP 780 lap joint static tensile results for different filler metal and CR conditions are shown in Figure 9. The results are expressed in terms of joint efficiency and the strain at peak load. The data indicates joint efficiencies ranged from about 50% to about 98%. Strains at peak load ranged from less than 3% to nearly 8%. Fracture occurred either in the far HAZ or at the weld fusion boundary. Filler metal strength had no discernable effect on the tensile properties. Figure 9 shows static tensile test results of the TRIP 780 butt joints. All the welds failed in the softened region of the far HAZ with joint efficiencies in excess of 89%. On average, welds made using higher CR experienced higher strains during loading than those made using lower CR. As was the case with the lap welds, filler metal strength did not appear to influence the static tensile properties. The abbreviations of high and low “CR” indicate high and low CR used for each weld.

Figure 9: Static tensile test results of TRIP 780 lap and butt joints.E-1

The static tensile test results of the DP 780 butt welds are shown in Figure 10. All welds failed in the softened region of the far HAZ. As shown, the high CR welds had joint efficiencies in excess of 90%. The high CR welds also appear to have slightly greater strains at peak load.

Figure 10: Static tensile test results of DP 780 butt joints.E-1

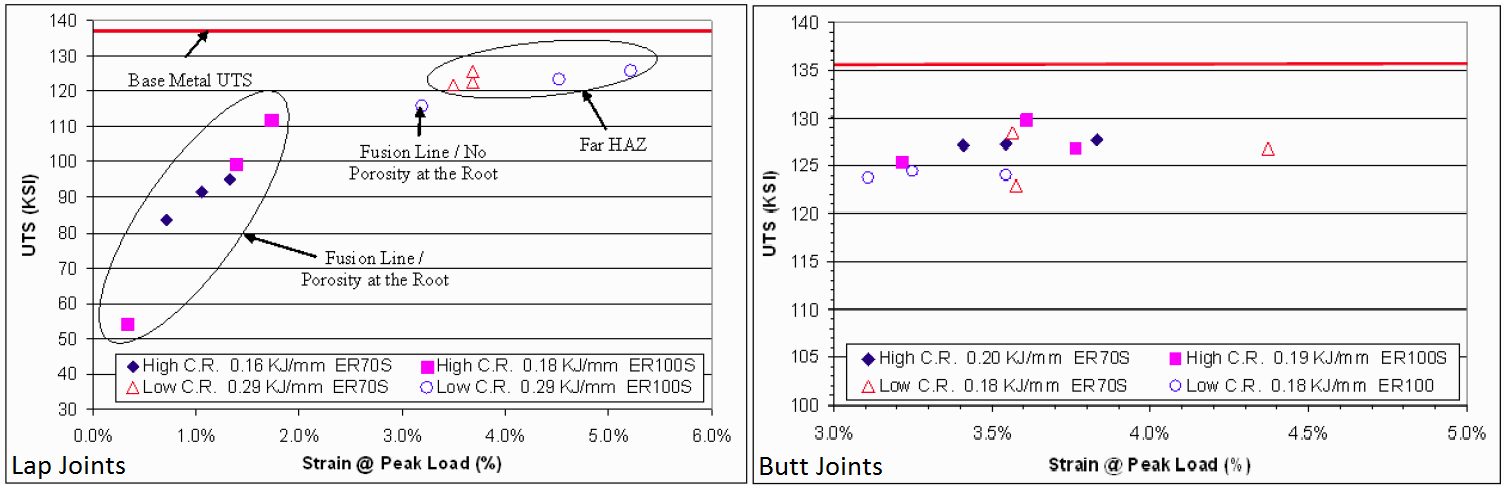

Figure 11 (left) shows the TRIP 780 lap joint dynamic tensile results for different filler metal and CR conditions. UTS ranged from 372 to 867 MPa (54 to 126 ksi) and strain at peak load ranged from less than 1% to over 5%. The high CR lap joints had lower strengths and strains at peak load. These welds failed along the fusion line presumably due to porosity present at the root. All the low CR lap welds produced with the ER70S-6 wire failed in far HAZ of the bottom sheet. Of the low CR lap joints produced with the ER100S-G wire, two dynamic tensile specimens failed in the softened region of the far HAZ, and one failed along the fusion line of the top sheet without the presence of porosity at the weld root. Analysis of Figure 11 (left) indicates that filler metal strength did not have a distinguishable effect on the dynamic tensile test results. Figure 11 (right) shows the dynamic tensile test results of the TRIP 780 butt joints. All failed in the softened region of the far HAZ. The UTS of the butt joints ranged from 840 to 896 MPa (122 to 130 ksi), and strain at peak load was generally between 3 and 4%. The figure indicates that neither filler metal strength nor CR condition had a distinguishable effect on the dynamic tensile test results of the butt joints.

Figure 11: Dynamic tensile test results of TRIP 780 lap joints and butt joints.E-1

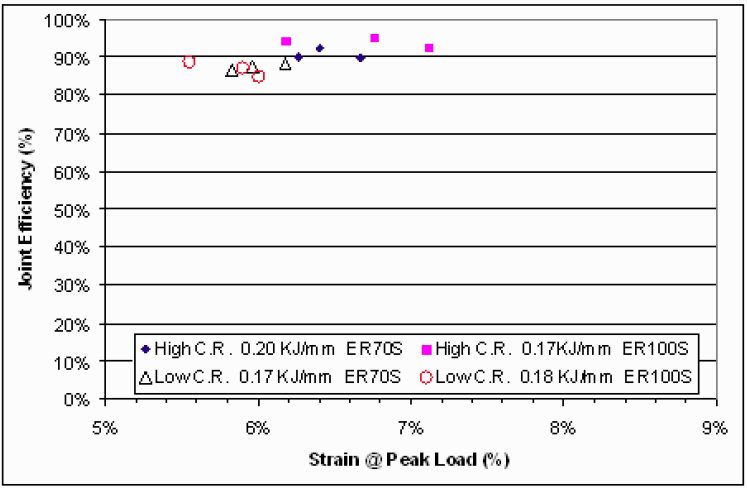

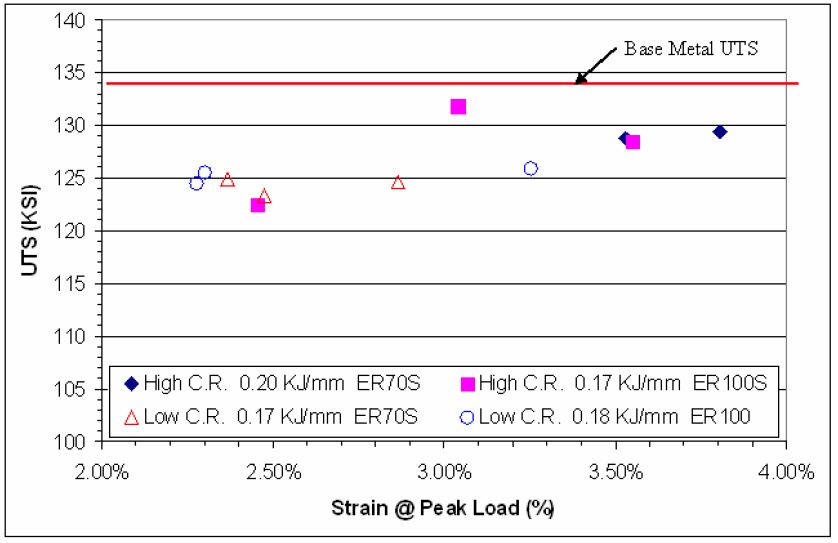

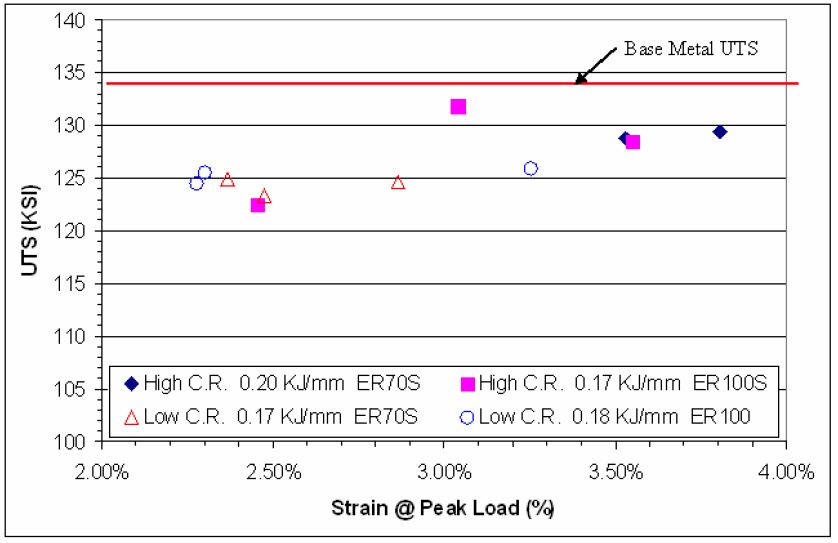

The dynamic tensile test results of the DP 780 butt joints are shown in Figure 12. All failed in the softened region of the far HAZ. UTS ranged from 841 to 910 MPa (122 to 132 ksi), and strain at peak load ranged from 2.25% to less than 4.0%. It should be noted that similar UTS were obtained for the DP 780 and TRIP 780 butt joints. On average, TRIP 780 butt joints had slightly higher strain at peak load. Neither filler metal strength nor CR condition appears to have a distinguishable effect on the dynamic tensile properties.

Figure 12: Dynamic tensile test results of DP 780 butt joints.E-1

Back To Top