Automotive Welding Process Comparison, Blog, Joining

Car body-in-white (BIW) structures, such as pillars and rails, are increasingly made of complex stack-ups of advanced high-strength steels (AHSS) for vehicle lightweighting to achieve improved fuel efficiency and crashworthiness. Complex stack-ups comprise more than two sheets with similar/dissimilar steels and non-equal sheet thicknesses.

Resistance spot welding (RSW) of complex stack-ups can be challenging, especially when a thin sheet of low-strength steel is attached to multiple thick AHSS sheets with a thickness ratio of five or higher (thickness ratio = total thickness of the stack-up/thickness of the thinnest sheet). In such a case, the heat loss is much faster on the thin sheet side than on the thick sheet side, and consequently, obtaining sufficient penetration into the thin sheet without expulsion on the thick sheet side can be challenging.

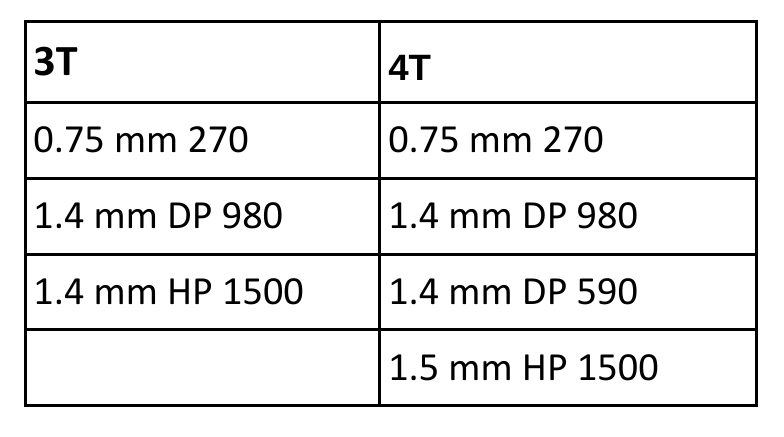

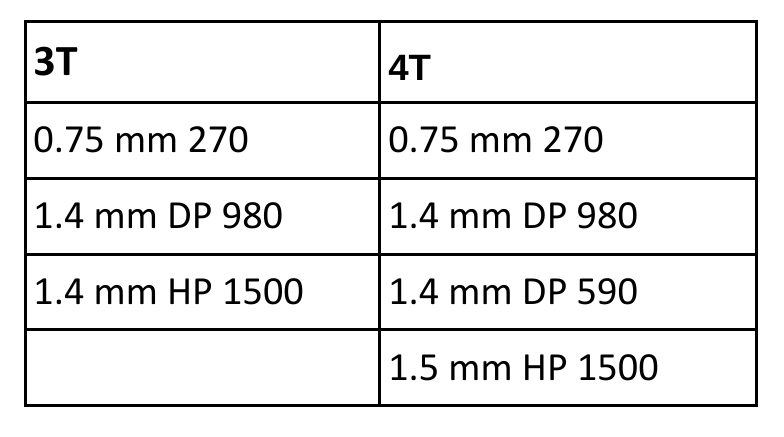

An example of two automotive applications involving complex AHSS steel stack-ups is shown below.

Examples of automotive applications involving complex AHSS steel stack-ups

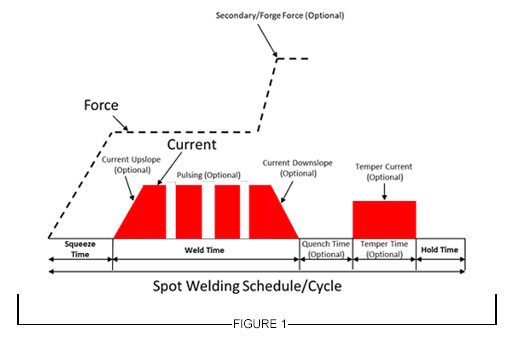

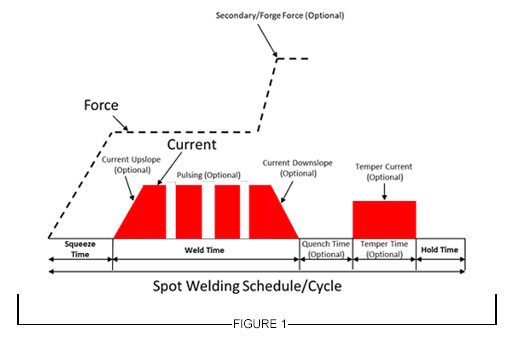

For welding 2T steel stack-ups, the weld schedule may be relatively simple and utilize just one current pulse with a specific weld time. However, typical RSW machines and controllers can customize and precisely control each parameter indicated in Figure 1.

Figure 1: General Description of Resistance Spot Welding Schedule

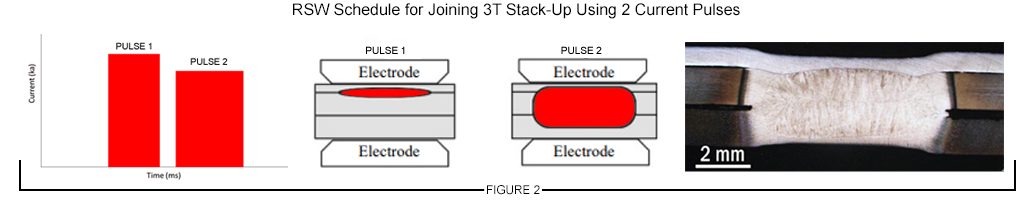

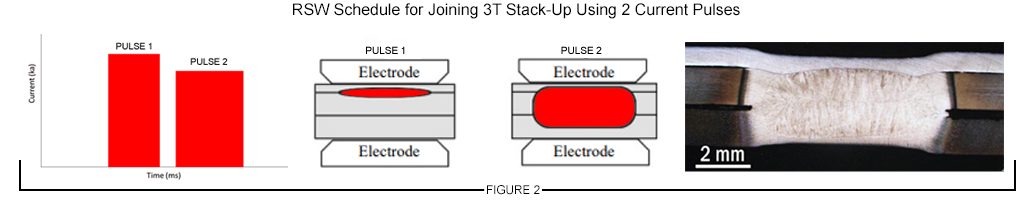

For RSW 3T and 4T applications, more advanced schedules are needed to achieve good weld nugget penetration through all the interfaces in the stack-up. To achieve this objective, the use of multiple current pulses with short cool time in between the pulses showed to be most effective, and in some cases, the application of a secondary force showed to be beneficial.

Figure 2 describes a method for joining the 3T stack-up using two current pulses. The first one is a short-time pulse that does not allow enough time for the electrode cooling to dominate at the top sheet, so a weld can easily form between the top and middle sheet. Once that nugget has formed, the second pulse utilizes a lower current and longer time to form the second nugget, which then grows into the first nugget to form a single weld.

This approach can be also used with electrode force variation during the welding cycle to provide additional control of the contact resistances, but of course, it is limited to machines that are capable of varying force during the weld cycle.

Typical pulse times are 50 – 350 ms with cool times of 20 – 35 ms and current levels between 8 – 15 KA, depending on materials type and thickness.

Figure 2: Example of RSW Schedule for Joining 3T Stack-Up Using 2 Current Pulses

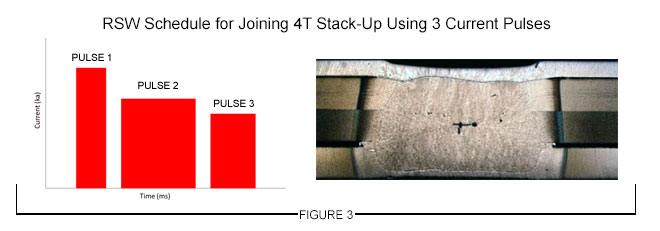

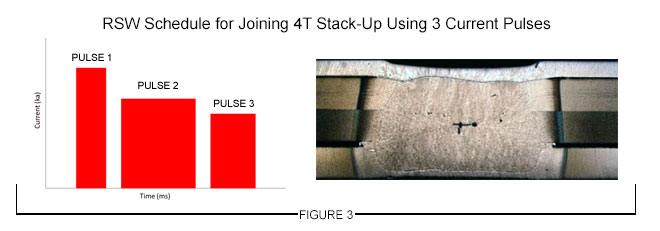

A 4T stack-up example is shown in Figure 3. In this case, a similar approach was used with three current pulses applied during the weld cycle to produce a weld through all interfaces.

The common theme in resistance spot welding all complex stack-ups is using a complex, multi-pulse weld cycle. These more complex schedules should be developed experimentally and potentially with computational modeling. Another consideration that may be beneficial in some cases is to vary the top and bottom electrode face diameter, such as that the smaller electrode face is on the thinner material side of the stack-up.

Figure 3: Example of an RSW Schedule for Joining 4T Stack-Up Using 3 Current Pulses

Thanks is given to Menachem Kimchi, Associate Professor-Practice, Dept of Materials Science, Ohio State University and Technical Editor – Joining, AHSS Application Guidelines, for this article.

Arc Welding

Fundamentals and Principles of Arc Welding

This section serves as an introduction to all the arc welding processes. The common features and important concepts and terminology of this family of processes are reviewed, with more process-specific details provided in the sections covering the specific processes.

Arc welding refers to a family of processes that rely on the extreme heat of an electric arc to produce a weld. They may or may not rely on additional filler metal to create the weld. Although generally considered “low-tech”, arc welding continues to be very popular primarily due to its low equipment cost and high flexibility. Some of the key discoveries that led to modern arc welding include the discovery of the electric arc in the 1820s (Davies), the first welding patent using a carbon electrode in 1886, and the first covered electrode in 1900 (Kjellberg).

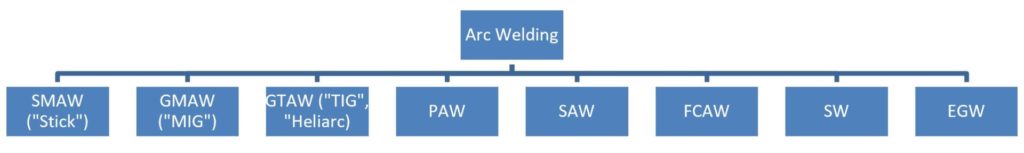

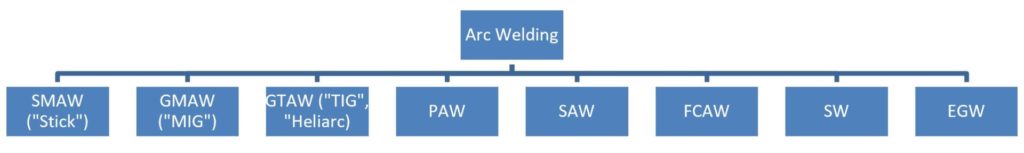

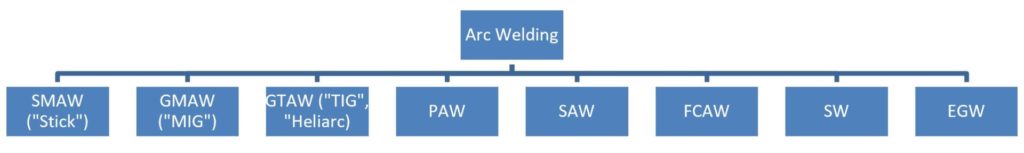

The most common arc welding processes today are illustrated in Figure 1. The abbreviations refer to American Welding Society (AWS)A-11 terminology as follows:

- EGW – Electroglas Welding

- FCAW – Flux-Cored Arc Welding

- GMAW – Gas Metal Arc Welding

- GTAW – Gas Tungsten Arc Welding

- PAW – Plasma Arc Welding

- SAW – Submerged Arc Welding

- SMAW – Shielded Metal Arc Welding

- SW – Arc Stud Welding

Figure 1: Common arc welding processes.

Whereas the welding engineer should always use proper AWS terminology during formal communications, in reality, the use of slang terminology for SMAW, GMAW, and GTAW processes is very common. Thus, where appropriate the “slang” terminology is included in italics.

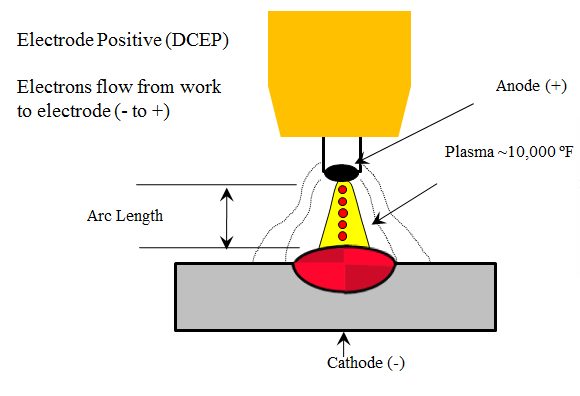

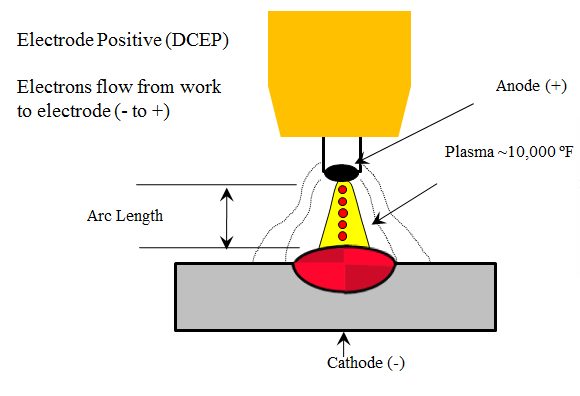

With all arc welding processes, the initiation of an arc basically completes (or closes) an electrical circuit consisting of the ground and work cables, the welding torch, the workpiece or parts to be welded, and the secondary of the welding power supply. Voltages provided by the power supply are commonly either 60 or 80 V. Such voltages are high enough to establish and maintain an arc, but low enough to minimize the risk of electric shock. Once the arc is struck, actual arc voltages commonly range between 10 and 35 V. Direct Current (DC) is most common, but Alternating Current (AC) is sometimes used. Pulsed DC is becoming a common feature in modern welding power supplies. The electrical polarity used during arc welding is very important, but it has different effects with different processes. The effect of polarity on heat input is especially important with GTAW and GMAW, but the effects are opposite. With GTAW, direct-current electrode negative (DCEN) produces the greatest amount of heat into the part and is the most common polarity. However, with GMAW, direct-current electrode positive (DCEP) produces the greatest amount of heat into the part and is used almost exclusively with this process (Figure 2).

Figure 2: DCEP – common with GMAW.

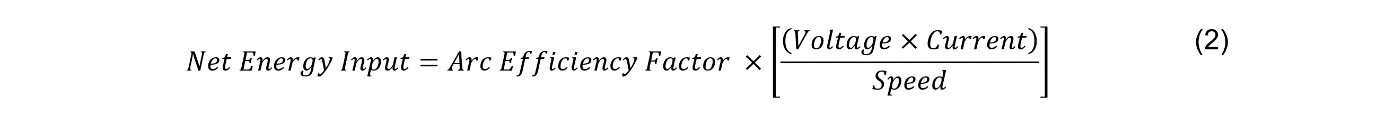

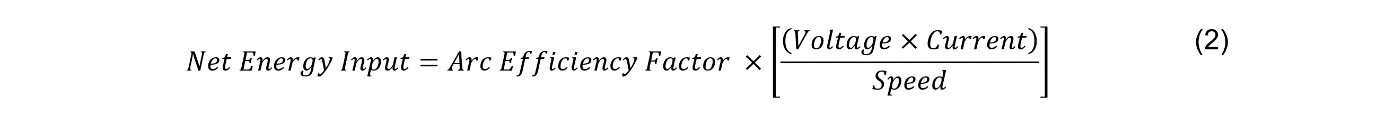

The heat input during arc welding is primarily a function of weld travel speed and current, based on the following equation:

Although voltage appears to play a prominent role in the heat input equation, it is a parameter that is chosen primarily to create the most stable arc, not to affect heat input.

AWS filler metal classifications vary somewhat depending on the process. A common example is the classification system for SMAW electrodes, “EXXXX” where “E” stands for electrode, the two digits following the E give the minimum deposited weld metal tensile strength in kips per square inch (ksi) (there will be a third digit if the strength is 100 ksi or higher), the third “X” provides information on what welding positions that electrode can be used for, and the final “X” provides information about the coating type. The electrode and filler metal classification schemes will be covered in more detail in the subsequent chapters covering each of the arc welding processes.

Shielding

When metals are heated to high temperatures approaching or exceeding their melting point, diffusion rates are accelerated and the metals become very susceptible to contamination from the atmosphere. Elements that can be most damaging are oxygen, nitrogen, and hydrogen, and contamination from these elements can result in the formation of embrittling phases (such as oxides and nitrides), and porosity. To avoid this contamination, the metal must be shielded as it solidifies and begins to cool. The arc welding processes all rely on either a gas or a flux, or a combination of both for shielding. The way these processes are shielded is their main distinguishing feature from one another.

Processes such as GMAW, GTAW, and PAW rely solely on gas shielding. Shielding gasses protect by purging the susceptible metal from atmospheric gasses. The GMAW process commonly uses argon (Ar), carbon dioxide (CO2), or blends of Ar and CO2. CO2 gas produces more spatter and a rougher weld appearance. It can produce fast welding speeds, is readily available, and is cheap. Additions of CO2 or small amounts of O2 to Ar can improve puddle flow. The choice of shielding gas for GMAW plays a major role in the type of molten metal transfer mode from the electrode to the weld puddle.

Arc Welding Weld Joints and Types

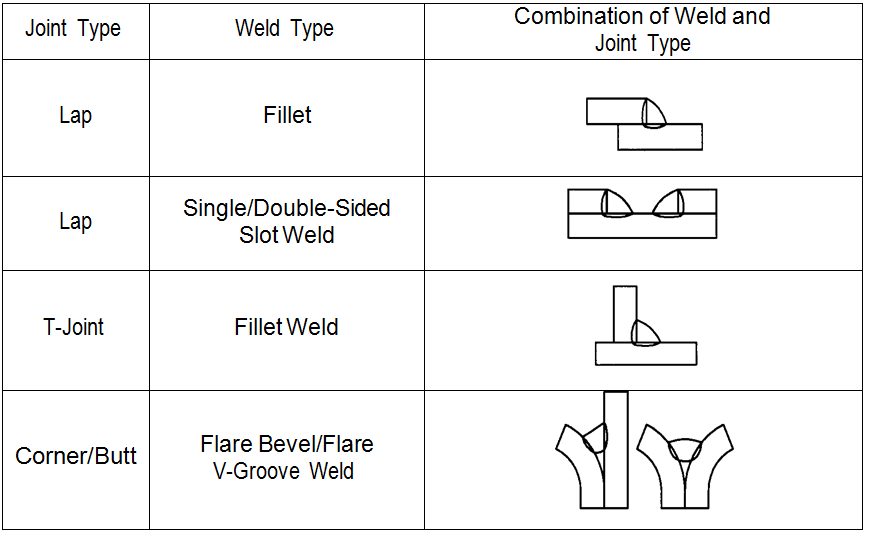

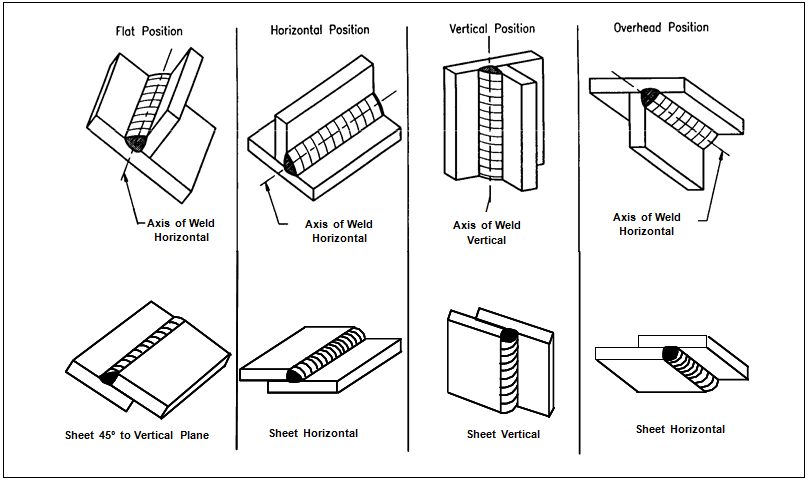

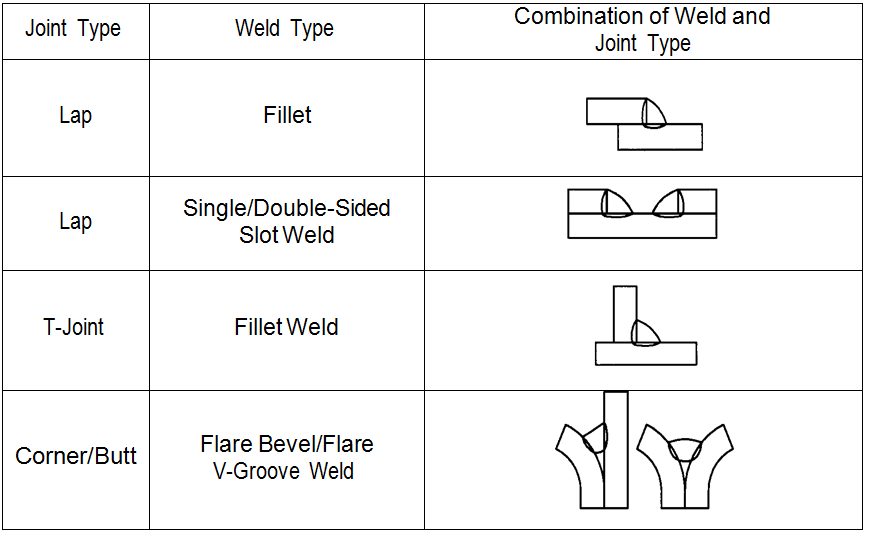

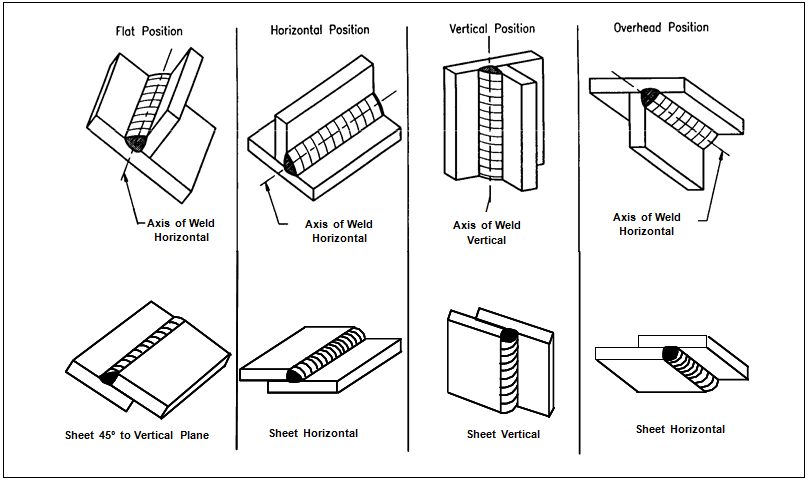

The selection of a proper weld joint and weld type is a very important aspect of arc welding. The joint refers to how the workpiece or parts that are being welded are arranged relative to each other, and weld type refers to how the weld is formed in the joint. Specifically in arc welding, there are numerous joint types, but only two weld types, a fillet and a groove weld. A fillet weld offers the advantage of requiring no special joint preparation because the geometry of the joint provides the appropriate features to place the weld. Groove welds facilitate the creation of full-penetration welds which are often required in critical applications. The choice of weld and joint type is often dictated by the design of the component being welded but will play a major role in the properties of that joint. The thickness of the parts being welded, as well as the material and type of welding process being used may also affect the choice of weld or joint type. Some very common arc welding joints and weld types are shown in Figure 3. Basic welding positions are shown in Figure 4. It is recommended that all welding joints be positioned for welding in either the flat or horizontal position whenever possible. The horizontal or vertical plane of the flat and horizontal joint may vary up to a maximum of 10 degrees.

Figure 3: Typical arc welding joint and weld types for automotive sheet steel applications.

Figure 4: Basic arc welding positions.

Electrode Feed Rate

When using the semiautomatic arc welding processes such as GMAW electrode feed rate (or wire feed speed) determines both deposition rate and current. Higher feed rates increase weld metal deposition and increase current since melting rates at the end of the wire must increase as the wire feed speed increases. As a result, with the semiautomatic processes, current is typically adjusted by changing the wire feed speed since the two are relatively proportional. Typical wire feed speeds are between 100 and 500 inches per minute (ipm).

Welding Travel Speed

Travel speed refers to how fast the welding arc is moving relative to the workpiece. The heat input equation clearly shows that travel speed, like current, plays a direct role in the amount of heat into the part. Faster speeds produce less heat into the part and reduced weld metal deposit. The choice of travel speed is typically driven by productivity, with the obvious desire to usually weld as fast as possible. Travel speed is independent of current and voltage and may be controlled by the welder or mechanized. Typical travel speeds range between 5 and 100 ipm.

Arc Welding Safety

There are many hazards associated with arc welding that are not only important concerns for the welder, but for personnel working around any arc welding operations. This section will provide a very brief overview of the most common hazards of which the welding personnel should be aware. It is strongly recommended regarding safety in arc welding and other welding and associated processes to refer to the American National Standards Institute (ANSI) Document Z49.1, “Safety in Welding, Cutting, and Allied Processes”.

Ultraviolet radiation from the arc can damage the eyes and burn the skin in the same way skin is burned from the sun. This requires the use of proper shielding for the eyes and protective clothing to cover any exposed skin. Personnel working near arc welders should be careful not to glance at an open arc without proper shielding. Sparks and spatter during welding mandate the need for proper eye protection for anyone near the welding operation. Additional protective helmets are needed for the welder. Although the low voltages used in arc welding are relatively safe, proper electrical safety must be exercised at all times, including grounding of parts and equipment and avoiding damp conditions.

Welding fumes can be hazardous to the welder when inhaled over long periods of times so proper ventilation is paramount. Shielding gases can produce suffocation in enclosed spaces, such as when welding in tanks. Ar is heavier than air, and in the absence of proper ventilation, will displace oxygen when it fills a room. Helium is lighter than air producing a similar risk for overhead welding. Compressed shielding gas bottles can explode when mishandled or abused, or an arc strike can weaken the bottle, leading to an explosion. Hot metal is always a hazard with fusion welding processes like arc welding. When working around a welding operation, one should always assume that any piece of metal is hot. Welding arcs and associated hot metal spatter are ready sources for ignition of flammable materials in the vicinity of welding. Many fires have been started by careless welders who are not aware of any combustible material.A-11, P-6

Arc Welding Procedures

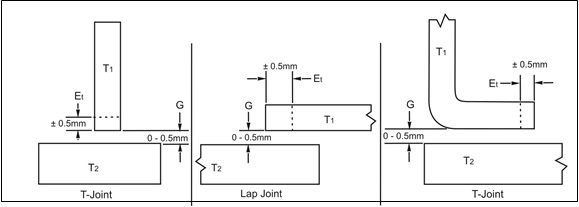

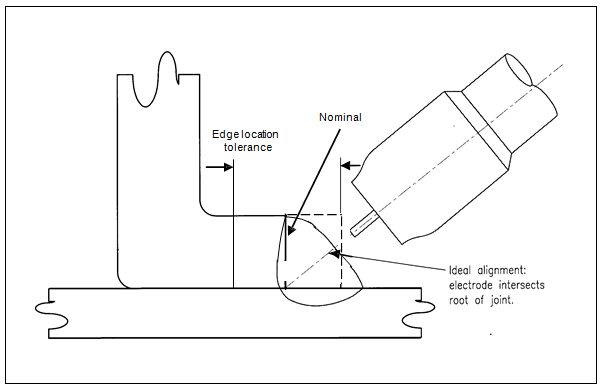

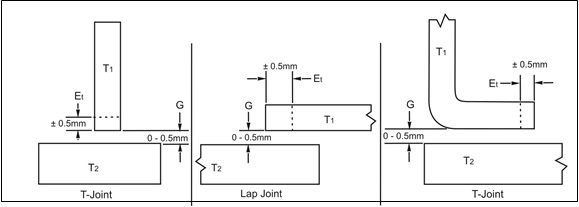

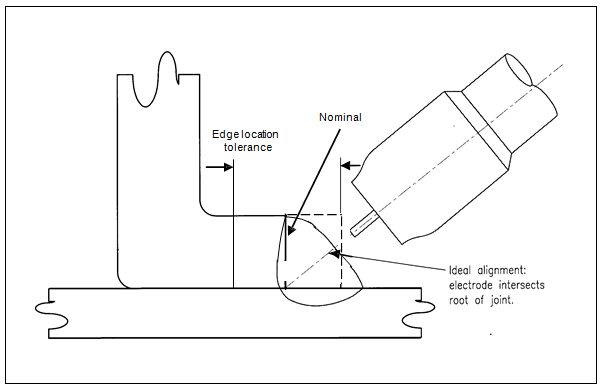

Conventional arc welding (for example GMAW, TIG, and plasma) can be used for AHSS in a similar way to mild steels. The same shielding gases can be used for both AHSS and mild steels. For automotive applications, a design gap tolerance (G) of 0-0.5 mm is allowed for all weld joints, as illustrated in Figure 5. An edge trim tolerance (Et) of ±0.5 mm is required where the edge is part of the weld joint, as shown in Figure 6. The variation in edge location causes variation in alignment of the electrode wire with the weld joint, as shown in Figure 6. Misalignment of the electrode may cause poor weld shape, improper fusion and burn-though. To control this variable, the trim tolerance at the weld joint must be held to ±0.5 mm and the electrode must maintain a root joint alignment tolerance of ±0.5 mm.

Figure 5: Joint design tolerance.A-12

Figure 6: Edge location tolerance for fillet weld in a lap joint.A-12

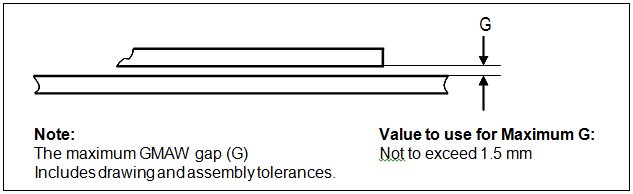

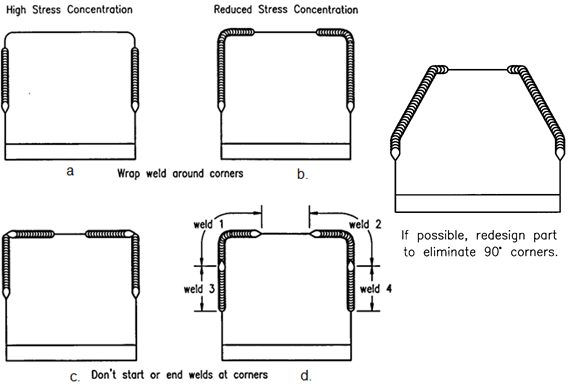

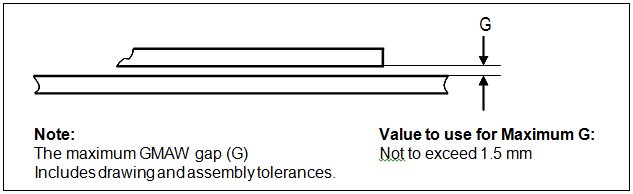

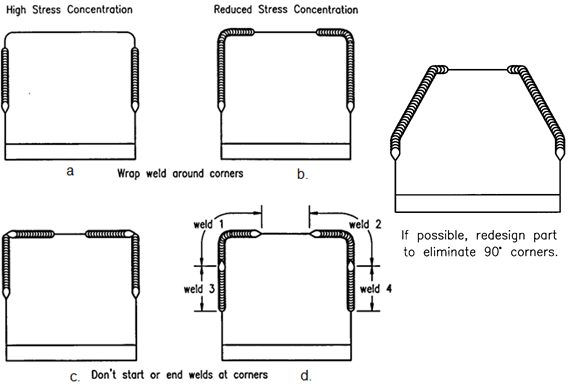

A tolerance stack-up review must be performed on all GMAW joints. The worst-case maximum designed gap including tolerance stack-up shall not exceed what is listed in Figure 7. It is preferable to target the smallest possible gap (the thickness of the thinnest sheet or 1.5 mm, whichever is smaller). High-stress areas defined by CAE analysis and/or functional testing should be reviewed for weld optimization. Figure 8 illustrates techniques used to reduce the fillet weld stress concentration and to improve weld performance. These techniques include placing the weld start/stop away from corners and other high-stress areas, avoiding abrupt weld line direction changes when possible, etc.

Figure 7: Maximum GMAW welding gap.A-12

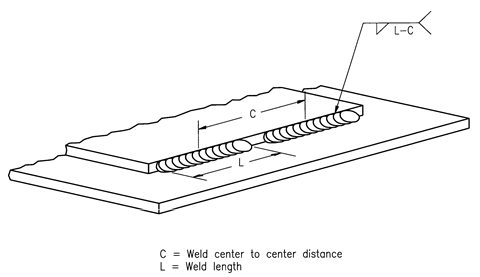

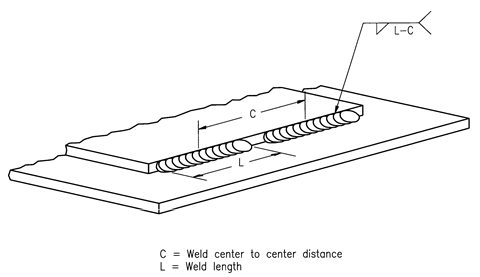

Intermittent welds that are properly sequenced can help keep joints closed by reducing the heat input which reduces distortion. Meanwhile, intermittent welds also introduce weld starts and weld stops, both of which are stress risers. Similar to continuous welds, weld start/stops of intermittent welds should be placed away from high stress areas. Intermittent welds are specified by the center-to-center distance (i.e., pitch) and weld length, as shown in Figure 9.

Figure 8: Reducing weld stress concentrations.A-12

Figure 9: Intermittent fillet weld spacing.A-12

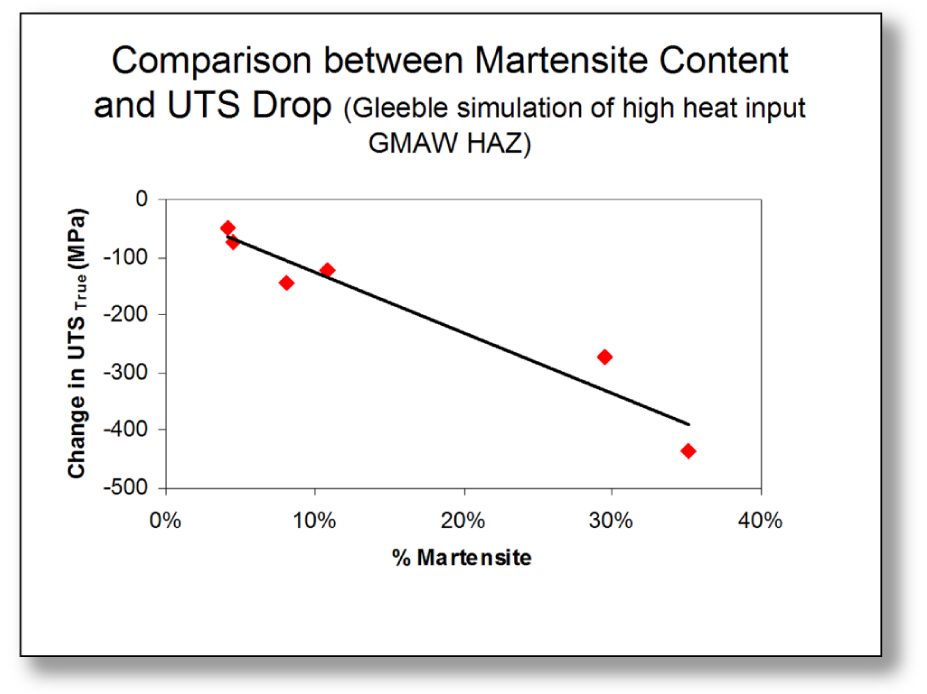

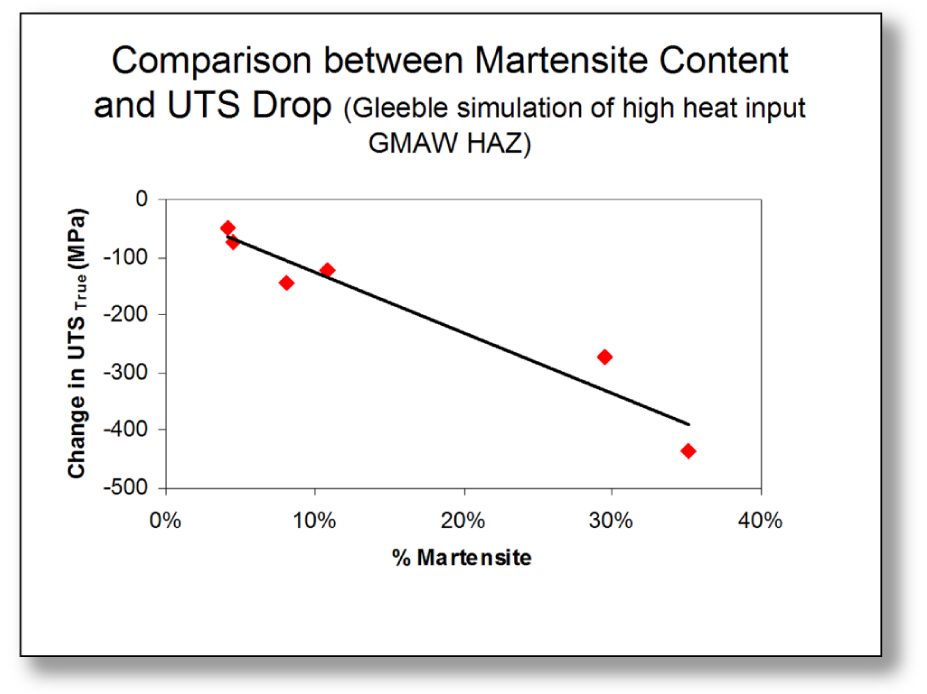

Despite the increased alloying content used for AHSS, there are no increased welding imperfections compared with mild steel arc welds. Changing from mild steel to AHSS may also result in a change of arc blow. The strength of the welds for AHSS increases with increasing base metal strength and sometimes with decreasing heat input. Depending on the chemical composition of AHSS [for example, mild Steels and DP steels with high martensite content and strength levels more than 800 MPa], the strength of the weld joint may be reduced in comparison to the base metal strength due to small soft zones in HAZ (Figure 10). For CP and TRIP grades, no soft zones occur in HAZ due to the higher alloying content for these steels in comparison to DP and mild steels.

Figure 10: Relationship between martensite content and reduction in true ultimate tensile strength (UTS) (Data obtained by thermomechanical simulation of high heat input GMAW HAZ.D-1).

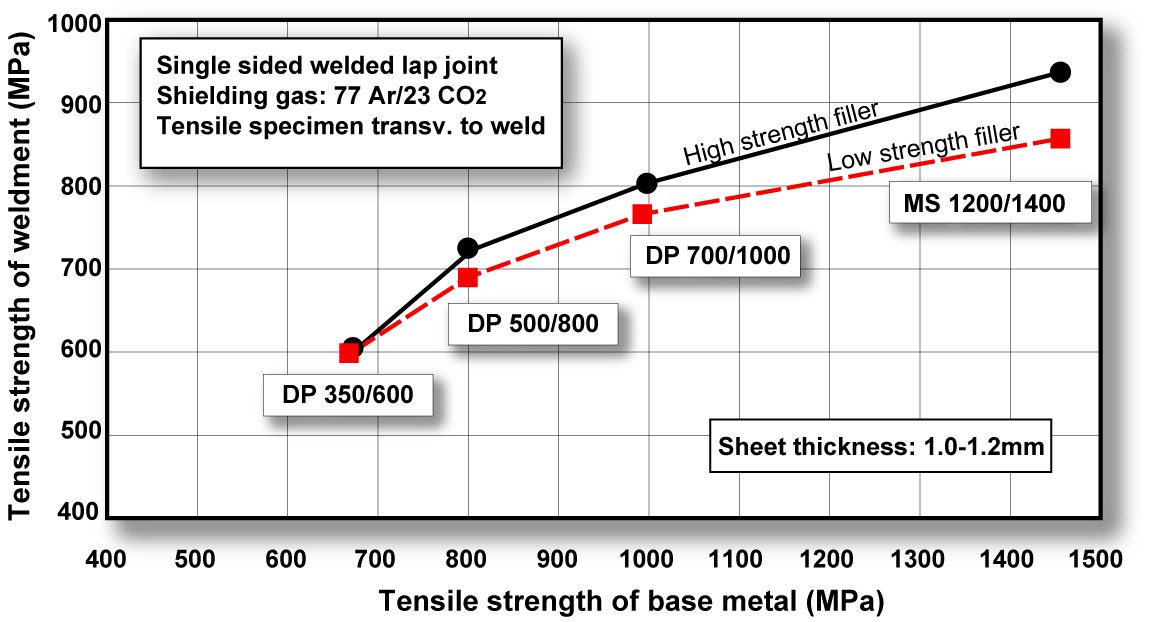

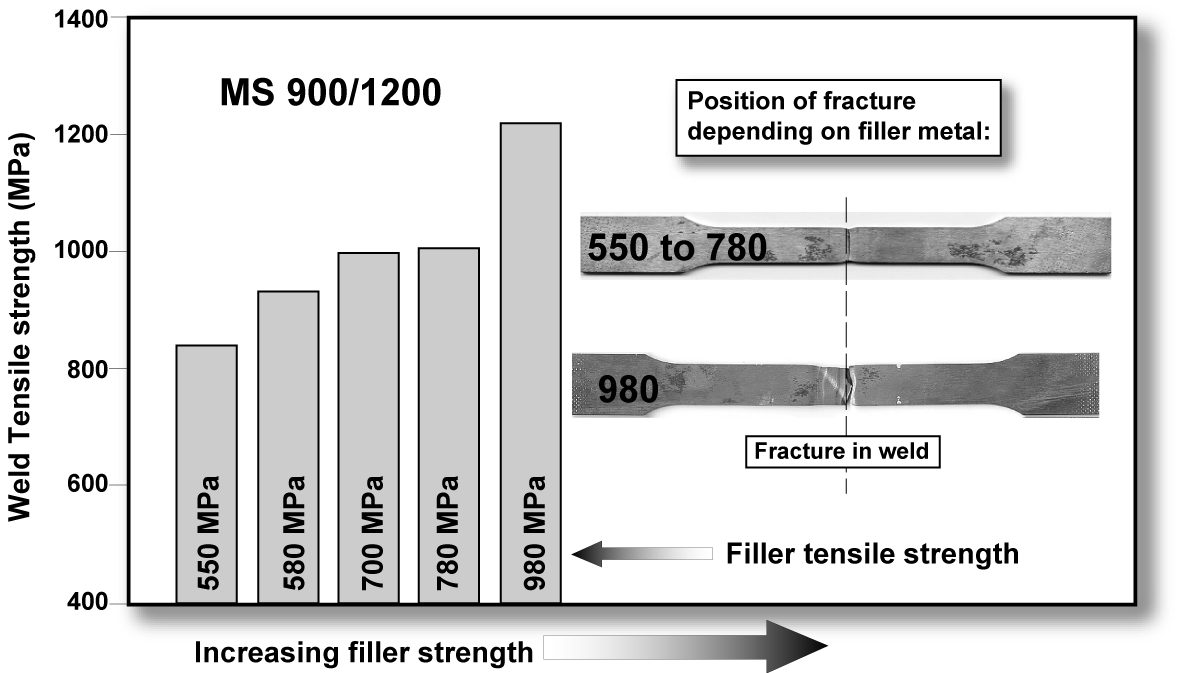

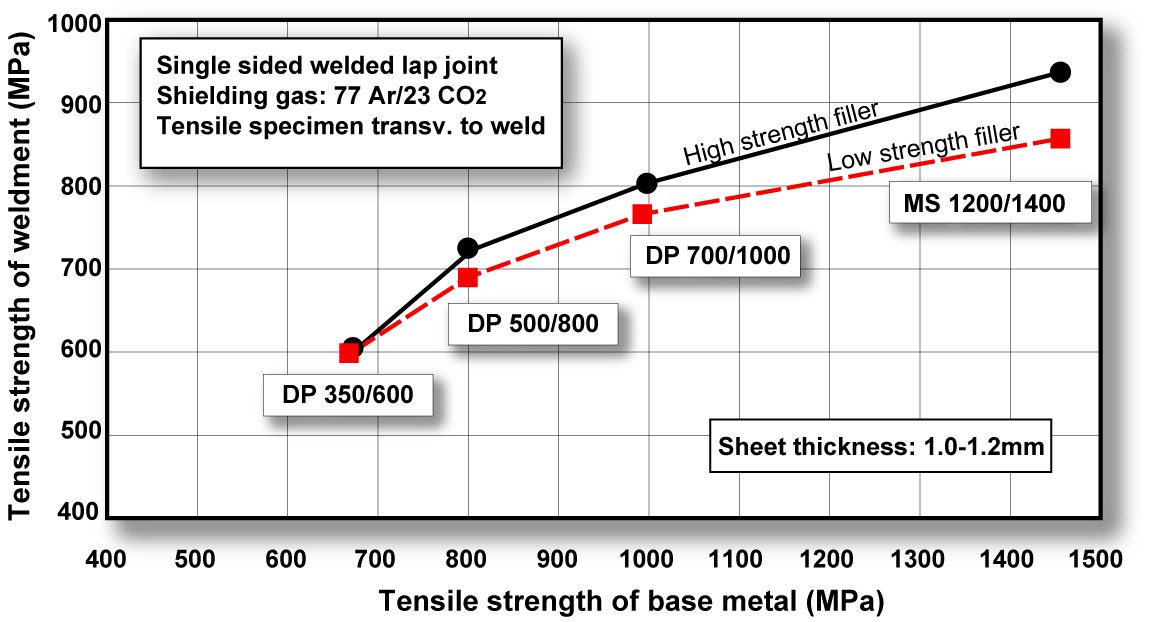

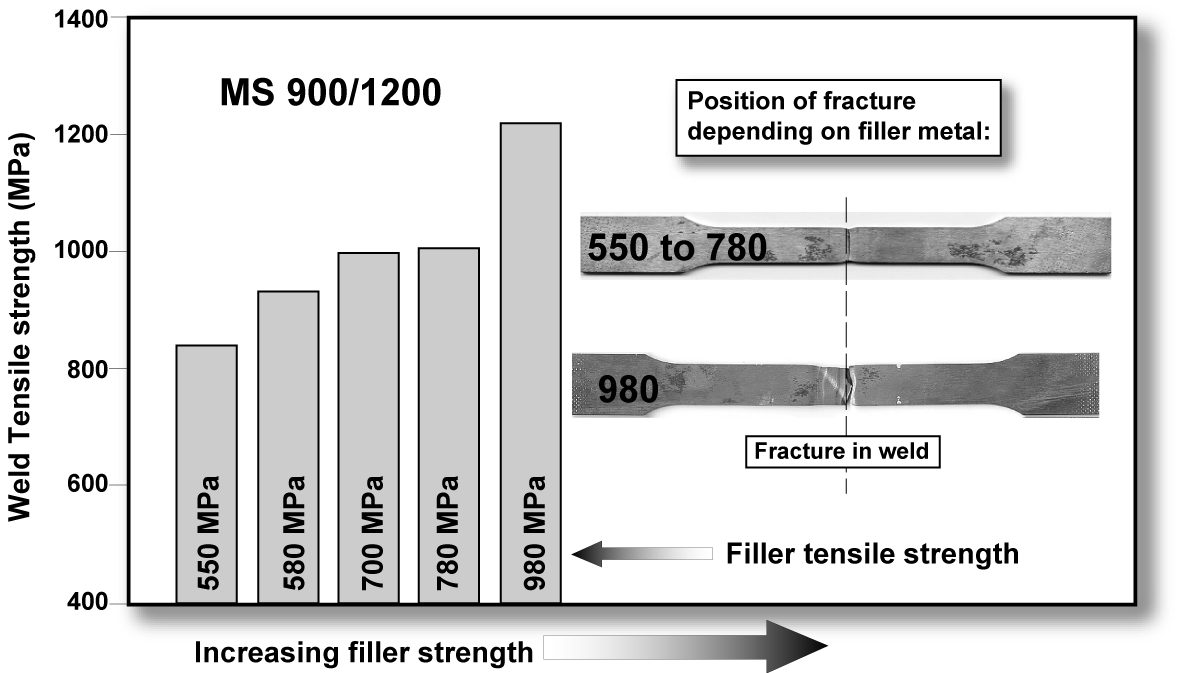

Higher strength filler wires are recommended for welding of AHSS grades with strength levels higher than 800 MPa (Figure 11 for single-sided welded lap joint and Figure 12 for butt joints). It should be noted that higher strength fillers are more expensive and, more importantly, less tolerant to the presence of any weld imperfections. When welding AHSS to lower strength or mild steel, it is recommended that filler wire with 70 ksi (482 MPa) strength be used. Single-sided welded lap joints are normally used in the automotive industry. Due to the asymmetrical loading and the extra bending moment associated with this type of joint, the strength of this lap joint is lower than that of the butt joint.

Figure 11: Influence of filler metal strength in arc welding of DP and mild steels. (Tensile strength is 560 MPa for low strength and 890 MPa for high-strength fillers. Fracture position in HAZ for all cases except DP 700/1000 and MS 1200/1400 combination with low-strength filler where fracture occurred in weld metal. Tensile strength equals peak load divided by cross-sectional area of sample.C-3)

Figure 12: Influence of filler metal strength in GMAW (butt) welding on weld strength for MS steel. (Filler metal tensile strength range is 510-950 MPa.B-1)

Arc welds are normally used in local areas of vehicles where the loads are high. As required with all GMAW of any grade of steel, care should be taken to control heat input and the resulting weld metallurgy. The length of the GMA welds is often quite short. The reduction in strength for some of the AHSS GMA welds, in comparison to BM, can be compensated by increasing the length of the weld.

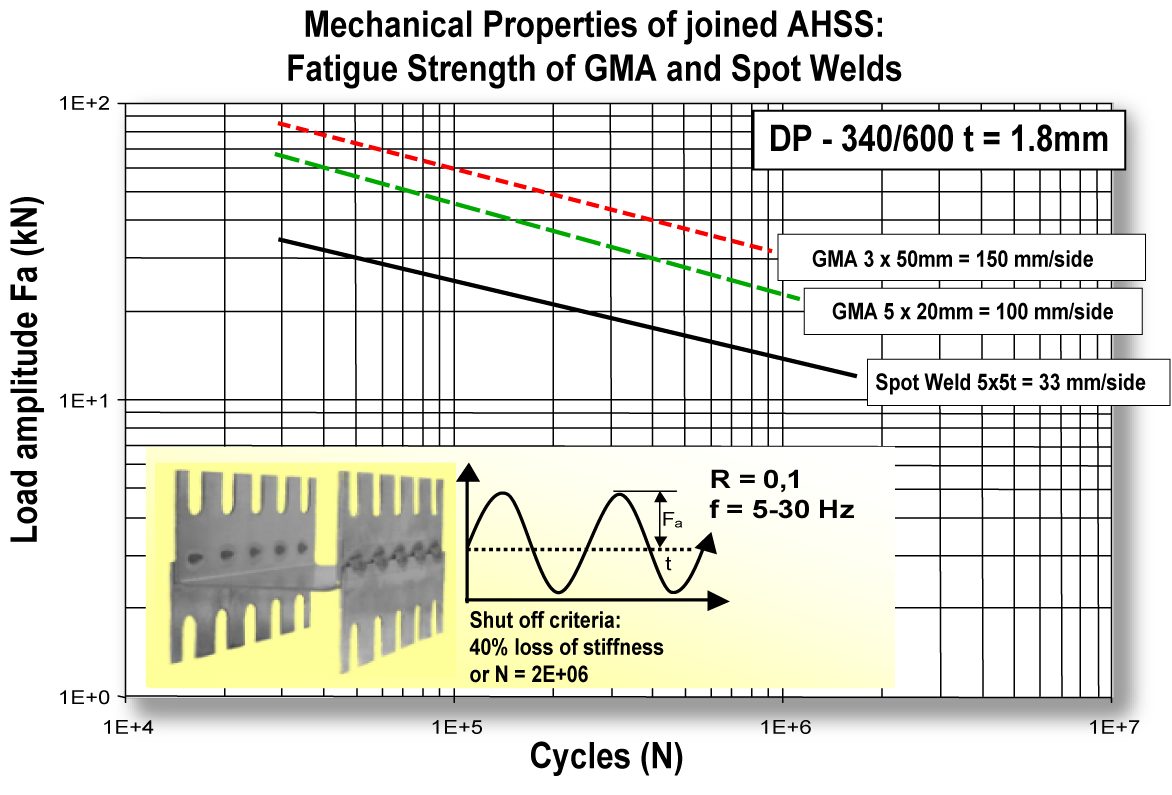

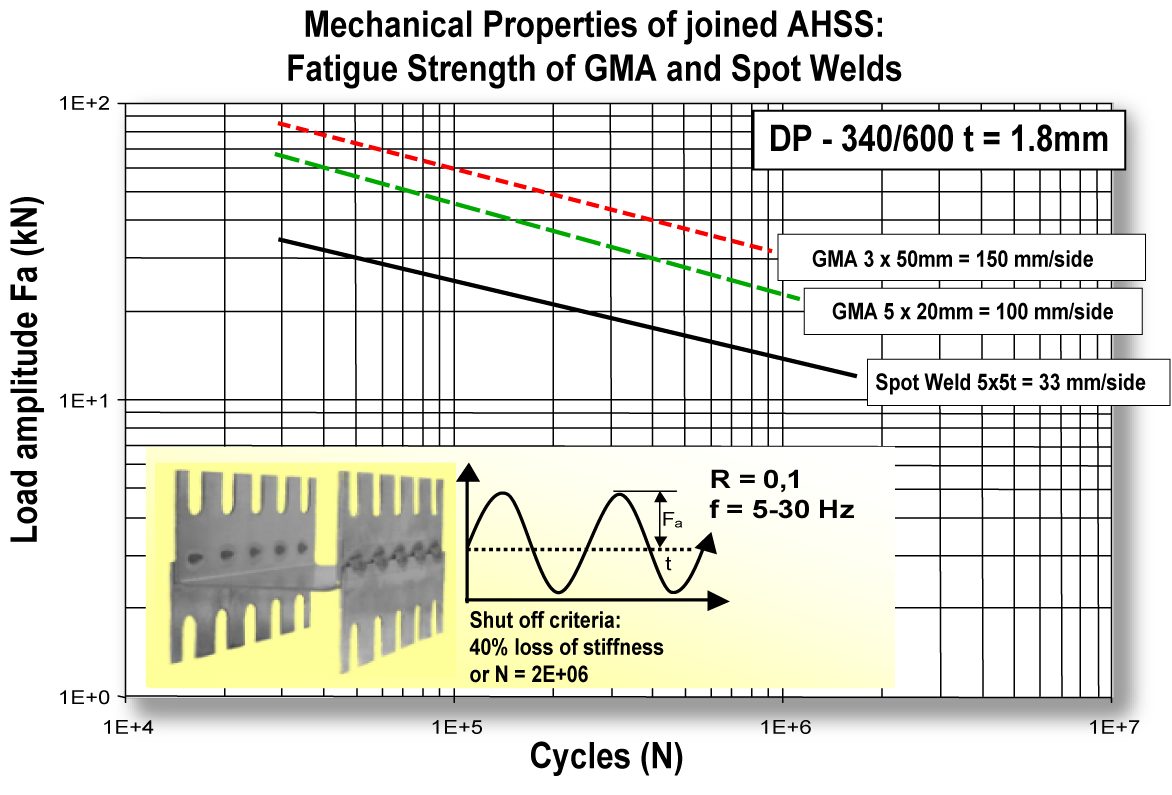

By adjusting the number and length (that is the total joined area) of welds, the fatigue strength of the joint can be improved. The fatigue strength of an arc-welded joint, in general, tends to be better than that of a spot-welded joint (Figure 13).

Figure 13: Fatigue strength of GMA-welded DP 340/600 compared to spot welding.L-2

Back To Top