RSW of 4T Stack Up

This article is the summary of a paper entitled, “Weld Nugget Penetration of a Four-Sheet Resistance Spot Welding Advanced High-Strength Steels”, by K. Namola, et al.N-11

Experimental Weld Nugget Penetration

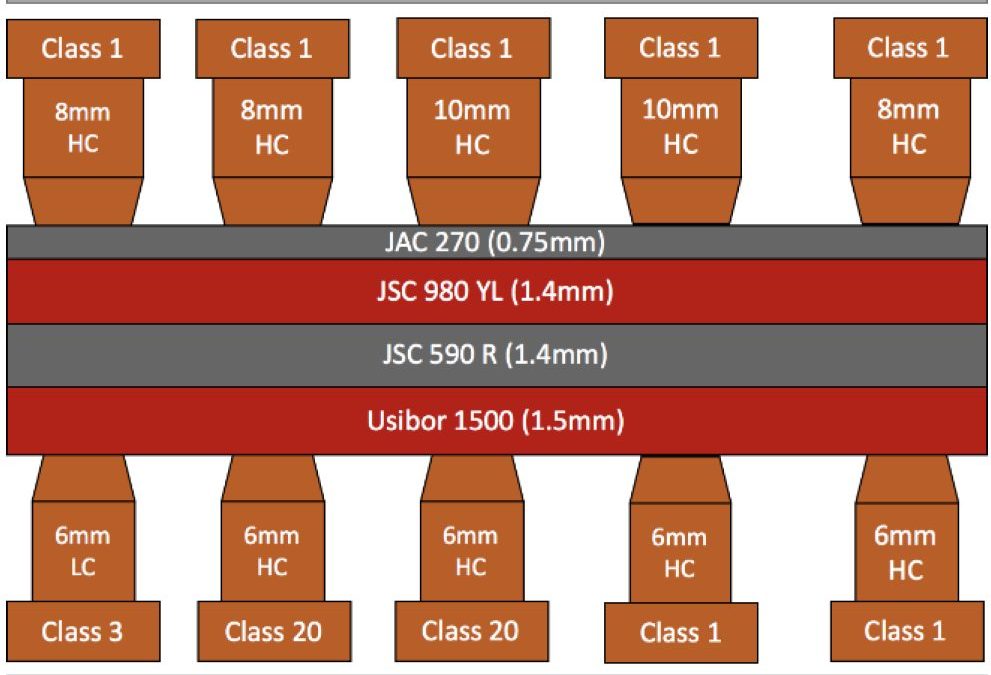

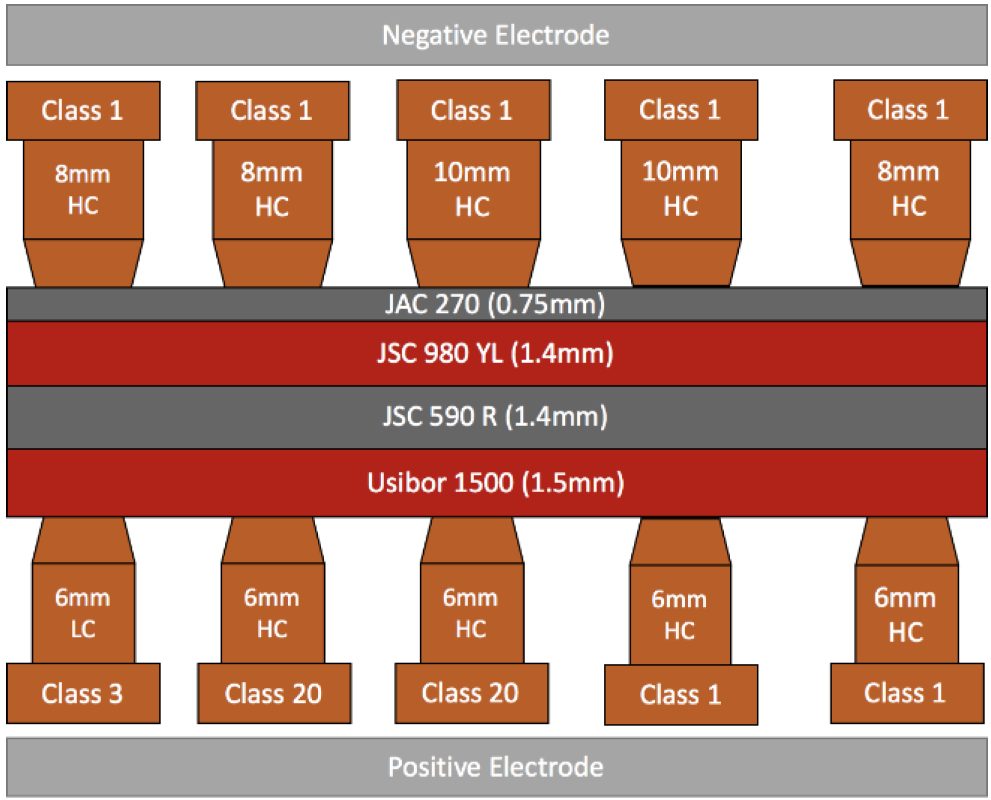

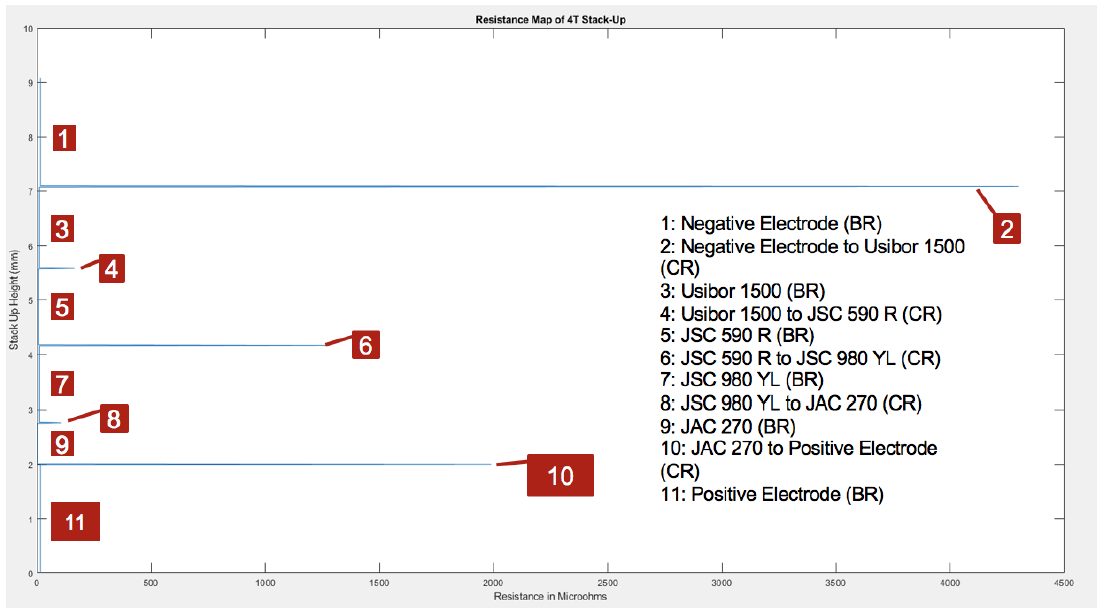

The study analyzes the effect of electrode size and composition on final weld nugget size and penetration. Nugget growth patterns were analyzed and weldability issues characterized. Figure 1 shows the arrangement of the four-layer stack-ups that were tested in this study. Truncated code electrodes used were a 6-mm Class 1, 6-mm Class 3, 6-mm Class 20, 8-mm Class 1, and 10-mm Class 1. Samples were welded in the as-received condition. JAC270 is a cold rolled Mild steel with a galvanneal coating having a minimum tensile strength of 270 MPa. JSC590 and JSC980 are bare cold rolled Dual Phase steels with a minimum tensile strength of 590 MPa and 980 MPa, respectively.

Figure 1: Resistance Welding Stack and Test Electrode Combinations.N-11

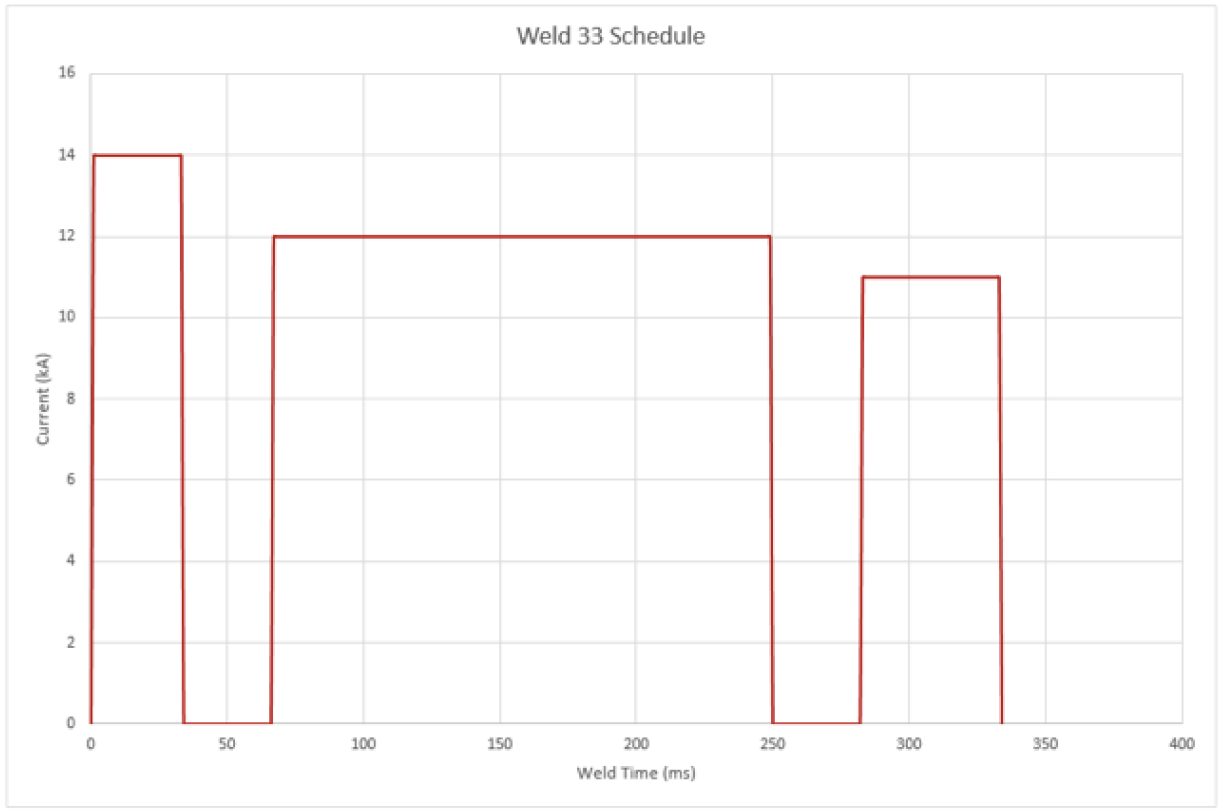

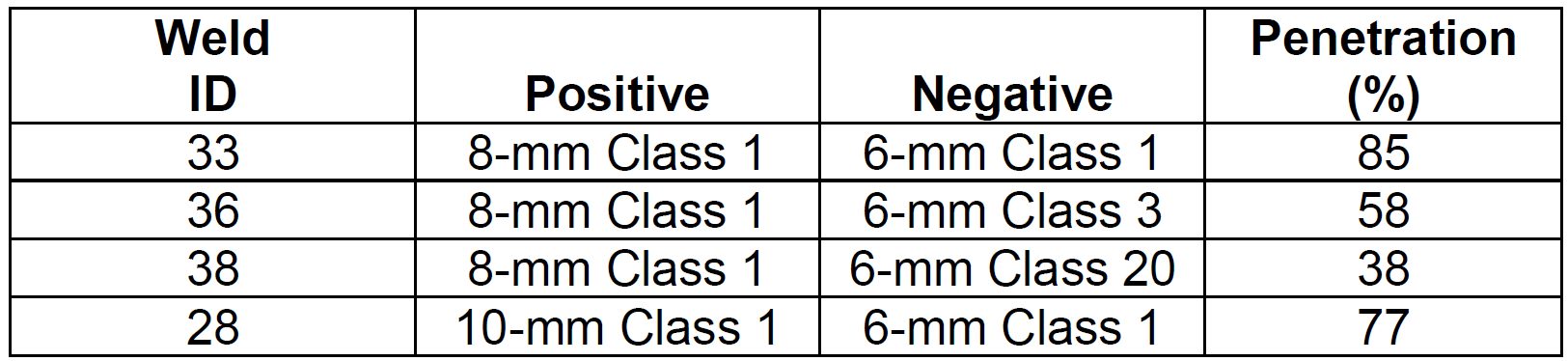

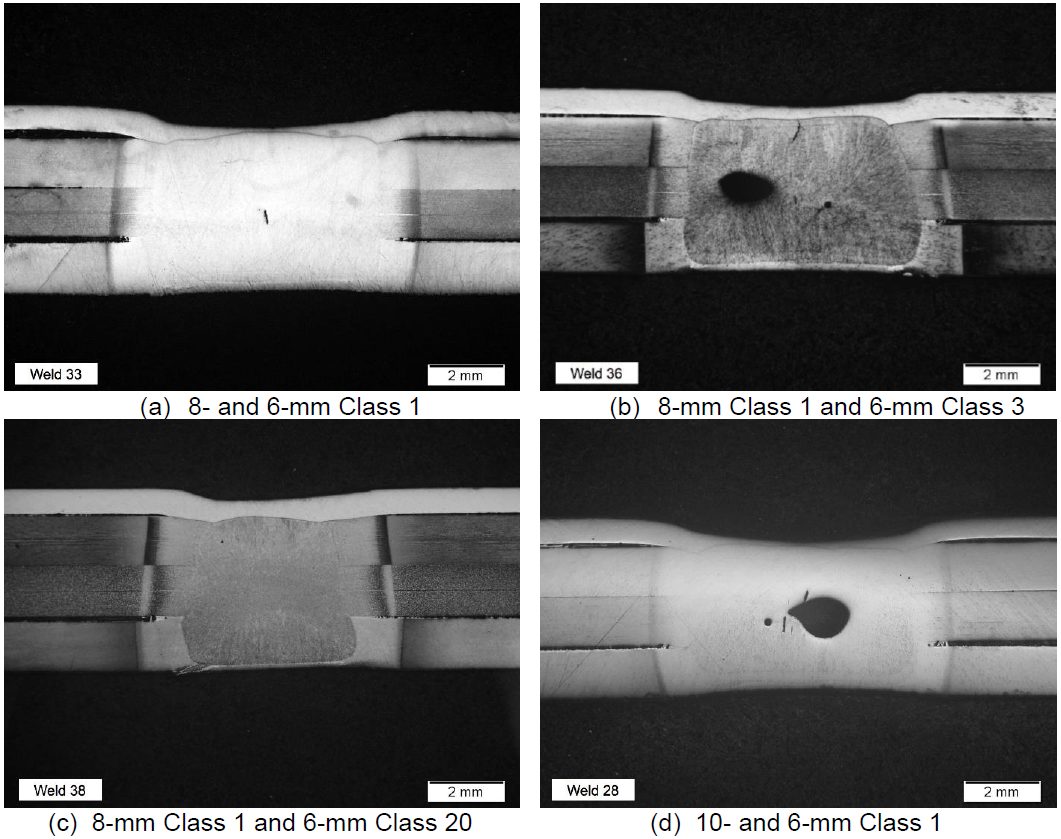

Best results from the iterative trials were obtained using an 8- and 6-mm Class 1 copper electrode with the weld schedule shown in Figure 2. This weld schedule was repeated using the electrode combinations listed in Table 1. Figure 3 shows cross sections of each weld listed in Table 1.

Figure 2: Down-Selected Weld Schedule from Trials.N-11

Table 1: Nugget Penetration Using the Down-Selected Weld Schedule from Trials and Different.N-11

Figure 3: Welds Made Using the Down-Selected Schedule and Different Electrodes.N-11

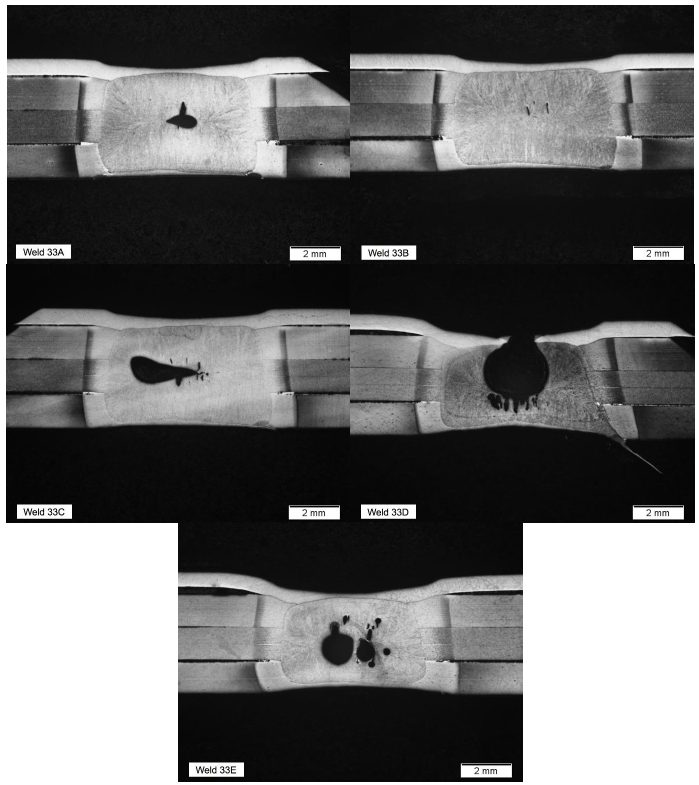

Figure 4 shows cross sections of five welds made starting with new 8- and 6-mm Class 1 electrodes. As can be seen, expulsion gets progressively worse over time but penetration does not. Penetration values into the JAC 270 were determined by metallography and are shown in Table 2.

Figure 4: Welds from Repeatability Study Using the Down-Selected Weld Schedule and 8- and 6-mm Class 1 Electrodes.N-11

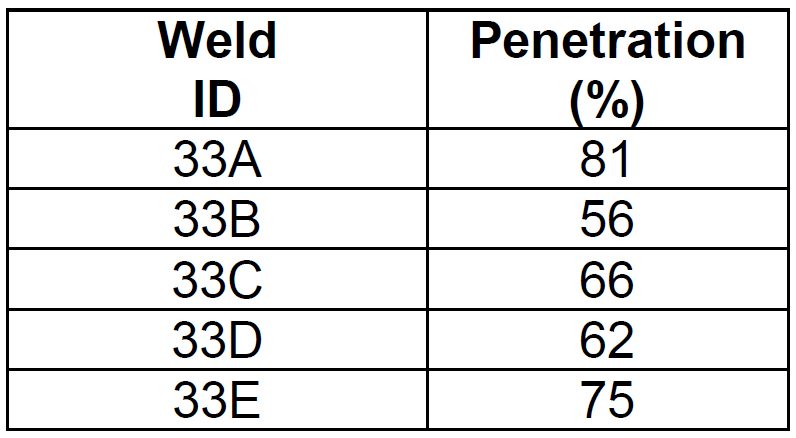

Table 2: Nugget Penetration into the JAC 270 During Repeatability Study.N-11

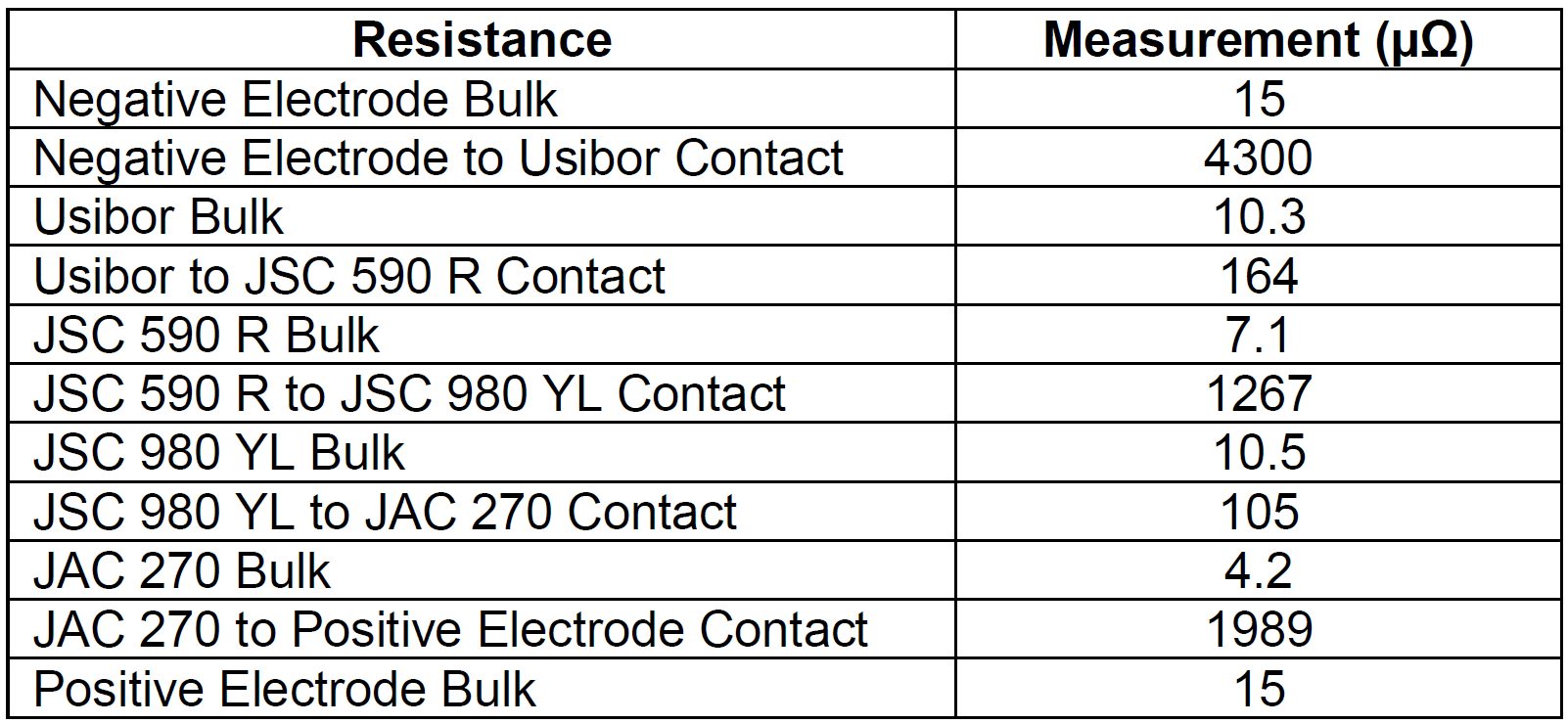

Table 3 lists the resistance measurements at the weld stack interfaces. Figure 5 shows the resistance graph of weld stack up.

Table 3: Resistance Measurements of Weld Materials and Weld Stack Interfaces.N-11

Figure 5: Resistance Graph of Weld Stack-Up.N-11

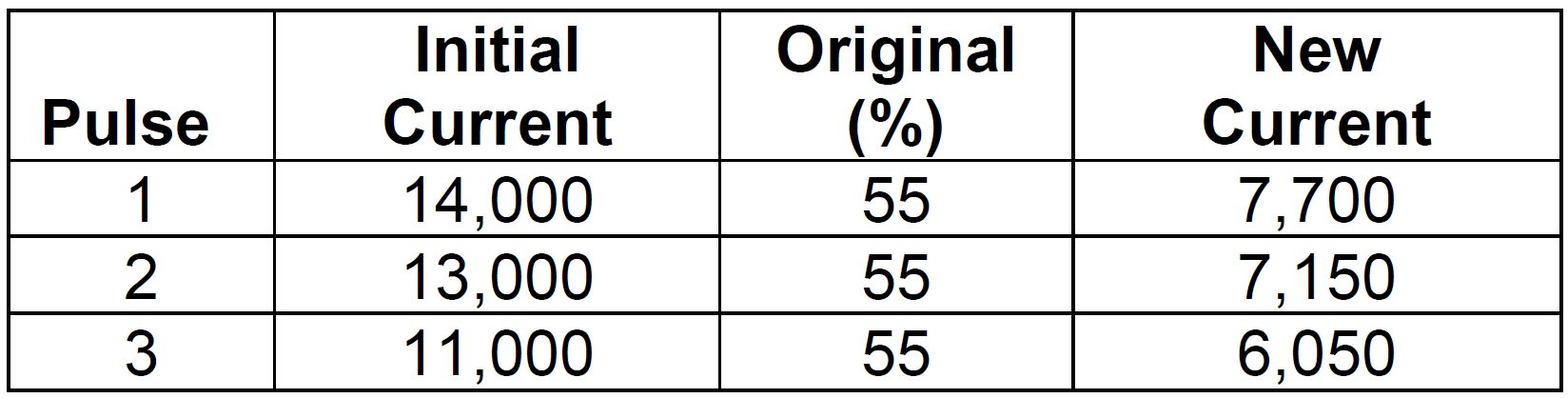

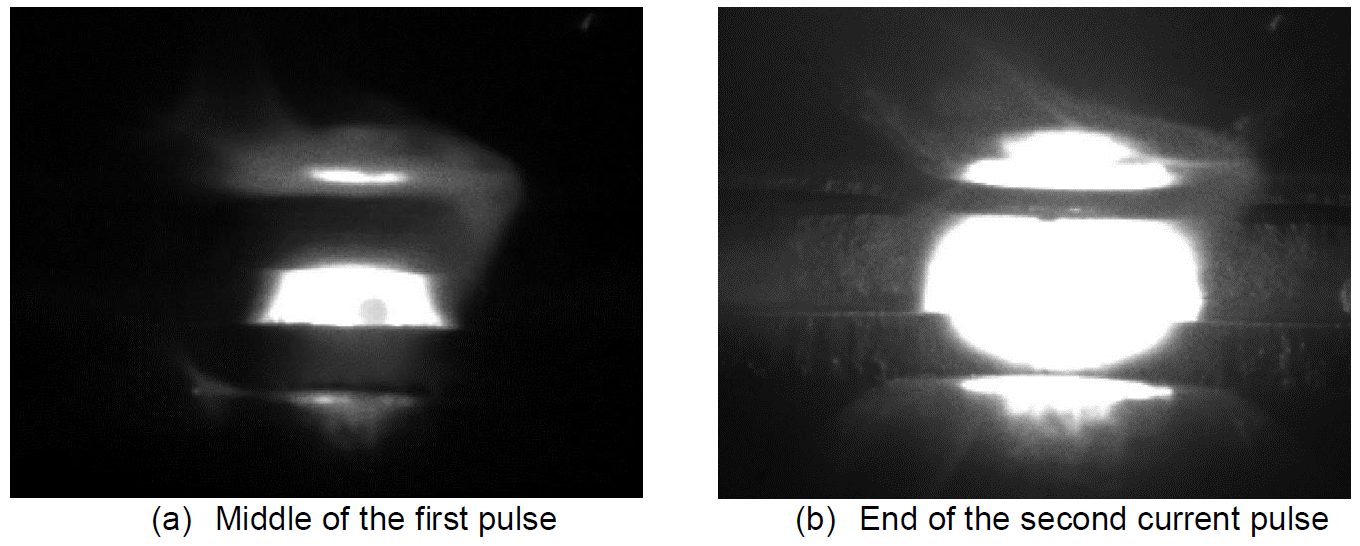

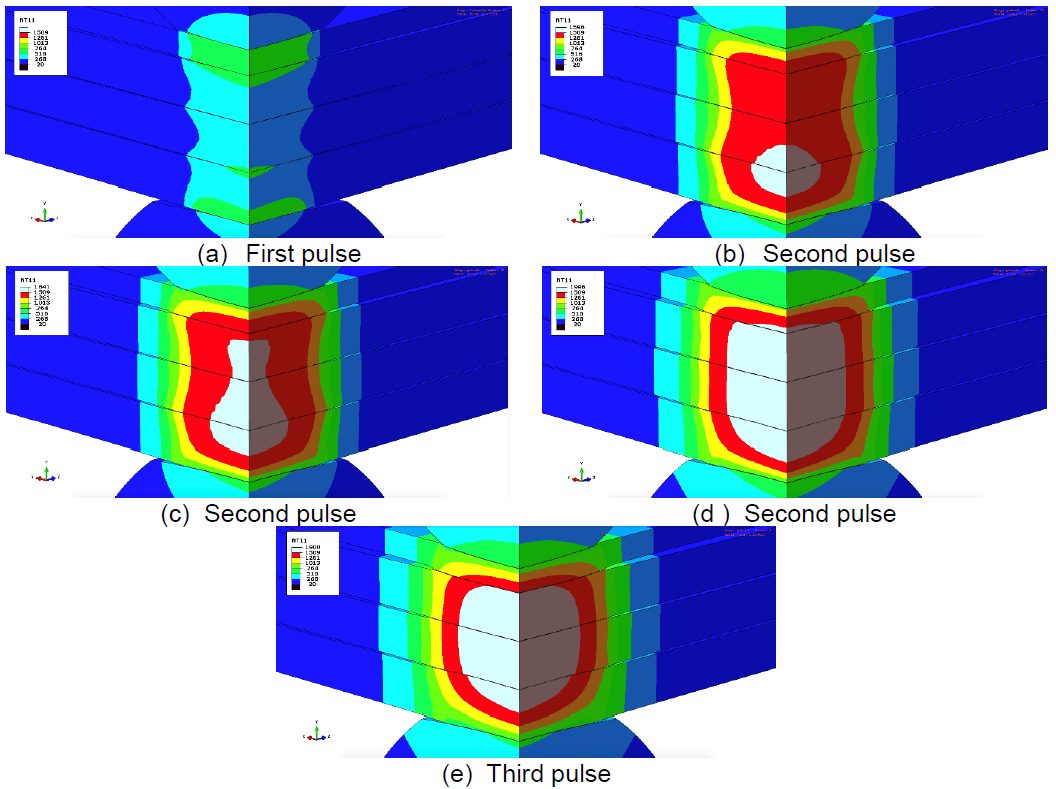

The weld force used was 2.3 kN and the current reduction values are listed in Table 4. Figure 6 and Figure 7 show the still images at each pulse. The heating pattern implies that the JAC270 is forged into the weld nugget.

Table 4: Current Reduction for High-Speed Video Welds.N-11

Figure 6: Still Images from High-Speed Video.N-11

Figure 7: Still Images from Weld Simulation of the Down-Selected Schedule using 8- and 6-mm Class 1 Electrodes.L-58