Coating-related Defect Avoidance

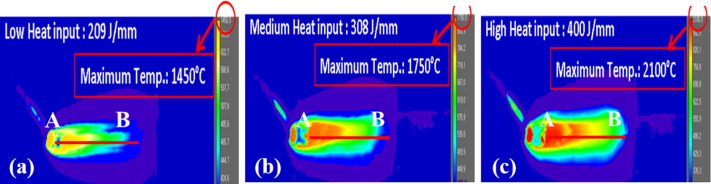

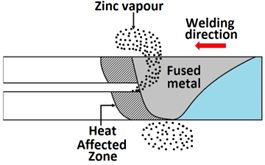

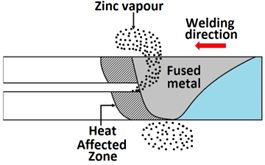

This article focuses on the role of Zinc coatings in causing so-called blowhole defects during gas metal arc welding of automotive body-in-white panels. Blowholes occur when vaporized coating material becomes trapped in the molten weld pool during solidification. This is more prevalent in overlap or T-joint configurations compared to butt joints, where vapors can escape more easily. Random variations can lead to differing pore rates in welded joints, necessitating a statistical approach to evaluation.

Experimental Plan and Methodology

An experimental plan, evaluating the factors contributing to blowhole formation, including heat input, filler wire type, gap distance, and welding conditions was used. Over 1,000 welds were performed to gather sufficient data for statistical analysis. The methodology focused on measuring pore rates and the length of defects through x-ray testing.

Figure 1: Blowholes are formed by vaporized Zinc escaping through the molten zone.

Solutions

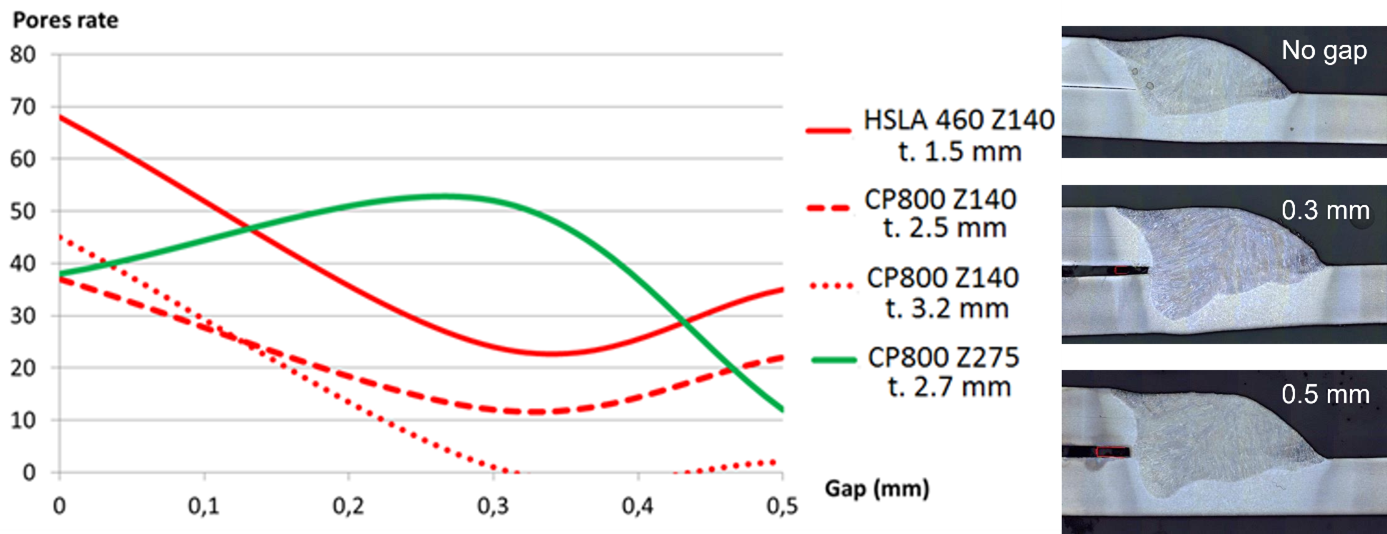

- Introduction of Gaps: A gap greater than 0.3 mm between sheets facilitates vapor extraction during welding, significantly reducing blowhole formation. Controlling the gap between sheets is challenging and costly in automotive assemblies. It may be an adequate solution, when the overlap width cannot be adjusted.

Figure 2: Pore rate in percent for different gap widths and steels (left) and cross-sections with increasing gaps (right). For normal coating level Z140, increasing the gap decreased pore and blowhole formation. Using a steel with significantly increased coating did not show this effect.

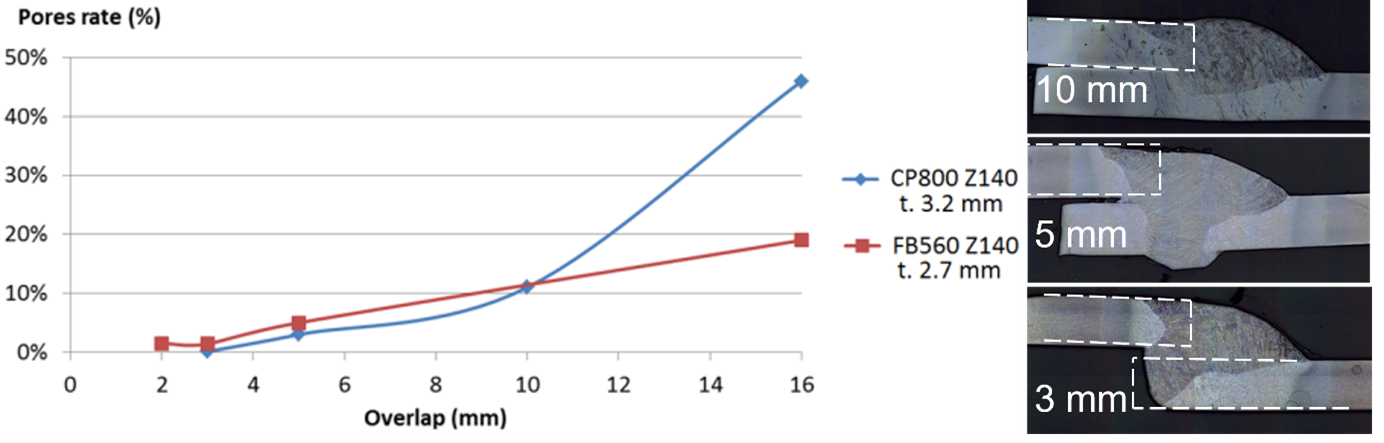

- Reduction of Overlap Width: Decreasing the overlap width not only helps vapors escape more easily but also reduces the overall weight of the assembly, making it the preferable solution

Figure 3: Pore rate in percent for increasing overlaps (left) and cross-sections with increasing overlap (right). Decreasing the overlap decreased pore and blowhole formation.

Effects on Mechanical Properties

Neither the gap nor overlap width significantly affected ultimate tensile strength (UTS) or fatigue performance, if the gap remained below 1 mm. The presence of blowholes did not adversely affect fatigue performance, although they could lead to reduced static strength of the joint if located at critical points within the load path.

Key Messages

- MAG welding of zinc-coated steels can lead to blowholes.

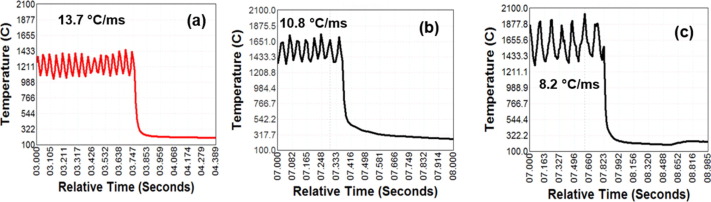

- Utilizing pulsed current may help minimize these defects, but welding parameters have limited effects on blowhole occurrence.

- Introducing a gap or reducing overlap width are effective strategies to mitigate these issues, with no impact on mechanical properties.

Source

J. Haouas, Solutions for improvement of zinc coated steels arc welding, ICWAM conference 2017, Metz