ULSAB/Early Steel Consortia

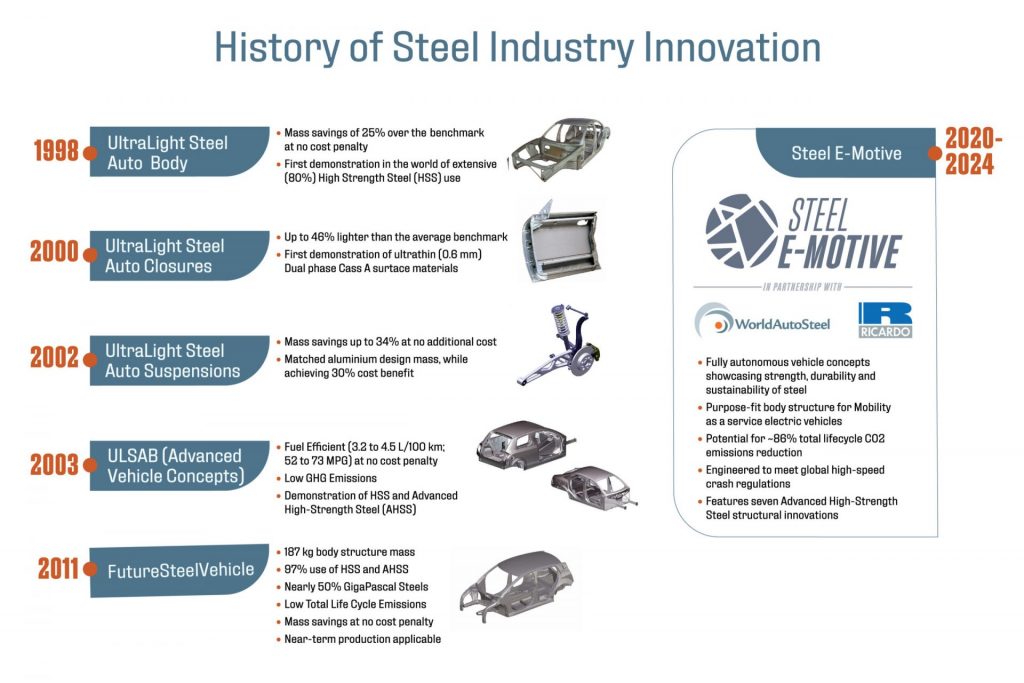

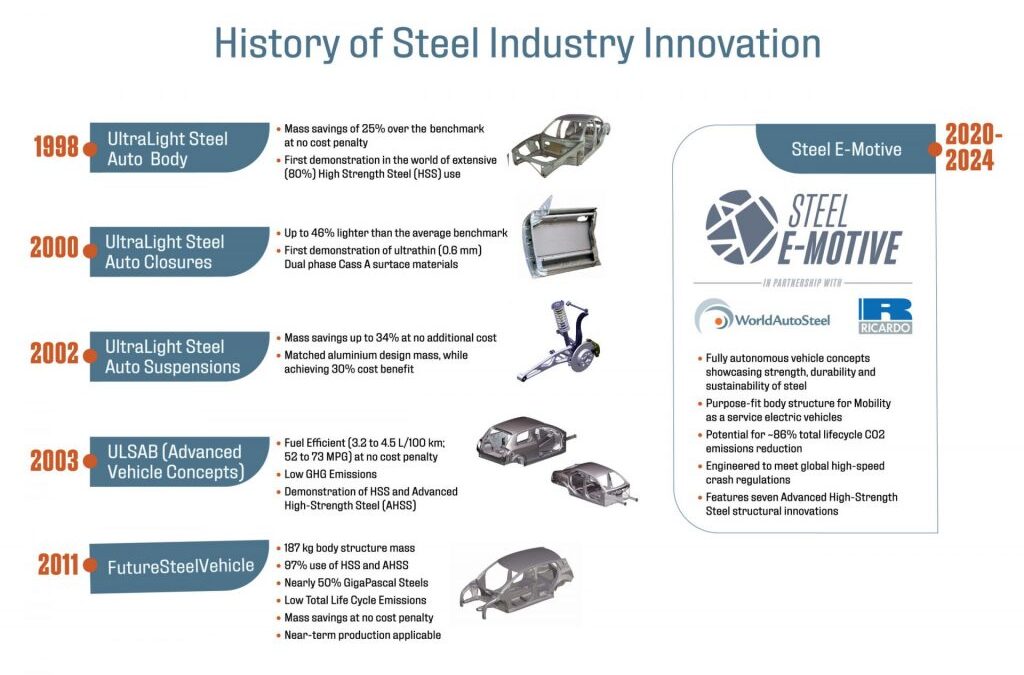

A consortium of 35 global sheet steel producers representing 22 countries began the UltraLight Steel Auto Body (ULSAB) program in 1994 with the goal of designing a lightweight steel auto body structure that would meet existing and proposed safety and performance targets.

The body-in-white (BIW) unveiled in 1998 validated the design concepts of the program, with the demonstration hardware achieving a 25 percent reduction of vehicle body structure weight at no cost penalty compared to conventional steel body structures of that time. ULSAB proved to be lightweight, structurally sound, safe, executable, and affordable.

ULSAB received wide acceptance by the automotive industry, to the point where is spawned three other steel consortia projects covering closures UltraLight Steel Auto Closures (ULSAC), suspensions UltraLight Steel Auto Suspensions (ULSAS) and full vehicle design UltraLight Steel Auto Body – Advanced Vehicle Concepts (ULSAB-AVC). Each one used an increasing percentage of high strength steels and Advanced High-Strength Steels (AHSS), along with advanced fabrication technologies such as tailored blanks, hydroformed tubes and continuous laser welding, each enhancing structural efficiency. At that time, AHSS use was in its infancy, and provided combinations of strength and ductility that were never-before realized, while still allowing for use of existing stamping and assembly fabrication equipment and production methods.

By 2008, the steel company consortium evolved into WorldAutoSteel, which began another program called FutureSteelVehicle (FSV), where steel members accelerated the development and deployment of new AHSS grades, further stretching the envelope for strength and ductility levels. FutureSteelVehicle took automotive steel applications to GigaPascal strength AHSS and added the dimension of designing for reduced life cycle emissions. W-11

FutureSteelVehicle featured clean-sheet steel body structure designs for advanced powertrains, including full battery electric vehicle (BEV), plug-in hybrid and hydrogen fuel cells – and demonstrated that sophisticated steel grades combined with engineering optimisation could reduce mass by more than 35 percent over a benchmark vehicle and reduced total life cycle emissions by nearly 70 percent. This was accomplished while meeting a broad list of global crash and durability requirements and enabled five-star safety ratings while avoiding high-cost penalties for mass reduction.W-11 More information about the FutureSteelVehicle is found here with greater details shown here: FutureSteelVehicle Reports

Steel E-Motive represents fully autonomous electric ride sharing vehicle concepts showcasing the strength and durability of steel with a critical focus on sustainability for reaching net zero emissions targets. The results are sustainable comfortable, safe and affordable body structures that support automakers in the continued development of Mobility as a Service (MaaS) ride sharing models. Some highlights of the Steel E-Motive program can be found here, with the entire program documented at https://SteelEMotive.world.

Another consortium, the Auto/Steel Partnership (A/SP) engages in research and demonstrates the value of AHSS through several programs. One such project, the Lightweight Front End Structure, used a holistic approach to meet goals of more than 20 percent weight reduction while maintaining crash worthiness.J-26 A-79 Manufacturability was examined and emphasized throughout this project. Another key program, the Future Generation Passenger Compartment project, examined the effect of mass compounding.A-80 U-15

Over the years since ULSAB, the successes of AHSS have motivated steel companies to continue research on both new types and grades of AHSS and to then bring these new steels to production. Essential for the growing use of AHSS has been the simultaneous development of new processes and equipment to produce and form the material. Some of these processes are described throughout these guidelines.