1stGen AHSS, AHSS, Steel Grades

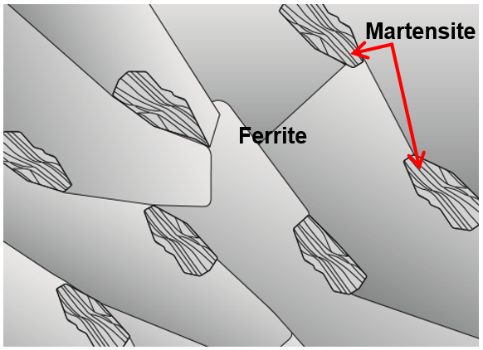

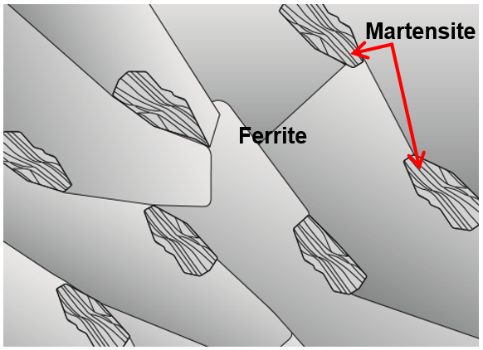

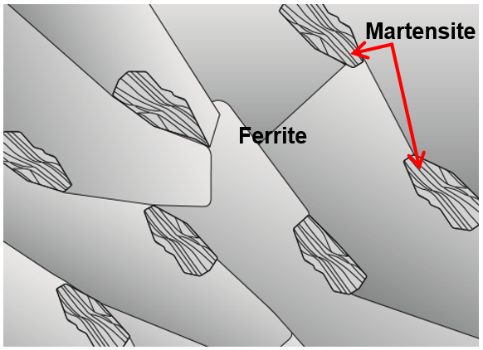

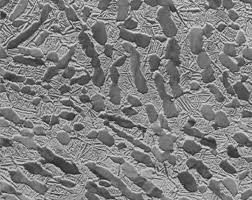

Dual Phase (DP) steels have a microstructure consisting of a ferritic matrix with martensitic islands as a hard second phase, shown schematically in Figure 1. The soft ferrite phase is generally continuous, giving these steels excellent ductility. When these steels deform, strain is concentrated in the lower-strength ferrite phase surrounding the islands of martensite, creating the unique high initial work-hardening rate (n-value) exhibited by these steels. Figure 2 is a micrograph showing the ferrite and martensite constituents.

Figure 1: Schematic of a Dual Phase steel microstructure showing islands of martensite in a matrix of ferrite.

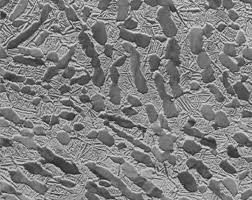

Figure 2: Micrograph of Dual Phase Steel

Hot rolled DP steels do not have the benefit of an annealing cycle, so the dual phase microstructure must be achieved by controlled cooling from the austenite phase after exiting the hot strip mill finishing stands and before coiling. This typically requires a more highly alloyed chemistry than cold rolled DP steels require. Higher alloying is generally associated with a change in welding practices.

In one possible approach, after exiting the last finishing stand of the hot rolling mill, controlled cooling facilitates the nucleation of ferrite. Then a more rapid cooling fast enough to avoid bainite formation is needed to reach the Ms (martensite start) temperature and begin nucleating martensite from the austenite that had not transformed to ferrite.

Continuously annealed cold-rolled and hot-dip coated Dual Phase steels are produced by controlled cooling from the two-phase ferrite plus austenite (α + γ) region to transform some austenite to ferrite before a rapid cooling transforms the remaining austenite to martensite. Due to the production process, small amounts of other phases (bainite and retained austenite) may be present.

Higher strength dual phase steels are typically achieved by increasing the martensite volume fraction. Depending on the composition and process route, steels requiring enhanced capability to resist cracking on a stretched edge (as typically measured by hole expansion capacity) can have a microstructure containing significant quantities of bainite.

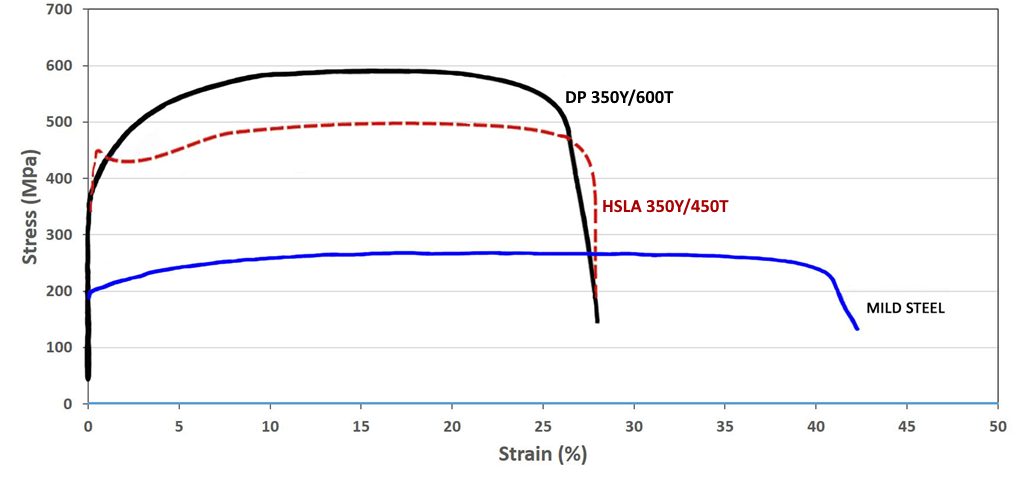

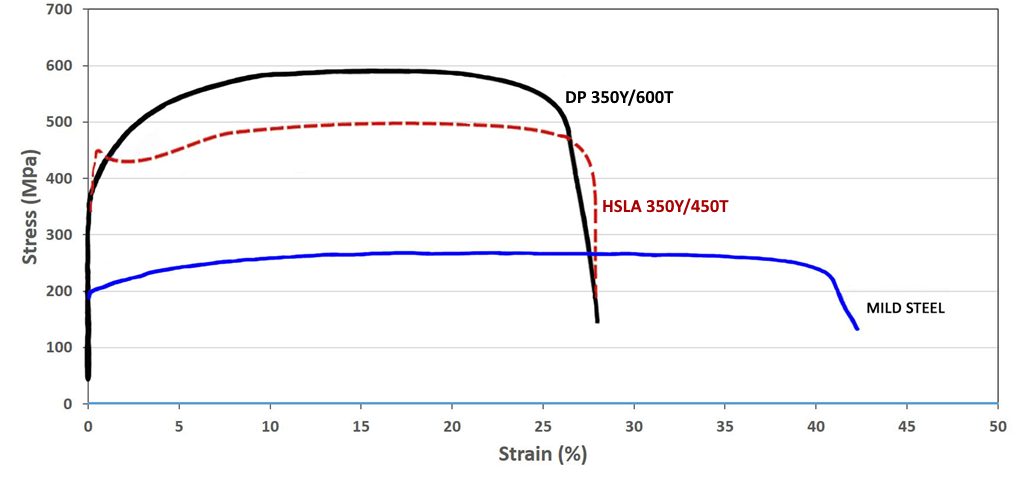

The work hardening rate plus excellent elongation creates DP steels with much higher ultimate tensile strengths than conventional steels of similar yield strength. Figure 3 compares the engineering stress-strain curve for HSLA steel to a DP steel curve of similar yield strength. The DP steel exhibits higher initial work hardening rate, higher ultimate tensile strength, and lower YS/TS ratio than the HSLA with comparable yield strength. Additional engineering and true stress-strain curves for DP steel grades are presented in Figures 4 and 5.

Figure 3: A comparison of stress strain curves for mild steel, HSLA 350/450, and DP 350/600K-1

Figure 4: Engineering stress-strain curves for a series of DP steel grades.S-5, V-1 Sheet thicknesses: DP 250/450 and DP 500/800 = 1.0mm. All other steels were 1.8-2.0mm.

Figure 5: True stress-strain curves for a series of DP steel grades.S-5, V-1 Sheet thicknesses: DP 250/450 and DP 500/800 = 1.0mm. All other steels were 1.8-2.0mm.

The volume fraction, morphology, and distribution of the martensite in the ferrite matrix is responsible for the mechanical properties of dual phase (DP) steels. The intercritical annealing temperature, cooling rate, and alloy content affect the martensite volume fraction in the finished product.

Martensite can have different appearances (morphologies) in the microstructure including needle-like, granular, and equiaxed, and these impact the strength and ductility of DP steels. The most favorable balance of strength and ductility usually is associated with a uniform distribution of equiaxed martensite islands.

These properties influence the hole expansion ratio, which measures the expandability of a sheared edge. The amount of carbon in martensite controls martensite hardness relative to the ferrite, and a greater hardness difference between martensite and ferrite is associated with decreased HER values.

The number of martensite colonies per unit area has a positive correlation with sheared edge stretchability, indicating that there is a greater dispersion of these islands of this high-hardness phase. A more homogeneous microstructure is known to have better HER and sheared-edge formability properties.T-57.

Although dual phase steels are more formable than HSLA steels at the same tensile strength, there is a greater risk of cut edge fractures forming and propagating during stretch flanging. This is due to the hardness difference between the ferrite and martensite phases.

In these steels, micro-voids form at the interface between the soft phase and hard phase at the sheared edge (Figure 6), and can fracture during flanging under tension. Reducing the hardness difference of the microstructural components is one approach to improve edge fracture resistance, which is one of the merits of using complex phase steels.

Figure 6: Microstructure at the punched edge of a DP steel.M-75

DP and other AHSS also have a bake hardening effect that is an important benefit compared to conventional higher strength steels. The extent of the bake hardening effect in AHSS depends on an adequate amount of forming strain for the specific chemistry and thermal history of the steel.

In DP steels, carbon enables the formation of martensite at practical cooling rates by increasing the hardenability of the steel. Manganese, chromium, molybdenum, vanadium, and nickel, added individually or in combination, also help increase hardenability. Carbon also strengthens the martensite as a ferrite solute strengthener, as do silicon and phosphorus. These additions are carefully balanced, not only to produce unique mechanical properties, but also to maintain the generally good resistance spot welding capability. However, when welding the higher strength grades (DP 700/1000 and above) to themselves, the spot weldability may require adjustments to the welding practice.

Dual Phase Steel for Exposed Panels

In recent decades, bake hardenable steels have been a common choice for outer surface panels. Many of these applications center around grades with yield strength of approximately 200 MPa and tensile strength below approximately 400 MPa. Work hardening (strengthening occurring from forming) combined with bake hardening (strengthening from the paint curing cycle during automotive production) usually adds around 70 to 100 MPa to the yield strength, enhancing the dent resistance of these panels.

To further support the lightweighting efforts of the automobile industry, steelmakers have developed dual phase steels with appropriate surface characteristics for exposed panel applications. The benefits of deploying dual phase steels in these applications include a higher yield strength from the steel mill (300 MPa minimum yield strength) and a greater strengthening increase from bake hardening (typically more than 100 MPa) in addition to the work hardening from forming. The strengthening increase allows the automaker to downgauge the sheet thickness to as low as 0.55 mm and maintain adequate dent resistance. More information on the bake hardenability of exposed quality dual phase steels can be found here.

The primary grade in this category can be described as HC300/500DPD+Z, where HC indicates that it is high strength cold rolled steel, 300/500 represents the minimum yield and tensile strength in MPa, DPD is “dual phase deep drawing,” and Z indicates that it is galvanized.

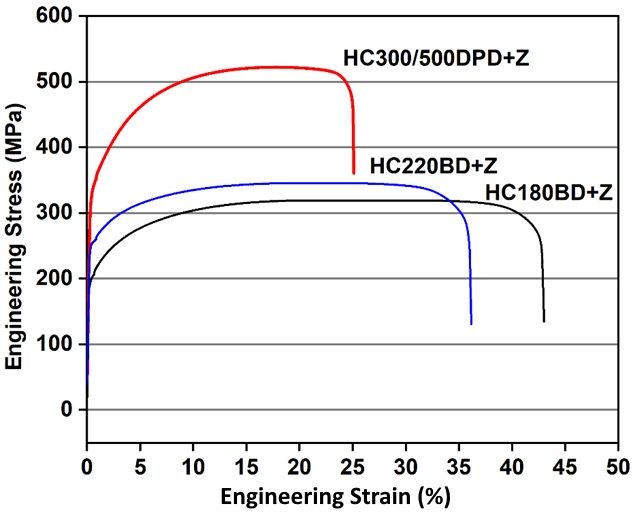

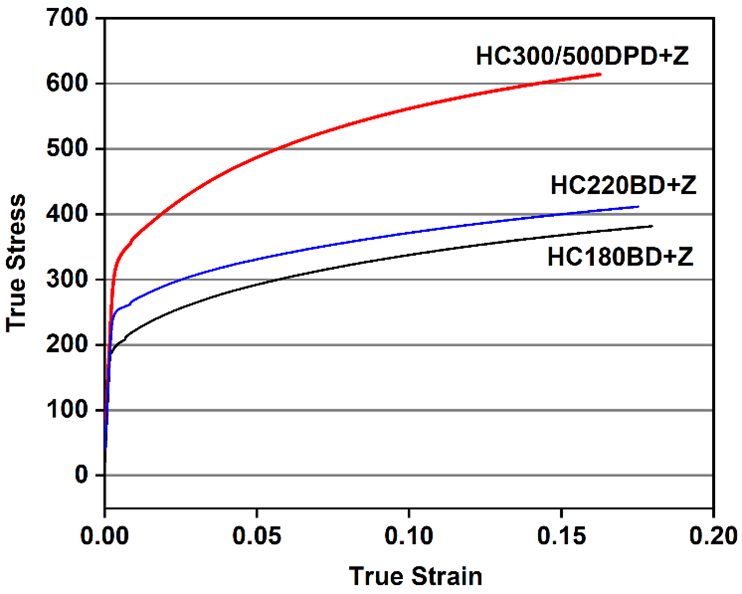

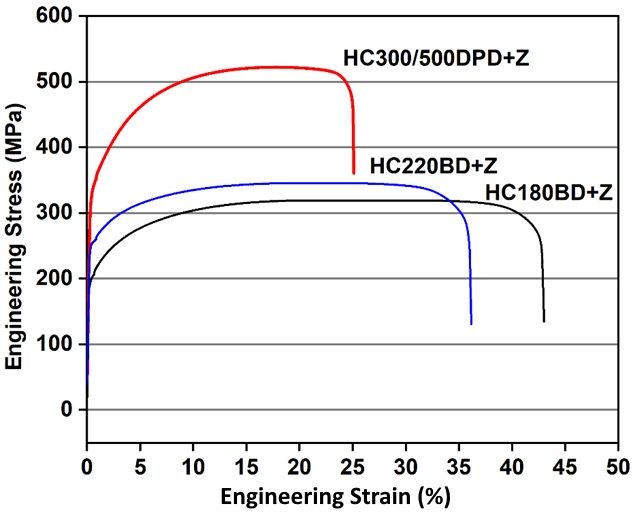

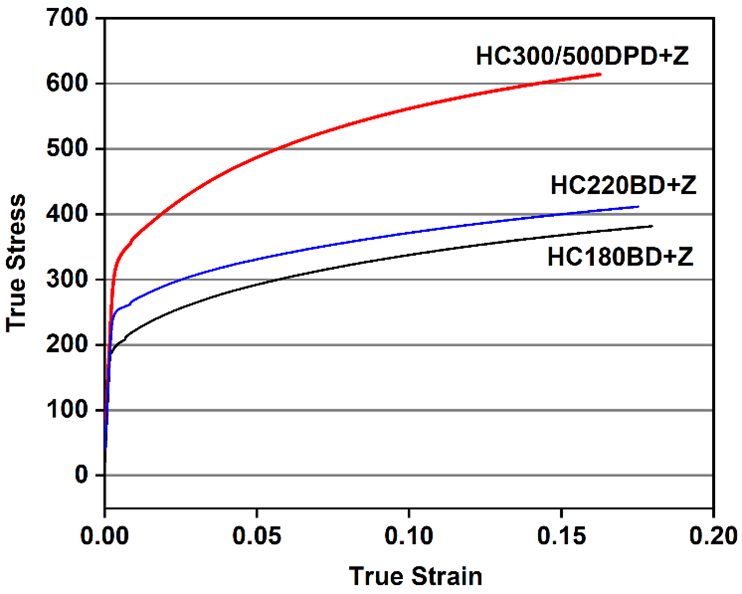

The stress-strain curves of HC300/500DPD+Z are compared with those of common traditional bake hardening grades used for automotive outer skin panels in Figures 7 and 8. The comparison of engineering stress-strain curves are shown in Figure 7, with Figure 8 comparing the true stress-strain curves.

The dual phase steel exhibits a higher tensile strength and greater work hardening (n-value) – especially in the 4% to 6% range that coincides with the strain range associated with stamping automotive outer panels.

Figure 7: Engineering stress-strain curves for 0.6 mm HC300Y/500T-DPD+Z (galvanized 500 DP in red), 0.75 mm HC220BD+Z (galvanized 220 BH in blue), and 0.65 mm HC180BD+Z (galvanized 180 BH in black).

Figure 8: True stress-strain curves for 0.6 mm HC300Y/500T-DPD+Z (galvanized 500 DP in red), 0.75 mm HC220BD+Z (galvanized 220 BH in blue), and 0.65 mm HC180BD+Z (galvanized 180 BH in black).

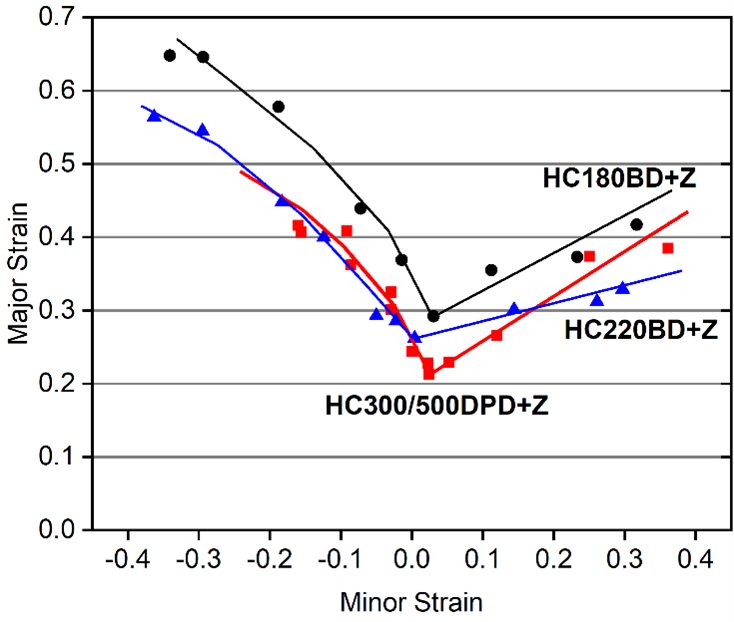

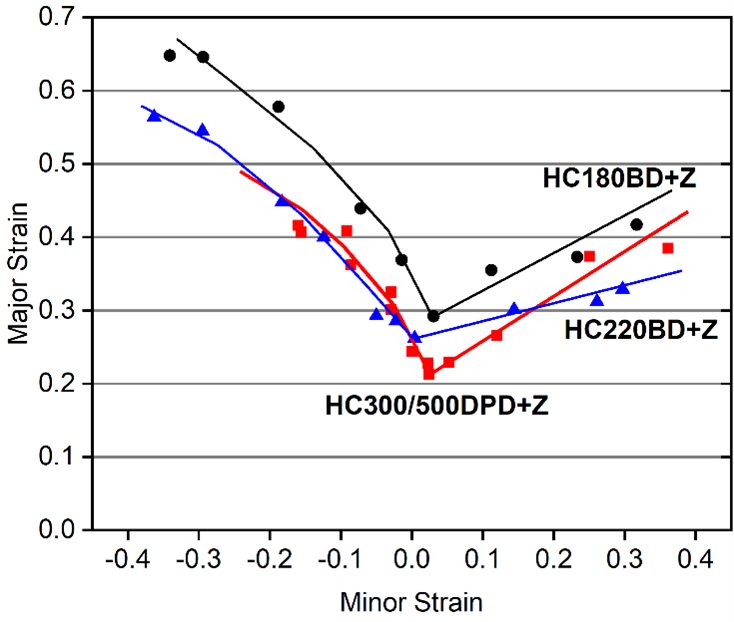

Figure 9 compares the forming limit curve for HC300/500DPD+Z steel to those of the typical bake hardenable grades. The dual phase grade has comparable to slightly less necking resistance than HC220BD+Z, a bake hardenable steel with 220 MPa minimum tensile strength. The necking resistance of HC180BD+Z is greater than both other grades.

Figure 9: Forming limit curves for 0.6 mm HC300Y/500T-DPD+Z (galvanized 500 DP in red), 0.75 mm HC220BD+Z (galvanized 220 BH in blue), and 0.65 mm HC180BD+Z (galvanized 180 BH in black).

While the thickness reduction offered by HC300/500DPD+Z benefits lightweighting, there is also an associated loss of stiffness. This reduced stiffness typically limits how thin automakers will specify for surface panels, rather than steel mill capabilities.

However, the lower stiffness, higher yield strength, and lower formability negatively influence dimensional accuracy and may contribute to welding challenges. Many of these challenges can be addressed virtually using metal forming simulation.

Examples of current production grades of DP steels and typical automotive applications include:

| DP 300/500 |

Roof outer, door outer, body side outer, package tray, floor panel |

| DP 350/600 |

Floor panel, hood outer, body side outer, cowl, fender, floor reinforcements |

| DP 500/800 |

Body side inner, quarter panel inner, rear rails, rear shock reinforcements |

| DP 600/980 |

Safety cage components (B-pillar, floor panel tunnel, engine cradle, front sub-frame package tray, shotgun, seat) |

| DP 700/1000 |

Roof rails |

| DP 800/1180 |

B-Pillar upper |

Some of the specifications describing uncoated cold rolled 1st Generation dual phase (DP) steel are included below, with the grades typically listed in order of increasing minimum tensile strength and ductility. Different specifications may exist which describe hot or cold rolled, uncoated or coated, or steels of different strengths. Many automakers have proprietary specifications which encompass their requirements.

- ASTM A1088, with the terms Dual phase (DP) steel Grades 440T/250Y, 490T/290Y, 590T/340Y, 780T/420Y, and 980T/550YA-22

- EN 10338, with the terms HCT450X, HCT490X, HCT590X, HCT780X, HCT980X, HCT980XG, and HCT1180XD-6

- JIS G3135, with the terms SPFC490Y, SPFC540Y, SPFC590Y, SPFC780Y and SPFC980YJ-3

- JFS A2001, with the terms JSC590Y, JSC780Y, JSC980Y, JSC980YL, JSC980YH, JSC1180Y, JSC1180YL, and JSC1180YHJ-23

- VDA 239-100, with the terms CR290Y490T-DP, CR330Y590T-DP, CR440Y780T-DP, CR590Y980T-DP, and CR700Y980T-DPV-3

- SAE J2745, with terms Dual Phase (DP) 440T/250Y, 490T/290Y, 590T/340Y, 6907/550Y, 780T/420Y, and 980T/550YS-18