- B-Pillar (Center Pillar)

- A-Pillar (Front Pillar)

- Exposed Quality Dual Phase Steel

- Align Alloy Selection to the Needs of the Part

Automotive engineers have substantially more steel grades to select from in their quest to balance properties, performance, manufacturability, sustainability, and cost.

Conventional dual phase steels, with a microstructure of simply ferrite and martensite, have excellent formability in the drawing and stretching deformation modes. However, the characteristics of this phase combination that work very well in these deformation modes lead to challenges in bending and edge-stretch deformation.

Complex phase steels have superior performance in bending and edge-stretch deformation, but are not as good as comparable-strength dual phase steel.

3rd Generation Advanced High Strength Steels are a family of grades that can combine the best features of other steels while minimizing some of their associated constraints.

Below are examples of how steel grades were applied to various parts in order to solve specific challenges.

B-Pillar (Center Pillar)

B-Pillars are a particularly challenging part for cold stamping applications. The upper section must be of sufficiently high strength to prevent cabin intrusion during a side impact, while the lower section needs to maintain at least moderate ductility to absorb crash energy. Stiffness improves with deeper draw depth and more shape, yet the necessary formability to achieve these are typically limited by the high strength requirements. Furthermore, the door opening regions require flanges to facilitate joining of outer and inner components. Production manufacturing constraints dictate that the blank edges are usually formed by mechanical shearing rather than laser cutting, and forming the targeted part shape puts these cut edges in tension – exposing the risk for edge cracks of these higher strength steels. The combination of these challenges contributed to many OEMs choosing to form B-Pillars and entire door rings using hot stamping of press hardening steels.

Development of new types of advanced high strength steels bring the cold stamping option back into focus.

B-Pillar Upper

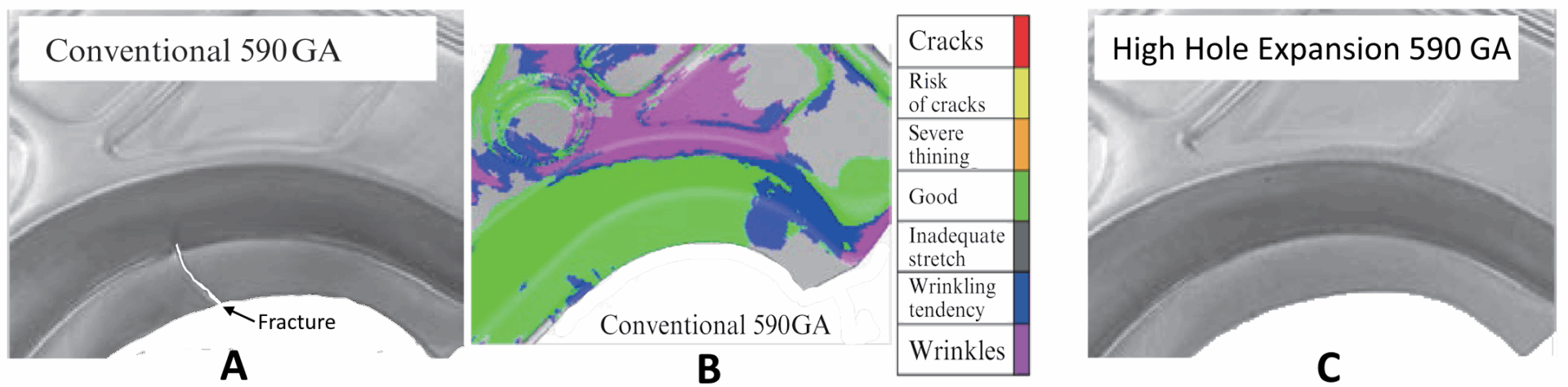

Metal flow when forming shear-cut blanks into B-Pillar Upper shapes puts the cut edges into tension along the front- and rear- door opening regions adjacent to the B-Pillar. Edge cracking propagating into the part, such as seen in Figure 1a, is frequently the outcome. Making this more challenging is that simulations have difficult predicting risk of cut edges, exemplified by Figure 1b which gives the false impression that there are no cracking or splitting concerns in this area.

Blank design countermeasures accomplish only so much. However, the steel industry now offers options at the same tensile strength but having better cut edge ductility as measured by the hold expansion test. The same part and process design is now capable of achieving the targeted part dimensions and characteristics, Figure 1c.

Figure 1: B-Pillar Upper stamped from conventional 590 GA (1a) and 590 GA with high hole expansion (1c). Figure 1b shows the simulation of the conventional 590 GA but does not indicate forming issues.S-125, J-30

Table 1 presents a comparison of the properties used to form these parts.

| Steel Type |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

HER* λ (%) |

|---|---|---|---|---|

| Conventional 590 GA | 365 | 610 | 29 | 45 |

| High Hole Expansion 590 GA | 410 | 600 | 33 | 80 |

| *HER: Hole Expanding Ratio, the index of stretch-flangeability. | ||||

B-Pillar Lower

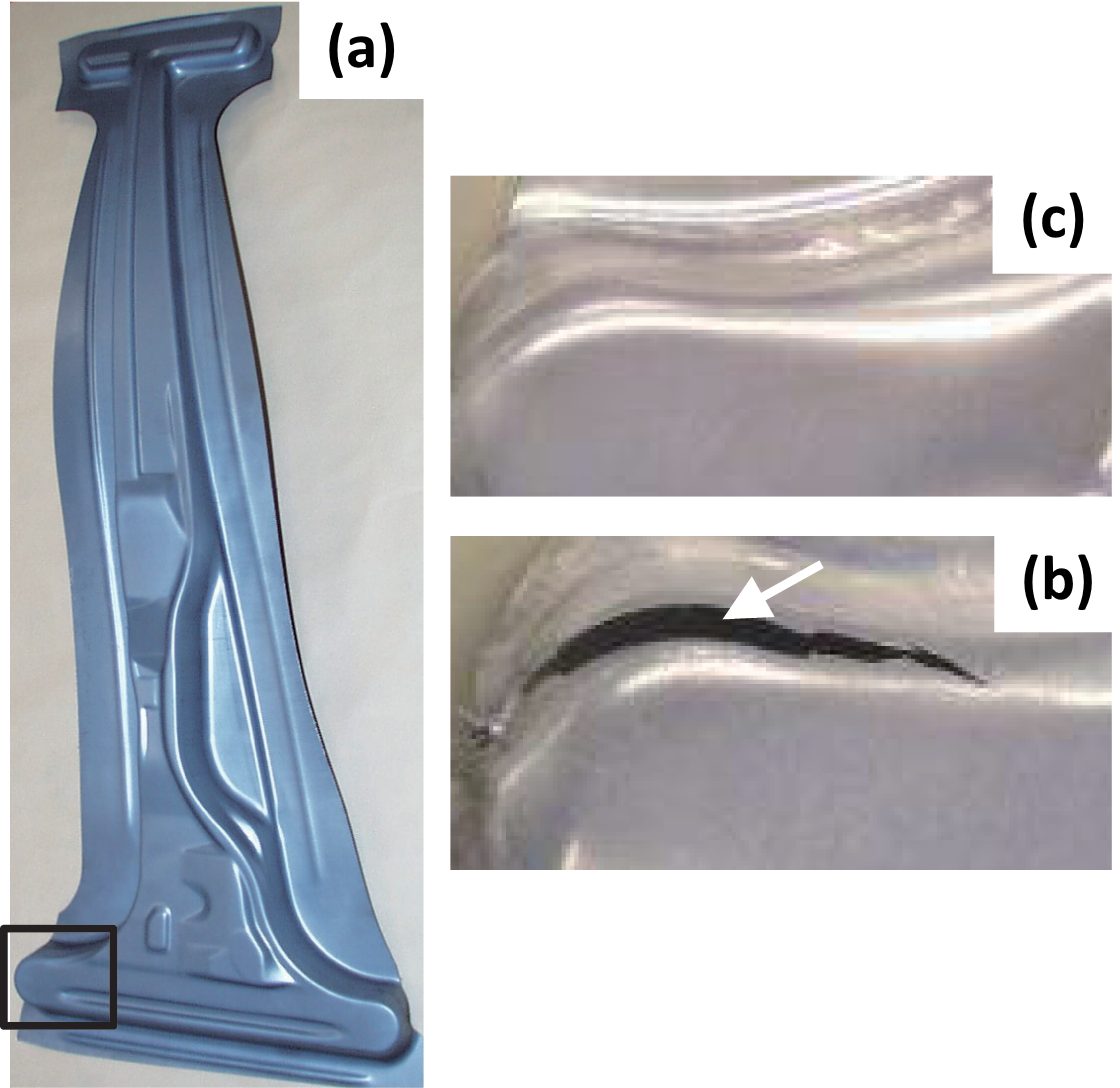

OEMs usually design B-Pillar Lower portions to absorb side impact crash energy. This means a combination of lower gauge and lower strength. Vehicle stiffness must be maintained, so the lower horizontal portion may have a relatively deep draw depth – also needed to accommodate the contours of the rocker shape. From a formability perspective, the deep draws and aggressive designs put these stampings (Figure 2a) at risk of splits due to insufficient elongation and n-value. An example of a split section is shown in Figure 2b. However, no issues were found when stamped from a 3rd Generation 980 MPa steel, Figure 2c.

Figure 2: B-Pillar Lower (a) showing splits when made from conventional 980 GA (b), and split-free when made from 3rd Gen 980 MPa (c).J-30

A-Pillar (Front Pillar)

A-Pillar Lowers, also called front pillar lowers, have similar formability concerns as the B-Pillar Lower, except that A-Pillars are usually formed from even higher strength grades since they are at the front corners of the passenger safety cage. The typical design leads to the fractures seen in Figure 3, arising from insufficient elongation and n-value in the steel. Application of a 3rd Generation 1180 MPa steel overcame these concerns, leading to robust and successful stamping.

Figure 3: Deep draw depths make A-Pillar Lower panels at risk for splitting. Converting to a 3rd Gen 1180 MPa steel may alleviate these concerns.S-125, J-31

Application of Dual Phase Steels to Exposed-Quality Surface Panels

Bake hardening steels frequently are used for exposed panels due to the extra strengthening occurring from the paint curing step. Of the bake hardenable grades, 340 BH is likely the most widely applied. In this terminology typically used in some parts of Asia, these grades have a minimum tensile strength of 340 MPa, and a minimum yield strength of approximately 200 MPa. As such, a 340 BH grade is similar to a 210 BH grade, using terminology more often associated with North America- and Europe based companies.

The option of a higher strength bake hardenable steel exists with a 440 DP product: a dual phase steel that has a minimum tensile strength of 440 MPa and has bake hardenability. The as-produced yield strength of 340 BH and 440 BH are similar, but the 440 BH grade has a larger strength increase associated with the paint curing step.F-51 The low yield strength of 440 BH is attributed to having martensite in the ferrite matrix. With a now higher strength panel, a thickness reduction of 0.05 mm is possible while still improving dent resistance.J-29

Table 2 compares these steels, with YP’ representing the in-panel and baked strength, which is the sum of the yield point (YP), work hardening (WH), and bake hardening (BH).

| Steel Type |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

n-value (6% to 12%) |

WH (MPa) |

BH (MPa) |

YP’ (MPa) |

|---|---|---|---|---|---|---|---|

| 340 BH | 242 | 354 | 41 | 0.21 | 33 | 35 | 310 |

| 440 DP | 257 | 455 | 37 | 0.23 | 62 | 57 | 376</td |

| YP’ (formed and baked strength) = yield point (YP) + work hardening (WH) + and bake hardening (BH). | |||||||

Align Alloy Selection to the Needs of the Part

Alloy Selection of 980 MPa Steel

Body structures often call for parts to be formed from 980 MPa tensile strength steel. Recognizing that strength is not the only characteristic that determines whether the part can be successfully and robustly stamped into the targeted shape and dimensions, the steel industry offers different Advanced High Strength Steel grades to meet the minimum tensile strength requirements.

Citations M-77 and M-78 compare three such grades: DP980, CP980, and QP980, all cold rolled steel at 1.6 mm thick. The DP grade is a standard dual phase steel, CP represents a complex phase steel, and QP indicates that it is a Quenched and Partitioned 3rd Generation AHSS grade. Table 3 compares the tensile properties of the 3 steels, and Figure 4 shows the stress strain curves for these grades. The bold portions of the curves in Figure 4b comes from tensile testing which generates data through uniform elongation. From that point, the curves are extrapolated to the true fracture strain εf determined by analyzing the dimensions of the fractured tensile bars.

| Steel Type |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Uniform Elongation (%) |

Total Elongation (%) |

True Fracture Strain (εf) |

|---|---|---|---|---|---|

| DP980 | 662 | 1,016 | 8.9 | 15.8 | 0.44 |

| QP980 | 654 | 1,005 | 15.9 | 22.1 | 0.78 |

| CP980 | 941 | 1,046 | 8.2 | 14.6 | 0.58 |

| Properties representative of samples evaluated in Citations M-77 and M-78. | |||||

Figure 4: a) Engineering and b) True Stress-strain curves for DP980, QP980, and CP980.M-77

Strain hardening was characterized as a function of strain, Figure 5. The lack of a constant n-value prevents use of the Holloman relationship to characterize the hardening curves. Necking occurs once the true strain equals the work hardening coefficient (ε = n).

The initial peak in Dual Phase steel at low strains comes from the high work hardening offered by the microstructural ferrite, but decreases as the ferrite strengthens with increasing strain. The plateau in the strain hardening coefficients for the QP980 and CP980 steels is consistent with the occurrence of the TRIP effect. The microstructural differences between the three AHSS types are directly related to their performance in formability characterization tests like tensile and bending.

Figure 5: Strain hardening coefficient as a function of strain for DP980, QP980, and CP980.M-77

As indicated in Figure 6, the steels have different microstructures. Dual phase steels are comprised of ferrite (α) and martensite (α’); the QP steel has ferrite (α), martensite (α’), and ≈6% retained austenite (γ); and the microstructural components of the CP steel include ferrite (α), martensite (α’), bainite (αb), and ≈6% retained austenite (γ).

Figure 6: Microstructural components of DP980, QP980, and CP980.M-77

In V-Bending tests described in Citations M-77 and M-78, the greatest strains were found in bends made on the DP980 steel, while the QP980 steel resulted in the lowest strains at the bend radius. The high n-value at high strains seen in QP980 reduces strain concentration along the bending line, and therefore reduces the peak strain at this location. The springback angle was the largest in the CP980 steel, which is consistent with having the highest yield strength.

Alloy Selection of 1180 MPa Steel

Stamped parts experience multiple modes of forming deformation, including drawing, stretching, and bending. Some, but not all, advanced high strength steels having a multiphase microstructure are sensitive to cut-edge stretching as measured in a hole expansion test. The key to stamping success is to deploy the correct steel grade that addresses the challenges and constraints of the part. AHSS grades offer options to address these challenges.

As one example, conventional 980DP and 1180DP was compared to 3rd Gen 1180 in these various deformation modes.M-54

The tensile and hole expansion properties of these grades are listed in Table 4, while Figures 7 to 9 shows the bendability, stretch formability, and deep drawability of the three grades. The forming limit curve of the 3rd Gen 1180 steel is comparable to 980DP. Additional testing confirms each of these steels are spot weldable with conventional techniques and have excellent resistance to delayed fracture associated with hydrogen embrittlement. M-54

| Steel Type |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

HER* λ (%) |

|---|---|---|---|---|

| 3rd Gen 1180 | 946 | 1,222 | 18 | 40 |

| 1180 DP | 910 | 1,185 | 10 | 51 |

| 980 DP | 640 | 1,020 | 17 | 25 |

| *HER = Hole expansion tested to JIS Z 2256; 1.4mm; JIS Z 2201 #5 tensile sample in transverse orientation | ||||

Figure 7: Bendability of 3rd Gen 1180 steel compared with 1180DP and 980DP. M-54

Figure 8: Stretch formability of 3rd Gen 1180 steel compared with 1180DP and 980DP.M-54

Figure 9: Deep drawability of 3rd Gen 1180 steel compared with 1180DP and 980DP.M-54