Normal vehicle use leads to repeated loading of components and joints. Stress concentrations in the body structure may lead to plastic strains at stresses below the yield strength due to cyclic fatigue. Conventional High-Strength Steel fatigue behavior correlates with their tensile strength. However, in multiphase steels, the strain distribution between phases within the steel microstructure affects the fatigue response, leading to a different response depending on which phases accommodate the strain.

The fatigue strength of DP steels is higher than that of precipitation-hardened steels or fully bainitic steels of similar yield strength for several metallurgical reasons. The dispersed fine martensite particles retard the propagation of fatigue cracks. For TRIP steels, the transformation of retained austenite can relax the stress field and introduce a compressive stress that can also improve fatigue strength. General categorization may not be possible – studies have reported cyclic hardening occurs in Dual Phase steels where the martensite volume fraction is less than 0.5 while Dual Phase steels at higher martensite content (higher strength) soften under cyclic loading conditions. C-15, W-27 Furthermore, fatigue limits are complicated by environmental factors like the presence of hydrogen.

Figures 1 and 2 illustrate the general improvements in fatigue capability offered by Advanced High-Strength Steel (AHSS) grades.

Figure 1: Fatigue characteristics of TRIP steel CR450Y780T-TR compared to conventional steels.T-24

Figure 2: Fatigue limit for AHSS compared to conventional steels.T-2

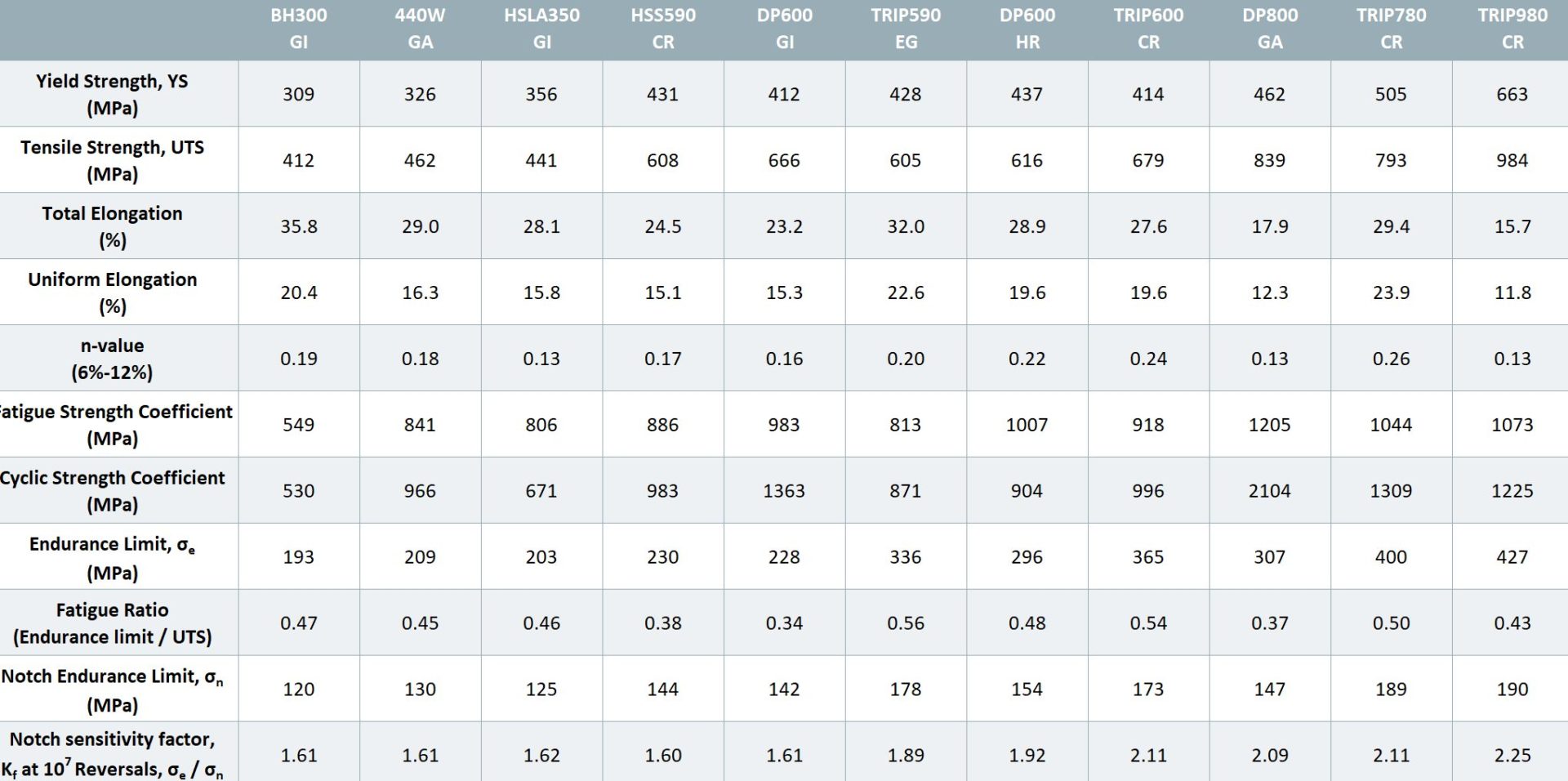

The table below lists some fatigue properties for conventional and advanced high strength steels.

Table 1: Fatigue properties for HSS and AHSS grades Y-11