Low density steels are the collective name for some Fe-Mn-Al-C alloys. Whereas the density of iron is 7.87 g/cm3, increasing the content of manganese (7.43 g/cm3) and aluminium (2.71 g/cm3) results in a product with an overall density lower than that seen in traditional low carbon steels. Since there is not a large density difference between manganese and iron, this article focuses on the impact of aluminium. There are other benefits aside from lightweighting associated with increased manganese, and these are covered in our section on medium-manganese steels and twinning induced plasticity steels.

Low levels of aluminium, typically around 0.04%, are used to deoxidize most continuously cast steels. Higher levels, around 1% to 2%, may be found in some TRIP or 3rd Generation AHSS grades. Still higher levels are used in an emerging family of products intended to retain the strength and formability benefits of advanced steels while exploiting the weight reduction potential that lower density aluminium offers.

Even though aluminium has a Face Centered Cubic (FCC) crystal structure similar to austenite, aluminium is a ferrite stabilizer in Fe-Al alloys having aluminium content greater than 6%. With sufficient carbon and manganese, this may change back to an austenitic structure.

In general, there are three classifications of high-aluminium steels for automotive applications. Ferritic alloys are mainly iron and aluminium. Two-phase austenite-ferrite alloys use C and Mn to stabilize austenite. Primarily austenitic alloys have relatively high levels of C and Mn, and are sometimes referred to as TRIPLEX steels because these have small amounts of ferrite and intragranular nanometer-sized precipitation of an ordered carbide known as the kappa (k) phase. Detailed reviews of these steels are found in Citations S-122 and G-54.

One studyZ-21 evaluated two automotive parts stamped from a conventional CR-330Y-590T-DP (DP600) steel as a reference, and compared those parts made from an austenite-ferrite grade and a fully austenitic grade. The parts were a front side member needing energy absorption, and an A-Pillar where intrusion prevention is the critical parameter. For each part, the thickness of the low-density alloys were adapted to match the DP600 reference performances in terms of energy absorption and section forces. The results showed that the austenite-ferrite grade allowed for a 20% reduction in weight, while a 30% weight reduction was feasible with the fully austenitic grade. See Table 1 for details.Z-21

| Phase Composition | CR-330Y-590T-DP (DP600; reference) α ferrite + martensite |

Iron-aluminium alloy with Austenite-Ferrite Microstructure Fe-Al: α + γ |

Iron-aluminium alloy with Austenite Microstructure Fe-Al: γ |

|---|---|---|---|

| Chemistry (weight %) | typical | Fe- 0.2 C- 8.2 Mn- 7.4 Al | Fe- 0.96 C- 25.8 Mn- 9.3 Al |

| YS (MPa) | 330 min | 646 | 812 |

| TS (MPa) | 590 min | 812 | 1027 |

| EL (%) | 21 min | 26 | 32 |

| Front side member | |||

| Grade | CR-330Y-590T-DP (reference) |

Fe-Al: α + γ | Fe-Al: γ |

| Thickness FR/RR | 1.7 mm / 2.1 mm | 1.5 mm / 1.8 mm | 1.3 mm / 1.7 mm |

| Total Mass per vehicle | 5.88 kg | 4.63 kg | 3.99 kg |

| Mass savings per vehicle | (reference) | 1.25 kg | 1.89 kg |

| Mass savings per vehicle | (reference) | 21 % | 32 % |

| A-Pillar | |||

| Grade | CR-330Y-590T-DP (reference) |

Fe-Al: α + γ | Fe-Al: γ |

| Thickness | 1.6 mm | 1.4 mm | 1.25 mm |

| Total Mass per vehicle | 6.11 kg | 4.84 kg | 4.12 kg |

| Mass savings per vehicle | (reference) | 1.27 kg | 1.99 kg |

| Mass savings per vehicle | (reference) | 21 % | 33 % |

Another company states that low density steels are suitable for parts requiring high formability and weight reduction, such as body side reinforcement panels, rear crossmembers, and upper/lower covers of battery packs. These can be formed via cold stamping or roll forming. Some properties associated with these steels are found in Table 2.

| Steel Grade | Typical Mechanical Properties | |||

|---|---|---|---|---|

| Standard/Typical | Yield Strength (MPa) | Tensile Strength (MPa) | Total EL in 80mm (%) | |

| CR-340/590-LD | Standard | ≥ 340 | ≥ 590 | ≥ 21 |

| Typical | 443 | 618 | 29 | |

| CR-370/780-LD | Standard | ≥ 370 | ≥ 780 | ≥ 15 |

| Typical | 410 | 834 | 17 | |

| CR-420/780-LD | Standard | ≥ 420 | ≥ 780 | ≥ 13 |

| Typical | 521 | 834 | 22 | |

| CR-400/980-LD | Standard | ≥ 400 | ≥ 980 | ≥ 10 |

| Typical | 428 | 1038 | 15 | |

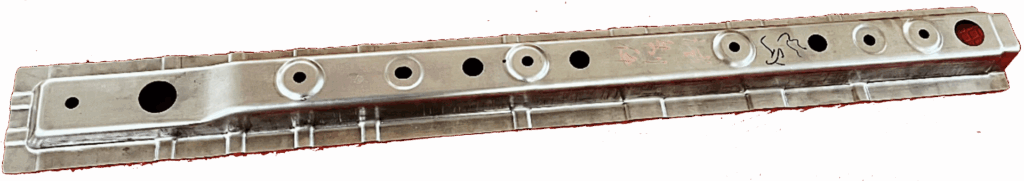

Figures 1 and 2 show two part made from low density steels

Challenge with Galvanizing Low Density Steels

The external oxidation of aluminium prevents good wettability of zinc during hot dip galvanizing. This is a similar issue in 3rd Generation AHSS grades that use higher levels of aluminium.

Increasing the dew point of the annealing furnace atmosphere from -50 °C to -10 °C promotes internal rather than external oxidation, and therefore is a viable strategy to improve galvanizability of low density steels.J-28