Citations

Citation:

L-38. X. Li, Y. Chang, C. Wang, P. Hu and H. Dong, “Comparison of the hot-stamped boron-alloyed steel and the warm-stamped medium-Mn steel on microstructure and mechanical properties,” Materials Science and Engineering: A, vol. 679, pp. 240-248, 2017, doi.org/10.1016/j.msea.2016.10.045.

Joining Dissimilar Materials, Resistance Welding Steel to Aluminium

Among various dissimilar material combinations, Al-steel is one of the most desirable combination. This section will address the number of fundamental issues faced during al-steel joining. Later section will discuss the current approaches to overcome these issues.

Strong and adherent aluminium surface oxide layer needs to be removed for a sound joint between aluminium and steel. The presence of this oxide layer creates uncertainty in the Resistance Spot Welding (RSW) process and deteriorates the electrodes, hence decreasing electrode life. Moreover, it creates wettability issues between steel and aluminium which is an essential for joint formation. Joint is established once surface oxide layer is broken.

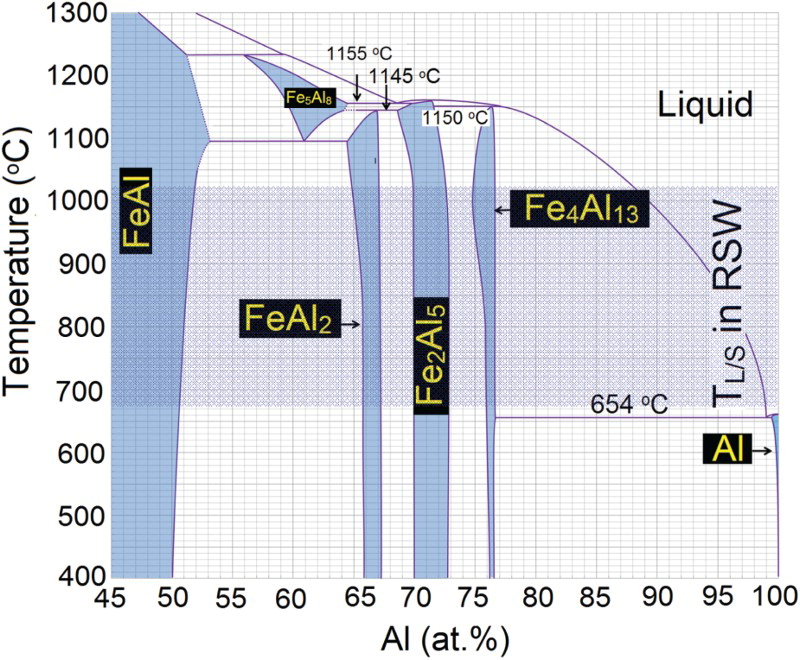

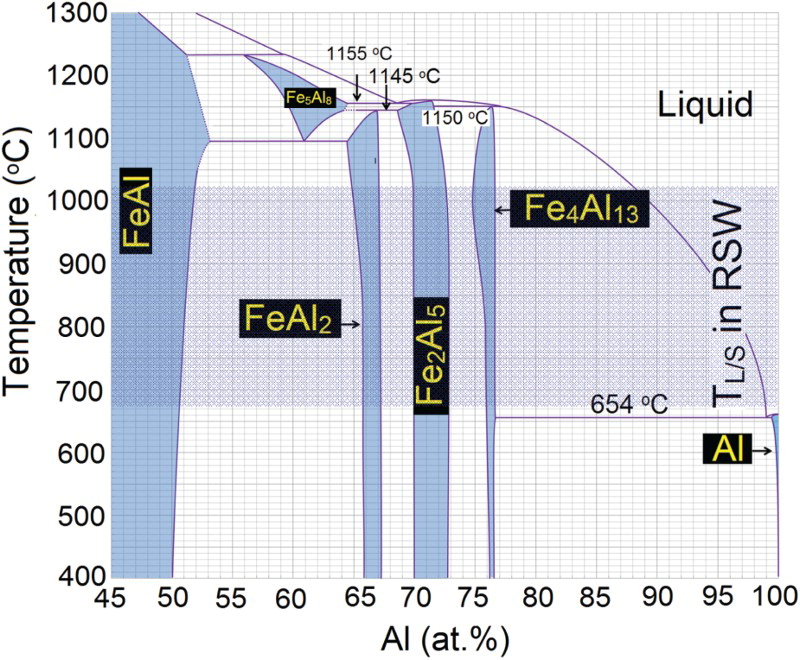

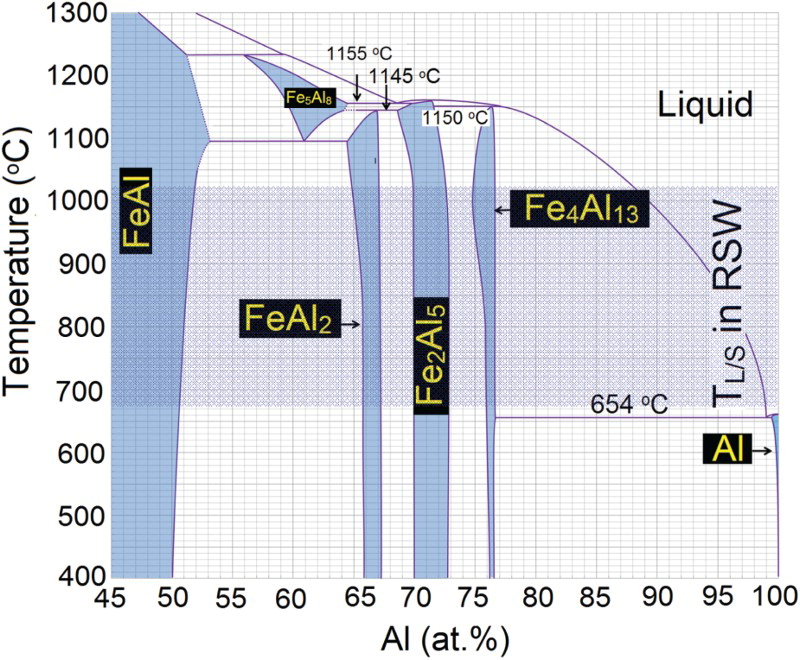

Formation of intermetallic compounds are unavoidable during Al-steel RSW joints. Figure 1 shows the phase diagram between aluminium and iron and from the phase diagram various intermetallics compounds are formed during the RSW process. Formed intermetallics could be iron rich or aluminium rich. Aluminium rich intermetallics are undesirable due to higher hardness compared to iron rich intermetallics. These intermetallics act as stress concentrators, increases the brittleness and making the Al-steel joints more susceptible to cracking.

Figure 1. Al-Fe phase diagramL-8

Another issue is to attain heat balance between aluminium and steel. Compared to steel, aluminium has more electrical & thermal conductivity, and lower bulk resistivity, usually requiring higher amount of current. A large variation in the melting temperature of the aluminium and steel make the RSW process more complicated. Moreover, the thermal conductivity of aluminium is much higher than steel, and a consequent thermal gradient exists and could result in an isolated nugget formation in steel. These factors make the selection of RSW process parameters more challenging.

Excessive electrode indentation in aluminium is another issue that determines the stress state of the joint during loading. It decreases the resistance to necking and decreases the peak load to failure.

Other defects include formation of voids and porosities due to shrinkage, vaporization, expulsion and lack of wetting. Other section in this menu will discuss the basic to advanced, updated approach utilized to improve the joint formation process between aluminium and steel.

Citations

Citation:

L-57. X. Li, A. Scherf, M. Heilmaier, and F. Stein, “The Al-Rich Part of the Fe-Al Phase Diagram,” J. Phase Equilibria Diffus., Vol. 37, No. 2, pp. 162–173, Apr. 2016.