Coating Effects

One of the methods by which the coatings are applied to the steel sheet surface is through a process called Hot Dipped Galvanizing (HDG). In this process, continuous coils of steel sheet are pulled at a controlled speed through a bath containing molten Zinc (Zn) at ~ 460° C. The Zn reacts with the steel and forms a bond. The excess liquid metal sticking on the sheet surface as it exits the bath is wiped off using a gas wiping process to achieve a controlled coating weight or thickness per unit area.

As mentioned earlier, AHSS are commercially available with Hot Dipped Galvannealed (HDGA) or Hot Dipped Galvanized (HDGI) coatings. The term “galvanize” comes from the galvanic protection that Zn provides to steel substrate when exposed to a corroding medium. An HDGA coating is obtained by additional heating of the Zn-coated steel at 450-590°C (840-1100°F) immediately after the steel exits the molten Zn bath. This additional heating allows iron (Fe) from the substrate to diffuse into the coating. Due to the diffusion of Fe and alloying with Zn, the final coating contains about 90% Zn and 10% Fe. Due to the alloying of Zn in the coating with diffused Fe, there is no free Zn present in the GA coating.

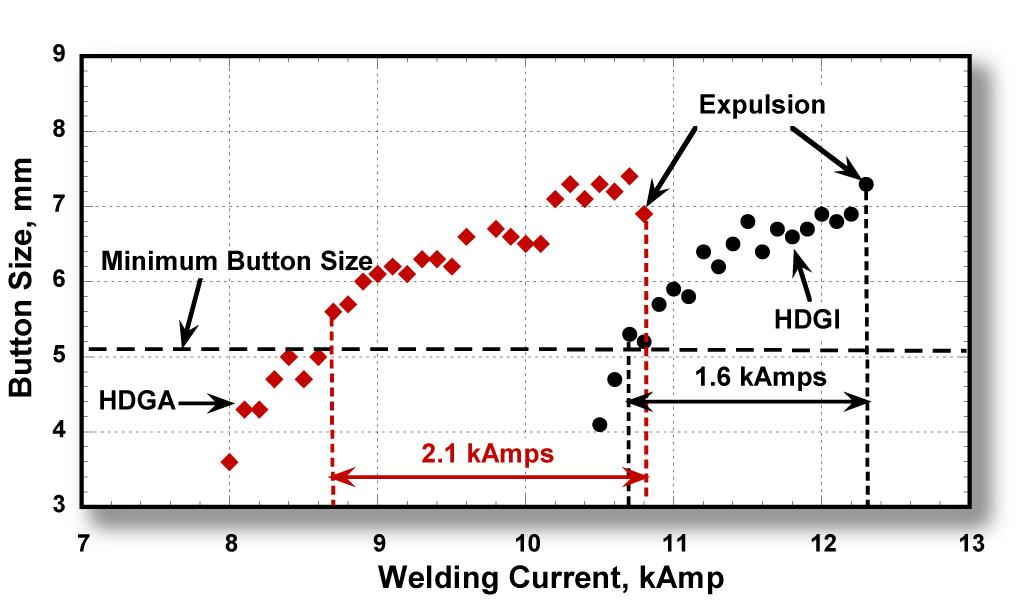

A studyT-7 was undertaken to examine whether differences exist in the RSW behavior of DP 420/800 with a HDGA coating compared to a HDGI coating. The Resistance SW evaluations consisted of determining the welding current ranges for the steels with HDGA and HDGI coatings. Shear and cross-tension tests also were performed on spot welds made on steels with both HDGA and HDGI coatings. Weld cross sections from both types of coatings were examined for weld quality. Weld micro hardness profiles provided hardness variations across the welds. Cross sections of HDGA and HDGI coatings, as well as the electrode tips after welding, were examined using a Scanning Electron Microscope (SEM). Composition profiles across the coating depths were analyzed using a glow-discharge optical emission spectrometer to understand the role of coating in RSW. Contact resistance was measured to examine its contribution to the current required for welding. The results indicated that DP 420/800 showed similar overall welding behavior with HDGA and HDGI coatings. One difference noted between the two coatings was that HDGA required lower welding current to form the minimum nugget size. This may not be an advantage in the industry given the current practice of frequent electrode tip dressing. Welding current range for HDGA was wider than for HDGI. However, the welding current range of 1.6 kA obtained for HDGI coated steel compared to 2.2 kA obtained for the HDGA coated steel is considered sufficiently wide for automotive applications and should not be an issue for consideration of its use (Figure 1).

Figure 1: Welding current ranges for 1.6-mm DP 420/800 with HDGA and HDGI coatings.T-7

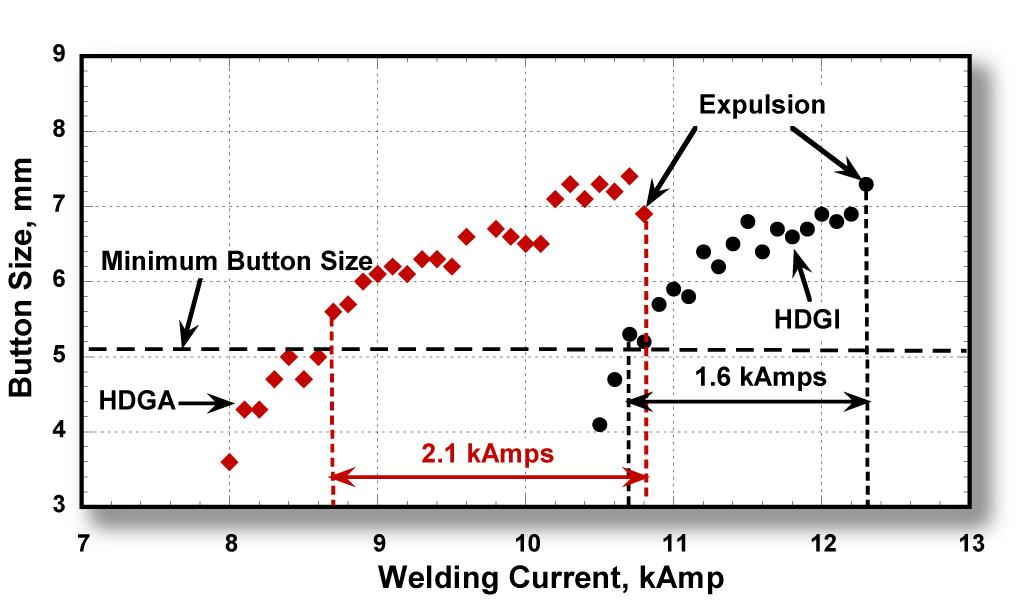

As was mentioned briefly in Resistance Spot Welding, electrode wear is a larger issue when welding coated steels. In high-volume automotive production of Zn-coated steels, the rate of electrode wear tends to accelerate compared to the rate when welding uncoated steels. The accelerated electrode wear with coated steel is attributable to two mechanisms. The first mechanism is increasing in the electrode contact area (sometimes referred to as mushrooming effect) that results in decreased current density and smaller weld size. The second mechanism is electrode face erosion/pitting due to chemical interaction of the Zn coating with the Cu alloy electrode, forming various brass layers. These layers tend to break down and extrude out to the edges of the electrode (Figure 2). To overcome this electrode wear issue, the automotive industry is using automated electrode dressing tools and/or weld schedule adjustments via the weld controller. Typical adjustments include increase in welding current and/or increase in electrode force, while producing more welds. Research and development work has been conducted to investigate alternative electrode material and geometries for improving electrode life.

Figure 2: Erosion/pitting and extrusion of brass layers on worn RSW electrode.U-2

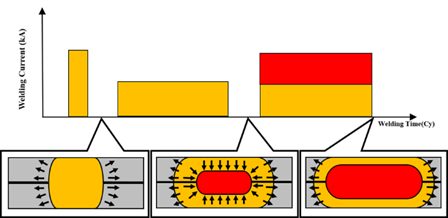

The resistance weldability of coated steels can also cause problems. In many applications, more intricate welding schedules are used to ensure welds meet the size and strength requirements. Studies have been conducted to determine the nugget growth and formation mechanisms to properly select parameters for each pulse of a three-pulse welding scheduleJ-2 (Figure 3). The first pulse, high current and short weld time, is used to mitigate the effects of the coating on welding and develop contact area at the sheet-to-sheet interface. The second pulse, low current long weld time, is used to grow the weld nugget and minimize internal defects. The third pulse, medium current and long weld time, is used to grow the weldability current range and maximize the nugget diameter.

Figure 3: Weld growth mechanism of optimized three-pulse welding condition.J-2