Resistance spot welding (RSW) is the most utilized joining process in car body assembly with exceptionally high demands on quality and reproducibility. Expulsion in RSW leads to ejection of metal from the weld and can cause equipment deterioration and re-working.

As the RSW process has many variables both from the process itself and from the to-be-welded component, prediction and avoidance of expulsion is challenging. This creates a large demand for new technologies that allow for RSW of steels with improved expulsion control.

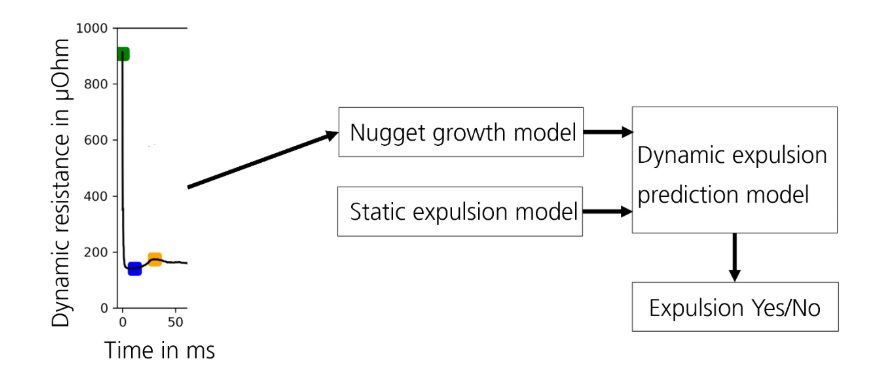

Recent developments aim to predict – and ultimately avoid – expulsion using artificial intelligence data analysis. Process data on current, voltage and dynamic resistance are readily available in RSW and can be augmented with simulation data for non-measurable phenomena such as the nugget growth rate to create predictive algorithms that eventually aim to avoid expulsion altogether.

An Introduction to AI Expulsion Prediction

This work focuses on utilizing artificial intelligence modeling for the prediction of expulsion during resistance spot welding (see Figure 1 for an image of expulsion on the left and metal residue on the surface after expulsion on the right). The primary objective is to forecast the formation of expulsion before it occurs, with the aim of improving the quality of the welding process. This effort is supported by a dataset of 500 welded spots of 2-sheet stack-ups made from one advanced high-strength steel (AHSS) and one mild steel joining partner. Two sequential AI models are trained: one for nugget growth prediction and another for spatter prediction.

Figure 1: Left: Expulsion leads to the ejection of molten metal. Right: Residues may form on the surface after expulsion.

Feature Engineering

A key aspect is the integration of multi-source data: The models leverage both static and dynamic inputs. Static inputs include input process parameters such as current, force, and weld time, which are set at the machine in accordance with a pre-determined weld lobe. Dynamic inputs encompass transient process signals like dynamic resistance and electrode force. In resistance spot welding, this data is usually readily available, because the welding power source measures electric flow and weld gun opening and forces. A further step is to include non-measurable data from simulation results concerning nugget growth rate.

To give time for process intervention, the predictive quality of the models was determined after only 30 ms of welding time, depicted in Figure 2.

Data evaluation and feature engineering are critical components of the modeling process. A welding and data-science expert needs to identify significant features from sensor time series data as input for the neural network AI models. These features can be physically meaningful, such as the minimum resistance during the process, or purely statistical with values such as longest continuous time above the average resistance.

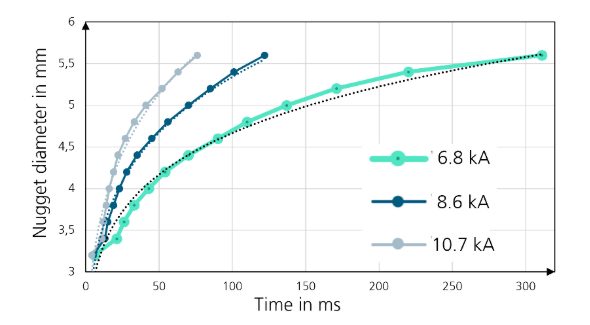

The simulation of resistance spot welding allows for the extraction of the non-measurable nugget growth rate. It is well documented that the nugget growth rate strongly correlates with expulsion formation and conducting simulations for different welding cases (gaps, misalignments, slightly changed contact resistances…) can add this physical behavior to the data-driven AI model. Figure 3 depicts different nugget growths extracted from the simulation with different welding currents. High currents lead to significantly faster growth rates and facilitate expulsion.

Figure 3: Weld nugget growth behavior for different welding currents extracted from a numerical welding simulation. Solid lines are simulation results; dashed lines depict a polynomial fit used to reduce data for AI input.

Model Accuracy

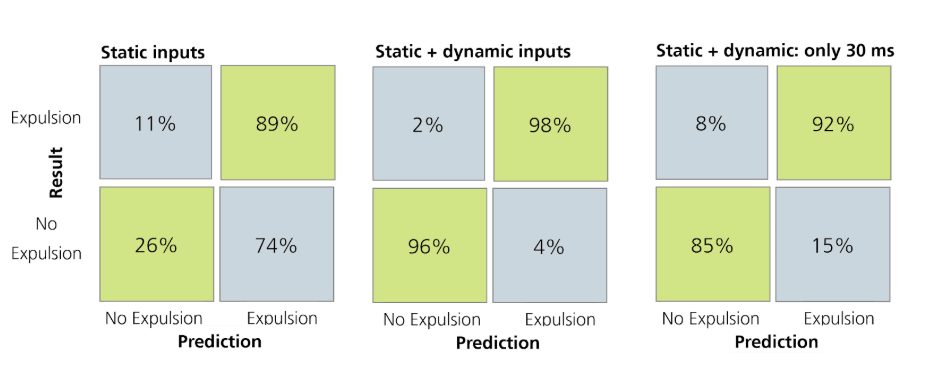

Figure 4 depicts the confusion matrices for the three different models. The bottom left and top right fields are the desired predictions, and the other fields depict false results of the models. The first model stage, which relies solely on static inputs, yields moderate prediction quality. However, when dynamic data from experiments and simulations are included, the prediction quality jumps to approximately 96%. The analysis focusing on the first 30 milliseconds to give time for subsequent intervention in the process, achieves a reduced, but still good, result quality of around 90%. Further improvements in prediction accuracy are expected with additional data.

Figure 4: Confusion matrices for static, static and dynamic and static and dynamic: only 30 ms inputs. A reliable prediction is possible using dynamic process and simulation data. If only 30 ms of dynamic data are utilized the predictive quality decreases.

The presented approach uses a data-driven AI model with different levels of input data to predict resistance spot welding expulsion. The data-gathering and feature engineering procedures are highlighted, explaining a need for in-depth knowledge of the welding process as well as data engineering. The approach yields a neural network with excellent predictive quality, if dynamic data is included in the model. Even if only 30 ms of transient data are used to allow for a subsequent process intervention, the result quality is still good. It is expected that the predictive quality improves when the data set is increased and additional data sources both from measurements and simulations are included. This approach can improve the control of automotive welding systems and ultimately avoid excessive re-working and equipment wear due to expulsion in resistance spot welding of advanced high-strength steels.

|

Thanks go to Dr.-Ing Max Biegler, AHSS Application Guidelines Technical Editor and Group Lead, Joining & Coating Technology at Fraunhofer Institute for Production Systems and Design Technology IPK |