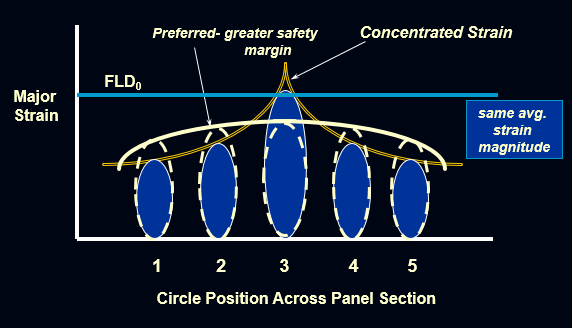

The mild steel currently being used for sheet metal stampings has higher n-values than High Strength Low Alloy Steel and Advanced High Strength Steel. The high n-value indicates that the material has a higher work hardening exponent making the steel much easier to stretch or form. The n-value describes how the material works together to resist localized fractures as stresses are applied. High strain patterns can be created in localized areas such as character lines and embossments. This strain pattern creates strain peaks or strain gradients. These strain peaks have much higher plastic deformation than areas on the rest of the material. The localized strain will cause the material to thin as it forms the character line or embossment. The die geometry does not allow the material to deform in stretch or draw modes, which means the material is in the plane strain mode of deformation on the Forming Limit Diagram (FLD). This deformation mode has the least amount of formability due to the location of the FLD₀anchoring point (See Figure 1).

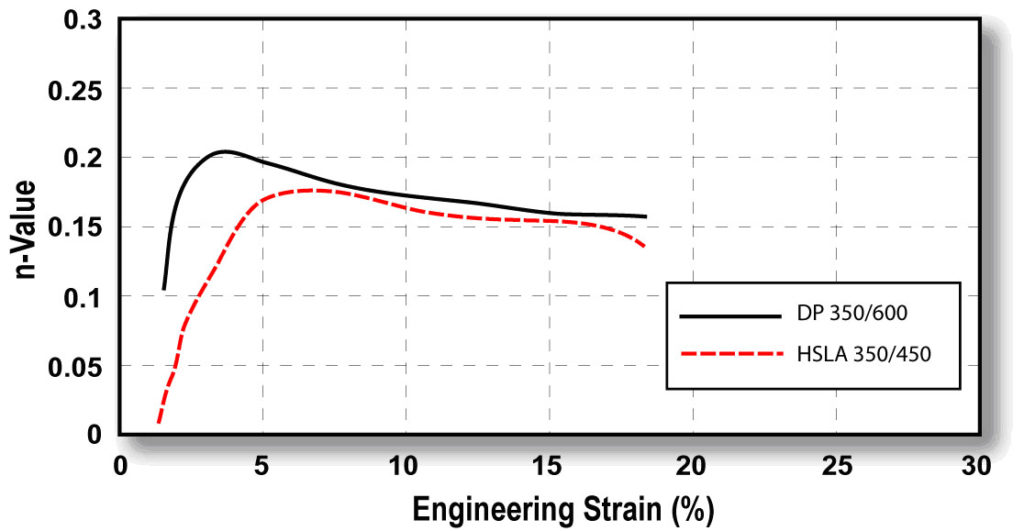

What does that mean for your stamping process? Mild steel has the ability to reach a high strain gradient due to higher n-values. High strength steels do not have the ability to reach the higher peak gradients due to lower n-values and less stretchability. These high strain areas will be more susceptible to a greater amount of thinning and/or fractures. If changes in the stamping process occur, such as reduced lube quantity, greater thinning can occur, at times exceeding minimum thickness and resulting in metal fracture. These concerns can be minimized through a better understanding of material capabilities, specific geometry effects, and the use of process recipe discipline. For example, Figure 2 compares the instantaneous n-value for Dual Phase steel, a member of the AHSS family, to HSLA steel. The early n-value increase reflects enhanced local formability, which is observed in stamped parts, contrary to what the typical stress-strain curve does not show the early n-value increase, which reflects enhanced formability in local regions of stamped parts. Other AHSS grades don’t show this tendency but have been developed with greater concentrations of bainite or finer dispersion of martensite within a ferrite matrix; both effects result in better localized forming.

Training die makers to understand these effects, while managing die geometry, will have a dramatic effect on the rework, downtime, and scrap associated with a conversion to AHSS products. The use of FLD₀ and formability analysis should identify areas of concern on the stamped part, but should also be coupled with hole expansion testing, or 2-D tension tests to more fully explore the formability condition. When trouble areas have been identified, there should be a review of the analysis and part with T&D managers, die makers, and quality personnel to formulate a corrective action plan. This plan should have specific and measurable direction, buy in, and understanding of the impact that die changes will have to the existing process.

BONUS!

Watch a video of renowned metallurgist Dr. Stuart Keeler explaining AHSS Instantaneous n-value:

Keeler On N-Value from worldautosteel on Vimeo.

Contributions made by Phoenix Group.

Figure 2 Image provided courtesy of Dr. Stuart Keeler.