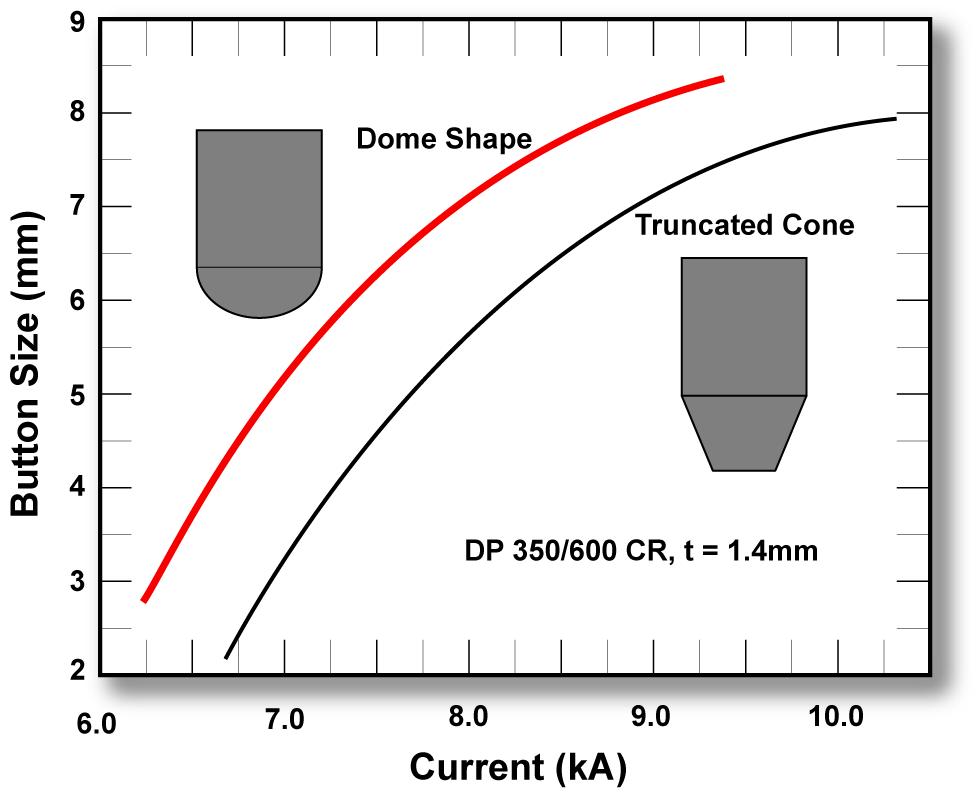

Although there are differences in weld process depending on weld tip material and shape (truncated cone and dome shape), AHSS can be welded with all weld tip shapes and materials. Dome-shaped electrodes ensure buttons even at lower currents due to higher current densities at the center of the dome shape (Figure 1). The curve of dome-shaped electrodes will help to decrease the effect of electrode misalignment. However, dome electrodes might have less electrode life on coated steels without frequent tip dressing. Due to round edges, the dome electrode will have fewer tendencies to have surface cracks when compared to truncated electrode.

Figure 1: Effect of electrode geometry on current range

using AC power mode and single pulse.L-2