The article “Paint Bake Effect on Generation 3 Steel Weld Strength Compared to Other AHSS” by Richard H. Wolf explores the strength increase of resistance spot welds (RSW) in Generation 3 (Gen3) advanced high strength steels (AHSS) due to the paint bake-hardening effect.

These steels, due to their carbon content, may yield welds that can be brittle. A crucial, and often overlooked, aspect of the automotive production process is the paint bake stage, which has been shown to improve the mechanical properties of AHSS welds. In order to correctly assess the strength of a weld, this article proposes to take the paint-bake effect into account.

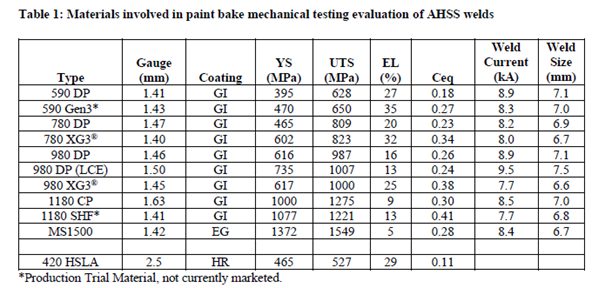

Table 1: Materials tested.

The experimental phase involved various AHSS materials, primarily with 1.5 mm thickness, with differing yield strengths and carbon equivalencies (Ceq). Resistance spot welding was performed under controlled conditions, and the effects of different paint bake temperatures and durations were analyzed.

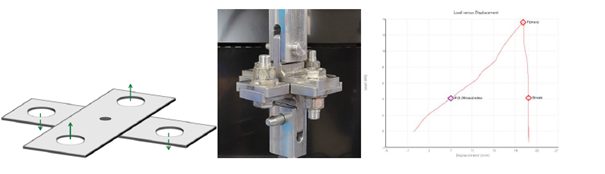

Figure 1: Testing setup

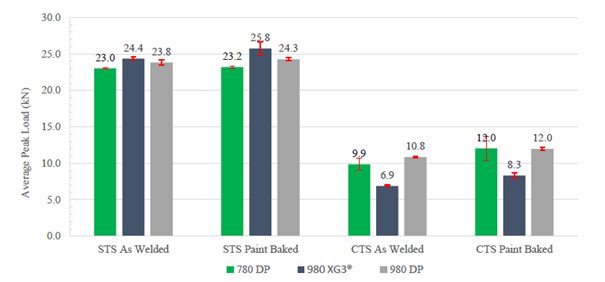

Results indicated that Gen3 steels exhibited a significant increase in weld strength following paint baking, particularly in cross-tension strength (CTS) tests. Higher Ceq values correlated with lower weld strength in the as-welded state, while the paint bake effect tended to equalize these strengths across different alloys.

Figure 2: Comparison of shear-tensile strength and cross-tensile strength of different steels with and without paint baking. Especially in cross-tensile testing, a significant increase in load-bearing capacity is visible.

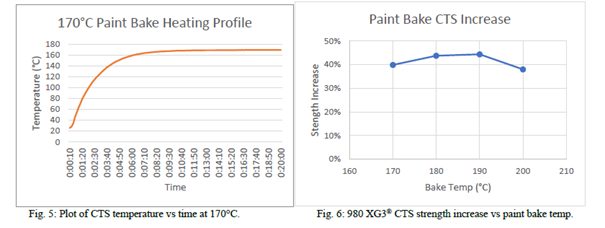

Hardness testing revealed a softening in the heat-affected zone after baking, suggesting that the weld microstructure became more homogenous, which reduces brittleness and improves fracture behavior. The investigation into heterogeneous welding between different steel types further elucidated the contribution of the fusion zone and heat-affected zone to overall weld strength.

Figure 3: Utilized paint baking profile and cross-tensile strength increase

In conclusion, the paint bake process significantly enhances the strength of AHSS welds, especially for Gen3 steels. This improvement should be factored into weld strength modeling for automotive applications. The author suggests establishing standardized paint bake simulations to ensure weld properties are accurately represented for automotive manufacturers.

Source

Richard H. Wolf, Paint Bake Effect on Generation 3 Steel Weld Strength Compared to Other AHSS