As with resistance spot welding in automotive applications, projection welding also is used to join two overlapping sheets of relatively thin metal. The process involves pressing a projection or number of projections in one of the plates and welding the two plates together at the projection locations.

The method can also be used for welding metal sheet to the ends of bars, rods or pipes, or for welding bolts, nuts, and other attachments to sheets. Such attachments are being used widely in the automotive industry. Wire grids (i.e. the crossing points of the wires) are also particularly suitable for projection welding (it is also called cross wire welding).

A modern car body may contains some 300 welded and punched fasteners, such as bolts, nuts, and studs. The quality of the attachment of these fasteners to the stamped body components is critical for the final product’s safety and reliability. Crucial components such as the front and rear axles are mounted to such fasteners, the seat belts and steering column are anchored to them, and they provide grounding for electrical wires.L-25

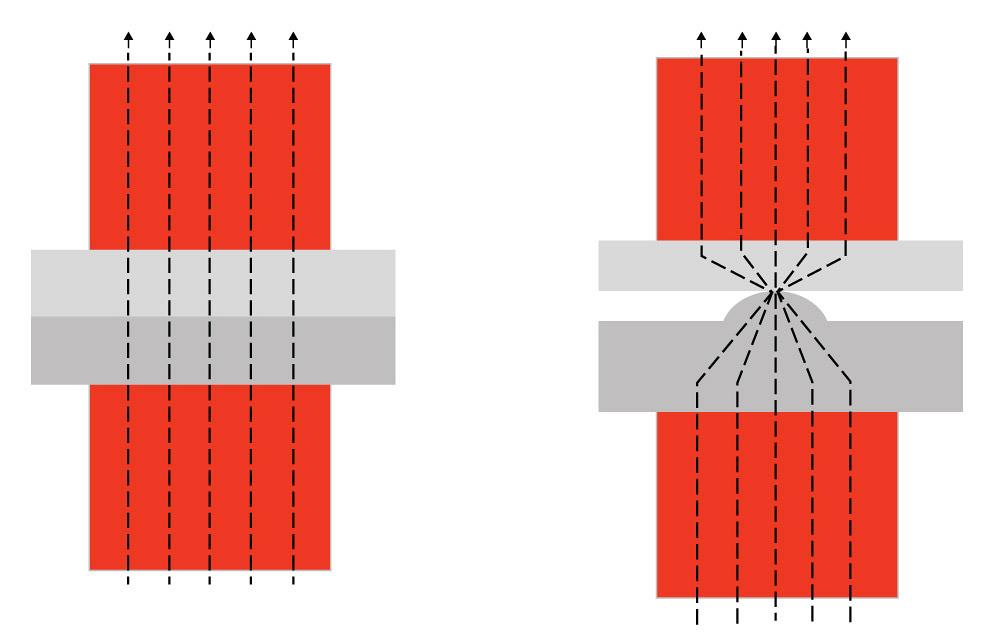

As noted, projection welding is similar to resistance spot welding. However, in the Resistance Spot Welding process, the size of the contact surface of the electrode cap tip determines the current flow, whereas in projection welding, the current flow is constricted to the embossed or machined projection as shown in Figure 1. Both AC and DC power sources are suitable for fastener welding. The heat balance for projection welding is affected by the following factorsA-11:

- Projection design and location

- Thickness of the sheet to which the fastener is attached

- Thermal and electrical conductivities of the metals being welded

- Heating rate

- Electrode alloy type

As compared to Resistance Spot and Seam Welding, Resistance Projection Welding is capable of welding much thicker parts, as well as parts with a significant thickness mismatch. As a result, it is often considered as a potential replacement for arc welding processes such as GMAW. One of the reasons for this is the drastic reduction in welding time that can be achieved. For example, a typical automotive part that might require several minutes or more of welding with the GMAW process may have the potential to be welded in less than a few seconds with the Resistance Projection Welding process. This is because the entire weld or multiple welds can be made at the same time in a single fixture. Another advantage of the process, relative to spot welding, is that there is less wear and tear on the electrodes.

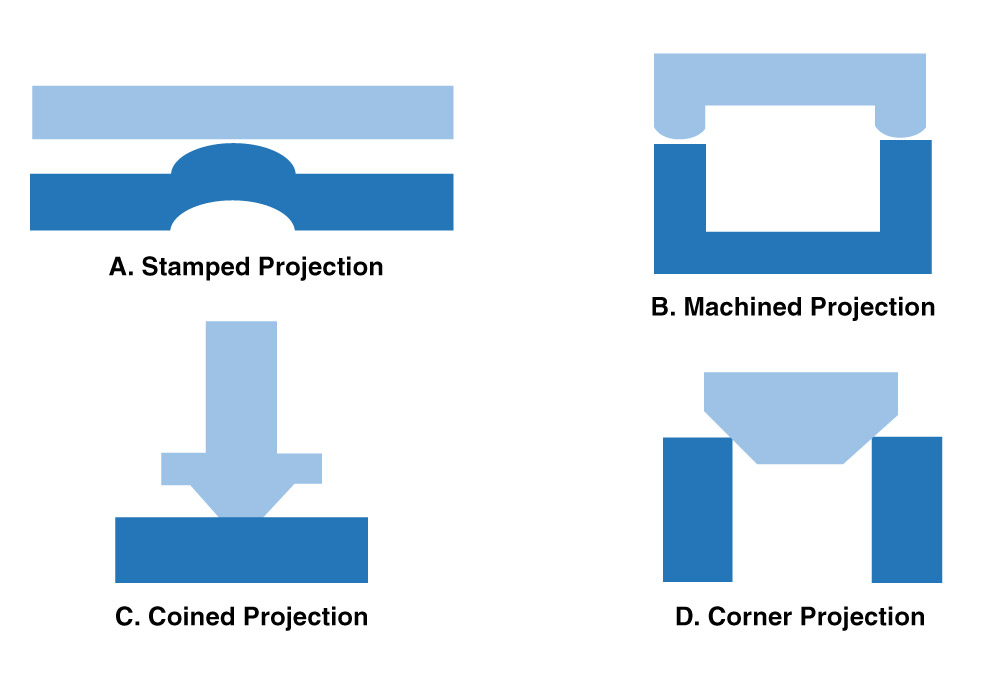

Different types of projections made by different methods are shown in Figure 2. It is important to note that the types of projections that are extensions of the part are known as solid projections (2-B and 2-D) and can only be produced by a machining or forging process, whereas the other projections are more easily produced by stamping with a punch and die. Projections produced with a punch and die usually involve the formation of a molten nugget during welding but not always. The solid projection designs mostly result in solid‐state welds that occur via a forging action as the projection is heated and pressure applied. A common Projection Welding application that uses solid projections involves the attachment of a wide variety of nuts, bolts, and fasteners. Many fasteners used on automobiles are attached this way.