This article investigates the MIG brazing capability of coated steel sheets for automotive applications, focusing on MIG brazing as a viable alternative to MAG welding, especially for chassis components. The study aims to evaluate the impact of coatings on brazing ability, wettability, and arc stability. MIG brazing is increasingly being used for joining Body-in-White parts, especially when Resistance Spot Welding is unsuitable. This research investigates the potential of brazing coated steels, noting that MAG welding often leads to defects such as blowholes.

MIG Brazing Process

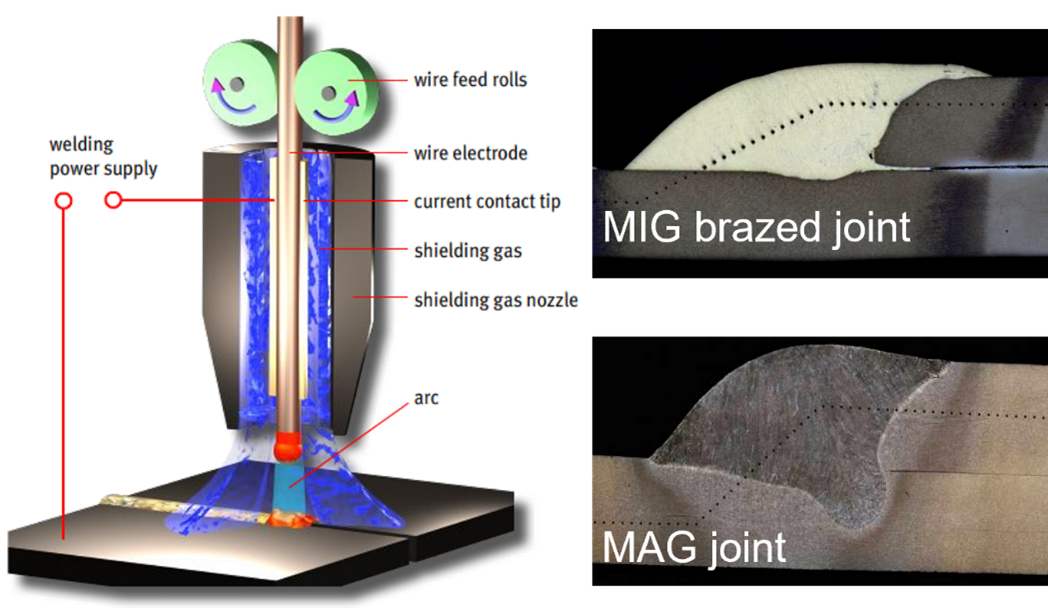

MIG brazing is similar to MAG welding but utilizes a low melting point filler wire, typically copper alloys, that does not melt the substrates. It primarily employs pure argon as shielding gas and a short-circuit transfer mode. The main advantages of MIG brazing over MAG welding include:

- Lower heat input due to the lower melting temperature.

- Reduced distortion, making it suitable for thin sheets used in automotive applications.

- Improved visual appearance and less coating degradation, leading to better corrosion resistance.

Figure 1: MIG Brazing process with representative cross sections from brazing and welding

Methodology

The study focuses on overlap joints without gaps, using CuAl8 and CuSi3 filler wires with a diameter of 1.0 mm, and employs a short-circuit waveform at a welding speed of 500 mm/min. The results are expressed in terms of brazing range, focusing on criteria such as wettability of different coatings and spatter formation.

Key Findings

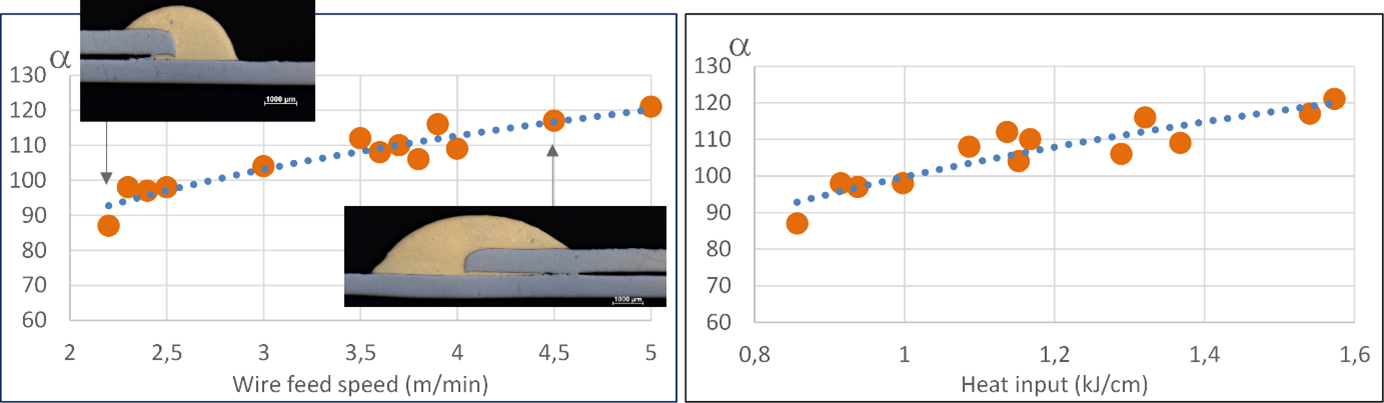

- Wetting Studies: Two methods were used to study wettability—real MIG brazed samples and a wetting pilot. The results indicated that higher wire feed speeds lead to increased current and voltage, which enhances heat input and improves wettability despite a rise in molten metal volume.

Figure 2: Effect of wire feeding speed and heat input on wetting angle using 0.8 mm thick sheets and CuAl8 filler wire

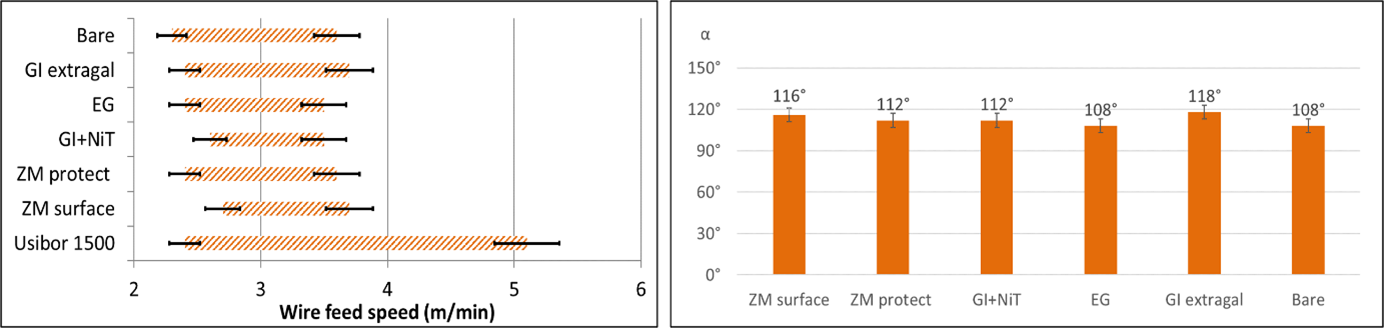

- Influence of Coatings: The coatings had no significant effect on the wettability or arc stability. The behavior of Zinc-coated steels were like that of bare steel, with AlSi coating showing a wider brazing range due to its thicker and more refractory nature.

Figure 3: Brazing range and wetting angle for different coatings using 0.8 mm thick sheets and CuAl8 filler wire

- Spatter Formation: Spatters measuring between 0.1 to 0.3 mm occurred, with a notable increase in spatter rates observed when using zinc coatings. This effect was consistent across various coatings.

Conclusion

The study concludes that the coating does not influence the MIG brazing capability, as the brazing range, wettability, and arc stability remained consistent. The AlSi coating exhibited a broader brazing range. Switching between coatings does not require a change in brazing parameters, although an increase in spatter is expected when brazing coated sheets in comparison to bare steels. In summary, MIG brazing is validated as an effective method for joining coated steel sheets in automotive applications, providing advantages in heat input and corrosion resistance over traditional arc welding. Source J. Haouas, MIG brazing ability of coated steel sheets for automotive applications, IIW 2020 conference, SC XVII